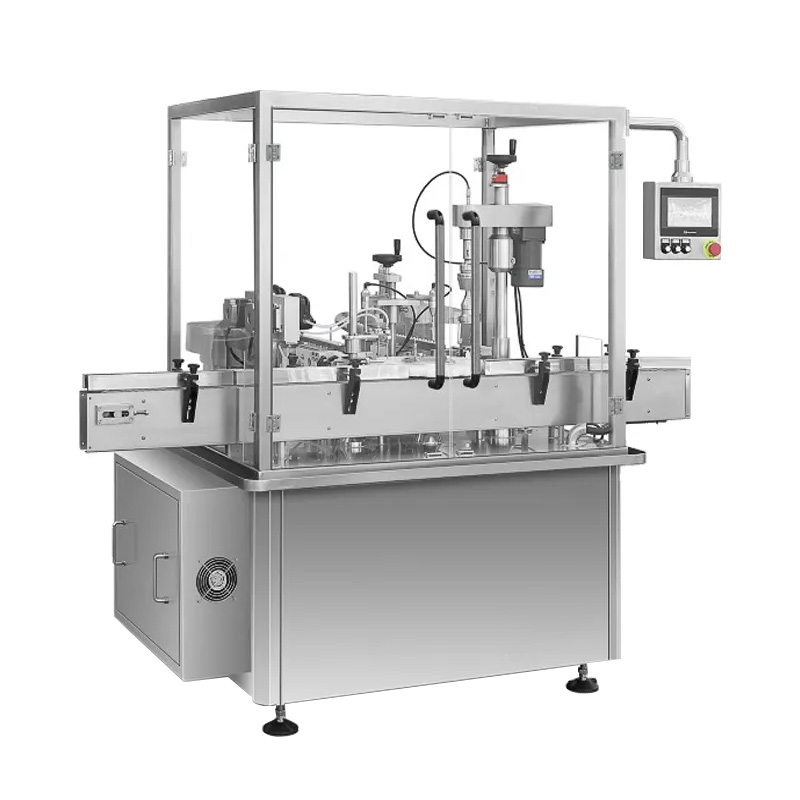

Pharmaceutical factory 5-20ml plastic bottle Eye Drops Filling Machine Production Line

AIPAK Engineering eye drop filling machine is applicable to the pharmaceutical industry 5-20 ml bottle eye drop filling and sealing process.It is a filling stoppering and capping machine suitable for eye drops and all kinds of bottle packaging, stoppering and capping.It can automatically complete the liquid filling,manipulator add stoppering and capping.According to customer technologic requirements configuration can add bottle feeder or bottle unscrambler.

All AIPAK Engineering eye drop filling machine can effective completion bottle sending. No bottle no filling. No bottle no add stoppering. No stoppering no add cap.The machine stoppering and add cap structure upgrading by our technical team, stoppering and add cap structure use manipulator, with precise alignment, finished eye drops pass rate can be more than 99.9%.

This eye drop filling machine has stable performance. According to your various packaging materials ,the eye drop filling machine can be customized,such as increasing the isolation protection system which can complete the aseptic production.And according to your different technological requirements,the configuration can also satisfy different specifications and production speed.

AIPAK Engineering Eye Drop Filling Machine Sample Display:

AIPAK Engineering Eye Drop Filling Machine Features:

1.This machine using stainless steel 304, material contact parts using 316L stainless steel, meet GMP requirements.

2.All electrical automatic control according to international standards, main components imported components, auxiliary components using the domestic high-quality products, with frequency control, continuously adjustable operating speed.

3.The filling head exploration to 2/3 of the bottle then start filling, second filling, to prevent the impact of large liquid foaming, no bottle no filling, no bottle no putting in inner stopper, no inner stopper no putting in cap.

4.Using a peristaltic pump filling, to ensure no leakage, no need to replace wearing parts, anti-drip completely.

5.Adjustable electronic load torque friction plates capping head, to prevent the original spring mechanical adjustment torque changes caused because of the elasticity of the spring rolling overshadowed loose or too tight, to prevent the cap outer wall wear.

6.Filling system with function of resorption, no drip.

7.Plugging and capping by manipulator automatically, can improve stability and rate of finished products.

8.Automatic stop function, if there is no filling, no inner plug in any rail, it may stop.

AIPAK Engineering Eye Drop Filling Machine Technical Specification:

| Filling nozzles | 1/2/4 |

| Packing materials | Plastic and glass bottle |

| Filling capacity | 10-120 ml |

| Filling precision | ≤± 1% |

| Filling speed | 10-60 pcs/min |

| Eligibility rate of inside tuck and outside tuck | ≥99% |

| Air supply | 0.6Mpa 0.6m³/min |

| Language choice(Touch screen) | English, Spanish, Russian, Arabic, French, Italian, Korean, can be customized. |

Eye Drop Filling Machine Related Products