Pharmaceutical Solutions

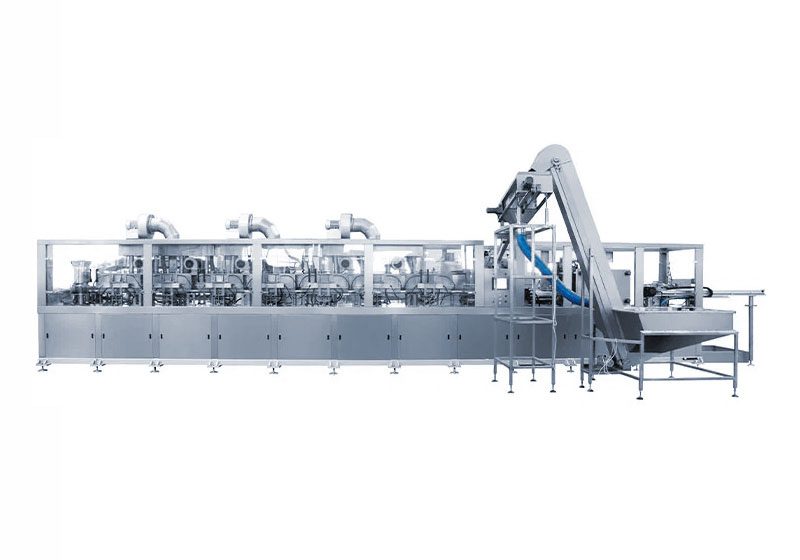

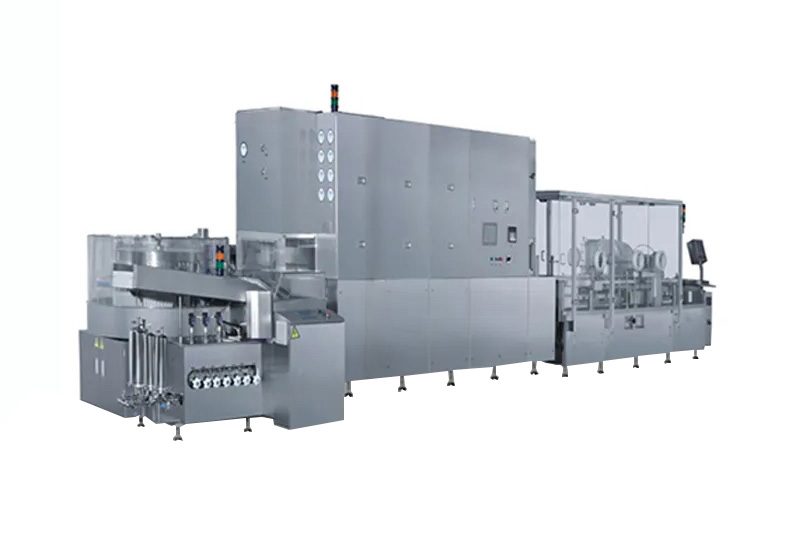

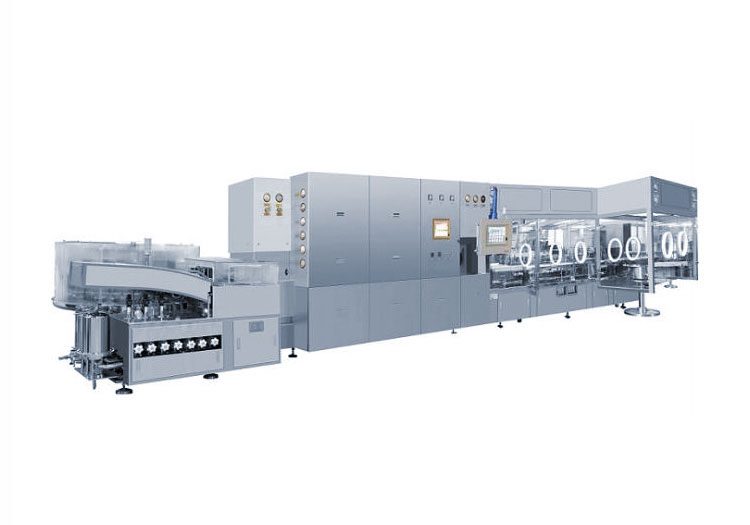

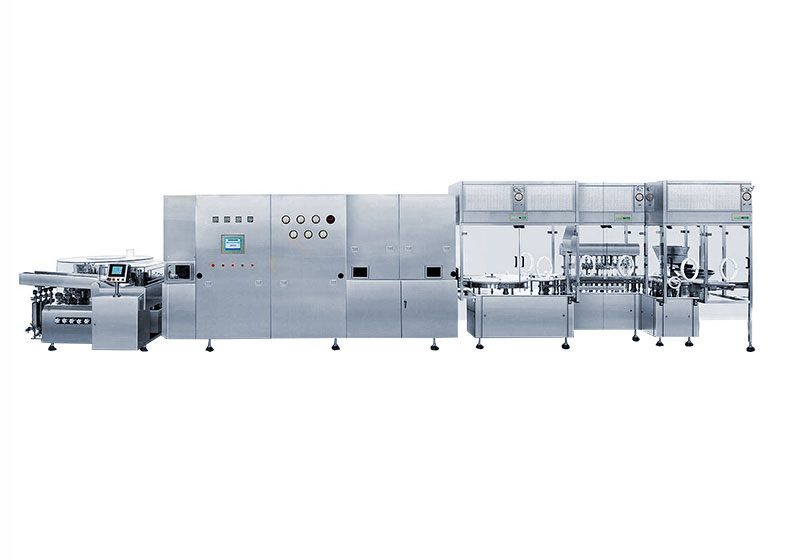

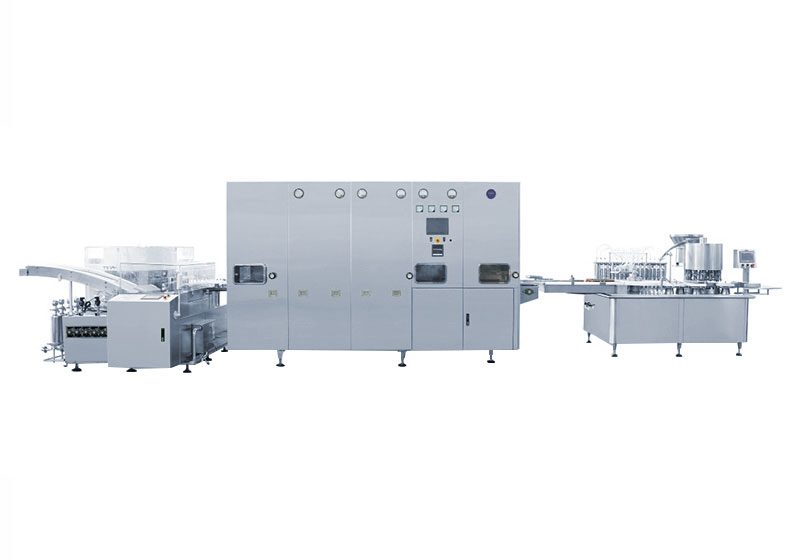

Looking for best pharmaceutical solutions?Explore our huge range of pharmaceutical solution production lines to discover the most suitable lines to boost your business.Whether you are looking to set up a pharmaceutical factory or medical plant,we have got you covered.

Why Choose Us

Over 10 Years Industry Experience&accumulated resources in the Pharmaceutical Industry.AIPAK Largest target is to create value for customers,understand their requirement well,provide them with high quality equipment.

All AIPAK Products design and construction complied to FAD,GMP,ISO9001 and 14000 quality standard,all AIPAK technical experts are familiar with most of the international GMP requirements, such as EU GMP / US FDA cGMP , WHO GMP, PIC/S GMP principle etc.

Hard-working Engineering Team

Good Pre-sale and After-sales Service

AIPAK Engineering professional sales engineers will connect with you at any time,provide you good pr-sale consultation and after-sales service with strong sense of responsibility and mission.

Our SUCCESSFUL Projects

Until now,AIPAK Engineering has already set up hundreds of pharmaceutical projects in more than 60 countries, such as Iraq, Indonesia, Thailand, Nigeria, Turkey, Uzbekistan,Russia,Poland,Israel,ect. We helped all customers realize their requirement,from design to installation,the whole pharmaceutical and medical plant built up ,we guarantee multi-language communication to ensure accuracy communication.We have helped more than thousands customer solve their most tricky problems for long time,and all these projects have won high praise from customers and high comments from their government.

REAL FACTORY Photos

All AIPAK Engineering pharmaceutical&medical equipment are manufactured following industry-grade standards and a strict quality control process,based on ISO9001:2008, follow the cGMP, European GMP, US FDA GMP and WHO GMP standards etc.We carried out complete quality inspection,logistical management,on-site equipment installation,commissioning and personnel training services to ensure all the needs of customers are satisfied.

Our FAST Shipment Process

Our manufacturing process is quick, efficient, and error-free. We always ensure you receive your orders within the agreed timeframe. Even during the pandemic, we adjusted our operations to meet clients’ requirements and deliver on time. Here’s how your order is prepared and shipped!

1.Project preparation & preliminary planning

2.Project design(Concept design, detail design, construction design)

3.Procurement (equipment, material and machine tools)

4.Construction: progress, quality and cost control

5.Commission & Acceptance

6.Personnel training

7.Completion acceptance

8.After-sales service

Our HAPPAY Clients

Can’t find the answer? Reach out to our Top Brands’ Reviews

Get in Touch With Our Pharma&Medical Consultancy Experts

- Turnkey Projects for IV Solution Plant From A To Z

- Unique advanced and reliable technique

- Team with more than 10 years’ industry

- Strict quality control and online FAT support

- Loyalty and sincerity to customer