Fully Automatic Aseptic Filling Machine For Anesthetic Liquid Bottle Filling Capping And Labeling Packing Line

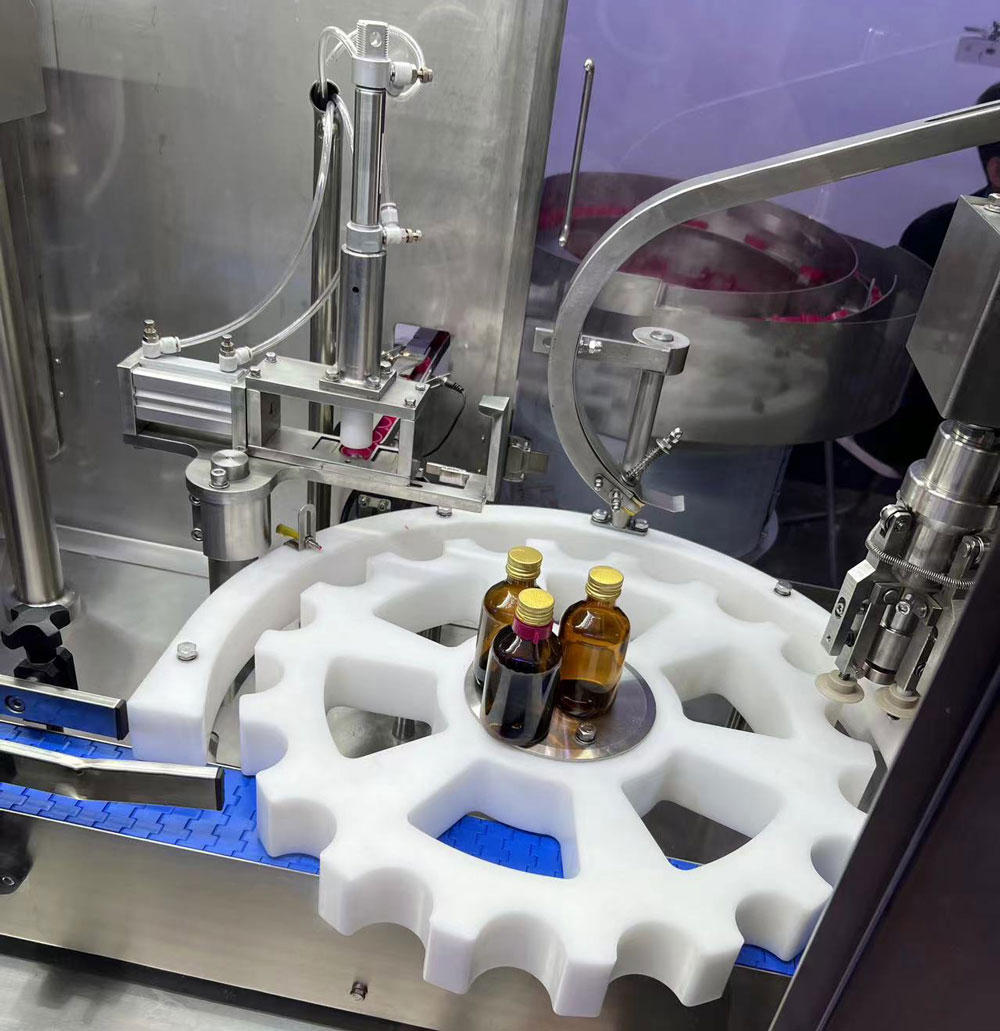

AIPAK ENGINEERING Aseptic filling machine for anesthetic adopts aseptic isolation technology to ensure the sterilization of filling materials, packaging environment and packaging containers. Sterilize the bottle and cap by soaking in disinfectant to ensure the sterility of the packaging container. The internal and external surfaces of the equipment are cleaned and sterilized by the SOP method, and the filling environment is kept at positive pressure by using sterile air to achieve a 100-level clean environment. The material pipeline is cleaned and sterilized by CIP and SIP, which ensures that the material after UHT sterilization is not contaminated, and ensures that the final product meets the commercial sterility requirements. The control technology of this aseptic filling machine for anesthetic is used to realize the communication between single machines and the control of the whole line, online display of the running status of the whole line and fault alarm, which greatly improves the level of automatic control and reduces the possibility of human mis-operation.

Details of AIPAK ENGINEERING Aseptic Filling Machine For Anesthetic

Frame Structure

1.Adopting welded frame for easy deformation and nut positioning.Features: Prevent hard force deformation. Surface coating with baked paint to prevent rusting.

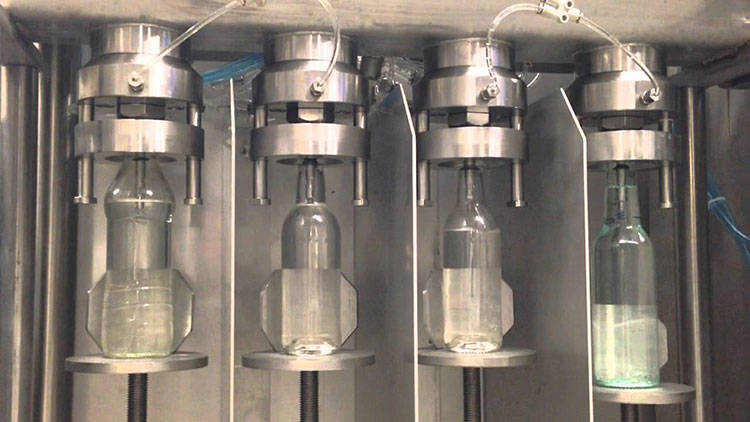

2.Filling part: Using stainless steel ceramic pump for filling, with high accuracy. Adopts stainless steel ceramic pump.

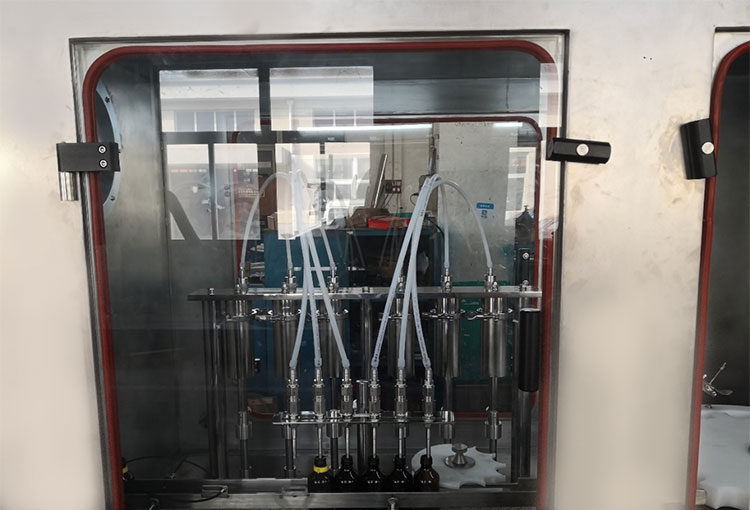

3.Block card structure, easy disassembly, with no bottle shutdown and no bottle capping function.

4.The filling needle rises with the increase of liquid level, so that the medicine anesthetic liquid will not splash out during filling.

Stainless steel ceramic pump filling with high filling accuracy

Cover with hanging cover method

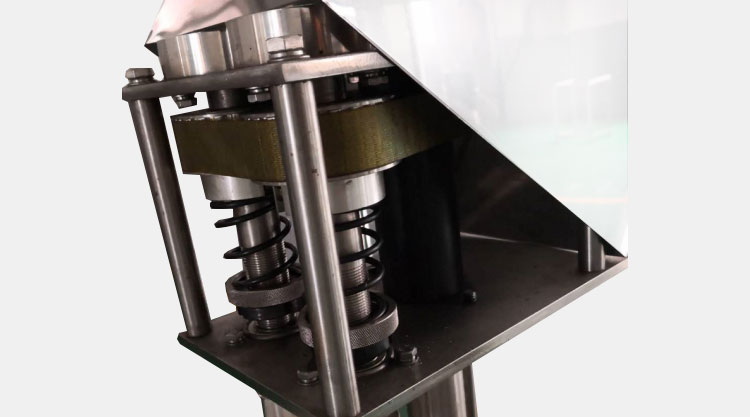

Fully enclosed filling design,adopting single head four blade capping, the capping will not be damaged after capping

Outer cover oscillator manual lifting

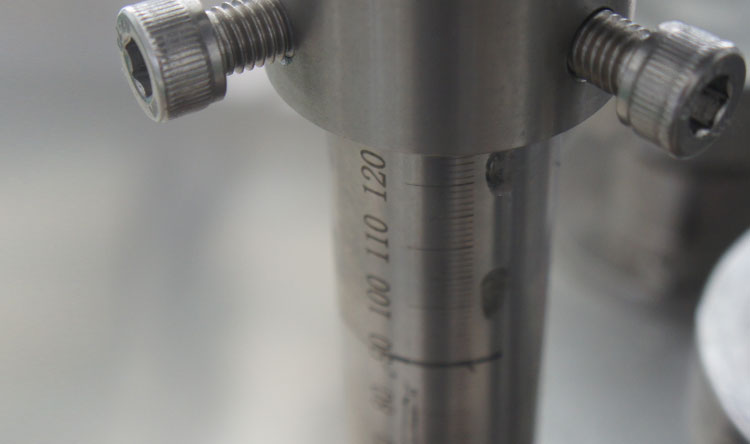

Height adjustment with scale

Anti dripping needle, lock the needle after filling, completely solve the dripping problem

Automatic loading of bottle neck collar

Remote control jog function (dedicated for debugging)

The turntable is marked with a scale, and the components are numbered

Siemens touch screen, can set three-level passwords, with emergency stop button

Upgraded capping box

Traditional capping boxes

New style capping box,the traditional belt structure has been eliminated, and it is processed with imported oily materials, which is wear-resistant and does not require the replacement of vulnerable parts, reducing noise and preventing the falling of particle caps

The sheet metal is processed and after matte treatment, the color is soft and non reflective

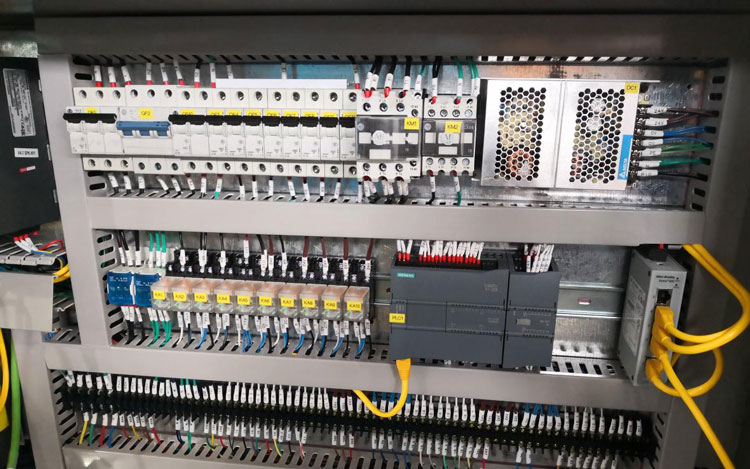

All electrical appliances are equipped with international first tier brands

Aseptic Filling Machine For Anesthetic Technical Specification:

| Capacity | 30-40Bottles/Min |

| Filling Head | 4 |

| Filling Range | 50-250ml |

| Filling Deviation | ≤±1% |

| Number of Capping Heads | Single Head |

| Production Qualification Rate | ≥99.9% |

| Speed Control | Frequency Control |

| Power Supply | 220V 50Hz |

| Power | 2.0kw |

| Dimension | 2800×1500×1700 |

Aseptic Filling Machine For Anesthetic Video

The Buyer's Guide

Aseptic Filling Machine for Anesthetic: The Complete FAQ Guide In 2025

Do you know anesthesia is more than sleep and you do not feel any pain under anesthesia? It is introduced into the body through inhalation or intravenously. Because of this, it should be sterility-packed.

With the evolution in pharmaceutical manufacturing, an aseptic filling machine for anesthetic is introduced in the market. It aseptically and securely packs the anesthetic agents. An aseptic filling machine for anesthetic is crucial in establishing patient safety.

Aseptic filling machine for anesthetic is facing continuous development; therefore, it is imperative to understand its role and functionalities. The purpose of this FAQ guide is to offer detailed information regarding the aseptic filling machine for anesthetic.

1.What is an Aseptic Filling Machine for Anesthetic?

Aseptic Filling Machine for Anesthetic

An aseptic filling machine for anesthetic is a vital part of aseptic manufacturing. It loads sterile anesthetic agents in sterile conditions and ensures there is no microbial contamination during any stage of processing and packaging.

It ascertains there is no contamination during the filling stage for retaining the efficacy and quality of the final anesthetic product. Aseptic filling machine for anesthetic has a significant role in ensuring the safety of medical products like anesthesia. This machine guarantees the complete absence of microbes in the anesthetic product.

2.Why Aseptic Filling Machine for Anesthetic is Important in Pharmaceutical Packaging?

The aseptic filling machine for anesthetic is a state-of-the-art system, protecting anesthetic integrity and effectiveness. Its ability to maintain sterility is what makes it important in the pharmaceutical industry. Some of these reasons for its importance are written below:

Sterility and Prevention of Cross-Contamination

Sterility- Picture Courtesy: Medical XPRT

Sterility is of paramount importance in the use of anesthetic agents. If there is any kind of contamination present in anesthesia it could lead to severe complications like infections. The job of an aseptic filling machine for anesthetic is to uphold sterility and prevent any kind of cross-contamination from the earlier batches and microbial contamination. It assures the purity of anesthetic products.

Complete Patient Safety

Complete Patient Safety- Picture Courtesy: Oral Science Pro — Oral Science

Aseptic filling machine for anesthetic safeguards patient safety by its aseptic filling. When anesthetic agents are free from microbes, they are rendered safe for administration to patients. So, there are no possible adverse outcomes by the sterile filling, which leads to the success of therapeutic agents.

Upholding Product Efficacy

Upholding Product Efficacy- Picture Courtesy: Medco

Aesthetic products should remain effective throughout their manufacturing, packaging, and administration. Active ingredients deteriorate when faced with harsh contaminants. However, an aseptic filling machine for anesthesia loads and packs anesthetic products in such a way, that they remain potent.

Boost in Shelf-Life

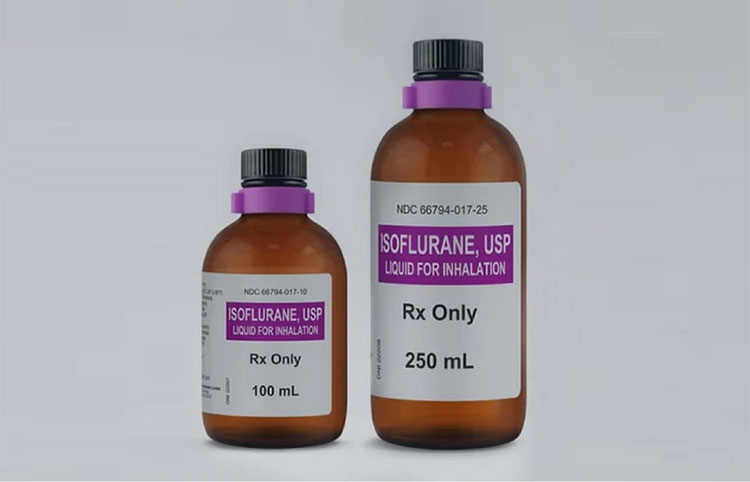

Boost in Shelf-Life- Picture Courtesy: Cetylite

An aseptic filling machine for anesthesia is good for extending the shelf-life of the products. It maintains the stability of the anesthetic agents but also decreases their wastage over time. This prolongation of the expiration period is because of the sterile filling of this machine.

Production Efficiency

Production Efficiency- Picture Courtesy: Piramal Critical Care

This machine often fulfills high-volume production demands by its production efficiency. Its automation increases its speed and efficiency, which means that it can easily fill and seal numerous anesthetic packaging containers in a short duration.

Consistency in Filling

Consistency in Filling

Human error in manual filling results in fill inaccuracies and customer dissatisfaction. But these things are quelled by an aseptic filling machine for anesthesia. It fills and seals products with absolute accuracy and decreases human error. It also increases the patient and healthcare professionals' trust in the quality of anesthetic products.

3.What are the Applications of Aseptic Filling Machine for Anesthetic?

Aseptic filling machine for anesthetic has diverse applications in different industries because of its aseptic packaging. This machine has proven its worth in different industries because hygienic packaging is key to a successful business. Some of its primary applications are written below:

Pharmaceutical Industry

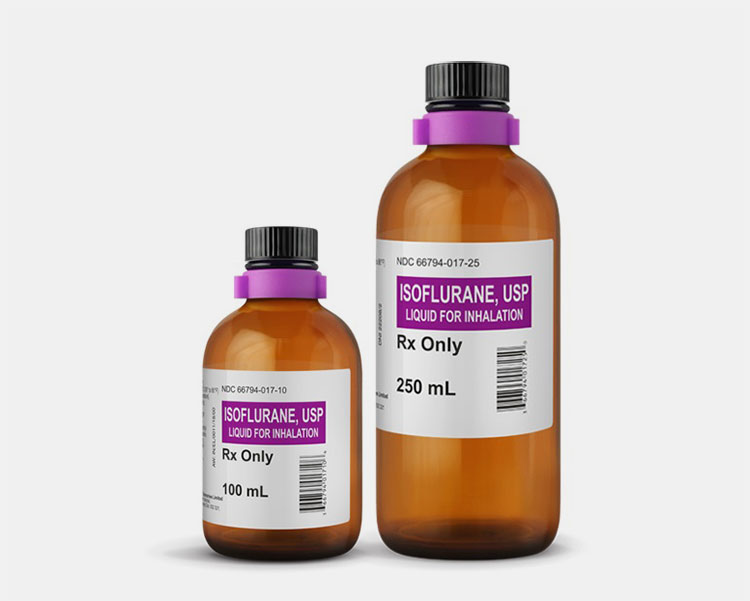

Aseptic Pharmaceutical Vials and Bottles- Picture Courtesy: Acdima – International

The aseptic filling machine for anesthetic is a versatile and adaptable unit, loading a wide range of pharmaceutical products like injectable drugs and antibiotics into bottles, vials, and ampoules. Mostly, it has a significant role in dispensing anesthesia for injections and inhalations into the bottles. This machine also packs different kinds of IV solutions.

Biotechnology

Aseptic Biotechnology Bottles- Picture Courtesy: 908 Devices

In this industry, it is crucial to process different kinds of biotechnology products aseptically, as otherwise, they will lose their effectiveness. Therefore, an aseptic filling machine for anesthetic has an integral application in the biotechnology industry because it loads diverse kinds of biologics and biopharmaceuticals. This machine maintains aseptic conditions while filling monoclonal antibodies, gene therapies, and recombinant proteins.

Dairy Industry

Aspectic Dairy Bottles- Picture Courtesy: Serac

To improve shelf-life of the dairy products like yogurt, milk, cream, and cheese, an aseptic filling machine for anesthesia is used in the dairy industry. It ensures an ultra-clean environment for the packaging of dairy products. It enforces sanitary rules during dairy loading.

Beverage Industry

Aseptic Beverage Bottles- Picture Courtesy: Sant Aniol

An aseptic filling machine for anesthetic is also required in the beverage industry for the filling of different kinds of beverages like water, juice, energy drinks, soups, smoothies, cocktails, etc. It maintains the freshness and safety of different beverages.

Nutraceutical Industry

Aseptic Nutraceutical Bottles- Picture Courtesy: M&R Label

Aseptic filling machine for anesthetic has a myriad of uses in the nutraceutical industry. It ensures sterile asepsis of different liquid and powdered vitamins, proteins, and probiotics. Thus, it directly maintains the viability and nutrition of different nutraceutical products.

Cosmetic Industry

Aspectic Cosmetic Bottles- Picture Courtesy: LinkedIn

Aseptically packed cosmetic products are high in demand because of their sanitariness and decontamination. Thus, an aseptic filling machine for anesthetic has paved its path in the cosmetic industry. It packs lotions, creams, and gels aseptically. Furthermore, it also handles medical cosmetic products like Botox and dermal fillers.

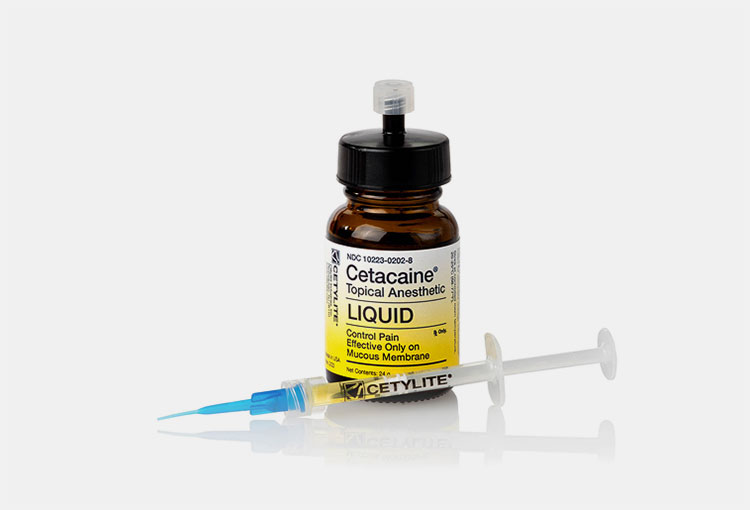

Veterinary Industry

Aseptic filling machine for anesthetic in vet industry- Picture courtesy: vetsurgeon

In this industry, aseptic filling machine for anesthetic is used to produce and fill the medicines required for safe procedures and operation of animals. This is included liquid and gas anesthesia filled in various size bottles.

4.Detail Step-by-Step Processing of Aseptic Filling Machine for Anesthetic?

The aseptic filling machine for anesthetic works meticulously to fill the anesthetic containers and to uphold the antisepsis of the packaging process. It cautiously loads the products to ascertain the potency of the packed products. Here is the step-by-step processing of the aseptic filling machine for anesthetic.

| Bottle Unscrambling

The working steps begin by placing bottles on the turn table. These bottles are sterilized before loading them on the turntable. Both the interior and exterior of anesthetic bottles and caps and stoppers are sterilized using heat or other sterilization techniques. The turntable conveys these bottles to the conveyor. |

Picture Courtesy: AIPAK Engineering |

| Filling

Different types of filling equipment smoothly fill the anesthetic products in packaging containers like bottles. Filling nozzles are the core parts responsible for precise and hygienic filling. There is a lack of direct exposure to working personnel during this step, ensuring contamination-free processing after sanitization. |

Picture Courtesy: AIPAK Engineering |

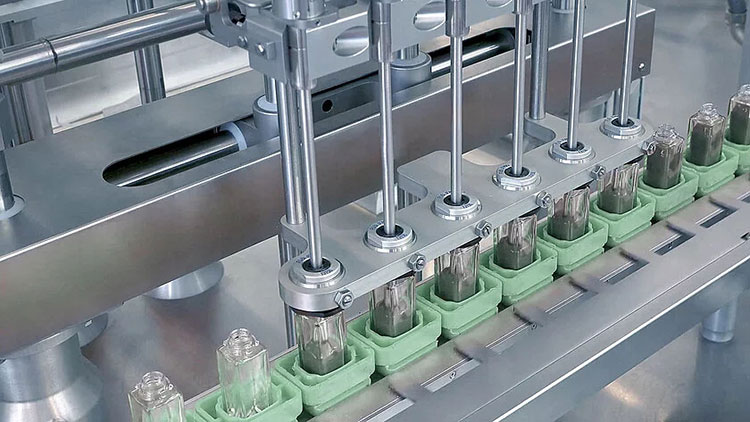

| Neck Ring Insertion and Capping

It is the last step in the operation of an aseptic filling machine for anesthetic. It is divided further into two steps. In the first stage, the head plugging system hygienically puts caps and neck rings onto the loaded containers to airtightly seal them. In the second stage, the capping screw applies torque to secure the caps and tightly seal the caps. The function of the neck ring is to keep the caps in place. |

Picture Courtesy: AIPAK Engineering |

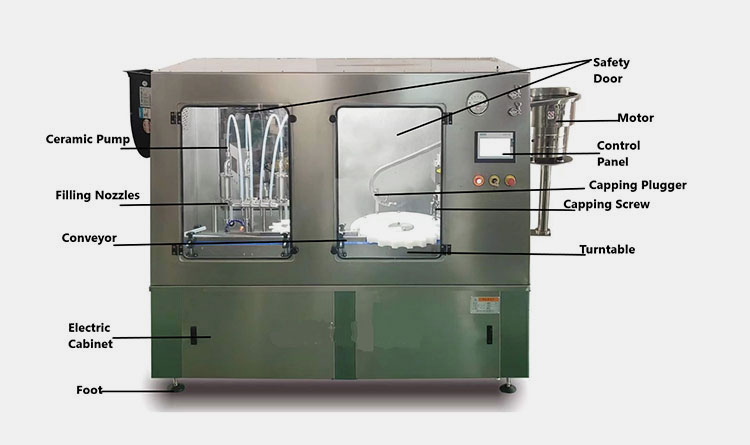

5.What are the Parts of Aseptic Filling Machine for Anesthetic?

Parts of the aseptic filling machine for anesthetic have a pivotal role in the smooth processing of the machine. These parts are discussed in detail below:

Parts of Aseptic Filling Machine for Anesthetic

| Ceramic Pump | The filling process occurs with the help of ceramic pumps. They are the high-precision device, manufactured using stainless steel. They have a block structure that is quite simple to disassemble. The ceramic pump is corrosion-resistant. |

| Filling Nozzles | It is an anti-drip filling system in which a specialized needle is employed. This needle seals the liquid opening after filling. To prevent spillage of liquids, the needle level rises with the liquid. |

| Electric Cabinet | It is the powerhouse of the machine and allows the housing of different electrical components like switches, relays, and circuit breakers. |

| Conveyor | A conveyor is the main transport unit of the machine. It has drive belts with the help of which it moves the anesthetic bottles across various sections of the machine. |

| Foot | The machine has four stable feet that support the full weight of the equipment. It maintains the equilibrium of the machine while it is working. |

| Safety Door | It is a negative pressure cover made up of tempered glass. It is the safety feature of an aseptic filling machine for anesthetic. It does not allow the operators to access the machine during the filling and capping processes. |

| Motor | It is a transformative unit that is powered by electric current and it generates mechanical energy for driving various parts of the aseptic filling machine for anesthetic such as conveyor and turntables. |

| Control Panel | It is an interactive touchscreen panel, located on the side of an aseptic filling machine for anesthetic. It has different programming options to operate and manage the machine. The control panel also has a remote control jog function that is used for debugging the machine. |

| Capping Plugger | The function of this part is to insert neck rings and caps into the opening of bottles. The capping plugger has an essential role in sealing the anesthetic bottles. |

| Capping Screw | It is part of the capping unit that screws the caps on the bottles to form a tight seal. It rotates the caps on the bottles to close the latter. |

| Turntable | It is rotated via a motor. The rotation of bottles on the turntable allows them to move through different capping units. It has pockets for holding different bottles. |

6. What Techniques are Implemented for Sterility of Components in an Aseptic Filling Machine for Anesthetic?

Numerous techniques are implemented for the sterility of components in the aseptic filling machine for anesthetic. These techniques are detailed below:

Steam

Steam Sterilization- Picture Courtesy: Precision Boilers

In this technique, steam is formed in the autoclave for sterilizing the equipment, tools, and other components. It is the most effective sterilization method, as it kills different pathogens. Steam is frequently used for sterilization. However, it has drawbacks, for instance, the deterioration of different devices from encountering heat and moist conditions.

Dry Heat

Dry Heat Sterilization- Picture Courtesy: BMT Medical Technology s.r.o.

Dry heat is produced in the dehydrogenation tunnel to destroy various kinds of pathogens. Components are heated at a high temperature for a specific time. It sterilizes different types of feed lines.

Gamma Radiation

Gamma Radiation Sterilization- Picture Courtesy: Pharmaceutical Online

It is utilized in combination with other sterilization techniques. It is typically employed to sterilize products like anesthesia. Immediately after sterilization with gamma radiations, products are loaded in containers to preserve their sterility.

Fumigation

Fumigation Sterilization- Picture Courtesy: Industrial Fumigant Company

Fumigation is usually used to sterile large parts of equipment. It also sanitizes equipment that cannot be conveniently accessed. Different types of chemicals like hydrogen peroxide, chlorine dioxide, and ionized hydrogen peroxide are utilized for sterilization. These chemicals emit gases that kill off microbes upon contact. However, this process has limitations like toxicity and it causes corrosion of components.

E-beam

E-beam Sterilization- Picture Courtesy: Nextbeam

It is the most innovative form of sterilization in which electronic beams inhibit microbes by damaging their important molecules like DNA or proteins. It passes through cartons or other packaging containers such as bottles; so, it is utilized for equipment and products that are already packed. Furthermore, it can decontaminate the exterior of machines and other surfaces.

7.What are the Filling Approaches in Aseptic Filling Machine for Anesthetic?

For sanitary filling, different innovative filling approaches are employed in the aseptic filling machine for anesthetic. They are essential in upholding the purity and cleanliness of the anesthetic products. These filling approaches are penned below:

Pressure Filling

Pressure Filling- Picture Courtesy: Rizzolio Semi automatic bottling systems

It is the most widely utilized method in the aseptic filling machine for anesthetic. In this approach, pressurization of both anesthetic products and packaging containers is carried out. And the product is dispensed in the container using pressure forces. It ensures rapid and uniform filling.

Diaphragm Pump Filling

Diaphragm Pump Filling- Picture Courtesy: Groninger-group

This technique uses diaphragm pumps for precise loading of anesthetic products. Fluid is fed into and expelled out of inlet and outlet valves, respectively with the movement of the diaphragm pump. These pumps have an aseptic design because the liquid is not exposed to internal parts.

Peristaltic Pump Filling

Peristaltic Pump Filling- Picture Courtesy: Groninger-group

This filling approach is quite popular in pharmaceutical manufacturing because of its gentle processing. Peristaltic pumps are equipped with rollers that squeeze flexible tubing to fluidize the liquid through the tubing. This pump works by contracting and relaxing the tube.

8.What Is The Difference Between an Aseptic Filling Machine for Anesthetic and a Traditional Filling Machine?

Aseptic Filling Machines for Anesthetic- Picture Courtesy: OnePointe Solutions

Sterility is the key difference between an aseptic filling machine for anesthetic and a traditional filling machine. The former is produced to uphold the sterility during the filling process. Sterility is not a requirement for the traditional filling machine.

The aseptic filling machine for anesthetic is equipped with cutting-edge technologies like isolators and other restricted systems to prevent contamination. These technologies restrict the access of working operators to filling and sealing operations. These systems are absent in the traditional filling machines. Moreover, the aseptic filling machine for anesthetic is operated under strict GMP guidelines.

9.What are the Regulatory Certifications of the Aseptic Filling Machine for Anesthetic?

Regulatory Certification- Picture Courtesy: ShipWizard

Aseptic filling machine for anesthetic must be designed and operated following regulatory guidelines to meet the safety, quality, and efficiency standards. These certifications ensure quality manufacturing, design, working, and cleanliness of the aseptic filling machine for anesthesia.

These regulatory certifications are detailed below:

| GMP | It is a global regulatory standard that imposes guidelines for clean, hygienic, and quality processing. An aseptic filling machine for anesthetic must be produced following obligatory guidelines of GMP. In this way, this machine ascertains sterility and decontaminated processing. |

| EMA | This stands for European Medicines Agency. It addresses the procedures included in the sterile manufacturing of medicinal products. It mandates the need for aseptic processing and utilization of cleanrooms. |

| FDA | The compulsory sanctions imposed by the FDA emphasize the requirement of fulfilling GMP standards. These sanctions are associated with manufacturing, packing, and storing anesthetic products. |

| ISO | It is essential certification to ensure consistent improvement in aseptic manufacturing. ISO regulatory certification requires the use of a clean environment during the production of anesthetic products. |

10.How Does Aseptic Filling Machine for Anesthetic Maintain Sterility?

Sterility in Aseptic Filling Machine for Anesthesia- Picture Courtesy: Contact Pharma

The aseptic filling machine for anesthesia is constructed in such a way as to avoid all possible contamination of sterile anesthetic products. Some of the important strategies by which the aseptic filling machine for anesthesia maintains hygiene throughout pharmaceutical filling are discussed below.

| Cleanrooms | HEPA filters in clean rooms are best for removing small particles of dust and debris as well as microbes from the air. They sterile the air in the cleanrooms. Furthermore, positive pressure is maintained in the clean room to prevent entry of contaminated air. |

| Cleanliness of Equipment | Different parts of the filling devices are sterile with steam or other sterilants. Moreover, different cleaning devices like Clean-in-Place and Sterilize-in-Place are present in the aseptic filling machine for the anesthetic to retain its sterility and sanitation. |

| Barrier Technologies | Different types of barrier technologies like isolators and RABS (restricted access barrier systems) are significant in limiting the operator's access to the critical area of filling and sealing. |

11.What are the Challenges and Solutions of Aseptic Filling Machine for Anesthetic?

An aseptic filling machine for anesthetic is an important component of anesthesia filling lines. With this machine, the sterility of the fill process is guaranteed. However, it can face several challenges that impact its efficiency and productivity. But with simple training and knowledge, these challenges are easily resolved. Some challenges and their solutions are:

Contamination of the Anesthesia

Contamination of the Anesthesia- Picture Courtesy: veichi

Sometimes, the sterility of anesthesia is compromised.

Causes

Due to leakage in the aseptic filling machine or involvement of the external environment.

It can be occurred by human error.

This can be caused by faulty sealing and filtration components

Poor cleaning and sterilization practices can result in contamination.

Solutions

It recommended to

Properly monitor the pressure in the fill area.

Train human operators to accurately handle the machinery.

Repair damaged sealing and filtration components.

Implement effective cleaning practices and regularly disinfect the machine.

Inconsistent Dosing

Inconsistent Dosing- Picture Courtesy: Maharshi Udyog

There are variations in the dosing volumes.

Causes

The causes of this problem are:

Erroneous calibration of fill devices.

Filling components like pistons or valves are defective.

Variations in the fill characteristics.

Solutions

It is recommended that:

Regularly calibrate fill devices as per manufacturer guidelines.

Replace old and faulty parts.

Ensure that the machine is compatible with viscosity and fill characteristics.

Poor Sealing

Poor Sealing- Picture Courtesy: Groninger

There are issues with the sealing integrity.

Causes

The major reason of sealing problems can be due to:

Inadequate setting of fill parameters.

Damaged stopper or caps.

There is a defect in the sealing and capping equipment.

Solutions

The suitable suggestions for this problem are:

Accurately set the fill parameters.

Use high-quality stoppers or caps.

Repair or replace the sealing and capping machine.

Clogged Nozzles

Clogged Nozzles

Clogged nozzles cause fill volume variations.

Causes

The main causes of this issue are:

The presence of foreign particles in the anesthetic product,

Anesthetic products accumulated in the fill nozzles.

Solution

It can solved by:

Properly filter the anesthetic solution before filling.

Regularly clean the fill nozzles.

Leakage in Sealing

Leakage in Sealing- Picture Courtesy: Groninger

There are gaps in the seal.

Causes

The major causes of this problem are:

There are variations in the sealing pressure and temperature.

Presence of foreign particles in the seal.

Seal materials are not matched with the machine.

Solutions

The recommended solutions to this problem are:

Maintain consistency in the sealing pressure and temperature.

Properly clean the sealing area and sealing materials.

Ensure that there is compatibility between the seal material and the machine.

12.What are the Buying Factors for Aseptic Filling Machine for Anesthetic?

It is hard to get a suitable aseptic filling machine for anesthetic because there are numerous types of machines present in the market, making selection a daunting task. Manufacturers usually go for machines with efficient packaging and strict quality compliance. Hence, you must consider several buying factors when purchasing the aseptic filling machine for anesthetic.

Production Size

Production Size

When investing in an aseptic filling machine for anesthetic, it is essential to determine the production size. You should select devices that not only easily accomplish your current production needs but also meet your future standards. Evaluation of production size decides the automation level of the aseptic filling machine for anesthetic. For instance, when the production size is large, you can satisfy the demands seamlessly with an automatic aseptic filling machine for anesthetic.

Speed

Speed- Picture Courtesy: Groninger

It is saying time is money and this statement is true for every industrial business, but especially crucial in the healthcare sector. So, you should opt for the machine with high speed because more speed translates into more anesthetic products, in turn resulting in more patients being treated.

Sterility

Sterility- Picture Courtesy: Groninger Group

It is important to take into account design and construction when purchasing the aseptic filling machine for anesthetic. The main purpose of this machine is sterility. So, it should have all the hygienic components. Moreover, filling nozzles and tubing must be manufactured using stainless steel. This machine must be tailored with Clean-in-Place and Sterilize-in-Place systems.

Compatibility

Compatibility

Numerous manufacturers strive to achieve top place in the market by procuring high-speed machines. However, the compatibility of filling technologies with product and container characteristics is of utmost importance. So, first, test your potential machine with your desired anesthetic product and packaging container before buying.

Cost

Price and Cost- Picture Courtesy: LinkedIn

Last but not least, cost is what makes or breaks your deal when it comes to buying the aseptic filling machine for anesthetic. When the machine has a lower cost but high-quality sterile components then immediately acquire it without further delay.

Conclusion

The aseptic filling machine for anesthesia is the biggest invention in pharmaceutical processing and it is synonymous with sterile processing. No pharmaceutical production operates without this machine because it is crucial in establishing hygienic and aseptic manufacturing and packaging. It helps deliver safe and high-quality anesthetic products to the patients. However, it is imperative to understand the functionalities and operation of this machine before buying. Hopefully, this blog helps you in this matter. Now, please contact AIPAK ENGINEERING to buy the best aseptic filling machine. Happy Shopping!!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Aseptic Filling Machine For Anesthetic Related Products