APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line

AIPAK Engineering APK-DZA600 High-speed prefilled syringe filling and capping production line is mainly used for the pre-filing and sealing of catheter irrigators. It is the filling machine in the batch production line and is suitable for aseptic filling of physiological saline, sodium chloride, liquid alcohol, liquid medicine and other products. The equipment is stable in operation, easy to operate, equipped with intelligent detection devices, high in automation, easy to maintain, and can also be customized according to user needs.

APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line Details:

APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line Applicable Materials:

APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line Features:

1.This product is widely used inkindtypePrefilled catheter flusher,Special TypesThe syringe alsocustomizable。

2.SurfaceSUS304 Stainless steel, contactmaterialsParts usedSUS316L Stainless steeland medicalclassSilicone Rubber,conform toGMP requirements。

3.The equipment is equipped with a rubber plug self-cleaning table and a cap self-cleaning table to enable the addition of rubber plugs and caps without stopping the machine.

4.Siliconization uses Japanese high-precision ultra-trace atomization spray valve.Spray volumeaccomplishexist0.5-2Adjust between mg,High-precision and stable spraying,No splash,nonedrip.

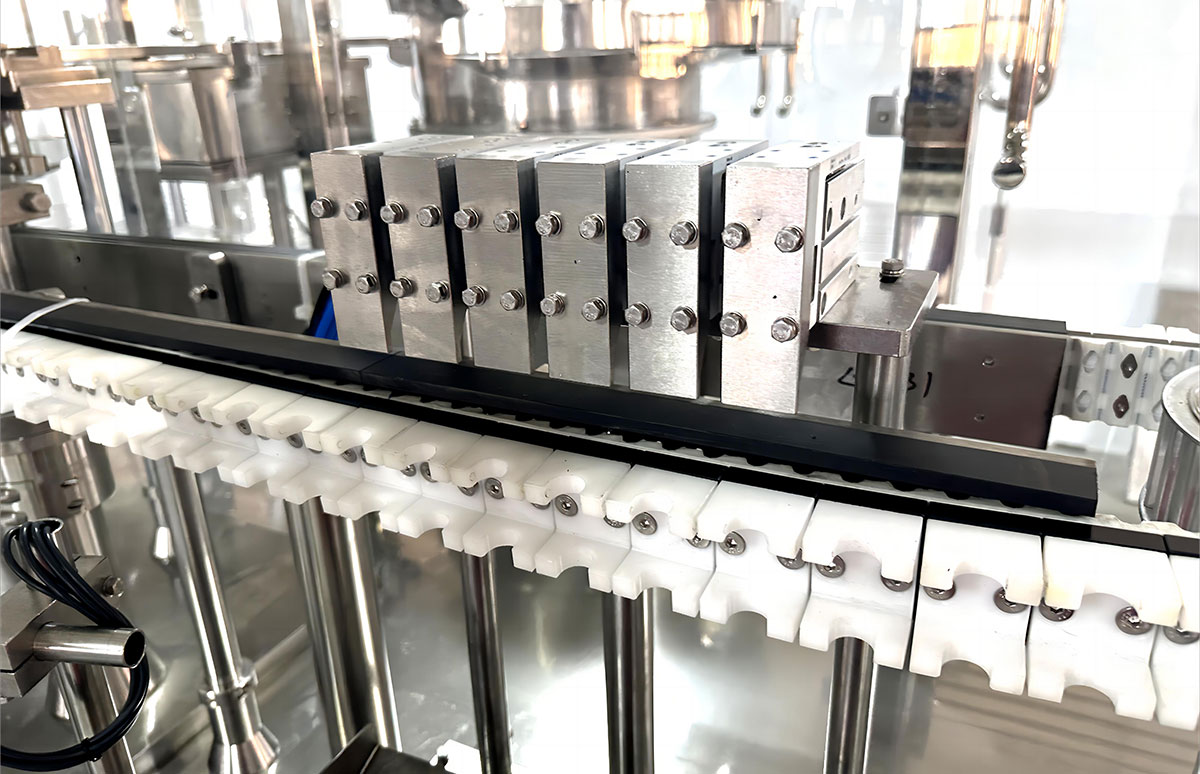

5.Ceramic plunger pump realizes quantitative filling, resistant to acid and alkali corrosion, wear and high temperature,High filling accuracy。

6.Plugs and capsofSortinganddeliveryIt is achieved through a vibrating plate, usingSUS316L Stainless steel clean tray,No cleaning dead corners,The top plate is removable and sterilizable。

7.Internationally renownedbrandThe electrical components implement interference-free modular control, and all synchronous actions are completed by servo motor control, which is accurate, reliable and easy to operate.

8.Depend onPLC The programmable controller controls the operation of the motor, and the human-machine interactive interface monitors and displays the working status of each station in real time, and automatically alarms and displays the fault location in real time.、Fault prompt.

9.A variety of filling doses and filling methods are available,Support multiple recipe parameter storage。

10.Fully automatic operation,Complete a series of processes including material sorting, loading, siliconization, stoppering, filling, capping, and waste removal.

11.An automatic refilling system is optional, which uses liquid level sensing to automatically refill when material is insufficient.

12.OptionalAGrade laminar flow hood to achieve high-requirement clean production.

APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line Technical Specification:

| Applicable materials | Liquid and ointment |

| Applicable specifications | eachkindtypePrefilled catheter flusher |

| Filling range | 0.1-30ml( The plunger pump needs to be replaced) |

| Injection needlequantity | 6indivual |

| Filling accuracy | ≤±1.5% |

| Production Capacity | 10800-12000branch/Hour |

| Total Power | 12KW |

| Voltage | 380V 50Hz |

| Compressed air | 0.6-0.7Mpa |

| Dimensions | L7118×W2750×H2030mm |

| Complete Machineweight | 2900KG |

Prefilled Syringe Solutions Related Products