AIPAK Engineering Pharmaceutical Water System

As we all know,pharmaceutical industry is one of the most rigorous and regulated industry in the world,each component of the pharmaceutical production process must be carefully purified and monitored to guarantee the hygiene or prevent any contamination to the products.So a good pharmaceutical water system play a significant role in every stage of the production process,especially for the research or manufacturing of pharmaceutical products.But also for various stage of the pharmaceutical manufacturing process,there should require different quality requirement to the water quality or each should meet its special testing requirements.AIPAK Engineering could provide the world leading pharmaceutical water system,the engineered products it served include purified water system,multi-effect water distiller,clean steam generator,water distribution system,cleaning system CIP and SIP system and the preparation system.

Purified Water System

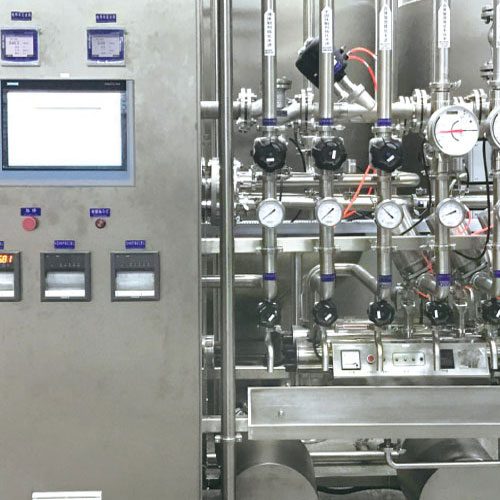

AIPAK Engineering High Efficiency CGMP Purified Water Treatment System

AIPAK Engineering purified water (PW) system is sufficient used as a diluent in the production of non-sterile products or used as a cleaning equipment during any pharmaceutical process.You can also use AIPKAK Engineering purified water(PW) system as pretreatment in the preparation of water for injection or pharmaceutical grade pure stem production.The other common uses of AIPKAK Engineering purified water(PW) system are making pill form drugs,noninjectable drugs,cleaning laboratory equipment,etc.

Modular design,

Compact structure

Beautiful layout and convenient operation and maintenance

AIPAK Engineering RO system for Pharmaceutical Purified Water Treatment System

AIPAK Engineering RO system is a specialized water purification system used in the pharmaceutical industry to produce high-quality, ultra-pure water for use in various pharmaceutical applications. These systems utilize advanced filtration technologies and precision engineering to remove impurities and contaminants from feed water sources, resulting in highly purified water that meets stringent quality standards.

Applied in areas where the salinity of raw water is high

Good electric conductivity of water produced

Low investment

Multi-effect water distiller

AIPAK Engineering GMP Standard S Series Multi-Effect Water Distiller

AIPAK Engineering multi-effect water distiller all the components and parts of the equipment are made of the 304 or 316L stainless steel. The distilled water generated from the water distiller is of high purity and without heat source, which is in full compliance with all the quality indicators of water for injection stipulated in the Chinese Pharmacopoeia (2010 edition). This equipment proves to be an ideal choice for manufacturers of such pharmaceuticals as various blood products, injections, and infusion solutions, biological antimicrobial agents as well as drinking distilled water.

Stable quality and high purity

Reasonable structure, easy operation

High heating efficiency, low consumption

AIPAK Engineering Automatic F Series Multi-Effect Water Distiller with CE and ISO

AIPAK Engineering pharmaceutical F Series Multi-Effect Water Distiller is designed through scientific calculation, the quantity of heat is utilized many times circularly, so they have high thermal efficiency. Compared with old type, single-effect distilled water equipment, the multi-effect distilled water machines can save more than two thirds of energy. They are presently the pioneer and the best energy saving distilled water equipment in China.

Adopt rising film for evaporation to solve the problem of uneven distribution of water

High thermal efficiency, 100% heat exchange

Save industrial steam consumption, 20% energy saving

AIPAK Engineering B Series Multi-Effect Water Distiller For Pharmaceutical Plant

AIPAK Engineering B series multi-effect water distiller ensures the production of highly purified water,which is essential for the preparation of pharmaceutical ingredients and stringent quality control. Likewise, in the medical field, it plays a crucial role in supporting sterilization processes and maintaining hygiene standards. Laboratories extensively utilize this high-quality distilled water for research and experiments. Furthermore, it finds applications in the electronics manufacturing and chemical industries, where it is employed for tasks such as component cleaning and chemical reactions.

Highest WFI Quality

Easy to Validate

Easy to Maintain

AIPAK Engineering Vapor Compression Water Distiller

AIPAK Engineering vapor compression water distiller(VCS) is widely used for producing distilled water for injectable use or WFI, which is compliant with the requirements of the International harmacopeias including USP, EP and JP. Water produced by this vapor compression water distiller has very superior quality than waterproduced by other multiple effect distiller. The feed water utilization is up to more than 92%. It is not subjected to pressure vessel rules and ASME pressure vessel supervision. The comprehensive energy saving is up to more than 50% for each unit capacity comparing to multi-effect distiller and waste heat recovery molule energy saving can be up to more than 70%.

Avoiding bacteria growth easy for cleaning and sterilization

Comply with FDA and cGMP requirement

No cooling water consumption

Clean Steam Generator

AIPAK Engineering Professional Pharmaceutical Clean Steam Generator Pure Steam Generation

AIPAK Engineering clean steam generator is heated by steam to produce high-purity steam without heat sources for sterilization and disinfection, and can effectively prevent heavy metals, heat sources and other impurities from stacking materials. Secondary pollution. The machine has advanced technology, novel design, compact structure, reasonable layout, good heat insulation effect of the shell, less heat loss, high thermal efficiency, small footprint, easy operation, good adjustability, easy installation, and meets the national GMP certification requirements.

Advanced technology, novel design

Compact structure, reasonable layout

Meet the cGMP standard

AIPAK Engineering Pharmaceutical Clean Steam Generator For SIP Process

AIPAK Engineering pharmaceutical clean steam generator is a kind of equipment which uses deionized water as raw material and uses steam heating to produce pure steam. It has reasonable structure, simple operation, high thermal efficiency and low energy consumption. It is an ideal equipment for sterilization and disinfection in hospitals, pharmaceutical, electronic, food and beverage industries, and the first choice for pharmaceutical industry to meet the cGMP standard.The clean steam generator is composed of evaporator, preheater and electric automatic control part.

All contact parts adopt SS 316/ SS 316 L

Electropolish internal contact surfaces with fewer gaps

PLC based automatic operating system

Water distribution system

AIPAK Engineering Pharmaceutical Pure Water Distribution Storage System

AIPAK Engineering pharmaceutical pure water distribution storage system is to compensate the peaks in water use. Circulation pumps are responsible for ensuring turbulent flow in pipelines and maintain the required pressure in the system. Depending on the number and location of consumption points, the distribution system may contain one or more circulation loops starting and ending in the storage tank.

Online monitoring instruments

Safety performance

Maintain the quality of water supply

AIPAK Engineering High Quality Stainless Steel Pharmaceutical Pure Water Distribution Storage System

AIPAK Engineering pharmaceutical pure water distribution system its main function is to ensure that the pressure, flow and temperature delivered to the process pipeline meet the process production requirements. The system uses online monitoring instruments such as flow, pressure, temperature, conductivity and TOC to conduct safety performance, real-time monitoring and trend analysis of water quality, and effectively control the load of microorganisms in water through periodic disinfection or sterilization.

Automatic control mode

Professional design software for equipment piping

Modular production structure

Cleaning System

AIPAK Engineering Pharmaceutical Industries CIP Cleaning System

AIPAK Engineering pharmaceutical CIP cleaning system is used for dairy items in-place cleaning of pipes and vessels, can also apply to the brewery, beverage plants, and general food production materials of pipes and equipment cleaning. It is designed with 3 tanks, an acid liquid tank, an alkaline liquid tank, water tank separately connected on the machine frame, the tanks are with a single layer, the water tank is with heating function, the tank covers are flat. It is made of high-quality SUS304 material, has a long lifespan. It is easy to use and operate.

Reliable and repeatable process

Advanced in cleaning process equipment

Built-in insulation system

Preparation System

AIPAK Engineering Pharmaceutical Stainless Steel Liquid Preparation Tank Liquid Preparation System

AIPAK Engineering pharmaceutical preparation system adopts advanced adapter plate design,the tank cleaning can be completely independent of pipe, so as to avoid leakage of materials, pollution and risk of false operation.The piping and equipment meets requirements of GMP standards, without blind pipe and dead corners. The control system can realize production process, online cleaning, sterilization, material transfer automatically. Relevant parameters of preparation system can be monitored and recorded in real time, to ensure quality tracking and tracing.

Concentrated preparation

Decarbonizing filtration

Diluted preparation, sterile storage

The Buyer's Guide

Pharmaceutical Water System: The Complete FAQ Guide In 2025

Water is used in every industry but water for pharmaceutical use should be purified and free of contaminants. Pharmaceutical water is a specialized type of water system used as the active ingredient, raw material, and solvent in the formulation of different types of medications.

It does not have bacterial contamination, rouging, and mineral contaminants. The water for pharmaceutical use is produced by the pharmaceutical water system. It is the system including different processes and equipment used to treat raw water and it makes different types of pharmaceutical water.

Now are you interested in adding to your knowledge about pharmaceutical water systems, then carefully read this FAQ guide as we have included information about every aspect of a pharmaceutical water system.

1.What is Pharmaceutical Water?

Pharmaceutical Water

It is highly purified water particularly created for pharmaceutical use. It is a misconception that pharmaceutical water is tap water that is filtered but this is not the case. There are various impurities in the tap water like minerals, dust, chemicals, bacterial and other microbial contaminants.

However, pharmaceutical water is free of all these impurities. It is produced after rigorous treatment in the pharmaceutical industry that removes all the above-mentioned harmful contaminants. Pharmaceutical water fulfills all the quality and safety standards by thorough purification.

2.What are the Types of Pharmaceutical Water?

Based on the usage of the pharmaceutical water, there are broad types of pharmaceutical water, which are listed below:

Purified Water

Purified Water- Picture Courtesy: Mable Direct

This type of pharmaceutical water is used as an excipient in the preparation of nonparenteral or oral medication. It is also used as a cleaning agent for pharmaceutical equipment. Purified water does not contain any ionic or organic chemicals and is protected from microbial presence. It is produced from the drinking water.

Water for Injection (WFI)

Water For Injection- Picture Courtesy: alcare.sg

This kind of pharmaceutical water is used as an excipient in the formulation of parenteral and other types of injectable medication. It does not have a microbial presence but also does not have an endotoxin presence. It meets stringent safety standards.

Water for Hemodialysis

Water for Hemodialysis- Picture Courtesy: Febris Health Care

It is purified water employed in the dilution of dialysis concentrated solution. It does not contain any harmful contaminants that could compromise the health and safety of the patients. Water for hemodialysis is stored in unreactive containers that do not leach harmful chemicals in it.

Pure Steam

Pure Steam- Picture Courtesy: pharma-equipment-gallery.com

It is produced from purified water or WFI in the steam generator equipment. Purified steam has an important use in the sterilization of equipment and different packaging containers. It is also used for humidifying the environment.

Sterile Purified Water

Sterile Purified Water- Picture Courtesy: Cytiva

It is generated from sterile purified water. It is used in the analytical preparation and added as a diluent during the preparation of nonparental medications.

Sterile Water for Irrigation

Sterile Water for Irrigation- Picture Courtesy: B. Braun Australia

It is produced from water for injection that is passed through different sterilization protocols. It is usually used for washing and soaking wounds and surgical areas.

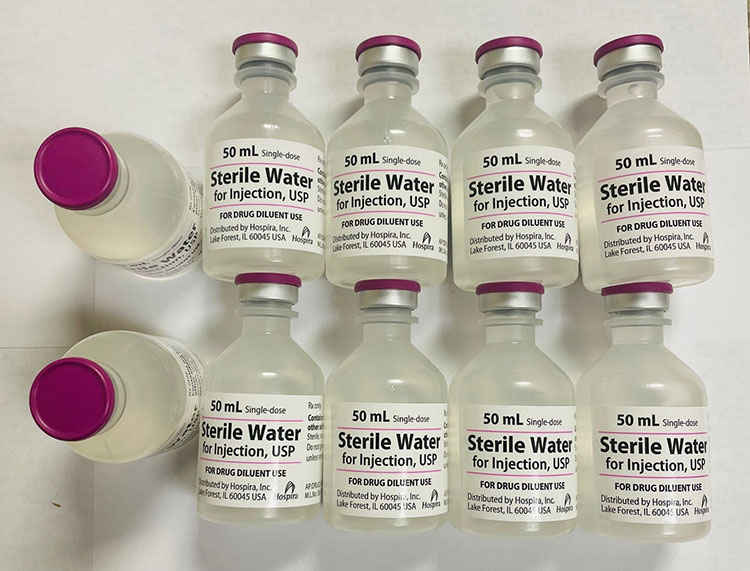

Sterile Water for Injection

Sterile Water For Injection- Picture Courtesy: Farris Labs

It is created from water for injection that undergoes sterilization to ascertain it is free of microbes. It is used as a sterile diluent for injection solution. It is packed in single-dose containers with a volume not higher than 1 liter.

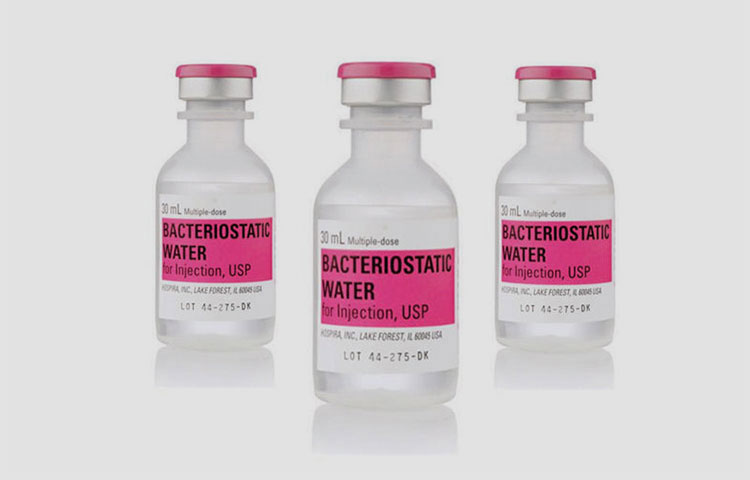

Bacteriostatic Water for Injection

Bacteriostatic Water for Injection- Picture Courtesy: Westend Medical Supply

It is generated from sterile water for injection and does have antimicrobial preservatives or bacteriostatic agents. It is used in multi-dose injection solutions and is packed in single-dose or multi-dose containers with a volume not higher than 30ml.

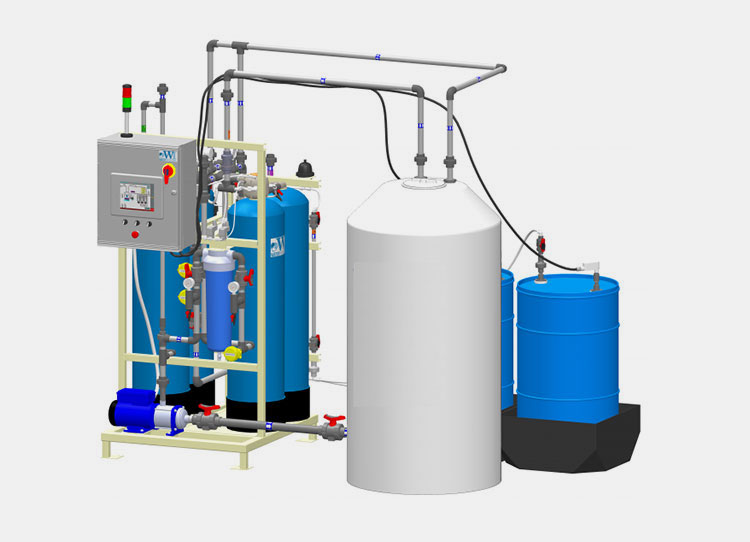

3.What is a Pharmaceutical Water System?

Pharmaceutical Water System- Picture Courtesy: Aquarion Group

The pharmaceutical water system is the core part of the pharmaceutical facility and its main job is to produce high-purity water for formulation and processing steps of different medications. It involves different equipment and steps for the creation of purified water.

It is a multi-step treatment process in which drinking water undergoes different purification steps to obtain water in the most purified form. A pharmaceutical water system is a complicated setup that generates and packs water for pharmaceutical manufacturing.

4.What is the Significance of a Pharmaceutical Water System?

The significance of the pharmaceutical water system is due to the safety and efficiency of medication prepared in the purified water. The reasons why the pharmaceutical water system is vital in the pharmaceutical industry are:

Upholding the Product Quality

Upholding the Product Quality- Picture Courtesy: Fagron Sterile Services

The pharmaceutical water system creates purified water which is essential in pharmaceutical formulation as a core ingredient. This purified water is present in both parenteral injection solution and nonparental solution. The pharmaceutical water system eradicates residues of impurities and microbial contaminants, ensuring the quality of the final drug formulation.

No Comprise on Patient Safety

No Comprise on Patient Safety- Picture Courtesy: Technical Safety Services

There must be no microbial and pyrogens presence in the purified water used in the manufacturing of injectable solution and other sterile products like wound dressings. Pharmaceutical water system guarantees the health safety of the patients by eliminating potential hazards from the water. The pharmaceutical water system utilizes meticulous purification methods to safeguard the health of the patients.

Meeting the Regulatory Compliance Standards

Meeting the Regulatory Compliance Standards- Picture Courtesy: PDH LABORATORIES (PVT) LIMITED

The manufacturing of medications and the use of purified water in pharmaceutical productions are strictly regulated by the drug regulatory authorities. Since the pharmaceutical water system produces highly pure and sterile water, it makes sure that pharmaceutical facilities meet stringent regulatory compliance ideals.

Production Efficiency

Production Efficiency- Picture Courtesy: Oncoera

Pharmaceutical water systems of modern times are automated and hence they have greater production efficiency. These systems generate a consistent supply of pure water in less time, thus ensuring the continuous distribution of pharmaceutical water throughout the medication production steps.

5.What are Common Methods Involved in the Pharmaceutical Water System?

There are broad range of common methods involved in the pharmaceutical water system such as:

Prefiltration

Prefiltration- Picture Courtesy: EPS Water

This technique removes the solid, coarse, and particulate materials from the water supply. This step protects the downstream equipment from impurities that can affect their working performance. It uses sieving technology that filters out large particles like dirt while passing water molecules.

Activated Carbon

Activated Carbon- Picture Courtesy: Cowaymega

It consists of activated carbon beds and removes certain organic compounds having low molecular weight by absorbing them. It also captures bacterial endotoxin, chlorine and chloramine compounds.

Organic Scavenger

Organic Scavenger- Picture Courtesy: AllWater Technologies

These are the scavenging devices that employ the anion-exchanger resins. These resins are capable of capturing and removing negatively charged organic compounds and bacterial endotoxin.

Additives

Additives

These compounds are added to the pharmaceutical water system to inhibit microorganism growth. These increase the elimination of solid materials and chlorine. It also fixes the pH of water by removing carbonates and ammonia compounds.

Softeners

Softeners- Picture Courtesy: Fresh Water Systems

These utilize sodium-based cation exchangers and capture ions like calcium, magnesium, and ammonium that cause water hardness. If present in water, these ions may affect the working performance of the downstream equipment.

Reverse Osmosis

Reverse Osmosis- Picture Courtesy: Global Filter

This technique uses a semipermeable membrane with a pore size large enough to pass the water molecules but small enough to filter out to chemical ions, organic materials, and microbes. It is an effective method and requires two passes to achieve pharmaceutical water purity.

Deionization

Deionization- Picture Courtesy: Water Innovations, Inc.

These devices are the improvement in cation and anion removal techniques. These devices consist of charged resins and permeable membranes that remove different ions from the pharmaceutical water by generating electric potential and attracting various ions.

Ultrafiltration

Ultrafiltration- Picture Courtesy: Genesis Water Technologies

This purity method is typically used at the last stages of water purification to capture endotoxins from the water. It also uses semi-permeable membranes but these membranes have large pores to prevent the passage of endotoxins.

Distillation

Distillation- Picture Courtesy: sinicmed.com

It is the process in which water is boiled to remove impurities. The water is condensed back separates the impurities having different boiling points. However, care should be taken for impurities that boil and condense with water as these will remain in water.

6.What is the Production Line of the Pharmaceutical Water System Made of?

The production line of the pharmaceutical water system is composed of several machines carrying out their function of purifying pharmaceutical water. These machines are detailed below:

Pharmaceutical Purified Water Treatment System

AIPAK Engineering Pharmaceutical Purified Water Treatment System

It is a compact and modular construction machine that separates impurities from the water supply using different methods like reverse osmosis, and thermal disinfection. Double softer can be added to this system to achieve maximum purity. The parts and pipes of this water treatment system are made up of 316L stainless steel material. The pharmaceutical purified water treatment system is equipped with a separate cleaning system to remove impurities from the system.

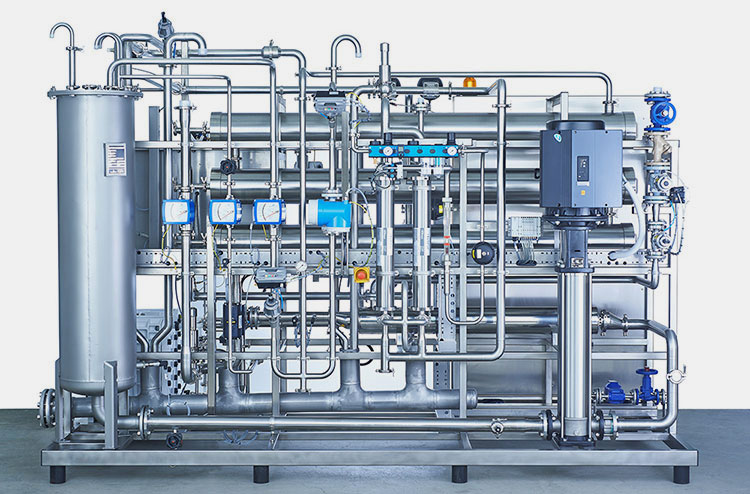

Multi-effect Water Distiller

AIPAK Engineering Multi-effect Water Distiller

In this machine, a multi-stage evaporation takes place to purify water. These evaporative stages are about five. It consists of a steam steam-reducing valve and it also has a device for removing non-condensable gases. It is composed of an external heater and condenser that heats water and condenses water vapors respectively. It conserves energy by only using heat for the first stage of evaporation rest of the next effect stages are performed by the steam.

Water Distribution System

Water Distribution System

The purified pharmaceutical water is mainly distributed from the unit to external packing and transportation by the water distribution system. It is a broad series of piping circulatory units made up of stainless steel that meets health regulations and quality standards. An effective pathway for water distribution without risks of contamination.

The water distribution system is composed of a control PLC system with a feeding water pump network, and recording mode that are designed in a modular structure.

Clean Steam Generator

AIPAK Engineering Clean Steam Generator

It takes water for injection or purified water to create pure steam for SIP process. A clean steam generator is a widely popular machine in the medical, pharmaceutical, and food sectors for cleaning and disinfecting different equipment. It has a simple and elegant structure with straightforward operation. This equipment consists of an evaporator and preheater and it is also equipped with an automatic control panel.

7.What is the Difference Between Hot and Cold Pharmaceutical Water Systems?

AIPAK Pharmaceutical Purified Water Treatment System

Both hot and cold pharmaceutical water systems are used for microbial control, but the main difference between them is the working temperature. Some of these differences are given below:

| Features | Hot Pharmaceutical Water System | Cold Pharmaceutical Water System |

| Origin | It is the old and traditional method for microbial control. | It is the recent advancement in microbial control methods. |

| Temperature | The pharmaceutical water is heated to a high temperature of 80°C to achieve microbial control. | Microbial control occurs at room temperature. |

| Techniques | Heat is utilized for inhibiting microbes. | Membrane technologies are used for purifying pharmaceutical water in the cold pharmaceutical water system. |

| Energy Consumption | High energy is consumed in the hot pharmaceutical water system, | No energy is consumed in the cold pharmaceutical water system. |

| Heat-Sensitive Medication | Heat-sensitive medications are degraded in it. | No degradation of heat-sensitive medications. |

| Biofilm Formation | No biofilm is formed in the hot pharmaceutical water system. | Biofilm could be formed in the cold pharmaceutical water system. |

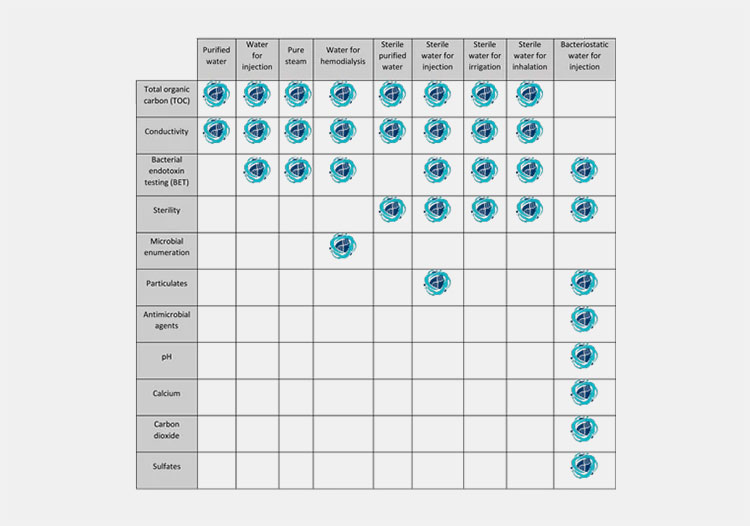

8.What are Quality Control Tests for Pharmaceutical Water System?

Quality control testing list required for pharmaceutical water system- Picture Courtesy: Pharmtech

Quality control testing is a critical gateway to ensure that the pharmaceutical water system is providing you with safe and therapeutically approved water that you can use in formulations. It is a cumulative sum of all procedures that assure the ‘identity & purity’ of the specific pharmaceutical (World Health Organization).

Therefore, quality control testing is composed of a few simple tests based on national pharmacopeia following official references. This procedure must be taken into account prior to its distribution.

| Total Organic Carbon (TOC) Testing

This test is required to trace the presence of organic substances from water sources, purifying as well as distribution systems, and growing systems. |

| Conductivity Testing

As its name suggests, this test is used to screen the ion facilitation of electrons from the water. It is well known that water molecules break down or dissociate into ions and pH and temperature fluctuate hence you can screen the conductivity. However, the conductivity can be affected in the presence of carbon dioxides, or the presence of inorganic particles in the water such as chlorides, nitrates, sodium, magnesium, etc., |

| Bacterial endotoxin testing (BET)

This is also known as a ‘pyrogen test’ because it results in the progression of microbes in mammalians and results in high-grade fever. The type of test involved the application of Limulus Amoebocyte Lysate reagent which is made from horseshoe crab blood. This reagent is utilized to measure the presence of bacterial endotoxin in pharmaceutical water. |

| Sterility testing

To determine the presence and amount or size of microorganisms, a sterility test is performed in pharmaceutical water. |

| Microbial Enumeration Testing

This is the test that allows you to know the quantitative enumeration of bacterial and fungal mesophiles that typically grow in the aerobic environment. Therefore, this test promises to determine whether water is free of microbes and is of good quality. |

| Particulates Testing

A specialized test for injections and parenteral formulation for assessment of mobile undissolved substances than air bubbles which is mostly presented unintentionally. This testing is of prime importance for pharmaceutical water systems to promise you that it is critically tested and safe for injectables. |

| Antimicrobial Agents Testing

This is the test that implies the effectiveness of antimicrobial growth prevention. This means you add preservatives to water to keep it safe. Sometimes sterile preparations are packed in a multi-dose container therefore to avoid its implementation repeatedly, this test is performed to ensure an optimum concentration of preservative is available in each individual or combined dose. |

| pH Testing

This test is performed to estimate the presence of a negative log of the hydrogen in pharmaceutical water. |

9.What are the Challenges in the Pharmaceutical Water System?

The pharmaceutical water system is efficient in maintaining the purity of pharmaceutical water and the formulation of medications. However, it may face some serious challenges that need consistent innovation to resolve them. These challenges are:

Biofilm Formation

Biofilm Formation- Picture Courtesy: Smile Brilliant

Colonies of live and dead microbes form a layer on the surface of devices present in the pharmaceutical water system. These layers or biofilms act as breeding sites for more microbial populations. It can cause contamination risk to the pharmaceutical water system. Properly designing equipment and regularly cleaning them may reduce this risk.

Treatment Effectiveness

Treatment Effectiveness- Picture Courtesy: Metalaire

With time, the effectiveness of different purification methods like filtration membranes and deionization resin is reduced and these systems do not remain effective in removing the impurities and microbes. To overcome, this challenge it is essential to regularly maintain and replace these devices.

Presence of Rouge

Presence of Rouge- Picture Courtesy: Reddit

Rouge is the discoloration of water due to the presence of iron oxide, and hydroxide salts in the pharmaceutical water system. It is referred to as rust or oxidative corrosion. This is usually present in the hot pharmaceutical water system. The concentration of rouge can be minimized using hygienic equipment made of stainless steel.

Energy Consumption

Energy Consumption- Picture Courtesy: UPES Blog

Maintaining elevated temperatures in the hot pharmaceutical water system is much energy demanding and expensive. Also, these high carbon emissions negatively impact the environment. Pharmaceutical manufacturers are introducing new techniques for purifying pharmaceutical water while decreasing energy demand.

Validation and Documentation

Validation and Documentation- Picture Courtesy: ICQ Consultants

Detailed and meticulous validation and documentation are needed for continuing regulatory compliance of the pharmaceutical water system. However, proper documentation is essential in maximizing the uptime and effectiveness of the pharmaceutical water system.

10.What are the Latest Innovations in a Pharmaceutical Water System?

The world of pharmaceutical water systems is continuously shaping itself with the latest innovations to overcome challenges and increase the efficiency of the system. Some of the latest innovations in the pharmaceutical water system are penned below;

Electro-deionization

Electro Deionization

It is a new technology that acts as a replacement for ion exchange resins employed in the deionization process. This technique works continuously unlike the ion exchange resins that require continuous regeneration. It increases uptime and decreases the maintenance requirement. Moreover, it is an eco-friendly innovation, as it does not need harmful chemicals for resin regeneration.

Membrane Distillation

Membrane Distillation- Picture Courtesy: Utilities Middle East

It is an innovative alternative to the traditional distillation. It separates contaminants from the water using a membrane instead of boiling them, as done in the old distillation method. This technique consumes less energy than traditional distillation.

11.What are the Consideration Factors When Designing a Pharmaceutical Water System?

Designing a pharmaceutical water system is a tough job so it is essential to carefully consider several aspects. These aspects play an important role in meeting specific requirements of the facility and complying with industrial regulations. These consideration factors are discussed below:

Water Quality

Water Quality- Picture Courtesy: Sensorex

The raw water whether taken from municipal supply or well water is filled with impurities. This quality of water supply hugely affects the pretreatment stages. So, first must analyze the composition of water and then select purifying methods accordingly.

Production Volume

Production Volume and AIPAK Multi-effect Water Distiller

Secondly, calculate the facility water demand and then design the pharmaceutical water system accordingly. Different facilities like oral preparation, injection formulation, cleaning, and disinfection have different requirements for pharmaceutical water. So, first, factor in the peak hours and possible future expansion before creating the pharmaceutical water system.

Material Selection

Material Selection- Picture Courtesy: Titulae

It is important to design a pharmaceutical water system made with hygienic and corrosion-resistant materials. These materials are easily cleaned and do not leach harmful chemicals into the pharmaceutical water.

Space Constraint

Space Constraints- Picture Courtesy: salepubsm.live

The floor space of the production plant impacts the design and footprint of the pharmaceutical water system. Bigger facilities usually go for the larger-sized pharmaceutical water system while production plants with space constraints should opt for a compact and modular-sized pharmaceutical water system.

Ease of Access

Ease of Access and AIPAK Pharmaceutical Water Distribution System

When designing the pharmaceutical water system, ease of access for cleaning and maintenance should be kept in mind. Easily available surfaces of the pharmaceutical water system increase the uptime and production efficiency.

Conclusion

The pharmaceutical water system is an engineering marvel and it is must have in the pharmaceutical and medical industries. It is essential in creating different types and grades of pharmaceutical water like purified water, water for injection, sterile water for injection, and many more. Different techniques are employed in the pharmaceutical water system like reverse osmosis, distillation, filtration, etc. to purify raw water. Hopefully, you have found this blog post interesting and informative. If this blog post tempted, you to add a pharmaceutical water system to your facility then consult AIPAK Engineering as we have a vast catalogue of pharmaceutical water systems at reasonable prices.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours