High accuracy 10ml 15ml small glass bottle nail polish filling machine

AIPAK Engineering Nail polish filling machine is mainly used for 5-15ml common nail polish bottle filling,it is the most practical and flexible solution to package small doses of nail polish.All AIPAK Engineering nail polish filling machines are simple to operate,of high speed and easy to clean,and are resistant and made of high quality materials in order to fill nail polish or any other kind of nail product.And all nail polish filling machines are designed to be incredibly accurate and does not waste product.

The nail polish filling machine is with multiple filling nozzle which can improve filling efficiency greatly.Each filling nozzle can be controlled separately.It is suitable for filling low viscosity liquid without particle like water,juice,milk perfume etc.This machine is widely used in food,beverage,cosmetics and daily chemical industries.

AIPAK Engineering Nail Polish Filling Machine Sample Display:

AIPAK Engineering Nail Polish Filling Machine Features:

1.It is applicable to different-shaped bottles and plastic bottles: PP , PE , PVC ,glass bottle and mould bottle.

2.The bottle-in and bottle-out has specialized structure .It doesn't drop bottles or nip bottles

3.The part which touches the liquid medicine is made of SS304 stainless material completely, meeting the requirement of CE GMP.

4.It can be connected with the bottle-washing machine and the label-attaching machine to form a complete set of produce line.

AIPAK Engineering Nail Polish Filling Machine Technical Specification:

| Filling nozzles | 1/2/4 |

| Packing materials | Plastic and glass bottle |

| Filling capacity | 10-120 ml |

| Filling precision | ≤± 1% |

| Filling speed | 10-60 pcs/min |

| Eligibility rate of inside tuck and outside tuck | ≥99% |

| Air supply | 0.6Mpa 0.6m³/min |

| Language choice(Touch screen) | English, Spanish, Russian, Arabic, French, Italian, Korean, can be customized. |

AIPAK Engineering Nail Polish Filling Machine Video

The Buyer's Guide

Nail Polish Filling Machine: The Complete Buying Guide in 2025

It is absolutely possible to get right nail polish filling process. But how?

OK, first of all, there’s no hard and fast or technical rule for completing this task, except you need an excellent one stop solution known as a nail polish filling machine.

This is the most advance and very cost-effective answer for those who’re running production businesses relevant to cosmetics. Also, this machine is very effective answer for those who’re seeking for filling viscous and non-viscous products as well. To know its exact answer; we would suggest going through this informative blog.

Let’s see the highlights that we have covered in this topic.

1.What Is Nail Polish Filling Machine?

The best solution of nail polish filling

A nail polish filling machine is the most practical and state of the art machine that perfectly fills small doses of nail color into specified containers or nail polish bottles. This machine is best known for its simple structure and easy to operate which you’ll see later in this blog.

This machine is good for dispensing viscous as well non-viscous materials which is also best fit in various industries for filling small and accurate quantities of solution.

Traditionally, the production and packaging of nail polishes were taken into account by using conventional fillers that are rapidly replaced by new and innovative technique in the form of nail polish filling machine that is a promising solution for several businesses.

2.Why You Need a Nail Polish Filling Machine?

You can imagine, how a nail polish filling machine is beneficial for you by knowing its various advantages when compared to other machines.

Stable Performance and Compact Structure

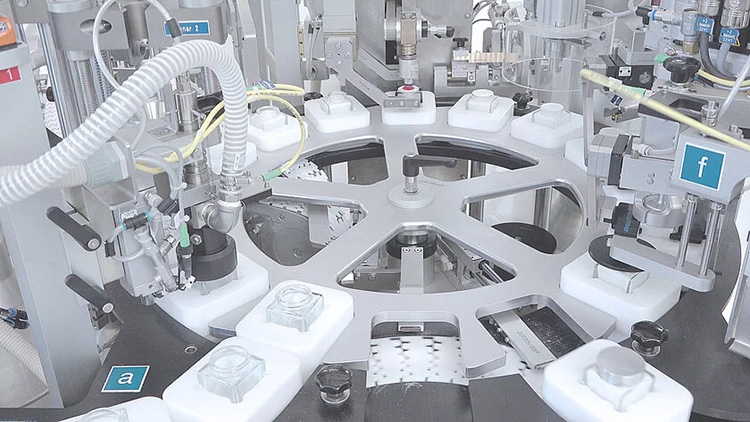

A strong and compact nail polish filling machine- Picture Courtesy: Groninger

A nail polish filling machine structure is created by following international quality requirements and standard SOPs. The machine gives you a stable performance and greater efficiency throughout the working process.

Also, if you see the structure of the machine, it is compact assembling various important units perfectly. So, you can install it anywhere i.e. large as well as small working facility.

Supporting Various Containers Shapes & Sizes

Various sizes and shapes cater by nail polish filling machine- Picture Courtesy: Kogan

A nail polish filling machine is highly flexible equipment that offers you the benefits of working with containers or bottles of various shapes and sizes, such as vials, ampoules, containers or bottles of glass or plastic, etc.

Easy Operation & Extremely Efficient

Easy operating tool of nail polish filling machine

The machine is ideal in the terms of easy operability. This is because you can use a touch screen system for simple and convenient entrance and the machine itself assists you automatic programming, alerts, memory, and notifications.

You can Get a Consistent Result

Say bye Product’s Variation

In addition to speeding up your production, a nail polish filling machine is going to remove inconsistencies in the filling process. Once you have set up the volume to be filled in each bottle, the machine gets to work, and you can relax. You don’t have to worry about one bottle being filled with more product than the other. The machine takes care of these inconsistencies for you!

No product Wastage

A strong stabilizing system for bottles and product dispensing

With a nail polish filling machine, you can say goodbye to spillovers. Minimizing product waste and enhancing customer satisfaction with accurate product volume each time is where these automatic filling machines shine.

Saving Your Time

Nail polish filling machine with Time saving features

If your company packages various products you are in luck! A nail polish finishing machine can be used to fill up bottles of different shapes and sizes. This allows you to reduce time during change and as a result, the production can be maximized.

3.Where do you use a nail polish filling machine?

The nail polish filling machine is an excellent development in the liquid dispensing sector catering to various industries with multiple applications. Some of the important fields are discussed below.

Pharmaceutical Industry

Uses of nail polish filling machine in pharma

This sector is involved with day-to-day manufacturing and packaging of various oral preparation such as syrups, antibiotics, and antiallergy, as well as ready to use vials, ampoules, small solutions, chemotherapeutic solutions that need nothing but nail polish filling machine for proper and accurate dispensing.

Cosmetics Industry

Picture Courtesy: Gorninger

The cosmetic industry is a hub of creating various products such as serums, nail polish removers, freshening sprays, facial foam, eye- creams, etc, items that need a nail polish filling machine to produce them professionally perfect.

Food and Beverage

A nail polish filling utilization in food industry

You have seen various products such as food colorants, flavoring, condiments, sauces, dressings etc that are dispensed in tiny bottles; yes, a nail polish filling machine is one stop solution for the food and beverage industry that allows containers to fill with the special food and beverage products in a smaller concentration.

Chemicals and Lubricants

Nail Polish Filling Machine application in Chemical Industry – Picture Courtesy: Dichem

This is the main sector of producing important chemicals including synthetic and natural items which are carefully dispensed by using nail polish filling machine. For instance, salts, organic products, inorganic solutions, various indicators used in the analysis of products (titration) etc., are mainly dispensed into small bottles via nail polish filling machine.

Personal Care Products

Nail Polish Machine uses in Cosmetic Industry- Picture Courtesy: Australian Natural Refill

A nail polish filling machine is of high value when dispensing products like essential oils, fragrances, deodorants, cleaners, toners, and others are needed into small vials, bottles, or jars.

Adhesive Industry

Nail Polish Filling Machine in Adhesive Industry

This industry required a nail polish filling machine for filling of materials such as, glue , adhesive, thinners, and sprays, which ensuring a promising output via 100% accurate filling.

Laboratories & Research

Nail Polish Filling Machine is popular in filling Research samples safely- Picture Courtesy: Pharmtech

A nail polish filling machine is of worth buying equipment if you’re working in R&D or clinical setups. This is because here various small sizes of reagents, solutions, samples, are needed to be accurately dispensed by this machine.

4.How Nail Polish Filling Machine Works?

The working of a nail polish filling machine follows a series of steps; each step has its own value and you must observe its importance upon reading the blog. We have provided you with a general overview of the working principle that would be helpful in understanding of the working features of the nail polish filling machine. so, Get Set Go!

| Container Loading

|

Consider an empty bottle as a prime entity that is subjected to the machine by unscrambling bottles into an upright and fully oriented manner. The conveyor brings the nail polish container into the machine where it further moves toward the next station. |

| Filling Station

|

Now bottles are moving around the rotary plate where it makes to facing toward the filling nozzle. Upon detecting the presence; it filled an accurate amount of nail color inside the bottle and send it to the next station. The nail polish is stored into the hopper which upon sending the message allows its flow toward to filling nozzles. The entire procedure is efficiently ran by a PLC unit. |

| Capping or Lidding

|

The conveyor moves and nail polish filled containers are now subjected to a capping or lidding unit where upon detecting the position a sensor notifies the machine and capping is dropped down into each available bottle. The set of grippers ensures proper fixation and twisting of the cap around the bottleneck. And that’s it. |

| Discharging

|

Bottles are now moved out of the unit for further steps such as labeling. |

5.How To Classify a Nail Polish Filling Machine?

Nail polish filling machine is a versatile machine available in various different categories that we talk now. For your clear understanding I have categorized them into the following sections such as:

Based on Filling Principle

The nail polish filling machine has a category which divide them into the following section based on its working principle.

Gravity Filling

Gravity Nail Polish Filling Machine

This special type of machine is designed and worked following a conventional method having a hopper or product reservoir at upper topmost position of the machine. the purpose of this design is to allow constant flow of nail polish using a gravitational force. The force of gravity expertness allows nail polish to drop down easily toward the filling stations.

Pressure Filling

Pressure Nail Polish Filling Machine- Picture Courtesy: TurboFil

This is a new and advanced working featured machine that follows a positive pressure to induce dispensing of nail polish into their assigned container. This machine is mostly recommended to various content displaying thick or high viscous consistencies. So, by applying the pressure the filling procedure gets very smoother and make your timely production goals.

Pump Filling

Pump Nail Polish Filling Machine- picture Courtesy: VKPAK Filler

A pump nail polish filling machine uses a peristaltic pump which is responsible for positive displacement of fluids and highly recommended for high or thick consistency fluids. A flexible pump is efficient enough to prevent the unit from clogging and offering a complete sanitary environment for every production batch.

Piston Filling Machine

A well-known piston nail polish filling machine that ensure flexible working using a narrow piston as a filling nozzle which promises easy flow rate with accuracy. You can use this filling machine for various other items such as creams, lotions, or other viscous preparations.

Based on the Number of Filling Nozzle

Every machine is designed with various different filling nozzles. some machines are accompanied by one and some are with more than one. Let’s see them.

Single-Head Nail Polish Filling Machine

This machine has one filling head which is able to cater only one container at one time. Of course, this machine offers you a limited filling capacity, so you can enjoy their features if running a small business.

Multi-Heads

Multi-Heads Nail Polish Filling Machine

Running a large nail polish filling projects would be ideal if you have this machine which is accompanied by more than one filling head. You can call it multi-head nail polish filling machine that offers you various amazing features such as an auto sensor, fast operation, large working output, and more.

Based on Automation Level

The nail polish filling machine works by approaching various automation as well. Some of the important mechanization equipment are discussed below.

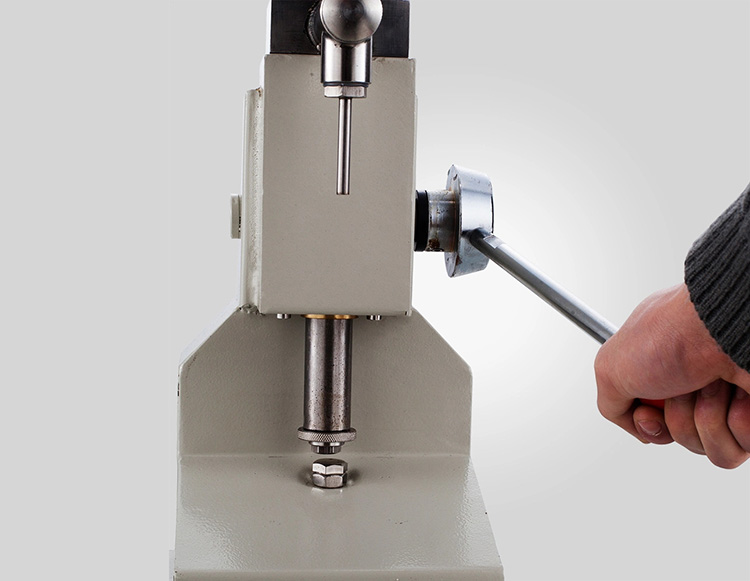

Manual Nail Polish Filling Machine

A Manual Nail Polish Filling Machine

This machine is very simple and works by requiring your involvement all the time. This means you need to put the solution into the hopper then by placement of containers must be exact below the filling nozzle. Once everything is in its order, you need to press the handle to allow the required amount of nail polish into the bottle. Now remove and place the new one.

Semi-Automatic Nail Polish Filling Machine

Semi-Automatic Nail Polish Filling Machine

This machine is ideal when you are planning to run a moderate business. Because this is suitable for small to medium-production-scale operation. A semi-automatic nail polish filling machine is indeed featured with modern keys and operating tools but this machine also needs your involvement for placing and removing the container once they’re filled.

Automatic Nail Polish Filling Machine

Automatic Nail Polish Filling Machine

This is a super ideal equipment for running large scale businesses where entrance till discharging of the container including filling, capping, and movement from one station automatically.

The machine is highly advanced so you need to enter the right protocol using touch screen parameters such as speed, filling volume, speed of rotary plate, detection (no bottle-no filling), entire processes without the involvement of any technician.

Based on Container Movement

Inline Nail Polish Filling Machine

Inline Nail polish Filling Machine- Picture Courtesy: Genicose

In this machine, the movement of empty containers toward filling and capping till discharge is carried out in a linear fashion. This is a conventional method but still featured in various modern machines.

Rotary Nail Polish Filling Machine

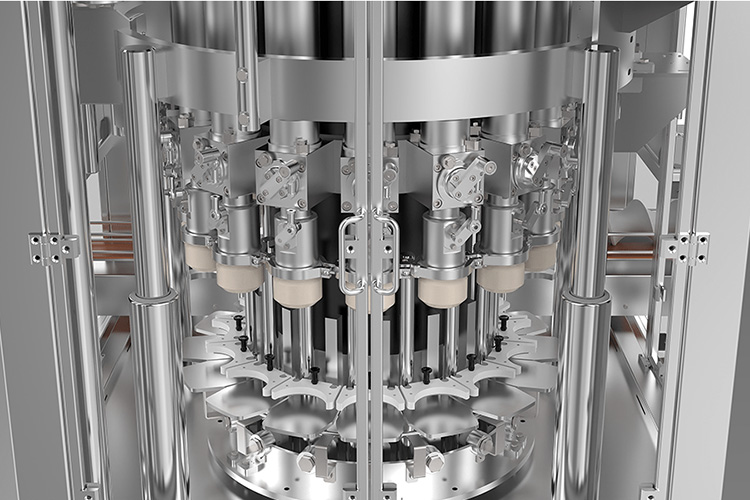

Rotary Nail Polish Filling Machine

In a rotary machine, the introduction of container till its final exist, all steps are carried out in a circulatory fashion. This machine is advanced version and used in various large industries for fast and high productivity. The machine itself is composed of a compact structure and offering you excellent features that you always look for.

6.What are basic parts of nail polish filling machine?

If you see the nail polish filling machine, you might be thinking of its complexity and multi-functional structure. But in-depth, you will be surprised to see how simple it is with amazing operability.

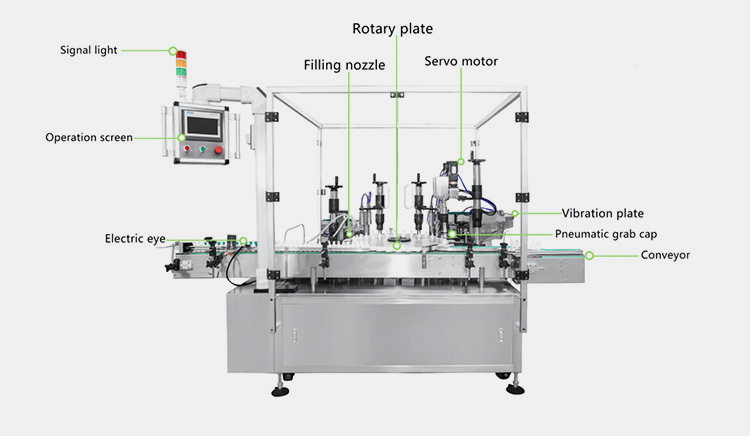

Let’s break down each of them and understand their function from above mentioned illustration.

| Signal Light | What is the current state of the nail polish filling machine, this signal light tells you everything about it. You can call it as an indicator of machine’s health.

Green signal means machine is ok to work. Yellow indicates something to inspect or anything alarming in the future; while red is something wrong such as electric problem or machine malfunctioning. |

| Operation Screen | As it name shows, this is a touch screen interface where you need to enter the keys relates machine operation. For example, filing speed, filling volume, number of bottles per minute, number of hours to be operated, and much more.

Also, if you’re facing any technical problem, a touch screen interface can help by notification and adjusting the settings. |

| Rotary Plate | This is movable unit of the nail polish filling machine which is featured with holding properties of empty bottles that comes in contact with fillers and moves toward the next station for further steps. The rotary plate is moved by the help of motor driven unit controlled by a specialized unit known as a PLC so entire sequential steps are followed in a smooth manner. |

| Filling Nozzle | Yes, you have directly understood the exact purpose of this unit by its name. The filling nozzle of the machine is narrow and sharp designed dispenser ensuring filling of nail polish inside the empty bottle with accurate and precise manner.

The opening and closing of filling nozzle are taken place by the help of automatic sensors attached to it so a maintained flow rate and minimized or no spillage is noticed by filling nozzles. |

| Servo Motor | This is mechanical part of the nail polish filling machine which works by converting electrical energy into mechanical energy for movement and filling of the bottles inside the machine such as movement of the rotary plate, filling capping etc., operations are followed by servo motor. |

| Vibration Plate | If you see the video or any illustration of nail polish filling machine, you may noticed the presence of vibratory plate that promising you in the settlement of air bubble present in the solution as well as it ensuring a uniform flow rate of the nail polish hence overall better efficiency is observed. |

| Pneumatic Grab Cap | This unit is responsible for grabbing a cap or lid which has to be adjust over the filled bottles. The working of pneumatic grab cap is very simple, the filled bottle comes in contact with position where sensor detects the presence of bottles and a compressed air help in the releasing of the lid which directly flip down over the bottle and twisted by grippers. Remember the entire functionality is taken place in a fraction of the minutes. |

| Conveyor | Do you know how different bottles comes into the machine and leaves the unit once they’re filled. Yes, this is efficiently done by a transporting device known as a conveyor. This is driven by a motor and helps them to flow them in a systematically and synchronized manner so bottles won’t be fall or neither incorrect packaging material can comes through the machine. |

| Electric Eye | This is an important unit of the machine that observes and senses presence of empty bottles and proceed the further steps. If there’s no bottle; there’s no filling. the container comes in contact where an electric eye views them and transmits the signals towards PLC and communicates so filling of nail polish into the bottle takes places. Also, capping over the bottle neck is carried out by help of electric eye. |

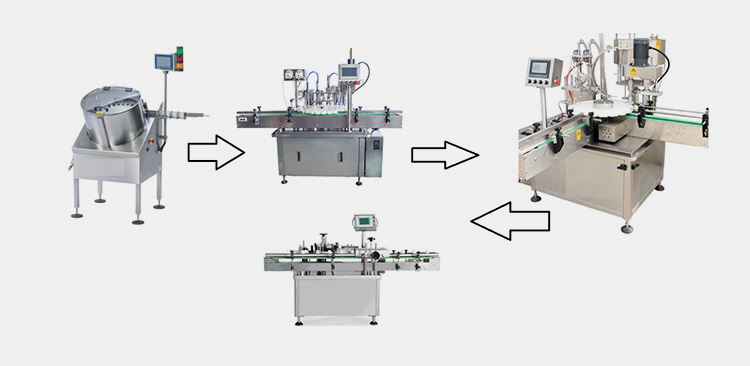

7.What Other Machines to Cooperate With Nail Polishing Machine To Form A Complete Production Line?

Number of Machines to Cooperate With Nail Polishing Machine

| Bottle Unscrambler

|

An important piece of equipment, a bottle unscramble selects bottles of different sizes or shapes and feeds them via machinery into a bottle filler machine for effective filling of nail polish.

The machine works by using a vibratory and rotary force that helps in the orientation of the bottles or containers in an upright position. Once bottles acquire their correct form, they get transferred toward the next machine. |

| Nail Polish Filling Machine

|

As discussed above, machine receives correct form of containers and treat them via passing through different stages and send a filled container out of the machine toward the next step of the production line. |

| Capping Machine | To secure formulation, a capping machine cooperation is essential. This machine promises to maintain product’s quality through out its shelf life.

The capping machine via auto-sensors, recognizes the presence of filled bottles then by the help of grippers twist the lid over the container and send it to the next machine. |

| Labeling Machine

|

The nail polish filling machine is integrated with an inkjet printing labeling machine that helps in printing attractive packaging designs, information, quotes, and necessary statements such as batch number, manufacturing, and expiry date., etc.,

You can feed the label roller and arrange the labeling connection on available section or assembly. Once the machine starts it will starts pulling them automatically for printing and adhesion over each container by the help of pressing rollers. |

8.What Products Do Nail Polish Filling Machine Fill?

If you’re running other businesses than nail polish, then don’t worry. A nail polish filling machine is an excellent and flexible machine that helps you in assisting dispensing of various other products such as:

Antibiotics Filling/ Vials and Ampoules

A nail polish filling machine is a reliable solution for filling highly sensitive products such as antibiotics, corticosteroids, and other medications in vials and ampuls effectively.

Paint Top-coats

If you are looking for dispensing machine to fill oil paints and water colors then this machine could be your solution which will enhance your business.

Nail Polish Removers

This is a non-viscous solution that is easy to evaporate, perfectly filled into each bottle or container by nail polish filling machine.

Lotions and oils

Various lotions and oils belonging to wide range viscosity consistencies can be filled by using a nail polish filling machine.

Stationery Items/ Glue/ Whites

Have you ever thought how various liquid stationery items are filled? Yes, a nail polish filling machine is ideal for filling glue, whites, erasers, and various products effectively.

Nasal and Intraocular Solution

Various nasal and intraocular solutions can be filled by using nail polish filling machine.

Mascaras

The most profitable and demanding cosmetic product has narrow tube cylinder filled with mascaras and lid using nail polish filling machine.

Lip Gloss

Highly viscous and popular cosmetic products with precise filling is achieved by using a nail polish filling machine.

Skin Foundation

Picture Courtesy: Revolutionary Beauty

The skin foundation, primers, and highlighters can be filled by using nail polish filling machine. The foundation containers are small, medium, and large in size varying from 20 ml to 200 ml can be catered by nail polish filling machine.

9.What are applicable Lids on nail polish filling machine?

A proper lid for a nail polish bottle is important for storing and using nail polish. For that purpose, nail polish filling machines require proper lids that fit on the bottles of the nail polish. Different types of lids are required for that such as;

| Applicable Lids on Nail Polish Filling Machine | |

Brush Lid It is the most popular lid for nail polish bottles, the lid is directly connected to a brush so it is easy to use. |

Snap Lid It is the most secure and convenient lid and easily snaps on the neckline of the nail polish bottle. |

Screw Lid Its lid has a screw that provides a secure and reliable seal so nail polish does not spill. |

Seal Lid This is the most aesthetically appealing lid which provides freshness and legitimacy to the nail polish. |

Square-shape Lid Modern and secure style of nail polish lid. This is a traditional style and easily compliant to the machine. |

Star-shaped Lid It is a whimsy and attractive style of nail polish lid that can be treated easily by the machine. |

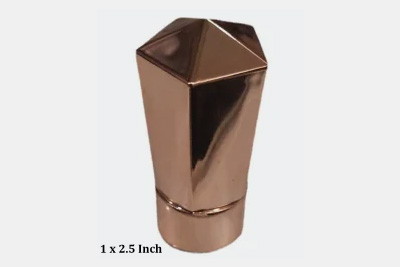

Pointed Lid The tapered and pointed-shaped lid of the nail polish bottle. The modern and stylish lid can be conformed to the nail polish filling unit. |

Rectangle-shaped Lid It is also a modern style of lid for nail polish bottles that provides secure packing and awesome style to the bottle |

10.What are available bottle sizes on nail polish filling machine?

The nail polish bottles are made up of lightweight glass, in some cases it is transparent whereas they may also be present in different colors. Nail polish used in the field of cosmetics, is available in different sizes.

Size of Nail Polish Bottle

The most widely used bottle size of nail polish includes with a minimum of 5ml and maximum of 25ml. But the most widely used nail polish bottles carry 10ml of nail polish which is also considered as a standard size for nail polish bottles.

Size of Nail Polish Vials

Nail polish is also stored in vials that have different sizes such as between 5ml to 15ml. The above presentation illustrates various sizes and measurements belonging to nail polish containers.

11.Is there any cleaning or maintenance requirement for nail polish filling machine?

CIP and SIP Cleaning of the Nail Polish Filling Machine- Picture Courtesy: Groningor

As you know that a nail polish filling machine is subjected to highly viscous formulation which is prone to stickiness upon certain conditions such as evaporation, dryness, and other.

You can not clean the system by simply using water and detergent. For that, manufacturers have introduce CIP which is known as Clean-In-Place and SIP or Sterilization-In-Place.

These are controlled machines designed to clean and wash inside levels of the machine including pipes, hoppers, and vessels with hot water and detergent of particular formulations. And SIP offering intense steam environment that vanish debris and clean the machine 99.99%.

The process of cleaning is composed of several different cycles or stages involving pre-rinsing, washing, steaming, and other process in the flow system.

The temperature range in the CIP system varies in between 120 to 140 °C, and SIP has 120-135°C for 30 minutes to purge unwanted particles.

12.How To Deal with Basic Problems with Nail Polish Filling Machine?

Like any industrial machine, a nail polish filling machine also strikes with some technical problem during working. What are those problems and how it should be manage is disuccsed below.

Clogging of Nail Polish Solution

| Problem

|

Solution | Picture |

| This is the most common problem which could be occurred due:

Temperature issues. Evaporation of Thinner. Incomplete Cleaning. |

To avoid this, we would recommend to:

Maintain the temperature of working environment. Keep using a compact and enclosed working condition to drop down the evaporation process and using an optimized thickener. Use CIP and SIP cleaning system to clear the sticky debris inside the machine. |

|

Inconsistence Nail Polish Filling Ratio

| Problem

|

Solution | Picture |

| This is another important problem which is occurred due to:

Improper settings of the machine. Machine lethargy. Blockade in circulatory pipes. Viscosity problem. |

To rectify this problem, we would suggest checking:

Debris or sticky particles cross the pipes and circulatory system and clear it. Reset the machine setting and re-calibrate it. Assess the viscosity range which should be under the define limit. |

|

Spillage or the product

| Problem

|

Solution | Picture |

| This is common problem which is occurred due to:

Excessive flow of the solution. Increase flow rate. |

To correct this problem, we would suggest checking:

Adjust the nozzle settings. Please check and correct the flow formulation to minimize the spillage. |

|

Air Bubbles Formation

| Problem

|

Solution | Picture |

| This problem occurred due to:

Variation in the flow rate. Machine incorrect setting. |

To correct this problem, we would suggest using:

Correct assessment of flow rate of the machine. Recheck the setting and calibrate it. Use degasser or vacuum to minimize formation of air bubbles. |

|

13.What Are the Expected Future Prospects of Nail Polish Filling Machine?

The nail polish filling machine future profitability forecast- Picture Courtesy: Groninger

The nail polish filling machine is expected to grow high significant spike in the future of the competitive world of packaging and manufacturing.

The primary driven demand is forecasted toward liquid formulation involving pharmaceuticals, cosmetics, chemicals, etc.

Moreover, the market size is also segmented into various sections that we discussed above, all of them would be showing their own worth and high values,

The market research shows that the following companies are considered as the largest manufacturers and suppliers worldwide. For example, syntegon, IMA, Optima, Allpack, Truking, etc.,

The data statistic estimated value of nail polish filling machines is 2.3 Billion USD in 2022 which is expected to increase in 2032 as US$ 3.5 Billion with Estimated CAGR from 2022-2032 around 4.2%.

Conclusion

A nail polish filling machine is one of the best machines that is used not only in cosmetics industry but other sectors too. This is all because, machine is efficient enough to offer several applications. We AIPAK Engineering, understands the significant of offering excellent, safe, and efficient filling machine to our clients focusing on their needs and budget. It is our commitment to protect your products, time, and improve future planning. If you’re planning to add nail polish filling machine and associated production line equipment; then contact us now. Our Team Member will shortly answer you to begin a new journey of success.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Nail Polish Filling Machine Related Products