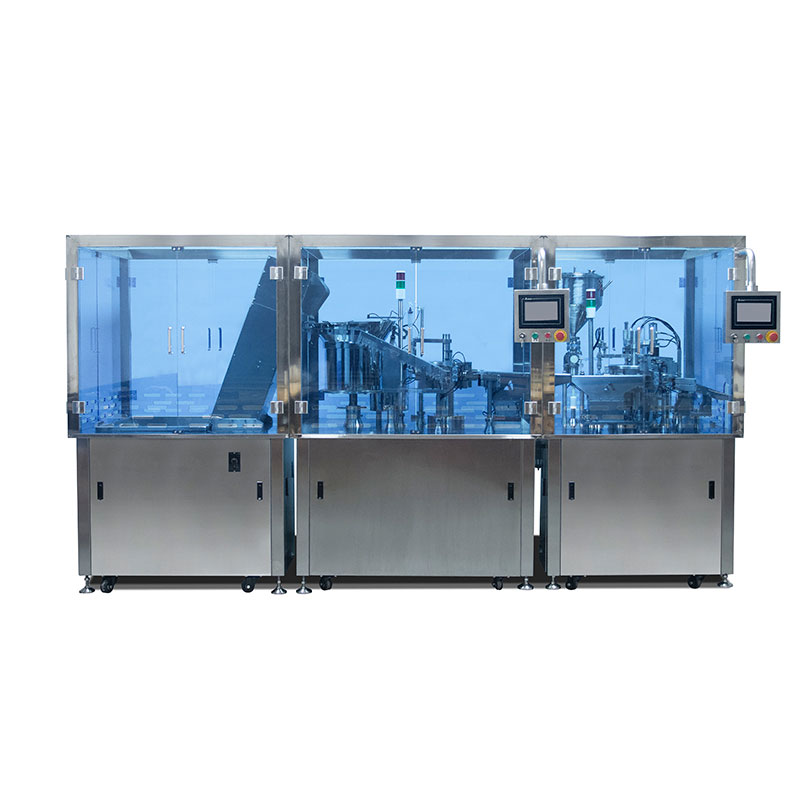

APK-DZA100 Prefilled Syringe Filling and Capping Production Line

AIPAK Engineering APK-DZA100 Prefilled syringe filling and capping production line is used for pre-filled filling of catheter flusher ,suitable for aseptic filling of products such as saline, sodium chloride, liquid alcohol, and other medicine.The equipment has stable operation,simple operation.It is equipped with intelligent detection device, high degree of automation and easy maintenance.It can also be specially customized according to user needs.

APK-DZA100 Prefilled Syringe Filling and Capping Production Line Details:

APK-DZA100 Prefilled Syringe Filling and Capping Production Line Applicable Materials:

APK-DZA100 Prefilled Syringe Filling and Capping Production Line Features:

1.This product is widely applicable to various types of prefilled plastic syringes, and special types of syringes can also be customized.

2.The surface is made of SUS304 stainless steel, and the contact parts are made of SUS316L stainless steel and medical silicon rubber, which fully meets the requirements of GMP specifications.

3.Siliconization adopts Japan's high-precision ultra-micro atomization spray valve to achieve high-precision and stable spraying with a diameter of 3-20 mm without external splashing and dripping.

4.The ceramic plunger pump realizes quantitative filling, is resistant to acid and alkali corrosion, wear-resisting and high temperature, and has high filling accuracy.

5.The conveying and sorting of the capsis realized by the vibratory feeder, which is made of SUS316L stainless steel clean plate with bright surface treatment and no clean dead corners.

6.It adopts internationally renowned electrical components and implements interference-free modular control.Synchronous actions are all controlled by servo motors, which are accurate and reliable and easy to operate.

7.The operation of the motor is controlled by the PLC programming controller. The human-computer interaction interface monitors and displays the working status of each station in real time, and automatically alarms and displays the fault location in real time, and the fault prompts.

8.A variety of filling doses and filling methods are available.

9.Fully automatic operation, automatic sorting, automatic feeding, automatic assembly, automatic filling, automatic cap arranging, automatic capping, automatic waste kicking.

10.The method of filling the syringe head can eliminate the air inside the syringe to the greatest extent and improve the qualification rate.

11.Modular design, easy to locate, easy to expand, can be used as a stand-alone machine, can also be connected with rotary rod machine, labeling machine, visual inspection and other equipment to form a production line.

12.Optional automatic replenishment system, using liquid level sensing, automatic replenishment when lack of material.

13.Optionalhundred-level laminar flow hood to achieve high-demand clean production.

APK-DZA100 Prefilled Syringe Filling and Capping Production Line Technical Specification:

| Applicable Materials | Liquid and ointment |

| Applicable Syringe Specifications | 0.5-50ml(Different specifications of syringes need to replace the mold) |

| Filling Range | 0.3-50ml(The filling pump needs to be replaced when the filling volume differs greatly) |

| Number of Filling Heads | 1 |

| Number of Capping Heads | 1 |

| Filling Accuracy | ≤±1% |

| Production Capacity | 1800-2400 p/h |

| Total Power | 6KW |

| Voltage | 380V/220V 50-60Hz |

| Compressed Air | 0.55-0.75Mpa 20L/S |

| Dimensions | L3400×W950×H1800mm(Without laminar flow hood) |

| Total Weight | 1100KG |

APK-DZA100 Prefilled Syringe Filling and Capping Production Line Video

Prefilled Syringe Solutions Related Products