Your Best Prefilled Syringe Filling Machine Manufacturer

AIPAK Engineering Prefilled Syringe Solutions

AIPAK Engineering prefilled syringe solutions could provide you all kinds of machines or production lines related with prefilled syringe manufacturing,including the prefilled syringe filing and plugging machine,syringe assembly machine, rotary rod labeling machine, nesting machine, light inspection machine, and various syringe filling production lines, etc., which are widely used in medicine, beauty, chemical and other fields. The products involved can provide a complete set of solutions from program design, production development,installation and commissioning, technical training to after-sales service according to the actual needs of customers.All the prefilled syringe machines meet the requirements of GMP certification and have passed the EU CE quality certification and have been spread all over the country , exported to more than 50 countries and regions in Europe, America, the Middle East, Southeast Asia, Africa, etc. and are favored and praised by users at home and abroad.

Prefilled Syringe Solutions

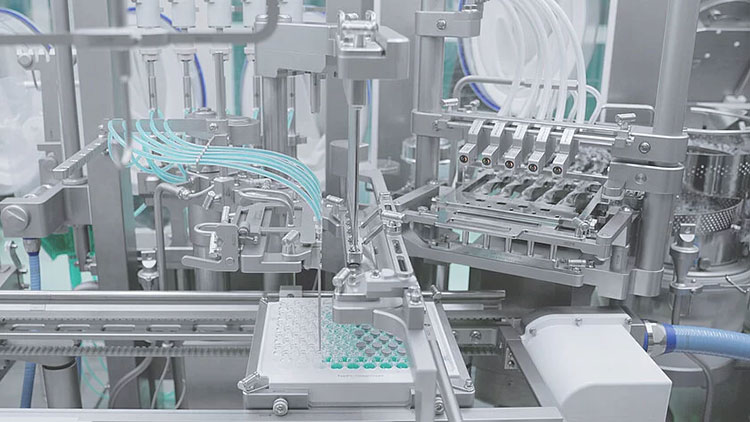

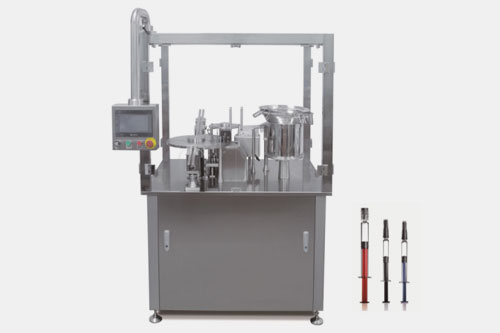

APK-GZB100 Automatic Prefilled Syringe Vacuum Filling and Plugging Machine

AIPAK Engineering APK-GZB100 prefilled syringe vacuum filling and plugging machine is an automatic packaging equipment for aseptic and high efficiency filling syringes specially designed for prefilled syringes. The equipment runs smoothly, is easy to operate.Equipping with an intelligent detection device, has 8 high degree of automation, and is easy to maintain. It is an ideal equipment for filling and plugging prefilled syringes.

Automatic filling and stoppering

Modular design, easy to locate, easy to expand

Ceramic plunger pump realizes quantitative filling

APK-GZB200 High-speed Injection Prefilled Syringe Vacuum Filling and Plugging Machine

AIPAK Engineering APK-GZB200 prefilled syringe vacuum filling and plugging machine is a pre-filler developed for laboratory filling prefilled syringes. Applicable to fill and stopper of 0.5-10ml plastic syringe. Vacuum is applied during filling to ensure that there is no air in the syringe and anti-drop at the end of filling. Vacuum is also applied in the pressure plug to ensure that the rubber plug can be completely added to liquid surface without bubbles in the middle.

Adopting internationally well-known electrical components

PLC programming controller&human-computer interaction interface

Automatic filling, automatic organizing and automatic capping

APK-TSB Prefilled Syringe Automatic Nesting Machine

AIPAK Engineering APK-TSB prefilled syringe automatic nesting machine is an automatic device that takes out the prefilled syringes stored in the nest box and distributes the prefilled syringes to the filling station in an orderly manner through intelligent control. It can be used with the filling and plugging machine or the plunger rod assembling and labeling machine, which solves the problems of slow manual material distribution and easy breaking, and improves the production efficiency.

Fully meet the requirements of GMP standards

PLC programming controller

SUS3 16L stainless steel and medical silicone rubber

APK-GZB1000 Prefilled Syringe High Speed Filling Production Line

AIPAK Engineering APK-GZB1000 Prefilled syringe high speed filling production line is mainly used for the unpacking, tearing, filling and plugging of disposable syringes in honeycomb trays in pharmaceutical plants. It's mainly for the production and packaging of various aseptic products such as vaccines, monoclonal antibodies, small molecule heparin, insulin and hyaluronic acid.With advanced servo control for honeycomb tray unpacking, de-nesting, conveying, filling, plugging, and tray output,electromechanical integrated control for stable, high-automation operations.

Stringent adherence to new GMP regulations from design to commissioning

Ensures product quality, integrity, and safety

Achieves pass rates ≥99.9% for uncompromised quality

APK-DZA100 Prefilled Syringe Filling and Capping Machine

APK-DZA100 Prefilled syringe filling and capping machine is is widely used for filling and capping of various types of plastic syringes, and special types can be customized.The surface is made of SUS 304 stainless steel, and the contact parts are made of SUS 316L stainless steel and medical silicon rubber, which fully meets the requirements of GMP specifications.The ceramic plunger pump realizes quantitative filling, is resistant to acid and alkali corrosion, wear-resisting and high temperature, and has high filling accuracy.

PLC programming controller, and the human-computer interaction interface

Fully automatic operation, automatic filling

Modular design, easy to locate, easy to expand

APK-DZA200 Prefilled Syringe Filling and Capping Machine

AIPAK Engineering APK-DZA200 prefilled syringe filling and capping machine is specially designed for Prefilled syringes,it is an automatic packaging equipment designed for sterile and efficient filling of syringes. The equipment runs smoothly, is easy to operate, and is equipped with intelligent detection devices, with a high degree of automation and easy maintenance.It is an ideal equipment for filling and capping prefilled syringes.

Ceramic plunger pump realize quantiative filling

Sorting and conveying of caps realized by vibrating plate

PLC programming controller

APK-DZA100 Prefilled Syringe Filling and Capping Production Line

AIPAK Engineering APK-DZA100 Prefilled syringe filling and capping production line is mainly used for the unpacking, tearing, filling and pluging of disposable syringes in honeycomb trays in pharmaceutical plants. It's mainly for the production and packaging of various aseptic products such as vaccines, monoclonal antibodies, small molecule heparin, insulin and hyaluronic acid.The design, materials, manufacturing, assembly and commissioning of the entire line are in accordance with the new GMP regulations.No friction between the contact surface of the pluger and the drug solution and the bottom rail during transport.

Filling accuracy: ≤ ± 1%

Pass rate ≥99.9%

Configurable filling system CIP/SIP system

APK-DZA600 High-speed Prefilled Syringe Filling and Capping Production Line

AIPAK Engineering APK-DZA600 High-speed prefilled syringe filling and capping production line is mainly used for the unpacking, tearing, filling and plugging of disposable syringes in honeycomb trays in pharmaceutical plants. It's mainly for the production and packaging of various aseptic products such as vaccines, monoclonal antibodies, small molecule heparin, insulin and hyaluronic acid.The design, materials, manufacturing, assembly, and commissioning of the whole prefilled syringe manufacturing process are in accordance with the new GMP regulations.

Fully automatic control and monitoring

Variable frequency speed regulation

Adopts a servo control system to automatically complete the processes

APK-XGJ100 Syringe Rotary Rod Machine

AIPAK Engineering APK-XGJ100 syringe rotary rod machine is mainly suitable for the automatic rotary rod after filling the prefilled syringe, and it is an integrated equipment designed for the packaging process of the preilled syringe. It can be equipped with an automatic nesting machine for automatic feeding, and at the same time, it can be equipped with a semi-automatic light inspection machine to realize synchronous labeling detection and other functions.

Accurate and reliable, and easy to operate

Modular design, easy to locate, easy to expand

Meets the requirements of GMP specifications

APK-XTJ100 Syringe Vertical Rotary Rod and Labeling Machine

AIPAK Engineering APK-XTJ100 vertical rotary rod and labeling machine is a device developed by our company for syringes. The equipment can automatically complete a series of actions such as rotary rod labeling, inkjet or laser printing batch number, production date, etc, to realize the rotary rod and labeling of syringes. This equipment has the advantages of compact structure, light weight, simple operation, reliable operation,convenient maintenance, stable rotary rod, fast labeling speed, flat and beautiful labeling, strong adaptability, etc, and can adjust the labeling speed according to the filling speed of the previous process.

Intelligent software, precise settings for each step

Adopts the rectifying mechanism

The label does not deviate,with multi angle adjusting system

APK-XTJ200 Syringe Vertical High Speed Rotary Rod and Labeling Machine

AIPAK Engineering APK-XTJ200 vertical high speed rotary rod and labeling machine can be used with high-speed centrifugal tube supply equipment or our high-speed syringe production line to achieve seamless integration.The whole machine is controlled by servo motor, which accurately controls the work of each station, is accurate and reliable, and is easy to operate.The vertic al high-speed rotary rod and labeling machine can fully automatically and quickly complete a series of actions such as rod loading, rod rotation, labeling, inkjet coding or laser printing of batch numbers and production dates, greatly improving production efficiency.

Intelligent software, precise settings for each step

Accurate and reliable, and is easy to operate

Fully automatically and quickly complete a series of actions

The Buyer's Guide

Prefilled Syringe Solution: The Complete FAQ Guide in 2025

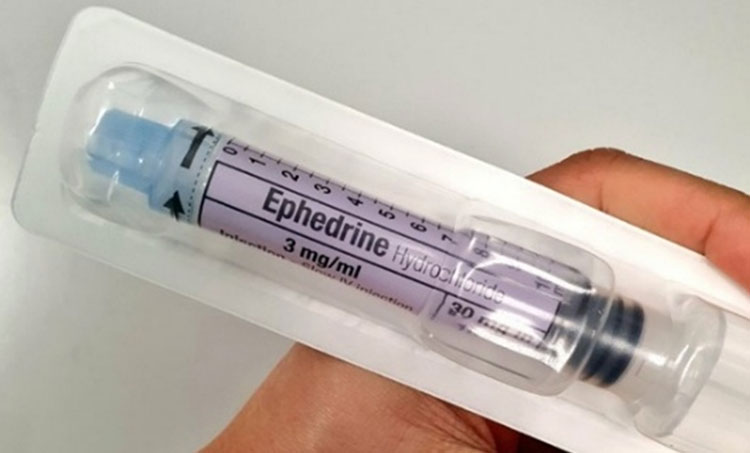

Picture Courtesy: C.A.P.S Pharmacy

Do you know a parenteral route can offer fast action and 100% bioavailability? Among that, a prefilled syringe solution is a widely accepted mode of administration to get a quick and optimized volume of medicines. The prime objective of this post ‘Prefilled Syringe Solution: The Complete FAQ Guide in 2025’ is to provide relevant and essential information related to prefilled syringe solutions; how it is prepared, where to apply, their market sizes, and various other aspects. We promise by the end of the article, you be cleared and polished related to unsolved queries. So read on to explore.

1.What is a prefilled syringe solution?

Prefilled Syringe Solution- Picture Courtesy: Plastic Today

A prefilled syringe solution is known as a ready-to-use unit that has fuelled a tremendous market profile across the globe by its excellent safety and flexible administration at the user site. This is a set of units that bring series of tasks involved in prefilled syringe preparation, such as loading, de-nesting, filling, capping, and labeling.

An easy-to-use syringe that is already subjected to an optimized and predetermined amount of medicine inside the complied with high hygiene and sterilization which minimized the potential for progression of contamination or error in doses.

That’s why it is widely accepted by healthcare workers as the most preferable mode of injectable administration for exact and precise doses without any leftovers of any medication.

2.Why there’s need for a prefilled syringe solution?

Benefits of prefilled syringe solution- Picture Courtesy: IDEO

The prefilled syringe solution offers unlimited benefits which improves the quality of healthcare treatment as well as patient results concomitantly. That is why, it is needed in the regimen of various ailments. Some of the very important benefits of prefilled syringe solution are discussed below.

Elimination of overfilled solution

Exact Dose Filling

When using a prefilled syringe solution, there are no chances of overfill or spillage of expensive medications, therefore, you can save them simply with an accurate and optimized medicine best filled with lower chances of product wastage.

Ease Of Administration

Easy to administer- Picture Courtesy: ESAIC

When using a prefilled syringe solution, you are free from making drug reconstitution, and certain formalities such as dose calculation, adjustment of vials and ampoules, etc., therefore you just have to unpack the prefilled syringe solution, and the deliverable doses are just right to use.

No Medical or Healthcare Malpractice

No medical malpractice

This is a quick way of drug administration where you just need to pick up the syringe and administer it carefully. Therefore, whether you’re in a hurry or new in this field, this mode ensures no malpractice, misidentification, or medical errors.

High Degrees of Patient Safety

High Degrees of Patient Safety- Picture Courtesy: Berkeley Political

These syringes are considered the safest mode of medication as it is quite precise. Therefore, whenever any healthcare provider offers these injections they are quite confident that you are getting the right dosage without extensive monitoring in measurement and compounding.

You Are Getting a Stable Medication

Promising treatment mode- Picture Courtesy: American Hospital Association

This is a well-known mode of delivering medication with a stable storage period under a controlled environment.

Despite this, conventional injections offer limited time once you reconstitute them, i.e., around 24 hours or a maximum of 48 hours. Thus, prefilled syringe solutions have an extended lifetime with more drug stability typically range for a high expiration date, and are very effective for management.

With Improved Patient Compliance

Patient compliant

Not only healthcare providers but patients also prefer using prefilled syringe solutions because it is already available in prepared doses and safe designs that prevent patients from risky pricking from needles. Therefore, it encourages the patient to follow proper medical regimens.

3.Where prefilled syringe solution is applicable?

The option of using prefilled syringe solution is highly applicable in the broad spectrum fields such as:

Vaccinations

Uses in vaccination preparation- Picture courtesy: Lander and Roger

Yet not all vaccinations are available in the prefilled syringe solution, but various stakeholders worldwide are working on it to bring a greater option to pursue rather than a traditional one.

Previously vaccination was packed and distributed in vials, but a greater improvement was noticed since COVID-19. According to GMP practice, today it is the strongest preference among the various health care providers and is known for its high patient-effective outcomes with the minimized potential for microbial cross-contamination or transmission.

Biological And Research Medication

Research and biological sciences- Picture courtesy: Pharmtech

Many biological solutions, such as complex biological samples and small molecules, monoclonal antibodies, cancer medicines, and antiviral therapies require so much accuracy in dose protocols and administration. Therefore, prefilled syringe solution allows sensitive medication preparation and dispensing in an optimized manner.

In Emergency Departments

Hospital Emergency

In emergency treatment, the prefilled syringe solution is the priority and recommended for rescue patient management without any delays in the preparation of drugs or requiring any human resources.

Thus, it is eliminating unnecessary measures in managing patients with immediate actions. For example, the administration of prefilled syringe solution adrenaline, anesthesia, etc reduced the number of medication errors.

In Beauty Clinics

Facial aesthetics prefilled syringe solution- Picture courtesy: family dental clinic

It is mainly known as state of art prefilled syringe solution for aesthetic treatment that everyone can rely on. Cosmetic prefilled syringe solution is an ideal and elemental treatment that is comfortably accepted by doctors as well as users for optimized and more precise dosages.

It offers you secure needles, used in cosmetic surgeries, fillers, and antiwrinkle procedures. These syringes offer you high mechanical resistance and allow minor administration of doses over your face with lesser pain sensation.

There is no chance of the needle popping off or breaking. For example, hyaluronic acid, collagen, and others.

In Chronic Ailments

Chronic Health Problems- Picture Courtesy: Healthcentral

Many people avoid using prefilled syringe solution from their prescribers, though, for chronic management it is the best treatment with fewer adverse effects.

There are certain conditions such as diabetic mellitus, gestational diabetes chronic pain management, etc, you may require a consistent application of prefilled syringe solution. Despite finding them uncomfortable, it is usually hurt less than a finger pricking by a lancet and, therefore can be utilized for long-term management easily.

In Veterinary Applications

Veterinary uses- Picture Courtesy: OWEN mumford

The bio-compatible prefilled syringe solutions are used for veterinary treatment and are available to deliver the medication belonging to multivitamins, standard medications, and others with formulation types of liquids, pastes, gels, and solvent drops, in a sterile and cleaned packed that allows you to administer single and multi-shots to animals.

Home Healthcare

Prefilled Syringe Solution Homecare Kits

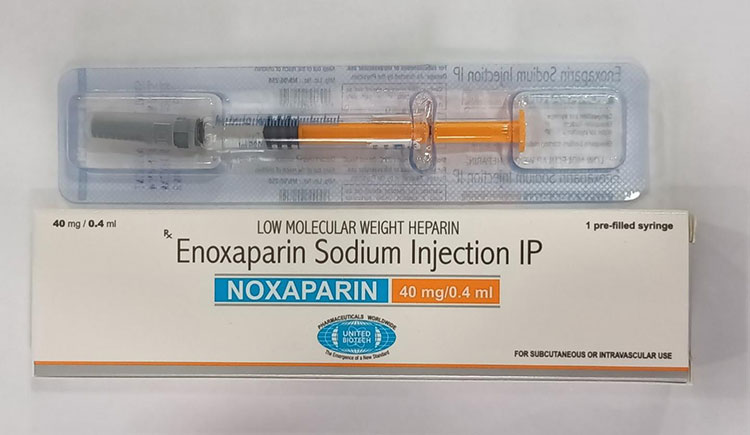

You must have heard about insulin shots, blood thinners, Hepatitis C treatment prefilled syringe solutions management, and others. Many of these treatments are available in monthly and yearly packaging in prefilled syringe solution prescribed by practitioners for home healthcare treatments so can be applied by self-administration or nurse. For example, Insulin, Clexane injections, etc.

Agriculture Setup

Prefilled syringe solution- Picture Courtesy: D.B.M

Prefilled syringe solutions are available in a predetermined volume with certain substances that are required for the management of agriculture and crop-related issues. This included pesticides, insecticides, herbicides, and commonly crop boosters with pre-specific dosage designs by researchers and marketed with pre-confined and safe dosage designs.

4.What are the components of the prefilled syringe solution?

Parts of AIPAK ENGINEERING Prefilled Syringe Solution

| Parts | Description |

| Box Loading Tray | This is the unit to load a box containing a nest of empty syringes. |

| Box De-lining Unit | Here, either manually or mechanically gripers remove the sticky cover applied over the syringe box. |

| Transportation Unit | The prefilled syringe solution production line is mainly designed with a smooth rail system of conveyors that ensures flexible movement of the syringe box before and after filling. |

| Syringe Loading | A de-nesting unit that loads the syringes from the box into the turntable unit which is composed of pockets to hold the syringe for filling purposes. |

| Filling Nozzles | Well-controlled peristaltic pumps are mainly subjected to ensure precise dispensing of medication into each syringe. |

| Stopper Loading | the vibratory tray that ensures the sorting of stoppers and guide them toward loading for plugging into each prefilled syringe. |

| PLC Touch Screen | A PLC touch screen is responsible for the feeding of processing protocol, such as volume of medication, number of syringes, speed of process, etc., troubleshooting, and relevant tasks. |

| Prefilled Syringe Solution Discharge | These filled and sealed prefilled syringes leave the unit via the discharge unit. |

5.What injectables types a prefilled syringe solution can fill?

Prefilled syringe solution- picture courtesy: cytivalifescience

A prefilled syringe solution can fill two different types of injectables. Such as:

Based on Needle Type

Two commonly used types of prefilled syringe solutions can be filled commercially.

Needle-Free Prefilled Syringe Solution

Needle-free Prefilled Syring Solution- Picture Courtesy: OpenPR

For vaccines, needle-free prefilled syringe solution is used and mainly included with a ‘Luer-Lock attachment’ for the needle setting. There is some tamper-proof prefilled syringe solution with an elastomer stopper. The Luer Lock attachment is designed with a cap that should be deliberately twisted to break the tamper design and associated attachments.

Staked in Needle Prefilled Syringe Solution

Staked in Needle Prefilled Syringe Solution- Picture Courtesy: Dali Medical Device

A staked needle which is also known as a pre-attached needle syringe prefilled solution that has designed injection cannula and is also available in dual chamber designs for the administration of combination drugs for patient compliance. Nowadays, this technique has emerged with high user compliance due to ease in pharmaceutical doses and unique properties. That’s why, these staked-in needles are mostly used for biological or pharmaceutical medications.

Based On the Dosage Type

A prefilled syringe solution comes in different types that mainly depend upon patient-to-patient and their particular requirements. The commonly used types are:

| Single-dose Prefilled Syringe Solution

A single dose is a convenient mode of drug dispensing that has a particular dose designed dispensed inside each syringe for each patient. Once it is used, it is recommended to discard immediately therefore offering reduced progression of contamination or dose reconstitution. |

Picture Courtesy: La region |

| Multi-dose Prefilled Syringe Solution

This type of syringe is mainly used in emergencies to reduce drug-making and volume measurements of multiple doses. Hence, it is a convenient way to pick ready-to-use injection that encompasses multiple doses of medication and can be used in a repeated way in a particular timeframe. This syringe solution is designed with a specialized rubber plunger and fixed closure to sustain the stability of the medication in order to maintain the integrity of the medication. |

Picture Courtesy: Bio-Process |

| Prefilled Flush Syringes

As its name shows, it is composed of flush solutions such as normal saline or any other solvent required in common health settings for flushing purposes in intravenous applications, catheters, etc in order to ensure proper flow and avoid blocking. |

Picture Courtesy: D.B.M |

| Safety Prefilled Syringe solution

This is a specially designed prefilled syringe solution with self-retractable needles that draw back into the syringe barrel after administration to the patient and it has a shielding cap for the needle ensuring extra protection. |

Picture Courtesy: Owen Mumford |

| Customizable Prefilled Syringe solution

Various healthcare setups demand customizable prefilled syringe solutions from manufacturers that are mainly composed of the design of various combination medication regimens specific based on individual patient requirements. This is mainly suitable for attaining specific combinations, with particular dosages for flexible- administration. |

Picture Courtesy: Wistech |

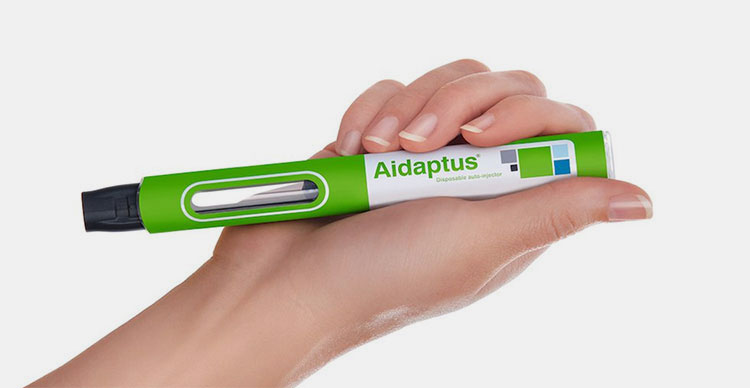

| Autoinjectors

Mainly patients with auto-immune disease or allergic problems are prescribed with auto-injectors that are prefilled syringe solution ensure ease and safe self-administration of particular medication. |

|

6.What are the different types of prefilled syringe solution Machines?

For flexible operation, there are tremendous series of prefilled syringe solution equipment that have emerged in the market with a multitude of properties and sizes. we have enlisted them below.

Automatic Bulk Prefilled Syring Solution Machine

Automatic Bulk Prefilled Syring Solution Machine- Picture Courtesy: Syntegon

To produce prefilled syringe solution in a bulk quantity is way more challenging. Here, every syringe takes lesser stay time and is subjected to faster treatment time.

Therefore, you may face difficulties when requiring bulk demand. For this reason, the bulk prefilled syringe solution machine is used to process ready-to-use syringes and encompasses a broad output following impressive features in order to make you achieve desirable results.

This machine transports the syringe box automatically via a strong gripping and clip system towards the working station, where sensor-based operation allows precise filling without chances of product wastage or spillage.

Automatic Prefilled Syringe Solution Machine

AIPAK ENGINEERING Prefilled Syringe Solution Machine

This is automatic equipment to bring a sterile and hygienic treatment for prefilled syringe solution facilitated by automatic filling and sealing processes in an aseptic condition.

The equipment is capable of running the entire procedure very smoothly concomitantly highly intelligent detecting units offer a high degree of automation. It can run solutions of less viscous to high viscosity such as gels.

This machine is easy to maintain and ideal if you’re looking for filling and plugging of the syringe in one machine hence it offers a vacuum filling and plugging to eliminate the chances of air-bubble inside the syringe solution.

Semi-Automatic Prefilled Syringe Solution Machine

Semi-Automatic Prefilled Syringe Solution Filling Machine

A suitable solution if you’re running a small business or using it in a clinical or laboratory setup. The machine is equipped with a hopper for solution storage and all essential parts needed for precise and accurate filling of syringe solution safely.

It’s working based on a piston filler that is operated by a motor by pressing a pedal that sucks an optimized volume of solution, and filled-in syringes positioned by the technician just on the exact nozzle.

The machine is capable of running processes by regulating speed and has a very simple structure with excellent operation. Once the prefilled syringe solution is completed you can just replace it with a new syringe manually.

7.How is a prefilled syringe solution prepared?

Prefilled Syringe Solution Preparation- Picture Courtesy: Groninger

In the dynamic era of innovation, the pharmaceutical industry demands more and more precise prefilled syringe solutions for accurate administration of medication in order to meet the desirable demand in the healthcare market.

Therefore, this machine has emerged as a game changer to bring a streamlined production of prefilled syringe solution rapidly and safely. Certain working steps are performed by the prefilled syringe solution machine for filling and plugging the syringes prior to sending them as a finished product.

| Step | Description | Picture |

| Prefilled Syringe Tub Loading | This is the first step where a prefilled syringe tub is loaded on the machine via a continuously movable conveyor that gently brings the sealed box of syringes to be treated. |

Loading |

| Removal of Tyvek or Cover Lid

|

By a stable and adjustable conveyor unit, the tub reaches towards the Tyvek removal zone. The robotic arm which is known as an automatic de-lid or de-liner fixes at the edge of the box and de-lines the surface to expose the syringe nest. |

Cover Removal |

| Liner Chucking | There’s no chance of error in the removal of the stick end with a strong pneumatic chuck. Thus, the entire process is kept safe and sterilized once the liner is removed. |

Pneumatic Chucking |

| Prefilled Syringe De-Nesting

|

This is the section that received the unpacked syringe box in order to send it in de-nested form to the filling and sealing machine. It features with vacuum rubber arm pad for strong griping of the syringe nest and move it next. |

De-Nesting- Picture Courtesy: SIMTRA Biopharma |

| Rubber Stopper Feeding - Capping

|

Various shapes of rubber stoppers are introduced into the feeding unit with the help of a vibratory unit which is subjected to provide a continuous flow of rubber stoppers to the filling and sealing machine.

They are supplied to the next unit with the help of well-structured guided rails to keep them oriented and unscrambled. |

Rubber Stopper Supply |

| Prefilled Vacuum Filling & Sealing

|

This is the main unit that received de-nested syringes, and rubber stoppers in order to fill and seal them. The filling machine is commonly presented with vacuum working to eliminate possible chances of air-bubble inside the prefilled syringe. The machine is highly accurate and allows feasible flow of solution ranges from less viscose to high viscosity.

The following machines are designed with an expendable number of filling heads with vacuum rubber stoppers or plugging properties. Once they are filled, the machine sends the unloaded nest back to the tub for reuse. |

Prefilled Vacuum Filling & Sealing- Picture Courtesy: Stanley Milton |

| Prefilled Syring Solution Tub De-loading

|

High-speed vacuum adjustable pads conveyor unit gently loads the filled syringes into the tub. The final product is received by a technician for an automatic integrated unit for further processing. |

Final Prefilled Syringe Solution |

8.What is the prefilled syringe solution production line?

Prefilled syringe solution- Picture Courtesy: Medical Plastic News

A production line of prefilled syringe solution is based on a sophisticated series of machines that ensures a complete series of working steps. For example, unboxing, de-nesting, filling, capping, and labeling, etc. The cartridges used for this purpose are disposable and do not need to be sterilized and washed. So, this ultimately minimizes the cost and time. The following list of machines is integrated to form a production line.

| Automatic Prefilled Syringe Solution Denesting machine

An automatic prefilled syringe solution denesting machine is required for safe, gentle, and reliable denesting of the syringe packed in a nest. It is all due to the presence of robotic trajectories and strong grippers set that grip the nest of syringes and fix it at denesting unit. With the help of a conveyor belt, it sends the product toward the filling and sealing station for the precise filling. The entire workflow is taken place rapidly, and it is estimated that this machine is capable of denesting the syringes range approx. hundreds of strokes per minute that is mostly around thousands (24000) syringes per hour. |

Automatic Prefilled Syringe Solution Denesting machine |

| Prefilled Syringe Solution Filling and Capping Machine

A sterilized mode of filling equipment that is featured with automatic units for sensing the empty syringe nozzles and fills them via a specific pumping system such as peristaltic, pump, or piston, etc to allow flawless filling of medicines inside the syringe chamber followed by automatic capping with maintained sterility throughout the process. |

Prefilled Syringe Solution Filling and Capping Machine |

| Prefilled Syringe Solution Labeling Machine

The specialized unit is designed for the production line to carry an elemental role in prefilled syringe solution such as labeling including laser print, and inkjet printer, for batch number, date of manufacture, expiration date, doses, branding, etc. The reliable equipment that is proposed with a compact structure and fast processing that is suitable to adjust with a series of machines to bring an ideal working series for large production. |

Prefilled Syringe Solution Vertical Rotary Rod & Labeling Machine |

| Prefilled Syringe Solution Inspection Machine

This machine is integrated with a prefilled syringe solution filling and sealing machine for running the packaging process of filled syringes. The equipment is already designed with de-nesting properties also with semi-automatic sensor system for synchronization of prefilled syringe solution such as labeling, appearance, and related functions. |

Prefilled syringe rotary rod machine inspection machine |

9.What common medications come as a prefilled syringe solution?

Common Medications in Prefilled Syringe Solution- Picture Courtesy: European Pharmaceutical manufacturing

Due to the high preference of user compliance, several lists of medications come in prefilled syringe solution form. This is all because of saving significant time, saving your expensive medication, and spending less on each prefilled syringe solution than conventional injections.

According to research surveys, there are certain types of medication that has shown top-the-list availability and most are purchased in prefilled syringe solution. This high acceptance of drugs is all due to their ease in administration, exactness of dosage, expanded lifetime, and safety. The below list is commonly available formulations showing high market.

| Phenylephrine | 30.56%

|

| Lidocaine | 27.78% |

| Ephedrine | 22.22% |

| Propofol | 19.44% |

| Succinylcholine | 19.44% |

| Fentanyl | 16.67%

|

| Neostigmine | 16.67%

|

| Dilaudid | 16.67% |

| Rocuronium | 8.33% |

| Glycopyrrolate | 8.33% |

| Labetalol | 8.33% |

| Midazolam | 5.56% |

| Ketamine | 2.78% |

| Cefazolin | 2.78% |

| Bupivacaine | 2.78% |

| Ropivacaine | 2.78% |

Research report courtesy: Outpatient Surgery Magazine Survey, May 2019 105 respondents

10.What is the difference between a prefilled syringe solution and an injection solution?

There are some major differences between prefilled syringe solution and injection solution. For example:

Prefilled Syringe Solution vs Injection Solution- Picture Courtesy: Avery

| Prefilled Syringe Solution | Injection Solution |

| This is a specific formulation available in reconstituted form in prefilled syringes. | The injection solution comes in vials or ampoule form that has to be sucked into the syringe before administering to the individual. |

| This is way more convenient as it is already prepared medication. | It involves medication measurement or dose calculation prior to administration. |

| A ready-to-use syringe does not require expertise for dosage design. | It requires expertise and some steps to prepare such as mixing, picking specific doses carefully, and removing air bubbles. |

| It ensures safe and contamination-free drug administration as it is prepared in a controlled environment. | There should be extra safety measures taken to maintain sterility when drawing medication from an ampoule or vial. |

| No dose adjustment is needed. | Dose adjustment is required carefully. |

| It allows unpacking and direct administration thus saving your time. | Additional time is needed when using injection solution due to its preparation. |

11.What is the capacity range of a prefilled syringe solution?

Prefilled syringe solution- Picture Courtesy: GF Planen

A prefilled syringe solution mode of injectable is available in various volumes depending on patient conditions and high demands.

The actual and commonly used doses that are already suggested in confined doses are filled and sealed during manufacturing to ensure ease in administration for injection to save time and avoid unnecessary handline.

The commonly used volume capacity of prefilled syringe solution mainly ranges from 0.25 ml to 5.0 ml. The following medication doses are mainly subjected to administer either subcutaneously or intramuscularly.

12.What are the defects of a prefilled syringe solution?

When manufacturing prefilled syringe solution, there are certain defects that may encounter you. We have enlisted some common defects and their possible solutions.

Problems and solutions- Picture courtesy: Outpatient Surgery Magazine

| Problem | Cause | Solution |

| There are cracks in the prefilled syringe container.

Picture Courtesy: Dikysa |

This could have occurred during handling, filling and sealing, or denesting. | Before marketing, it is recommended to pass a leak test to prevent the prefilled syringe solution market.

Machine handling must be observed and the entire procedure must be carried out gently. Visual inspection must be done to avoid this problem. |

| Drug-drug interaction, some medications become unstable when dispensed in combination.

Picture Courtesy:La Neuva Espana

|

Failure in medication solubility may lead to an instability solution | When preparing prefilled syringe solution, medication literature must be reviewed and confirm the drug-drug interaction. The medication must be stable if dispensed in combination formulation. |

| Labeling problem

Picture Courtesy: Dairi Mes |

The machine is unable to identify the presence of a syringe and the wrong application of the label is taken place. | An automatic labeling machine must be calibrated and capable of sensing the presence of each prefilled syringe solution for identification and application of the label.

the detector must be clean to identify the correct positioning of the item. |

| Foreign particles or contamination.

Picture Courtesy: MedXL |

Due to improper sterilization of solvent and prefilled syringe solution can progress to microbial growth. | It is suggested that prior to subjecting the solution and prefilled syringes, they must be passed through the sterilization unit, and autoclaving to ensure the material is sterile for the filling procedure. |

13.How long a prefilled syringe solution is effective?

Effectiveness Of Prefilled Syringe Solution- Picture Courtesy: Taisei

To keep the prefilled syringe solution effective, it should be safe from microbial growth invasion and oxidation. Therefore, it can have a more extended shelf life and keep your medication protected against unwanted physical reactions and contamination.

Therefore, the manufacturing of prefilled syringe solution takes place under highly sterilized conditions where each step is based on a high degree of sterility and an aseptic environment to assure quality standards and safety. The sterilization is mainly involved with autoclaving or in some cases ionized gamma radiation at 25-50 kGy, which is best known for its high efficacy for all components of prefilled syringe solution.

So, once it is filled and plugged completely, it is entirely aseptically packed to remain stable for a longer time. Hence it is suggested that an unpacked prefilled syringe solution is safe and potentially active for two to three years. Moreover, once it is opened, it is effective for around 24 hours under a controlled environment and temperature. Thus, it is suggested to use it immediately and discard it soon after opening.

14.How big is the prefilled syringe solution market?

Market Size Of Prefilled Syringe Solution- Picture Courtesy: The Quarter

Due to the greater prevalence of homecare health services and the upsurge of injectable medication, the market of prefilled syringe solutions is growing with greater expansion globally and was valued at 13.6 Bn USD estimated in 2021.

Moreover, it is anticipated that it will grow higher in the coming years and will be striking more than 35.7 Bn USD around the end of 2031 (report courtesy: transparency market research).

Therefore, the biological sectors and pharmaceutical companies show more demand which presents a greater opportunity for manufacturing industries that are processed in providing prefilled syringe solutions to the global market to make their profile and attain more profit.

Conclusion

In summary, a prefilled syringe solution is already available in medication in the injectables that are designed and manufactured by pharmaceutical companies. Due to tremendous safety and ease of application, today this mode of injectable is hooked to higher demand worldwide than in previous years, especially for the treatment of chronic ailments. A large population and various age groups are more likely to use them as a self-administration medication. In the blog ‘Prefilled Syringe Solution: The Complete FAQ Guide in 2025’, we have tried our best to deliver all essential information about prefilled syringe solutions. If in case, you’re still confused or want to know more; send us a query. The AIPAK ENGINEERING team would love to answer it soon after receiving it.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours