Your Premier IV Fluid Solutions Provider

- High production efficiency

- Stable product performance

- Simple and reliable operation

AIPAK Engineering IV Fluid Production Lines

AIPAK Engineering IV fluid production line can automatically complete the processes such as film opening, printing, batch number printing, bag making, filling, automatic cap feeding, cap welding and bag discharge.The production line can be equipped with soft bag transmission, sterilization, leak detection, light inspection, packaging and other auxiliary equipment to complete the whole production line. It is mainly used for automatic filling of conventional infusion, special infusion, flushing / urinary, par-enteral nutrition, dialyzate, antibiotics, blood products, lipids and special drugs.The design, manufacturing, assembly and debugging of the whole IV fluid production line meet the requirements of the new GMP standards for drug production.Adopts hot plate stamping with single color, the whole production line can print production date, validity period, approval number at the same time.

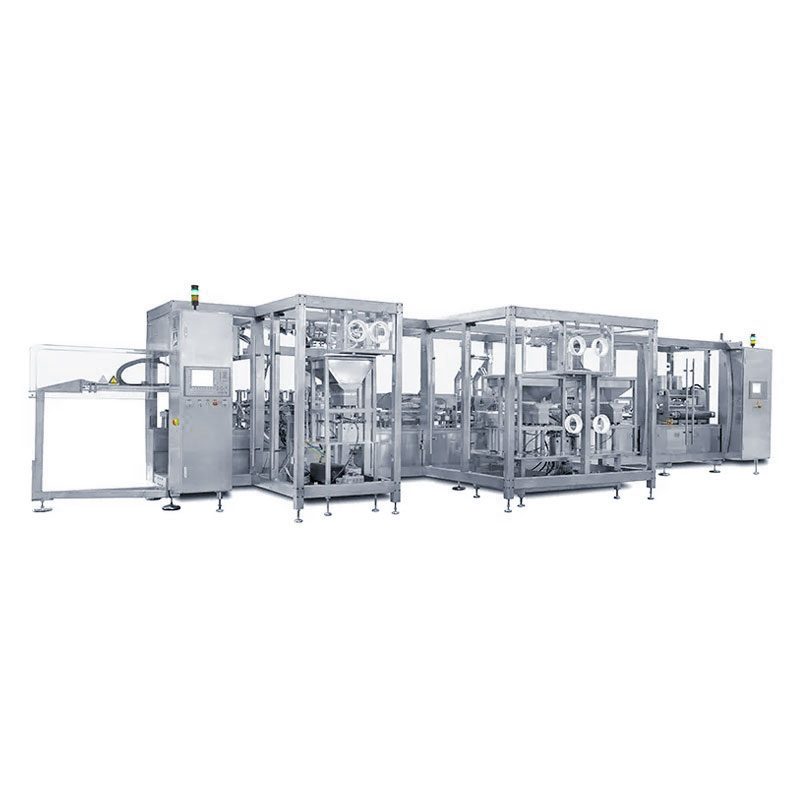

Non PVC Infusion Soft Bag IV Production Line

SRD(Single Hard Port) series Non PVC soft bag IV solution production line

AIPAK Engineering SRD(Single Hard Port) series Non PVC soft bag IV solution production line is used to automatically produce 1200-6000ml single hose Non-PVC soft bags. It is designed for Aiapk Engineering use according to the GMP and FDA guidelines.It can automatically complete the processes such as film opening, printing, batch number printing, bag making, filling, automatic cap feeding, cap welding and bag discharge; the production line can be equipped with soft bag transmission.

GMP standards for drug production

Filling Accuracy of soft bag filling machine: ≤ ±1%

Fully automatic control and monitor of production process

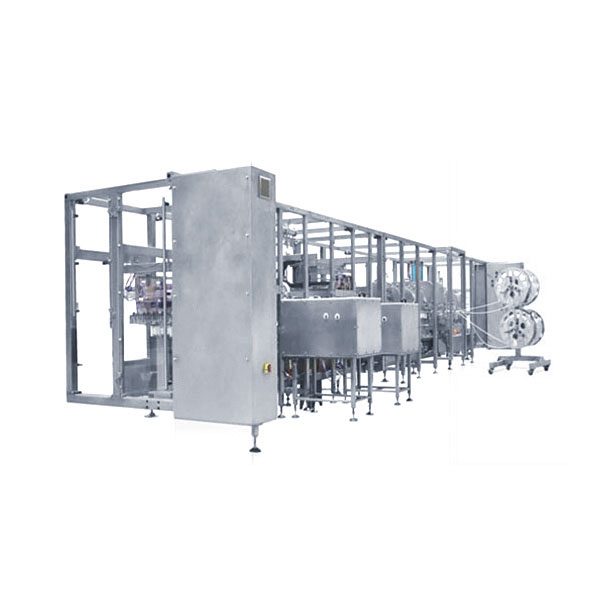

SRDS(Double Hard Port) series Non PVC soft bag IV solution production line

AIPAK Engineering SRDS(Double Hard Port) series Non PVC soft bag IV solution production line can automatically finish film feeding, printing, bag making, filling and sealing in one machine. It can be applied to 1000-5000ml Non-PVC soft bag for general solution, special solution, dialysis solution, parenteral nutrition, antibiotics, irrigation and disinfectant solution etc.Because of the different material and thickness between the boat type ports and the film, it adopts 2 pre-heating, 2 heat seal welding and 1 cool welding,to enable it to suit with different plastic material and film, bring the user more selection, higher welding quality, low leakage rate within 0.3‰.

Bag making high efficiency

Compact structure,reduced workshop

Low energy consumption

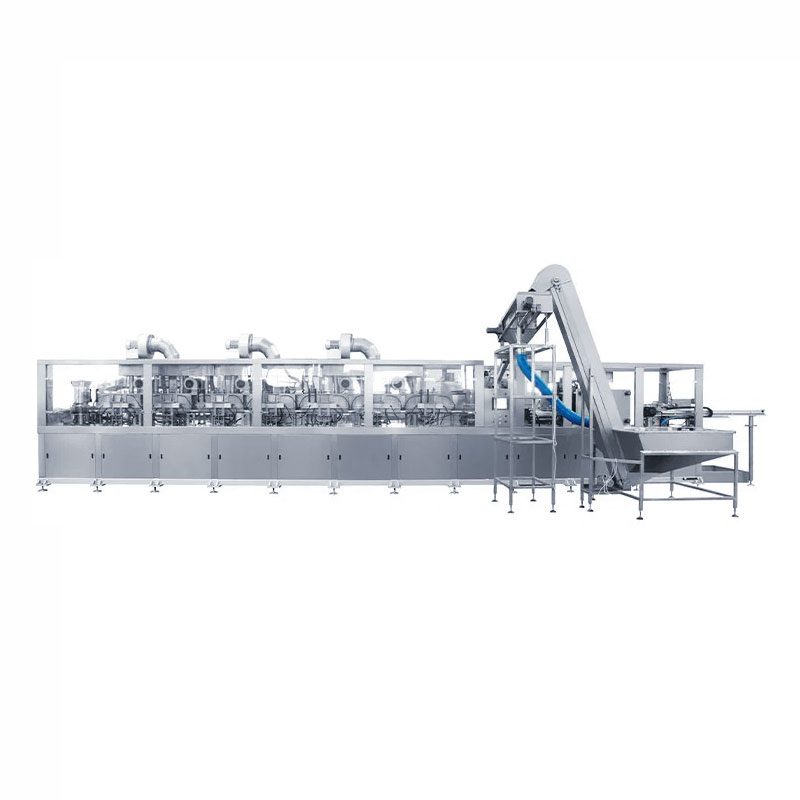

SRDRS(Double Soft Tube) series Non PVC soft bag IV solution production line

AIPAK Engineering SRDRS(Double Soft Tube) series Non PVC soft bag IV solution production line can automatically feed film to the printing and forming station, the film roll is fixed by easy operated cylinder clamps. The fixation doesn't need any tools and manual labor.Adopts peripheral welding with bilaterally open moulds structure, up and down moulds are opened bilaterally and equipped with cooling plate, to heat both moulds to the same temperature up to 140ºC and above. No film over-baked during bag forming or machine stopping. Improve the product welding quality and save more film.

Short debugging time

Small area occupation

Easy operation&clean

Glass Bottle IV Production Line

Glass Bottle IV Solution Production Line

AIPAK Engineering glass bottle IV solution production line is composed of bottle unscrambler, rough washing machine, fine washing machine, filling and stoppering machine, capping machine. It can complete bottle unscrambling, rough washing, fine washing, nitrogen filling, vacuumize, stopper unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process. Each machine can be used separately or in linkage line.

Smooth operation at high speed

Adopts a unique capping technology

High filling accuracy and large production capacity

Plastic Bottle IV Production Line

Plastic Bottle IV Solution Production Line

AIPAK Engineering plastic bottle IV solution production line is composed of plastic bottle injection molding machine, two-step blowing machine and washing, filling and sealing machine; the production process is mainly that plastic particle is molded into bottle embryo by injection molding machine, and then bottle embryo is heated by far infrared ray, and then bottle is blown by biaxial stretch blow molding process. Finally, molded bottles complete the production processes such as bottle washing, filling and sealing through the line.

The filling adopts hard pipe connection

No filling and no cap delivery without bottle

PLC program control and automatic completion of each process

BFS(Blow Fill Seal) Production Line

Plastic Bottle BFS(Blow Fill Seal)Machine LVP (large volume parenteral) Production Line

AIPAK Engineering plastic bottle BFS machine LVP production line is an advanced technology that integrates molding, filling and sealing under complete control, which enables liquid to be packaged in polypropylene/high-density & low-density polyethylene plastic bottle, and the whole production process automatically completes extruding plastic particles into plastic preform at high temperatures,then the preform is blown into a container by sterilized and filtered air,flling liquid that have been sterilized and filtered,tight sealing of containers after filling in a controlled environment (aseptic environment).

Stable and reliable performance

Filling Accuracy: ≤ ±1%

Configurable on-line monitoring system

Plastic ampoule BFS(Below Fill Seal)Machine SVP (small volume parenteral) Production Line

AIPAK Engineering plastic ampoule BFS machine SVP production line can be used for the production of small volume injections, eye drops, oral liquid, ear drops, and other products. The filling range is 0.1ml-20ml, output depends on the filling quantity and mould cavity number.It is for blowing/filling/sealing plastic ampoule in the same machine during asepsis situation in Aiapk Engineering field.And this is an asepsis packaging technology, combines the following step: Plastic ampoule forming, Plastic ampoule filling, Plastic ampoule sealing.

High filling precision

High precision color touch screen operation monitoring

Advanced equipment, unique and reasonable structure

Multi Chamber IV Bag Production Lline

Multi Chamber IV Bag Production Line

AIPAK Engineering offers whole a range of multi-chamber bags – double, triple or customized – for different applications such as parenteral nutrition or drug reconstitution machine. Multi chamber IV bag machine are intended for automatic, semiautomatic or manual & various production needs from 50mL-5000mL & T.P.N Multi-Chamber depending on local environmental.Multi-chamber bags for parenteral nutrition offer many advantages. They enhance patient safety as they reduce handling and thus the risks of contamination of the nutritional mixture.

Ensure trouble-free operation

Reduced maintenance cost

Long-term reliability

The Buyer's Guide

IV Fluid Solution: The Complete FAQ Guide In 2025

Today, IV fluid solution is considered as safe and frequently used in clinical and hospital practice for all group age populations. However, it is required with high skills, certifications, and proper professionals to implement them.

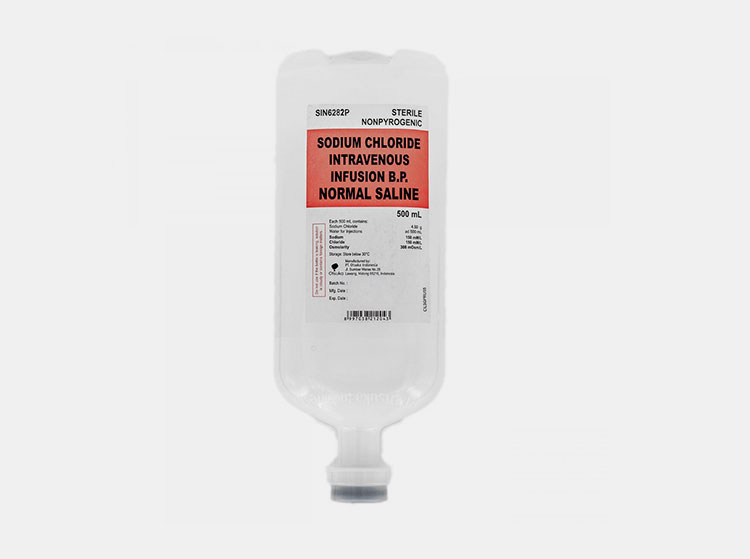

IV Fluid Solution- Picture Courtesy: Stepward

But what is actually an IV fluid solution? And what should you know if you’re associated with this field?

In this blog, we are going to discuss IV fluid solutions, their types, significance, and relevant details.

1.What Is IV Fluid Solution?

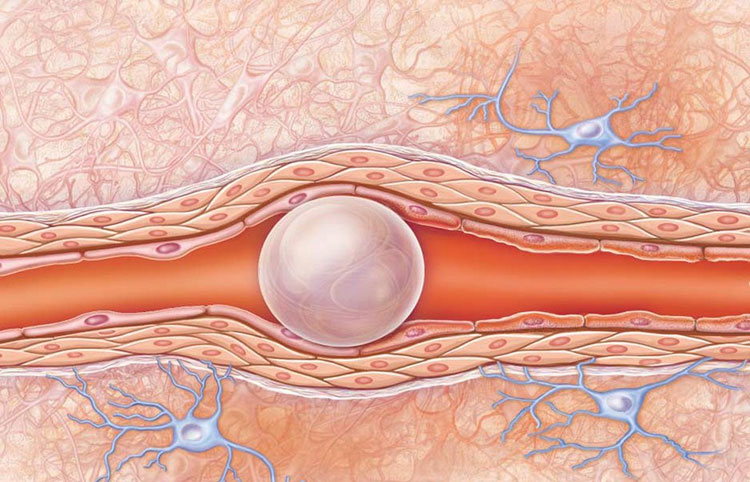

IV Fluid Solution- 3d Molier International

IV fluid solution or intravenous fluid solution is an effective therapy to replenish your body with essential minerals, trace elements, and nutrients to normalize physical activities.

It is actually an enriched volume of purified water cocktail with essential electrolytes carefully prepared under a strict and sterile environment as it has to be directly combined in your bloodstream to regularise weaknesses.

It is commonly prescribed in case you’re unable to use the oral route; this could be due to many reasons, i.e. digestive disturbance, weakness, unconsciousness, etc., so IV fluid solution can be directly administered into your vein and restore the electrolyte level efficiently.

2.What is the history of IV Fluid Solution?

IV Fluid Solution history- Picture Courtesy: Empower Pharma

Today’s successful IV fluid solution therapy is not associated with little experimentation. Its history began in 1667 when Dr. Jean Baptiste Denis tried to transfuse blood from animal to human which bans this trial due to various serious side effects.

In 1796, Dr. Physick was the first who successfully propose human-to-human blood transfusion which was exceeded by Dr. Blundell in 1818. However, after a few years, in 1831 further advancement emerged that included IV fluid solution by Dr. O’Shaughnessy in the mid-1800s.

In 1950 further research and revolution in IV fluid solution came to emergence when plastic catheters were introduced by Dr. Massa that was considered as safer and more reliable to the patients.

The regular IV fluid solution became in regular practice in the 1960s in many American healthcare setups. Till now, it is best known for its cornerstone of new and modern medicines which keeps going on further improvisation.

3.What are the benefits of IV fluid solution?

In the healthcare sciences, the IV fluid solution offers unlimited benefits, therefore, it serves as a significant division in the clinical and hospital setups. The most common and essential benefits of IV fluid solution are discussed below:

Gateway of Fast Medicinal Effects

Rapid Medication Activity- Picture Courtesy: Mobile IV nurse

This is commonly used to deliver medicine directly into your bloodstream. The medicine cocktail is prepared when you infuse a particular dose of it in the IV fluid solution and administer it into the vein to achieve fast effects.

An Effective Fluid Replacement Therapy

Effective Fluid Replacement Therapy- Picture Courtesy: NPR

There are several health conditions where the body suffers dehydration or loss of essential electrolytes. Once this indication occurs, you start feeling faint and hypotensive with other important physiological imbalances. Thus, IV fluid solution is an effective and rapid therapy to rehydrate your body and maintain your vitals.

Direct Infusion of Medication

Direct infusion of medication- Picture Courtesy: UShopitalproducts

An IV fluid solution is used to provide direct incorporation of medicine into your blood circulation and achieve a desirable onset of action.

Patient Compliance

High Patient Compliance- Picture Courtesy: CIA Medical

There are several stages of diseases where patients are capable of taking medicines and sometimes fail to accept them. For example, if the patient is suffering from food poison, this would be difficult to accept oral medication due to frequent episodes of vomiting.

On the other side, patients suffering from stomach problems are also unable to take medicine by mouth. Therefore, IV fluid solution is a good method to provide effective treatment and restore normal health.

4.What are the different formulations & Types of IV fluid solution?

IV fluid solution is particularly designed that be compatible with your body's physiology highlighting osmosis. Similarly, it depends on what your goals are about your body's vitals.

Formulation of IV Fluid Solution

The IV fluid solution is of two types, either crystalloids or colloids.

Crystalloids

Crystalloid IV fluid Solution- Picture Courtesy: RCVS

These are the tiny molecules that can assemble and penetrate well into the cell’s membrane. If you examine the cell membrane, it has minute holes through which the osmosis process can happen. This membrane hole is capable of passing each molecule at one time. So, IV fluid solution crystalloids are capable of adjusting well from these tiny holes and are better for cell equilibrium.

Colloids

Colloid IV Fluid Solution- Picture Courtesy: Vet Education

Colloids, as compared to crystalloids, are much larger molecules that are unable to fit via holes of cell membranes like crystalloids. That’s why, the colloid solution remains in your bloodstream instead of entering the cells of the body.

Types of IV Fluid Solution

There are different types of IV fluid solution, this is necessary to understand the differences and the right indications for each type. The types include:

Normal Saline

Normal Saline- Picture Courtesy: Aclare Pharmaceuticals

A sterile and non-pyrogenic preparation which is composed of crystalloid fluids means it can easily penetrate into the cell membrane and reach the target. It is a commonly used IV fluid solution that is useful in maintaining body fluid volume and sustains proper hydration levels in the body of a patient with diarrhea, vomiting, or certain related ailments.

A normal saline IV fluid solution should be cautiously used in patients with hypertension, or cardiac problems as it can fluid retention in your body and increase sodium levels which is harmful to people with such conditions.

Indications

- It is used in patients with:

- Metabolic alkalosis,

- Severe hyponatremia Postural Orthostatic Tachycardia Syndrome

- Fluid replacement therapy

Half Normal Saline

Half Normal Saline IV fluid solution is a commonly used fluid that is hypotonic form and composed of crystalloid. As compared to normal saline, it is mostly used in combination with dextrose 5% to maintain the fluid in the patient with nutritional deficiency or not accepting food. It should not be given to patients who require rapid hydration. For example, food poisoning, viral, or gastroenteritis.

In hospital practice, the common cocktail is used by following D5% 1/2NS + 20 meq KCl in the protocol.

Ringer Lactate

Ringer Lactate IV solution- Picture Courtesy: Healthline

This is probably the most commonly used IV fluid solution that you might have not known of before. If you have ever encountered serious injury, or have been through surgeries, then you’re likely to be administered with ringer lactate doses.

This is basically composed of an optimum amount of sodium, calcium, chlorides, potassium, and of course lactate. This complete mixture composition of IV fluid solution is as similar as your blood that’s why it is suitable for rehydration.

Indication

Ringer lactate mostly supports treatment protocols of:

- Burn patients

- Fluid loss and dehydration

- Blood loss

- Fluid replacement

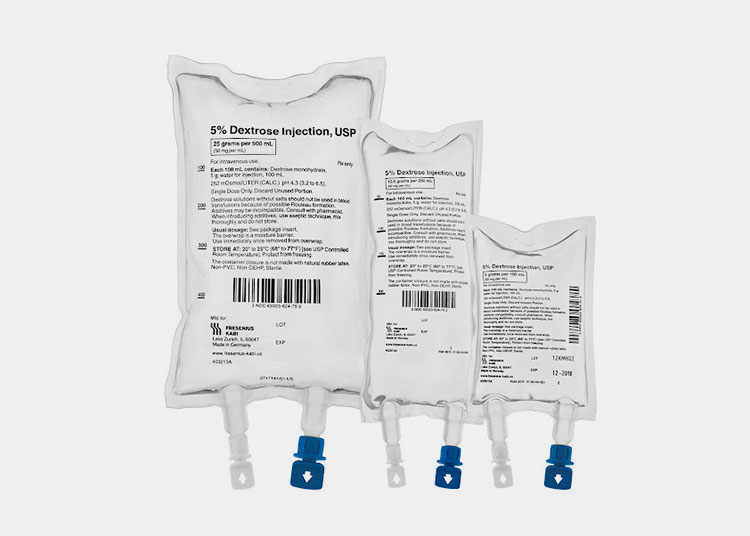

Dextrose

Dextrose- Picture Courtesy: Promea

You might have heard about dextrose before which is simple sugar. This is also similar to glucose and used in various food products, but it also offers you some clinical indication therefore used in medical setups.

In IV fluid solution, it acts as a carrier and offers sugar to malnourished cells and boosts them. This form of IV fluid solution is compatible with water, normal saline, and ringer lactate.

Indication

5% Dextrose + saline can be combined and used for the treatment of

- Nutritional deficiency

- Body dehydration

- Dose administration in patients with hypernatremia or hypertension.

5.What are the Different IV Fluid Solution Bag Dosages?

IV fluid solution Volume Ranges- Picture Courtesy: dipideomas

The IV fluid solutions are available in different dosages. For example,

| Normal Saline (0.9% Sodium Chloride) | Normal saline 0.9% sodium chloride is available in 1000 ml or 1 Liter, or in a 100 ml small pack. This volume is basically used for hydration or diluting your medications. |

| 0.45% Sodium Chloride or Half Normal Saline | This concentration of sodium chloride is available in 500 mL & 1000mL or 1 Liter. This is used for body fluid maintenance. |

| Ringer Lactate Solution | The ringer lactate solution is commonly available in a 1000 ml or 1 Liter bag which is a mixture of essential minerals that can help you balance your body physiology. |

| 5% Dextrose in Water (D5W) | This is available in several concentrations, the 5% dextrose or sugar pack is normally available in 250 mL, 500 mL, and 1000 mL or 1 Liter. |

| 5% Dextrose in 0.9% Sodium Chloride (D5NS) | This cocktail of 5% Dextrose in 0.9% Sodium Chloride (D5NS) is mostly available in volumes of 250 mL, 500 mL, and 1000 mL or 1 Liter which is used to replenish nutritional deficiencies. |

| 10% Dextrose in Water (D10W) | This concentration of dextrose is commonly available in volumes of 500 mL and 1 Liter which is administered parenterally to control hypoglycaemia. |

| 3% Sodium Chloride (Hypertonic Saline) | This is available in various size dosage formulations such as 250 mL, 500 mL, and 1000 mL (1 Liter) in conditions like hyponatremia and neurological emergencies. |

6.What are the Applications of IV Fluid Solution?

The uses of IV fluid solution are discussed below:

Nutritional Support

Nutritional Support- Picture Courtesy: PRICPHMA

Various bedridden patients are encountering nutritional deficiencies as for a longer time they’re unable to acquire proper diets. IV fluid solution helps in this way it nourishes your body by providing essential trace elements, supplements, vitamins, etc., the IV fluid solution is used as an adjunct therapy with other nutritional supplements to offer a complete nutritional way to the patient.

Chronic Ailment Treatment

Serious Illness- Picture Courtesy: Intelycare

There are various health problems where disease management can be done by utilizing IV fluid solutions. For example, in cancer patients, chemotherapy is done by making an infusion of a chemotherapeutic agent with an IV fluid solution. Similarly, treatment of certain infections or auto-immune disorders requires IV fluid solution to bring effective therapy protocol.

Emergency Treatments

Emergency Management- Picture Courtesy: Trusted Nurse Staff

IV fluid solution is significantly important for treating ‘Emergency Situations’ in hospitals such as extensive bleeding, controlling poisoning, or administering antidots, and associated vitals.

Chemotherapy

Cancer Management- Picture Courtesy:Intelycare

Cancer patients are often prone to dehydration, but IV fluid solution is used to prevent electrolyte imbalances and keep them adequately hydrated.

Burn Centres

Burns Management- Picture Courtesy: Texas Med Clinic

IV fluid solution is considered an essential strategy for managing burn patients. Fluid loss, skin damage, and electrolyte imbalances are pretty common in such patients that can be deal by infusing an IV fluid solution to maintain vital organs and the patient’s life.

Renal/Peritoneal Dialysis Centre

Dialysis- Picture Courtesy: Kidney Health Australia

In dialysis centres, you may observe many patients with IV fluid solution administration during the procedure to help adequate fluid balance. The IV fluid solution ensures the patient is safe from dehydration and other complications related to electrolyte imbalances.

7.What are available treatments with IV Fluid Solution?

There are different available treatments with IV fluid solution, each treatment has specified results. For example,

Detox Treatment

Body Balance- Picture Courtesy: German Heart Centre

This is a very popular IV fluid solution treatment that is used for cleaning your body and eliminating unwanted and toxic matter present inside. It helps in nourishing and balancing electrolytes and rehydrating the body.

Energy Booster

High Energy- Picture Courtesy: Metabalance

This formulation of IV fluid solution offers a natural way for hydration and boosting energy levels as it subsides lethargy and fatigue caused by foods.

Vitamin Treatment

Nutrient Via IV Fluid Solution route- Picture Courtesy: Sonder Private Clinic

This is composed of all essential nutrients that can boost your immunity and restore those elements lacking in your body.

Antioxidant treatment

Antioxidant- Picture Courtesy: Wellness MD

This is a type of treatment used to elevate antioxidant activity in the body by fighting against inflammatory mediators ultimately making you extra charged against diseases.

Anti-Aging Treatment

Anti Aging- Picture Courtesy: WFLA

The most popular treatment is where IV fluid solution is mixed with anti-aging agents such as glutathione, vitamin C, etc to enhance anti-aging properties inside your body’s cell.

8.What are the risks of IV fluid solution?

IV fluid solution is a completely safe procedure and is free of risks. But a few rare complications are associated with this procedure such as:

Air Embolism

Air Embolism- Picture Courtesy: Elcam Safety

It is also called a gas embolism. If IV fluid solution introduces too much air in the vein then air embolism occurs. It has fatal consequences like possible death.

Fluid Overload

FIuid Overload- Picture Courtesy: Medical News Today

If the speed of the IV fluid solution is too high, then the patient can suffer from headache, high blood pressure, and breathing difficulty. This risk is prevented by giving IV fluid solution at the required speeds.

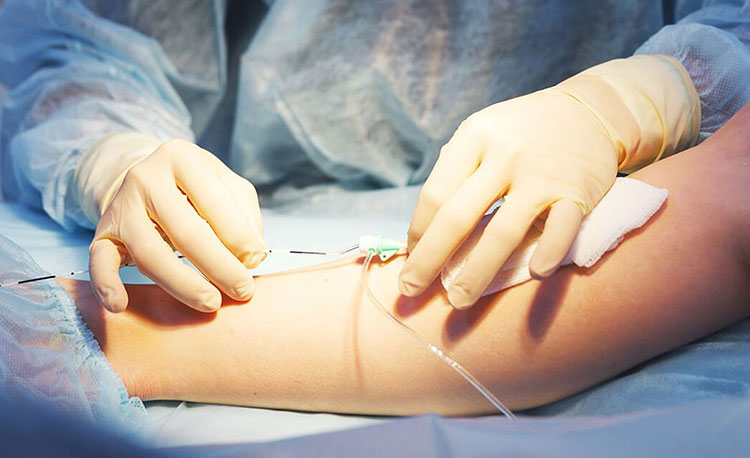

Collapsed Vein

Collapsed Vein- Picture Courtesy: Miami Vein Center

If the IV fluid solution is injected for a longer period in the vein then it collapses. However, it is easily resolved by removing the IV fluid solution line.

Hematoma

Hematoma- Picture Courtesy: HemAware

With the leakage of blood from the vein in the surrounding tissues by the insertion of the needle, hematoma occurs. A bad bruise is a sign of hematoma.

Infection

Infection- Picture Courtesy: Medical News Today

Improper cleaning of the needle insertion area can result in unwanted infections. Antibiotics are given to treat these infections.

Phlebitis

Phlebitis- Picture Courtesy: Medical News Today

It is characterized by the swelling of a vein due to the injection of IV fluid solution. It is one of the most common risks associated with the IV fluid solution. However, by removing the IV fluid solution needle, the symptoms of phlebitis are resolved.

9.How is IV fluid Solution Prepared?

The preparation of the IV fluid solution is an important process, requiring great care, caution, and precision. Its preparation also needs aseptic conditions to ascertain the safety and effectiveness of IV fluids. Here is a brief detail of the steps performed in preparation for the IV fluid solution.

| Water Purification | Water is an important component of IV fluid solution, so in the first step, water purification is performed using the distillation method or reverse osmosis method. These two methods help in the removal of impurities, debris, and microbes from the water. |

| Solution Preparation | In the second step, IV fluid solution is prepared by dissolving accurate quantities of different solutes, for instance, glucose, salts, and electrolytes in purified water. By dissolution, IV fluid of the required composition is formed.

IV fluid must have an acceptable pH for administration. So, by adding acid or alkali in desired quantities in the prepared IV fluid solution, its pH is adjusted |

| Filtration | In the last step, a series of filtration steps are performed to eliminate any impurities or particles. This IV fluid solution is passed through a different filter to obtain a sterile solution. The last filtration step removes bacteria and other microbes from the solution. |

10.How are IV fluid solution bags manufactured?

Complete sterility is required when making IV fluid solution bags. A complete process of bag manufacturing is given below:

Film Extrusion and Lamination

Film Extrusion and Lamination

Plastic pellets like polyvinyl chloride (PVC), polyethylene (PE) or polypropylene (PP) are extruded to create a continuous layer of film. These film layers are laminated together to form a tough and durable film that presents a strong barrier material.

Film Loading

Film Loading

The laminated film is then fed into bag making machine. It begins to unwind and passes through a series of rollers to arrive at the forming station.

Bag Formation

IV Fluid Bag Forming Machine

At the forming station, the film is folded, doubled, cut, and sealed to fabricate a smooth bag. Bag making at the forming station is a continuous process in which automatically forming components and sealers work simultaneously to form a bag of the desired shape and length.

Printing, Labeling & Sterilization

Labeling of IV fluid solution bag- Picture Courtesy: Fresenius Kabi USA: Product Details

After bag formation, printing and labeling of bags are carried out using an inkjet printer or thermal transfer printer. This step labels important information like batch number, bar code, IV fluid solution ingredients, and composition and usage instructions.

Then bags are sterilized using different agents like gamma radiation, ethylene oxide gas, and heat. These sterilization methods are dependent upon the bag materials and the characteristics of the end product.

11.What quality control tests are required for IV fluid solution?

Quality Test of IV Fluid Solution- Picture Courtesy: Innotechlab

To ensure the health safety of the patients and the quality of IV fluid solution, different quality control tests are implemented. These tests are detailed below:

| Sterility Test | A sterility test is carried out to detect the presence of microbes in the IV fluid solution. It measures the sterility of the IV fluid solution. It is important because the incidence of microbes in IV fluid solution could harm the patients. |

| Endotoxin Test | This test is done to ensure there is no toxic endotoxin in the IV fluid solution. The endotoxic are produced by bacteria and are harmful to the health of patients. |

| pH Test | The pH test is conducted to ascertain the pH of the IV fluid solution is under the required range. An inadequate value of pH impacts the composition balance and could cause incompatibility reactions within the body. |

| Concentration Test | This test is carried out to avoid the risk of under and over-dosing. It measures the quantities of active ingredients and ensures they are within the desired range. |

| Combability and Stability Test | To measure the stability of the IV fluid solution over a specific period, compatibility and stability tests are conducted. It also determines the compatibility of the IV fluid solution with bag and tube materials. This ensures the storage container materials do not leach harmful chemicals into the IV fluid solution. |

| Bag Seal Integrity Test | It measures the seal integrity of the bags and vials. It ascertains seals of the IV fluid solution storage container are completely intact till use. This test is essential for sterility. |

| Volume Test | To prevent the risk of incorrect dosing, the volume check test is performed. It examines the required volume in the bag and makes sure it is the same as the labeled volume. |

12.What should be considered when starting an IV fluid solution business?

Various factors must be considered when starting the IV fluid solution business to ensure the safety and quality of the IV fluid solution. These factors contribute to the success of the business. A complete detail of important factors that should be taken into account is penned below:

Regulatory Compliance

Regulatory Compliance- Picture Courtesy: RK Machiner

First learn and understand the regulatory guidelines that are imposed on the production, printing, distribution, and retailing of the IV fluid solution. After understanding, apply for essential licenses from the drug regulatory authorities of your country.

Manufacturing Plant

Manufacturing Plant- Picture Courtesy: Teflon

Establish an up-to-date clean and sterile manufacturing plant that should comply with good manufacturing practices and regulations. This facility should have a state-of-the-art set-up, raw materials, instrumentation, and technologies to produce IV fluid solutions. Moreover, it should fulfill regulations of cleanliness and pollution control.

Product Manufacturing

Product Manufacturing- Picture Courtesy: Packaging of the World

Manufacture different IV fluid solutions customized to satisfy the requirements of health care and medical sectors. The constitution, volume, packaging, and labeling of produced IV fluids should be according to market/

Marketing and Distribution

Marketing and Distribution

Last but not least, create a thorough marketing strategy to promote and distribute IV fluid solutions to different healthcare and medical sectors. Organize various seminars and trade shows to raise awareness about your product.

Conclusion

An IV fluid solution is a growing field of science due to the high prevalence of health-related issues and demand. From its making to final administration, each step is required with high sterilization and critical management. Therefore, if you’re planning to step in this direction, we would recommend contacting manufacturing companies that are particularly hooked on this field. We understand, how to bring this sensitive task in a flexible way. AIPAK Engineering is a promising solution to help you from the beginning till your finished product. For purchasing machines related to IV fluid solution, please contact us now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours