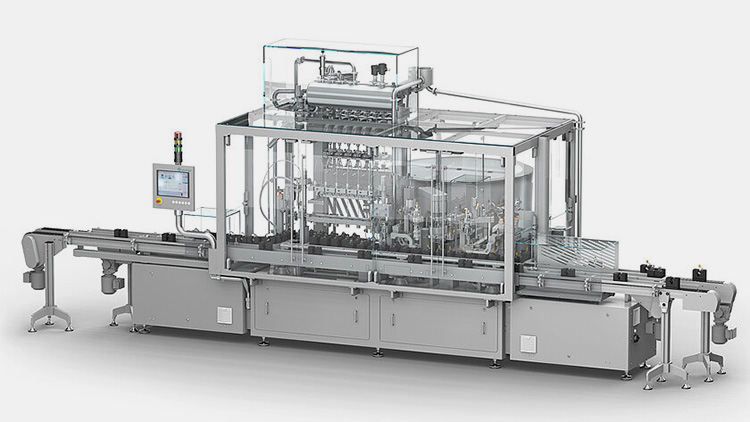

High accuracy spray pump automatic spray filling machine

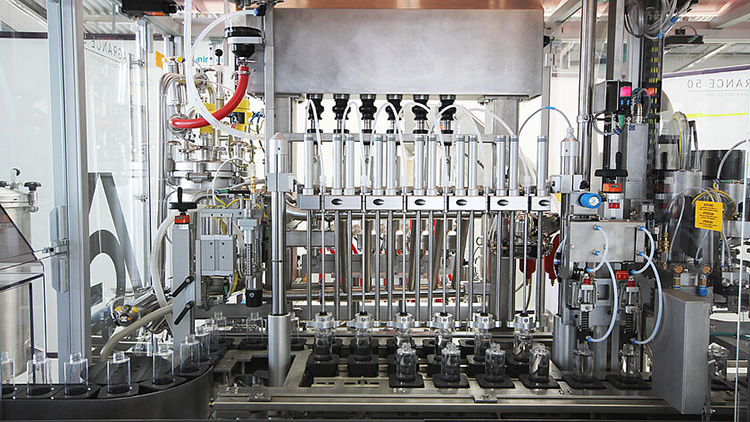

AIPAK Engineering Spray filling machine adopts Germany’s advanced technology, with specifical liquid filling and capping design.The filling parts of the machine adopts piston pump filling, PLC control, filling high precision, easy to adjust the filling range, automatic cap feeding and placing,capping part use rolling capping sealing, sealing beautiful, seal firmly. The machine design is reasonable, stable and reliable, easy to operate and maintain, in full compliance with GMP requirements,in addition ,this equipment also has no bottle no filling function.The spray filling machine can also form production line linkage with the washing machine, tunnel sterilization oven, light inspection machine, labeling machine and so on .

AIPAK Engineering Spray filling machine Sample Display:

AIPAK Engineering Spray Filling Machine Features:

1.All filling head adopts SUS316L

2.With automatic pump cap feeding

3.With capping head,magnetic force no damage for the cap

4.Adopts Siemens HMI-famous brand.

5.The control cabinet and all elements mounted on.It must have a degree of protection against dust and moisture according to the IP 54 standard,clean and tidy.

AIPAK Engineering Spray Filling Machine Technical Specification:

| Bottle specifications | 30 -100ml glass bottle(can be customized according to client’s require) | |

| Production speed | 30-40 b/m | 60-80 b/m |

| Filling head | 4 | 8 |

| Stoppering heads | 1 | 2 |

| Capping heads | 1 | 2 |

| Qualification rate | ≥99% | |

| Power Supply | 220V/50Hz,2.5KW | |

| Weight | 800 Kg | |

| Dimensions | 2400*1700*1750mm | 2800*1800*1750mm |

The Buyer's Guide

Spray Filling Machine: The Complete Buying Guide in 2025

Today, sprays are popular dispensing formats for solvents, lubricants, glues, and, pharmaceutical drugs. The spray filling machine is a renowned machine that accurately and smoothly dispenses liquids inside spray bottles and cans.

It is a state-of-the-art unit that offers convenience and flexibility in spray filling. The popularity of spray products has boosted the expansion of spray filling machine market. With its capable and fast pumps and piston filler, it processes larger batches at a fast pace.

This machine is also designed to accommodate smaller and medium productions. Planning to add this machine to your production? Then go through this blog to increase your knowledge about spray filling machines.

1.What is a Spray Filling Machine?

Spray Filling Machine- Picture Courtesy: lenis machines inc.

A spray filling machine is distinct equipment with a spray filling nozzle that measures and loads exact quantities of liquids and aerosol in bottles and cans. This machine is adopted in every production regardless of size.

This machine is manufactured with different level sensors and weight-measuring systems that contribute to precise dosing. This system also comes with a special actuator placing head that attaches the actuator for spraying on the opening of the container.

Moreover, it is a versatile system, processing both glass and plastic polymer containers with its quick tooling change.

2.Why is Spray Filling Machine Popular?

Due to innovation in machinery, the spray filling machine has become a staple source for loading various misty products inside stylish and diverse applications. This machine is popular due to its various economic and commercial benefits.

Some of its pros are:

Time-Saving

Time-Saving with Spray Filling Machine- Picture Courtesy: Shemesh Automation

This machine has automated technology and efficient filling systems, allowing businesses to fill spray containers at a much quicker rate than the speed that is impossible with manual spray filling. Numerous filling heads load higher volumes of products in containers, consequently hitting higher filling objectives.

Minimal Filling Error

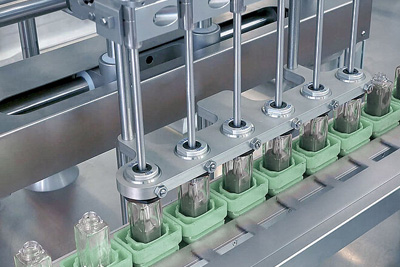

Minimal Filling Error with Spray Filling Machine- Picture Courtesy: groninger

With mechanical controls and highly precise sensors present in the spray filling machine, there is little chance of filling error. No product wastage is possible with this machine, because it does not overfill liquid product that could cause spillage. This machine also does not underfill products and has fewer recalls.

Consistent and Reliable Performance

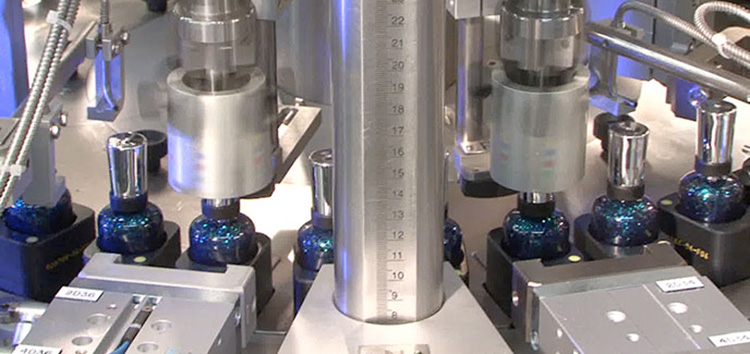

Accuracy of Spray Filling Machine- Picture Courtesy: COVEN EGIDIO SRL

Accuracy and precision are the main performance measuring factors that give the spray filling machine an edge over manual filling. Due to meticulous fillers, it achieves fill consistency in every batch. The products are precisely loaded depending on weight, volume or other assessing parameters.

Flexibility and Versatility

Flexibility of Spray Filling Machine

A spray filling machine does not fill the same type of misty product in the same sized container. But rather with simple filling parameter adjustment and quick part change, it dispenses products in intricate and multifaceted containers. This means it is capable of meeting the fast-changing filling requirements of businesses.

Simple Control and Quick Maintenance

Simple Control and Quick Maintenance

At one glance, it seems that the spray filling machine is hard to operate and maintain but instead, it is designed with simple operating controls that require little to no beforehand knowledge. Also, it has fewer parts that are disassembled for maintenance and cleaning, reducing the burden on operators.

3.Where is the Spray Filling Machine Used?

A spray filling machine is a high in demand machine because of its diverse applications in far-ranging industries. Some of these industrial uses are discussed below:

Cosmetic Industry

Spray Filling Machine In Cosmetic Industry

This industry is one of the main users of the spray filling machine. It is an ideal system that accurately and securely loads a huge range of cosmetics and personal care products, for instance, perfumes, colognes, primers, makeup setting spray, sunblock, hair sprays, deodorants, and many more in fashionable and elegant consumer bottles.

Food industry

Spray Filling Machine In Food Industry

Some food products need spray for water and oil for their settings, so spray filling machine is a major part of the food industry. The components, for instance, filling nozzles are created with food-grade materials so loading of oils, colouring agents, flavouring agents, creams, and cooking spray is possible with a spray filling machine.

House-Hold Industry

Spray Filling Machine In Household Industry

Different household products require misty spray, therefore, the spray filling machine is predominantly added in the household industry for dispensing and packaging products like cleaners, polishes, air fresheners, varnishes, and paints, to name a few.

Pharmaceutical Industry

Spray Filling Machine In Pharmaceutical Industry- Picture Courtesy: Everyday Health

Drug formulations for nasal, oral, ocular, and ear delivery come in the form of spray and aerosol, consequently, this machine is fundamental filling equipment in the pharmaceutical industry. It is used for filling nasal sprays, eye drops, aerosol creams, etc in the pharmaceutical industry.

Art and Craft Industry

Spray Filling Machine In Art and Craft Industry

Art and craft products in aerosol containers offer convenience. With the help of aerosol paints and aerosol glitters, artists create unique designs and patterns. A spray filling machine is regularly utilized in the art and craft industry to pack these aerosol products.

Chemical Industry

Spray Filling Machine In Chemical Industry- Picture Courtesy: Fine Homebuilding

Various chemical industries use the spray filling machine to load a diverse range of chemicals in spray bottles and cans. This machine fills lubricants, greasing agents, disinfectants, sealants, thinners, etc. in the spray containers.

Agriculture and Gardening industry

Spray Filling Machine In Agriculture and Gardening Industry

Often plants and crops need delicate sprays of insect repellents, herbicides, fertilizers, pesticides, and bug control instead of large pour. Thus, spray filling machine is frequently used in the agriculture and gardening industry.

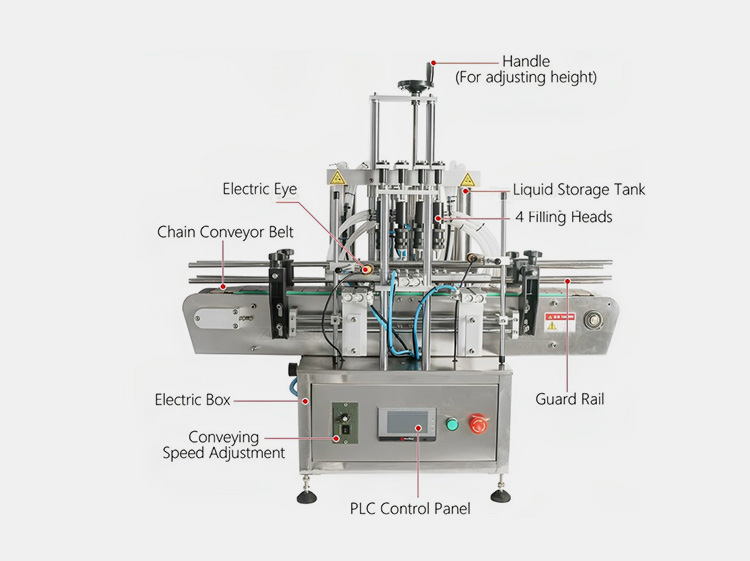

4.What are the Technical Components of a Spray Filling Machine?

This machine is formed from high-tech mechanical, electric, and computerized components that assist the spray filling machine in giving its best. A detailed description of these parts is penned below:

Parts of Spray Filling Machine

| Electric Eye | This is the main detection part of the machine that is essential in determining the accuracy of the filling process. It detects the positioning of a container and identifies alignment filling components. This sensing eye targets the light beams on objects and then estimates the reflected light. |

| Chain Belt Conveyor | It is the transporting channel of the equipment and is created by the chain belts that provide support for placing containers. |

| Electric Box | The switches, relays, and breakers are housed in the electric box of the spray filling machine for powering machine components. |

| Conveying Speed Adjustment | It is a button panel that controls the moving speed of the conveyor. This part is integral in attaining synchronicity of conveyor speed with the speed of filling. |

| Rotating Handle | It is turned to alter the height of the conveyor. It provides the means for adjusting the level of the conveyor to accommodate different sizes of spray containers. |

| Liquid Storage Tank | This component is a cylindrical container present at the back of a spray filling machine. It is a hopper-like component that upholds a bulk quantity of spraying liquid. |

| Guard Rail | It is a barrier stand present at the sides of conveyors. They support the moving container and keep it from falling. |

| Filling Heads | This part controls the rate of filling. It is a cylindrical tube-like device that is in direct contact with the spray container. The spray liquid trickles down from filling heads into the bottles. |

| PLC Control System | It is the brain of the spray filling machine that controls and commands every component of the machine. This processing centre is programmed to transmit signals to components for performing particular functions. |

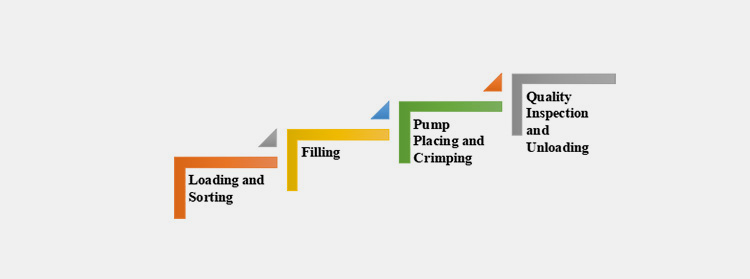

5.How To Define the Working Principle of a Spray Filling Machine?

Different components in the spray filling machine work together in synchronicity for seamless and continuous spray filling. Different working steps of the spray filling machine are stated below for your information.

Loading and Sorting

Loading and Sorting of Containers

With the help of a bottle unscrambling machine and sorter, the bottles or other containers are loaded in the correct bottle on the servo-driven conveyors. The containers are placed in a single file for transport towards the filling station. Also at the start, a large volume of product is deposited in the hopper.

Filling

Spray Filling- Picture Courtesy: groninger

As soon as containers are detected under the filling nozzle, the volumetric dispensing of spray product starts. Efficient pumps are used for transferring the product from the holding tank into the filling nozzles.

Depending upon the type of the spray filling machine, compressed air or other propellent gases are employed for loading the products into the container. Level sensors measure the volume of filled product during the filling cycle.

The product loading stops on attaining the required fill volume.

Pump Placing and Crimping

Pump Placing and Crimping- Picture Courtesy: Jack Du YouTube Channel

Upon filling, the containers are transferred to the pump placing and crimping section. The pumps are sorted and fed through vibratory bowls. Pump placing head fixes and secures the actuator pump on the spray container.

This actuator is the main device for dispensing liquid in the form of spray or mist. Afterwards, crimping heads crimps and seals the pumps.

Quality Inspection and Unloading

Quality Inspection and Unloading- Picture Courtesy: Dara Pharma

The spray filling machine may be designed with a quality testing section that determines the correct fill volume, seal integrity, and quality before removing the container. If the filled container passes every quality test, it is unloaded from the system and passed to the next packaging equipment.

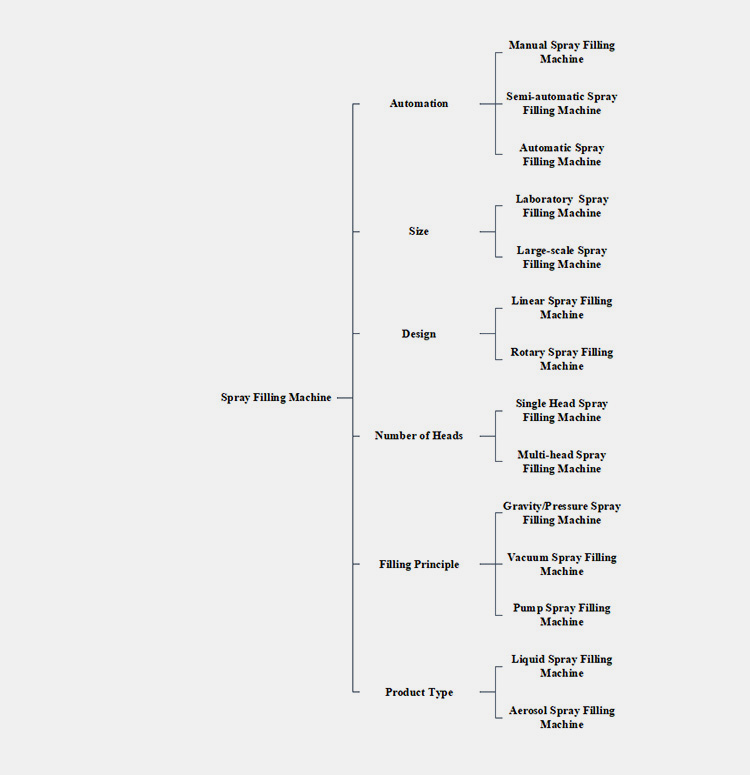

6.What is the Classification of Spray Filling Machine?

Spray filling machine comes in different design, sizes, and automation level. It also has diverse filling and product types. Here is a complete account of the classification of spray filling machines to aid you in your selection process.

According to the Automation

Manual Spray Filling Machine

Manual Spray Filling Machine

It is a small straightforward equipment that is assembled with rotating levers and handles for dispensing liquids into the spray containers. A small hopper and one filling head allow for limited filling capacity, thus it is usually found in small-scale industries and lab settings. However, it is labour-intensive as technicians have to place and remove containers from the machine.

Semi-automatic Spray Filling Machine

Semi-automatic Spray Filling Machine

It is a medium-sized compact equipment generally well-aligned with small and medium-sized production goals. It features one to two filling heads and a small conveyor for transporting and filling a few spraying containers per minute. This machine is labour-demanding as there is a need to load and unload containers manually from the machine.

However, the filling of containers with this unit is independent and does not require operator assistance.

Automatic Spray Filling Machine

Automatic Spray Filling Machine- Picture Courtesy: PKB Machines

This machine is ideal for big businesses because it features multiple filling heads, a fast conveyor system, efficient filling systems, and advanced controls. These parts aid in attaining efficiency and precision during product loading.

Automatic devices aid in the absolute streamlining of working steps for instance, loading, unloading, filling, and closing are fully automated in this system.

According to Size

Laboratory Spray Filling Machine

Laboratory Spray Filling Machine- Picture Courtesy: Zigler

It is a small benchtop machine having little processivity hence, it is installed in laboratories and research and development for developing experimental spray products. One or two filling nozzles load one to two containers in one cycle. Its main benefit is its cost-efficiency and lower footprint.

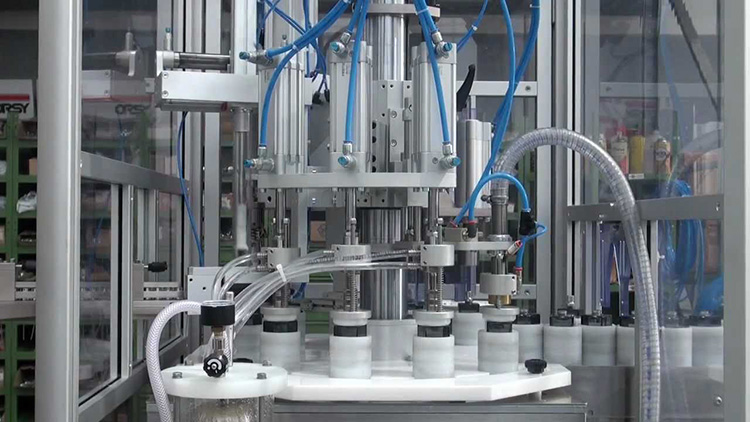

Large-scale Spray Filling Machine

Large-scale Spray Filling Machine -Picture Courtesy: groninger

Yes, this machine is adopted in large processing units that dispense multiple products in one cycle. A robotic loading system, large conveyor, efficient filling heads, PLC controls, and hoppers, ensure a high filling rate. Absolute synchronicity of machine parts aids in coordinating working steps with perfect diligence.

According to Design

Linear Spray Filling Machine

Linear Spray Filling Machine- Picture Courtesy: Rejves Machinery S.r.l.

The construction of this type of spray filling machine is a straight line in which every component is arranged in a sequence. It comes with conveyors that carry the containers to different stations. This system has a discontinuous mode of working with conveyors stopping while awaiting container filling. It is easily added to the existing processivity line due to its modular design.

Rotary Spray Filling Machine

Rotary Spray Filling Machine- Picture Courtesy: Aile

A rotary carousel or turn table gives this machine its name. In this machine, different filling and closing heads are configured circularly. It has a large design and has a continuous mode of operation which involves consecutive filling and sealing of multiple containers in a single run. Due to its fast pace, it is routinely found in heavy-duty processing.

According to Number of Heads

Single Head Spray Filling Machine

Single Head Spray Filling Machine- Picture Courtesy: vkpak

This machine has manual, semiautomatic, and automation levels of automation. It is designed with a single filling head that handles small batch sizes. A single container is filled in one cycle because of a single-filling nozzle. It is added in productions with small and medium processing mass.

Multi-head Spray Filling Machine

Multi-head Spray Filling Machine- Picture Courtesy: PKB Machines

It is engineered with more than one filling head, consequently offering faster and higher filling rates. The filling heads are present in straight-line as well as circular configuration. It is a large-sized machine, needing more room for installation and requires a high purchasing budget

According to the Filling Principle

Gravity/Pressure Spray Filling Machine

Gravity/Pressure Spray Filling Machine- Picture Courtesy: PKB Machines

It is one of the simplest types of spray filling machine when the latter is classified based on different types of fill principles. This machine fills spray bottles using gravitational or pressure force. Time is a determining factor for loading spray contents in the container and usually, it is pre-programmed at the start of a cycle.

It is employed for filling free-flowing liquids.

Vacuum Spray Filling Machine

Vacuum Spray Filling Machine- Picture Courtesy: Aile

This machine loads the spraying liquids in the container by creating an airtight lock around the fill heads through the opening of a container. This sealing forms a vacuum inside the spray container due to which thinner viscosity liquid is forced from a hopper into the filling container.

It features specially engineered nozzles for dispensing liquids.

Pump Spray Filling Machine

Pump Spray Filling Machine- Picture Courtesy: PKB Machines

Diverse type of pumps is present in the pump spray filling machine for moving thin, medium, or thick viscosity spray liquid from the upper holding tank into filling heads. The rotation of pumps exerts force for drawing liquid from the hopper into the spray container.

Pulse or time-based filling is generally adopted for dispensing liquids.

According to the Product Type

Liquid Spray Filling Machine

Liquid Spray Filling Machine- Picture Courtesy: Makwell

It is the most common type of spray filling machine. It is specifically tailored to dispense different consumer goods and cosmetics in the form of mist. With the help of a dedicated nozzle, the filling system loads exact quantities of spray liquids into containers such as bottles or cans.

Aerosol Spray Filling Machine

Aerosol Filling Machine- Picture Courtesy: SED Pharma

It is a specialized form of spray filling machine implemented in production lines for filling aerosol products, for instance, snow spray, paints, adhesives, and many more. It fills liquified or compressed air as a propellent in addition to aerosol liquid. Moreover, it has specific units like valve placing and crimping for closing and sealing aerosol containers.

7.What Types of Containers are Processed by Spray Filling Machine?

A spray filling machine is capable of filling different containers depending on the nature of the product. These container types are discussed below:

Tinplate Cans

Tinplate Cans- Picture Courtesy: Tecnocap

These are durable and robust cans with a typical cylindrical structure. Often a spray filling machine fill lubricants, adhesives, paints, and grease chemicals in these type of cans for long-lasting protection and containment of volatile liquids.

Aerosol Cans

Aerosol Cans- Picture Courtesy: NY Post

Due to the popularity of aerosol products, for instance, snow spray, deodorants, hair sprays, etc. among end-users, spray filling machine has become regular equipment in industries. This machine critically dispenses spray in aerosol cans and seals them with crimp valves.

Glass Bottles

Glass Bottles

Luxurious and high-end products for example perfumes, scents, Eau de Toilette, and body mist are packed in intricate and custom-designed glass bottles by the spray filling machine. These spray glass bottles are in every possible shape and form. The premium look of glass is tailored for deluxe consumers.

Plastic Bottles

Plastic Bottle

A spray filling machine is widely adopted for filling everyday spraying liquids like cleaners, disinfectants, sealants, and air fresheners in plastic bottles. These bottles are usually manufactured with light-density polyethylene and Polyethylene Terephthalate. Lightweight plastic spray bottles are not prone to breakage consequently, they are commonly used.

8.What Quality Standards Should the Spray Filling Machine Meet With?

Nowadays, a spray filling machine is a significant constituent of business, therefore, it must meet different quality standards to ensure the reliability of packed items and also for the safety of the operator and environment.

Following are some important quality standards for a spray filling machine:

| Good Manufacturing Practices (GMP)

|

It is one of the essential quality certifications accepted all across the globe and it guarantees that the filled product is manufactured in a state-of-the-art facility and is of the highest quality because of the clean and hygiene procedures of the manufacturing brand. |

| ISO

|

It is an international organization for standardization. ISO quality standard of a spray filling machine defines that the machine is manufactured by adhering to a quality management process and the manufacturing line is committed to improving their performance by addressing and correcting their inefficiencies. |

| OSHA

|

It is a safety standard implemented during the engineering of a spray filling machine and it ensures the health and workplace safety of operators managing the machine. It states that the machine applies all safety guidelines and does not pose any work-related strain or injury to operators. |

| IEC

|

It is a safety standard for electronic and electrical parts in the spray filling machine. A system meeting IEC guidelines assures that there is no chance of electronic failure or electric accidents when adding a machine to the production line. |

9.How to Troubleshoot Spray Filling Machine To Increase its Efficiency?

Technical faults in the spray filling machine could lead to interruption in the spray filling process and could be the reason for the loss of revenue. Here are some recommendations for troubleshooting these problems:

| Reason | Solution | Image |

| Dripping of Liquid from Filling Heads | ||

| Incompatible seals with filling nozzles

Damaged or worn-out seals |

Use seals that are according to the configuration of filling heads

Replace old seals |

Dripping of Liquid from Filling Heads- Picture Courtesy: PERFUME FILLING |

| Liquid Does Not Flow to Filling Heads | ||

| Improper positioning of hose

Worn-out hose causing a liquid leak |

Connect the hose pipe with the right fixture

Replace old and faulty hose |

Liquid Does Not Flow to Filling Heads- Picture Courtesy: STOPPIL |

| Imprecision in the Fill Volume | ||

| Filling devices are incompatible with liquid

Wear and tear in filling heads Loose nozzle seals Broken-down or run-out O-rings and seals of filling nozzle Incorrect fill program option Inaccurate alignment of nozzles with container |

Use right filling devices corresponding to the liquid

Place damaged filling heads Use screws to tight seals on the nozzles Install new O-rings and seals in the equipment Double-check fill settings and fix errors in the programming Realign nozzles according to height of the container |

Imprecision in the Fill Volume- Picture Courtesy: PKB MAachine |

| Container Tipping | ||

| Damage to the drive belts or chain of the conveyor

Faulty or worn-out transfer plates Missing part of the conveyor belt Incorrect speed of the conveyor |

Repair drive belts and chain on the conveyor

Repair or replace old transfer plates Replace the conveyor belt Alter the speed of the conveyor |

Container Tipping – Picture Courtesy: gorninger |

| Liquid Spillage | ||

| The fill time setting may be incorrect

Tight gripping of bottles by the holder could cause spilling of product out of the bottle |

Reprogram the fill time settings

Lose the gripper on the bottle or replace the bottle holder |

Liquid Spillage- Picture Courtesy: PKB Machines |

10.How Can You Choose Prefect Spray Filling Machine for Production?

Choosing a perfect spray filling machine is a fairly tiresome problem because a huge time and effort are put into the selection process. Nevertheless, this careful selection brings fruitful results later on. Therefore, we have compiled some tips to aid you in this tedious journey.

Spray Liquid Characteristics

Spray Liquid Characteristics- Picture Courtesy: PKB Machines

The type of product you are filling is a pivotal factor that dictates your spray filling machine selection. When planning to purchase equipment, first learn about the nature such as viscosity and chemical interaction of your liquid product.

A well-matched machine will swiftly and accurately dispense liquid while the purchase of a wrong machine could result in its jamming or varying fill.

Production Volume

Production Volume- Picture Courtesy: COVEN EGIDIO SRL

When you learn beforehand about your desired production goals, it will formulate a certain criterion that the desired machine must meet for selection. Production capacity is a meter estimated by the rate of filled spray containers per hour. Hence; if you have a higher filling capacity then choose a machine with a higher automation level and more filling heads.

Dimensions and Material of Fill Container

Dimensions and Material of Fill Container

It is yet another critical point because container size and material should be in line with the filling method and handling of a spray filling machine. The material of the container influences the decision-making process of the right kind of machine configuration.

Moreover, some spray filling machines are engineered to handle small bottles and cans and others are specific to bigger containers.

Durability

Durability- Picture Courtesy: Àuria Perfumes’ Post Linkedin

It is an important factor that makes or breaks your spray filling machine selection. A machine constructed using sturdy and tough materials and designed with high-tech gears is anticipated to last long. Do not compromise on quality when going for purchase as this machine will bring you a vast array of benefits.

Hygiene and Cleaning

Hygiene and Cleaning- Picture Courtesy: Syntegon

Last but not least, the spray filling machine requires routine cleaning and maintenance to give its absolute best. If you process food, pharmaceutical, or cosmetic spray, then look for a machine with easily dissembled parts for cleaning debris and product built-up. Fast-speed productions need a machine with few changes of parts to fulfil industrial hygiene and cleaning standards.

Conclusion

Spray filling machine is a must-have solution for manufacturing. The adoption of this machine in the industry guarantees rapid processing and filling reliability. Hopefully, by reading this guide, you have gained an insight into different aspects of a spray filling machine. If you are still in the process of weighing your options and are hesitant to choose a particular machine, then immediately message us your inquiry. We, Allpack are experienced manufacturers of high-grade machines and we will aid you in maximizing your profit.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Spray Filling Machine Related Products