Customization high accuracy automatic aerosol filling machine for small plastic bottle

AIPAK Engineering aerosol filling machine for small plastic bottle is mainly applied to various material round bottle, flat bottles. Filling material could be small dose of liquid, like syrup, essential oil, perfume, royal jelly, oral liquid, face cream etc. The aerosol filling machine can finish all works of bottle feeding, filling, putting inner plug if there is and capping outer covers automatically.

For bottles feeding, the pallet and the screw are used, and during the conveying, bottles will not fall. The turntable is made of high polymer material, and the size is decided by the user. The graduator drives the turntable to have the fixed rotation, provide correct positioning for lids (stoppers) feeding & the capping, and the capping rate is high. The 3-paw manipulator is used for the lids taking. With the magnetic capping head, when having the fastening, lids will not be damaged. When having the capping, bottles will be clamped tightly automatically, so the bottle will not be rotated.The vibrating tray is used for the lids unscrambling. Lids are conveyed on rails. The fixed-position lids feeding is adopted. When there is no bottles, there will be no lids feeding.

AIPAK Engineering Aerosol Filling Machine Features:

1.PLC control system, color touch screen display.

2.This machine has function of no bottle no filling/ no adding cap.

3.Stainless steel piston pump quantitative filling, pneumatic adding cap, elevating screw capping. Has advantages of accurate filling measurement, smooth screw capping, and simple operation.

4.Main electrical elements adopts foreign well-known brand.

5.Filling nozzles are made by 316 stainless steel.

6.Machine body is made by 304 stainless steel, machine is full compliance with GMP requirements.

AIPAK Engineering Aerosol Filling Machine Technical Specification:

| Bottle specifications | 30 -100ml glass bottle(can be customized according to client’s require) | |

| Production speed | 30-40 b/m | 60-80 b/m |

| Filling head | 4 | 8 |

| Stoppering heads | 1 | 2 |

| Capping heads | 1 | 2 |

| Qualification rate | ≥99% | |

| Power Supply | 220V/50Hz,2.5KW | |

| Weight | 800 Kg | |

| Dimensions | 2400*1700*1750mm | 2800*1800*1750mm |

The Buyer's Guide

Aerosol Filling Machine: The Complete Buying Guide in 2025

Do you know the concept of aerosol began since 1790 by a carbonated beverage? Today, you can see various different products available in gaseous suspension forming a mist of liquid molecules. It is an interesting science that will be discussed with you in this article.

Now, industries have grown this mode of dispensing in a way that you can observe a huge spike in the demand of aerosol filling machine. Yes, this is a significant solution offering this complex job completely flexible.

Planning to buy aerosol filling machine? this blog is for you. I promise you’ll find it worth reading. Here, we go!

1.What is Aerosol Filling Machine?

An excellent designed aerosol filling machine

To fill aerosol into assigned container accurate and precisely an aerosol filling machine is required. First, you should exactly know, what aerosol is?

It is actually a suspension that s made up of liquid molecules suspended in a gaseous state. You must have seen body spray; and you shake well before spraying. Yes this done to fully interact active ingredients with gas molecules so it can gives you an effective fragrance for a longer time.

As we stated above, the concept of aerosol is very old, but first patent spray was emerged in 1927 by chemical engineer belonged from Erik Rotheim in Oslo. Means, by the time, in the field of aerosol manufacturing process, the series of steps were taken out to create the aerosol.

So, in ancient times, these steps were followed by manual aerosol filling machines which was by changed to modern machines including semi-automatic aerosol filling machine and automatic. In the competitive market, it has gained a lot of attention as this equipment is worth buying in the term of offering complex job in an easiest way.

2.Where is Aerosol Filling Machine Used?

The aerosol filling machine is of high value in various industrial applications. Some of important applications are discuss below, we hope your field would be there also!

Pharmaceutical and Medicine

Medicated aerosol solution with amazing dispensing mode- Picture Courtesy: New Scientist

Now a days, the worldwide major highly profitable business is making and selling of pharma products and medicines. The pharmaceutical preparations including nasal sprays, topical spray including anaesthesia, skin products, steroids, eye cleaners, nasal sprays, and dental sprays are highly demanding products which are perfectly filled with aerosol filling machine.

Automotive Industry

Aerosol Products related to automotive Industry- Picture Courtesy: Gomechanic

This is not uncommon for you to see major automotive content available in the spray formulation. The automotive industry needs aerosol filling machine to dispense products like thinners, rust cleaners, shiners, degreasers, and lubricants, etc.,

Household Cleaners

House cleaning Aerosol Products: Picture Courtesy: Bob Vila

Everywhere around your house you can see various products made up of aerosols such as glass cleaners, kitchen cleaners, oven cleaners, mold killers, washroom cleaners, tiles cleaners, air-freshener, etc. The aerosol filling machine is worth buying tool to fill these products effectively.

Paint and Coatings Industry

Aerosol Items manufactured by paint & Coating Sector- Picture Courtesy: Motor1

The paint & coating industry needs aerosol filling machine to fill paint in tin bottles, also other products like varnish, coaters, shiners, primers etc.

Pesticide Industry

Aerosol Sprays with various pesticides products- Picture Courtesy: Ugao

This industry is high in demand as it offers you pesticide killers require for agriculture, household, offices, hospitals and other fields. This industry requires aerosol filling machine to manufacture products like pesticides, insecticides, herbicides, etc.

Personal Care and Cosmetics

Various Aerosol Filled Products used in Cosmetic & Personal Care- Picture Courtesy: Loreal

Women around the world love make up; and grabs those products first that are aesthetically pleasant and effective. For example, body spray, face cleaners, face tonners, hair sprays, body fragrance or perfumes, facial masks, mist, and much more. All of these products are mainly available in aerosol formulations which is generated by aerosol filling machine. So personal care and cosmetic industry is incomplete without this robust solution.

Food Industry

Modern Food aerosol filled Products in Food sector- Picture Courtesy: Foodspray

Among above mentioned industries, food industry also requires aerosol filling machine but for certain products such as whipped creams, food grade oils, or flavorant, etc.,

Adhesives Industry

Adhesive in Spray Formats- Picture Courtesy: Montana Color

In this industry, an aerosol filling machine is used to fill products like adhesives, sealants, lubricants and other related items respectively.

3.What are Benefits of Aerosol Filling Machine?

Here are some significant benefits of aerosol filling machine that you must know prior to purchasing.

Your Product’s Safety

The machine is significantly important in offering safe filling solutions

Aerosol filling machine is meant for dispensing aerosol product without any worrisome about its spillage or leakage. This machine has capability to fill product inside packaging material safely.

High Efficiency

A promising effective solution

Aerosol filling machine is very efficient and simple to use equipment ensuring a right amount dispensing of product in an efficient manner. This is great to use when you need to reach your high production capacity in a limited time.

Excellent Sanitary

Automatic Aerosol filling machine- Picture Courtesy: Coster

An aerosol filling machine body is made up of specialized designed features with stainless steel; means you have perfect machine which is easy to clean and resistant to accumulation of debris of any product which results in cross- contamination. So, whether medicines or cosmetic, you can provide amazing and clean products to your consumers by using it.

Very Cost-effective

Aerosol filling machine is A pocket friendly solution in you business

This is easy to use machine which is quite economical to purchase. You can find various types of aerosol filling machine in a cost-effective price list. Means you can get it depending on your production capacity and your pocket by spending very less money.

More Durable

A strong and durable aerosol filling line- Picture Courtesy: Aerosol Filling Machine

You will be surprised to know that aerosol filling machine is very protective for your product and about itself. Machine is made up with stronger materials with excellent performance. Means you can use it for a longer time with maintained quality and effectiveness.

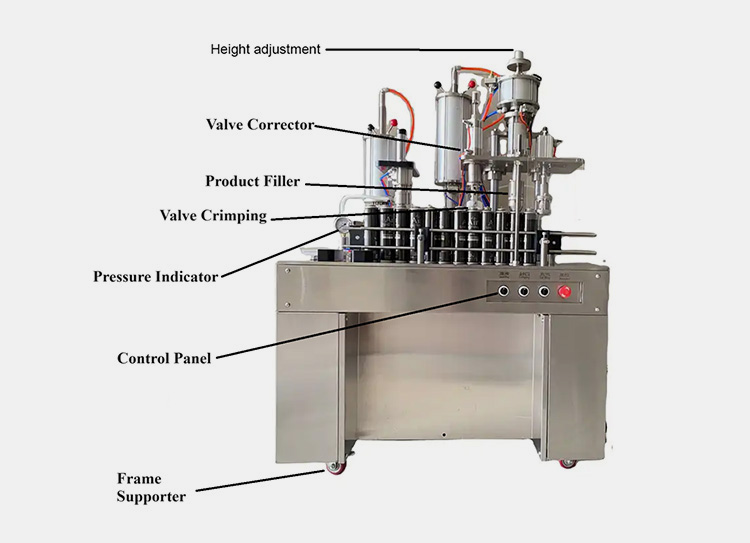

4.What are the Parts of Aerosol Filling Machine?

To understand the parts of machine, we have illustrated a labeled diagram of a semi-automatic aerosol filling machine. The parts of aerosol filling machine are discussed in:

Height Adjustment

This unit is very significant allows you to adjust the exact sizes of the filling cans for stable dispensing. The section is meant to assure you the step is carried out seamlessly or continuously. This can be operated using machine keys or manually.

Valve Corrector

To correct and adjust the alignment of the machine as well as positioning various categories of packaging material for aerosol filling, you can use valve corrector.

This unit is helpful in stabilizing the system and preventing from those issues that leads to inaccuracies or falling of cans or bottles from the machine.

Product Filler

This is the essential and important part of the aerosol filling machine which is accompanied by a filling nozzle allows you to dispense the aerosol into the can or bottle. This unit is mostly designed with different fillers such as piston, volumetric or weight-based units.

Valve Crimping

This section is also very important that helps in securing your product and the filled material by simply crimp a valve over the bottle or can. This sealing is very strong offering a tamper resistant securing lock over the bottle.

Pressure Indicator

This is small device attached to the machine where you can easily see the pressure build within the machine during running the procedure. This is helpful in the maintaining the level of pressure you need during processing.

Control Panel

What pressure you need, the number of bottles, concentration of suspending products, speed, timings, etc can be controlled by given keys in the machine which is entirely known as a control panel of the aerosol filling machine.

Frame of the Body

This is a structural supporter which is featured with tires, frame, that gives strength to your machine allowing a stable working without causing any vibration. You can smoothly run the machine as it withstands perfectly in industrial environment.

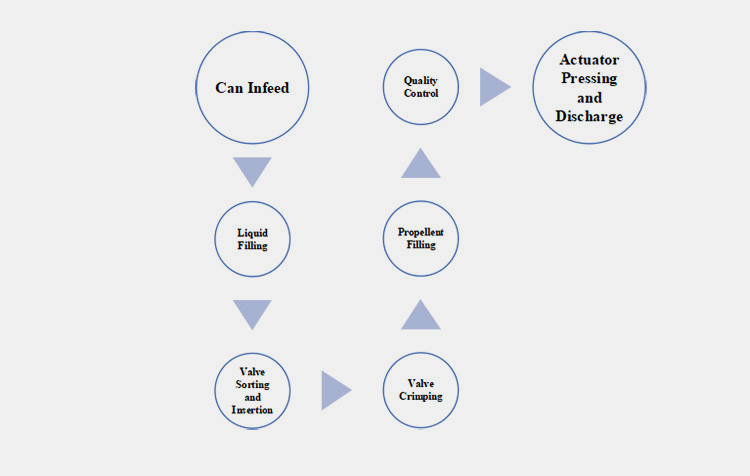

5.How does an Aerosol Filling Machine Fill product?

The aerosol filling machine is an integral part of the chemical, perfume, and, agriculture industries. The product filling principle of aerosol filling machines is somewhat complicated and is typically dependent upon the kind of aerosol filling machine.

The general working principle is as follows:

Can Infeed

Can Infeed- Picture Courtesy: R.A Jones

After product formulation, the next step is infeed of can usually be accomplished by the can unscrambling machine in larger productions. This machine places the can on the long conveyor after a fixed distance. This machine also sorts the cans in the upright position on the conveyors. In semi-automatic and manual types, this positioning of cans on the equipment is performed by the operator.

Liquid Filling

Liquid Filling- Picture Courtesy: Diamond Vogel

Can move towards the filling station where filling devices load the accurate quantity of liquids in the can through the filling nozzles. Different kinds of filler, for instance, gravity, pressure, and pump filler accomplish this task. The large hopper typically stores the liquid product and is critical in dispensing the product.

Valve Sorting and Inserting

Valve Sorting and Inserting- Picture Courtesy: Makwell

After filling, the conveyors carry the filled cans towards the valve-inserting station. The valves travel from a large tank and are indexed and sorted. A magnetic sorter for tinplate valves and a mechanical sorter are used for sorting the valves. The valve-inserting heads fix the valves on the opening of cans to control the product loading in subsequent steps.

Valve Crimping

Valve Crimping-Picture Courtesy: R&R Aerosol Systems

Then valves are crimped to secure the inner contents of the can. Crimping heads exert pressure force on the valve to hermetically seal the cans. This ensures that no product is leaked from the can. This is done either using a vacuum or a standard crimper.

Propellent Filling

Propellent Filling- Picture Courtesy: Makwell

Upon successful crimping, the cans are transferred to a propellent filling station, Here, different gases (LPG, HFA, DME, CO2, N2O, and Nitrogen) are loaded inside the cans. Filling nozzles dispense gases through pneumatic systems or hydraulic metering cylinders.

Quality Control

Quality Control- Picture Courtesy: MBC Aerosol

The next step is quality control in which the weight of the aerosol cans is checked and low-weight cans are rejected from the machine. Also, different leakage tests, for instance, water bath leakage tests are performed to detect the leakage inside the cans. This step is critical in eliminating low-quality products.

Actuator Pressing and Discharge

Actuator Pressing and Discharge- Picture Courtesy: R&R Aerosol System

Then high-quality aerosol cans are transported to the actuator pressing station. Actuators are placed on the cans by the robotic head. These heads exert a strong force of over 300 pounds for pressing the actuator on the valve of cans. Afterwards, the aerosol cans are carried to a capping machine for the down-the-line capping and sealing process.

You can smoothly run the machine as it withstands perfectly in industrial environment.

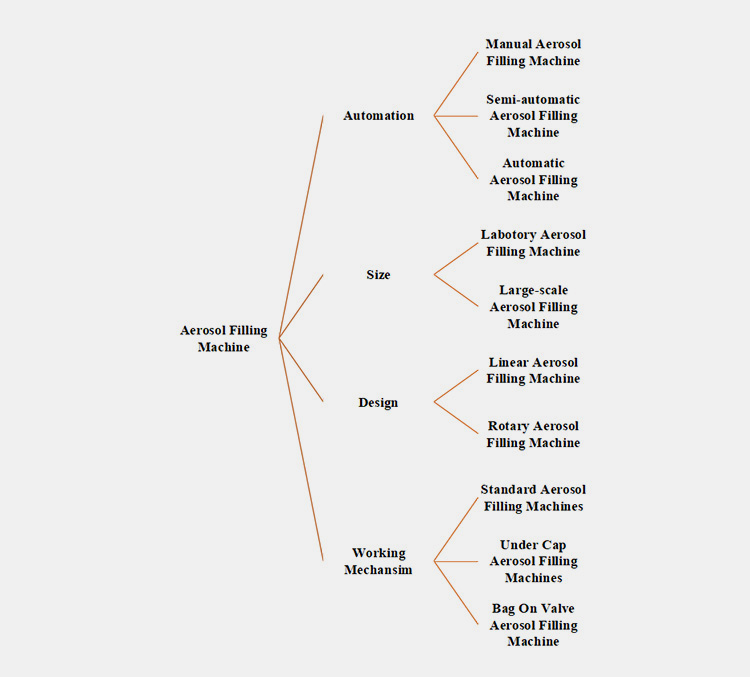

6.How to Classify an Aerosol Filling Machine?

Aerosol has been gaining popularity in recent years, therefore, manufacturers are finding new ways to innovate the aerosol filling machine. Thus, there is diversity in these machines. Here is the complete detail of the aerosol filling machine.

According to the Automation Level

Manual Aerosol Filling Machine

Manual Aerosol Filling Machine

It is a small-sized machine offering portability and ease of operation. It is easily fixed on desktops and other small counters. This machine is comprised of different levers and handles for manually loading the aerosol product in the cans and for crimping valves on cans. It features pumps and pistons for filling cans. It is limited productivity because a single can is packed in one cycle.

Semi-automatic Aerosol Filling Machine

Semi-automatic Aerosol Filling Machine

This machine is a compact unit consisting of three different stations, liquid filling, sealing, and gas filling. The filling and sealing heads work autonomously and dispense accurate quantities of aerosol. However, it requires one to two operators to manage the machine, as well as to load cans, and unload filled cans from the machine. Can move automatically through different stations via conveyors.

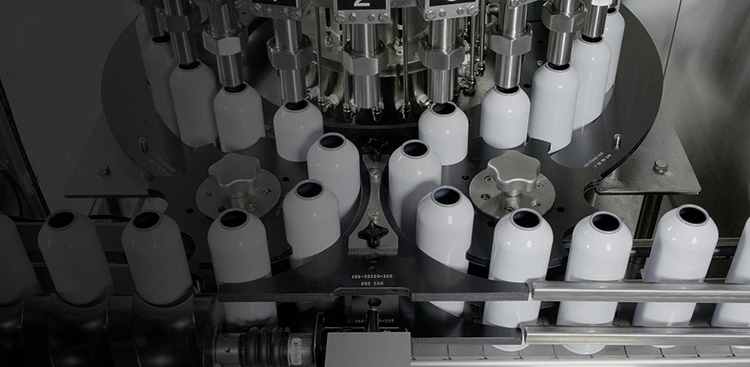

Automatic Aerosol Filling Machine

Automatic Aerosol Filling Machine- Picture Courtesy: SED Pharma

This machine is designed with advanced technology and mechanical filling nozzles, valve inserter, crimpers, and actuator pressing heads that run in synchronicity to automate aerosol filling and sealing operations. It is state-of-the-art equipment running efficiently under the guidance of PLC control. Operators simply just program HMI and every function is independently carried out.

According to Size

Laboratory Aerosol Filling Machine

Laboratory Aerosol Filling Machine- Picture Courtesy: Zigler

This machine is typically designed for research and development. It is a compact unit consisting of a single filling head, gas filling head, and valve crimping station. It is mostly found in small laboratories for product trials and formulations. This machine is made with a stainless steel table and pneumatic controls for regulating mechanical heads.

Large-scale Aerosol Filling Machine

Large-scale Aerosol Filling Machine- Picture Courtesy: Aile

It is a large-scale machine that is normally part of the heavy processing unit. It is available in U or L-shaped designs in which different modules of aerosol filling stations are fitted. Unlike laboratory aerosol filling machines, it has a huge number of different modules, for instance, liquid filler, valve inserter, nozzle presser, etc. This machine achieves high performance with its precise and fast systems.

According to Design

Linear Aerosol Filling Machine

Linear Aerosol Filling Machine- Picture Courtesy: Aile

As the name indicates, it is a linear or straight-line machine in which every station is found consecutively. Different operations are performed in sequence; hence, this machine offers limited productivity. Moreover, the conveyor transport pauses during different steps of aerosol filling. The cans are loaded on the conveyors that carry them through different aerosol-filling zones.

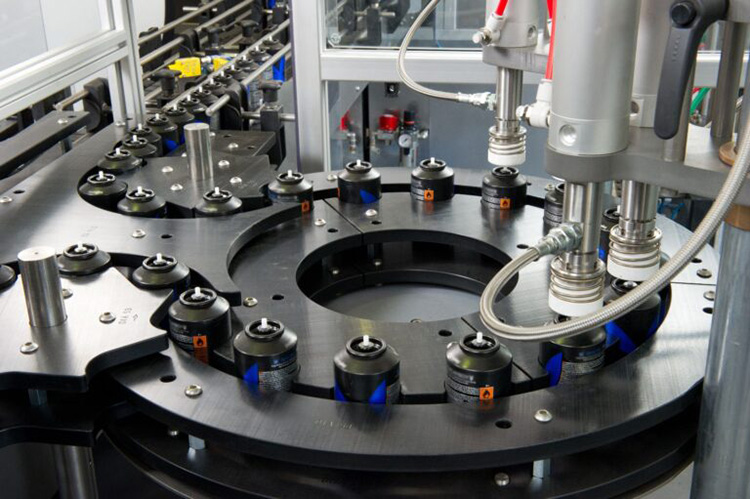

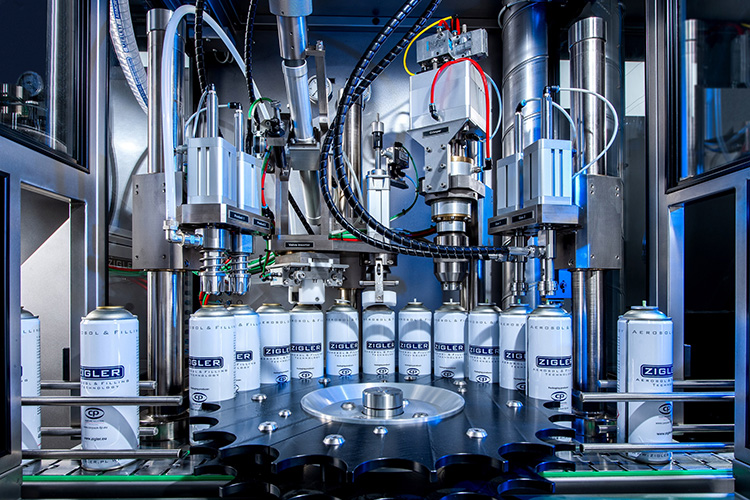

Rotary Aerosol Filling Machine

Rotary Aerosol Filling Machine- Picture Courtesy: Aile

The machine derives its name from a circular carousel that is designed for guiding cans through various units of the aerosol filling machine. Numerous processing heads are present in the rotary configuration to process multiple cans in one cycle. The carousel rotates to carry cans to each station. This machine is an all-in-one solution for larger production plants, filling thousands of cans per hour.

According to Working Mechanism

Standard Aerosol Filling Machine

Standard Aerosol Filling Machine- Picture Courtesy: Zigler

It is one of the earliest forms of aerosol filling machine and is still widely popular all across the globe because of its versatile processing. This machine is routinely employed in industries for filling both home-based as well as technical aerosol products, for instance, paints, perfumes, snow spray, and many more. In this machine, the order of working steps is liquid filling, valve crimping, and propellent filling.

Under Cap Aerosol Filling Machine

Under Cap Aerosol Filling Machine

In this type of aerosol filling machine, different working steps, for instance, valve vacuuming and crimping, propellent filling, and gas recovery are combined in a single processing area. The filling process varies from its other counterparts, as it typically vacuums the valve before liquid or gas filling. The filling is carried out through the valve or cap because filling liquids require a vacuumed environment. It is used for filling refrigerants and lubricants in air conditioners.

Bag On Valve Aerosol Filling Machine

Bag On Valve Aerosol Filling Machine- Picture Courtesy: Aerosol Filling Machines

This machine boosts efficiency in several ways and has acquired traction in the last few years over standard aerosol filling machines. It processes a flexible pouch present inside the aerosol cans. The valve separates the liquid product from the bag. The propellant gas does not have direct contact with the liquid product in this container.

It has a similar working as that of a regular aerosol filling machine but instead of filling product inside the can, it is filled in the bag. It is environmentally conscious but comes at a higher price.

7.What are common Problems and Solutions linked with an Aerosol Filling Machine?

An aerosol filling machine like other industrial equipment faces unexpected problems. However, it is integral that these are resolved quickly, otherwise, it would result in a loss of productivity and profit.

Some common problems and their solutions linked with the aerosol filling machine are penned below:

| Cause | Solution | Image |

| Failure in Valve Crimping | ||

| Improper settings of the crimping process

The difference in the structure of crimping head and neck of a can |

Adjust the settings of the crimping process

Use right-sized containers according to the crimping head |

Failure in Valve Crimping- Picture Courtesy: SHENZHEN PENGLAI Industrial Corporation |

| Liquid Filling Nozzles are Blocked | ||

| The presence of sticky residues or debris inside the nozzles

Poor cleaning of nozzles |

Wash and clean the liquid-filling nozzles

Maintain a consistent cleaning plan |

Liquid Filling Nozzles are Blocked- Picture Courtesy: Southernaerosol |

| Can Get Jammed in Machine | ||

| The presence of foreign objects on the conveyors

Misalignment of components |

Remove hindrance from the conveyors

Fix and align machine components |

Can Get Jammed in Machine-Picture Courtesy: Jrpacking |

| Inconsistent Aerosol Filling | ||

| Foaming of the products

Error in the machine level Wear and tear of fill nozzle seals Change in head pressure of supply tank Leakage in the airline |

Alter the fill settings to prevent foaming

Level the equipment properly on the ground Replace old seals in the fill nozzle Stabilize the head pressure in the supply tank Check and fix all airline connections |

Inconsistent Fill- Picture Courtesy: Beardworth Group |

| Propellant Leakage | ||

| Defect in the propellant injection component

Poor or damaged seal of propellant valves Leakage in the propellant dispensing pipes |

Repair the propellant injection component

Replace defective sealings of propellant valves Check and fix leaks in the propellant pipes |

Propellant Leakage - Picture Courtesy: AvantiGas |

8.How to Maintain an Aerosol Filling Machine?

Maintenance is the key to the accurate and consistent performance of the aerosol filling machine. Regular maintenance and cleaning boost the productivity of the equipment. Below are some important maintenance tips.

Automatic Aerosol Filling Machine- Picture Courtesy: Aerosol System Uk

| Daily Schedule | Clean the machine exterior frame and other surfaces daily to avert product stickiness, rusting due to corrosive liquids and dust accumulation.

Regularly clean the filling nozzles to avoid their blockage. Examine valve placing and crimping modules for accurate sealing and right alignment of valves. Check and locate issues in the compressed air system and fix them. |

| Weekly Schedule | Examine the levelling of conveyors and make adjustments in alignment if required.

Examine the running condition of the alarm, rejection systems, sensors, and air gaskets. Lubricate and oil mobile joints, bearings, nuts, and screws. |

| Monthly Schedule | Inspect the working condition of electric parts and secure loose wiring and cables.

Calibrate the filling system and valve placing components. Check the defects in the pneumatic system and replace the defective pneumatic components. |

| Yearly Schedule | Perform a yearly update of the software.

Critically examine every part of the aerosol filling machine for wear and tear and replace it if needed. Check and clean the air filtration system and replace it if there is an indication of wear and tear. |

9.What should you Consider when Purchasing an Aerosol Filling Machine?

An aerosol filling machine Line- Picture Courtesy: AS filling

The addition of an aerosol filling machine in the production line comes with hefty expenditure, therefore, it is imperative to make the right selection depending upon the production needs and container requirements for attaining maximum profits.

Here are some key factors that should be taken into account when selecting the aerosol filling machine:

Production Capacity

Production Capacity- Picture Courtesy: www.grupobsg.com.br

It is one of the major factors to consider when purchasing an aerosol filling machine. First, estimate the number of cans you need to fill during each cycle by examining your production requirements. A production with heavy processing needs must buy large-scale aerosol filling machines to effectively handle such volume.

Fill Can Design

Fill Can Design

Before buying, first determine the shape, size, and material of aerosol cans. Few models of aerosol filling machines are designed for filling particular types and sizes of aerosol cans, whereas other models offer versatility in filling when it comes to the shapes and styles of aerosol cans. Therefore, you must buy a machine that is aligned with your filling can style.

Easy Use and Maintenance

Easy Use and Maintenance- Picture Courtesy: Makwell

Select an aerosol filling machine that is simple to use and maintain. Ideally, it should have a simple control and detailed instructions. In addition, it is essential to consider, simplicity when it comes to cleaning and replacing components. Production efficiency can be increased by using machines that are simple to maintain and clean.

Fill Accuracy

Fill Accuracy- Cosmar

Always opt aerosol filling machine that has a higher level of accuracy with a minimal error rate. This is a must for maintaining product standards and reducing the rate of product recall. This also saves product. For this, look for a machine with advanced computerized systems and state-of-the-art filling devices.

After-Sale Support

When looking for a potential aerosol filling machine, select a machine with a reputable manufacturer. Also consider his customer service, warranty period, repair and installation service, and professional and technological assistance. Prompt and quality service will significantly lower your production downtimes and increase the effectiveness of aerosol filling.

Conclusion

Aerosol filling machine is quite different from other conventional filling machines and is comprised of specialized components that assist in carrying out aerosol filling with high competence and productivity. It is a huge challenge to find a perfect aerosol filling machine for businesses, that is well-aligned with processing objectives, product and container type. Confused about making your selection then quickly dial the AIPAK Engineering customer care helpline, we have highly professional assistance and we will be with you at each and every process of machine purchase.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Aerosol Filling Machine Related Products