Eye Drop Filling And Capping Machine: The Complete FAQ Guide In 2025

Are you looking forward for an innovative machine for the filling and capping of eye drop? If yes, then welcome to this FAQ guide! Where manufacturing of such a sterile medication requires thorough production line, the packaging is also considered very important step. This is done by using an Eye Drop Filling And Capping Machine.

This machine is highly specialized in processing eye drop filling and capping. It has automatic function which increase the production, reduce manual labor, and have easy operation and maintenance requirements. By following right working principles, you can get various benefits. So, let's delve deep into this FAQ guide!

1.What Is An Eye Drop Filling And Capping Machine?

AIPAK Engineering eye drop filling machine

Eye drop filling and capping machine is an intelligent equipment designed for small dose liquid filling. It comes with filling machine, stoppering and capping devices. The machine is made up of high quality material.

It has compact structure made up of non-toxic and corrosion resistant stainless steel. The machine has automated technology for performing the filling and capping of liquid eye drop solution. Throughout operation, it ensures precision to reduce product waste and maintain consistency.

2.Write Down The Benefits Of An Eye Drop Filling And Capping Machine?

Eye drop filling and capping machine has the advantages of high accuracy consistency, flexibility, and safety. It has been known for various benefits in terms of production efficiency. These all are explained below:

High Automation

Eye drop filling and capping process- Picture Courtesy: Groninger

Eye drop filling and capping machine is highly automatic in carrying out the entire process of bottles conveying, product weighing, filling, and bottles capping etc. It thus reduce the need for manual labor and increase the rate of bottles filled in each cycle which leads to production efficiency.

Consistency

Consistently filled and capped bottles- Picture Courtesy: Laiyang Packay

Throughout operation, the machine makes sure to weigh the same amount of product and fill into bottles. Therefore, each bottle is precisely filled and the same goes for their capping. Together, it helps in improving the packaging quality which is a necessary step for pharmaceutical products.

Reduce Waste

Bottles falling- Picture Courtesy: UPMACH

Another significant benefit of an eye drop filling and capping machine is its automatic detection for faults. This feature enable the machine to detect missing bottle and stop dispensing liquid solution. Similarly, bottles with missing caps are also detected to minimize errors.

Flexibility

Various sizes of eye drop bottles- Picture Courtesy: xinfuda-group.com

The machine is highly flexible that it can be easily customized to meet diverse production requirements. It can be used for filling different volumes of liquid solution into various bottle sizes and caps types.

Sterility and Safety

Hygienic environment for capping bottles- Picture Courtesy: Dara Pharmaceutical Equipment

Maintaining the hygiene for product processing during packaging is paramount in pharmaceutical industry. For this reason, an eye drop filling and capping machine process the material in controlled environment thereby reducing the risk of contamination.

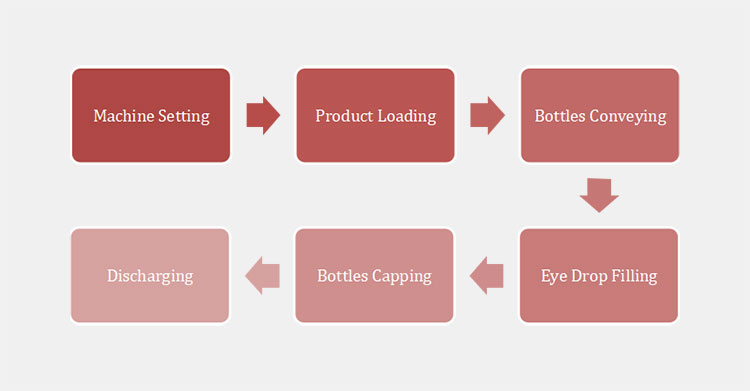

3.Explain The Working Principles Of An Eye Drop Filling And Capping Machine?

The working principles of an eye drop filling and capping machine involves series of steps. These include bottles transportation, hopper loading, material weighing, bottles filling and bottles capping till their discharging. You will know about these steps in detail in the upcoming paragraphs:

Machine Setting

The very first step involved in the operation of an eye drop filling machine include machine setting. At this stage, operator should check the machine for parts if they all are completed and fitted in a good way. Similarly, the parameters setting should be done by using a control panel for fixing the speed of conveyor, amount of product, and torque pressure etc.

Product Loading

The this phase, the machine is loaded with product. Due to the presence of two different units in the machine, the filling station and the capping station, operator shall load adequate amount of liquid eye drop formulation in the hopper of the filling station and supply caps the the capping station.

Bottles Conveying

Bottles conveying for filling and capping

Once the setting and loading of an eye drop filling and capping machine are carried out, it is ready to begin operation. Now, the conveyor start mobilizing the bottles from inlet towards the filling station.

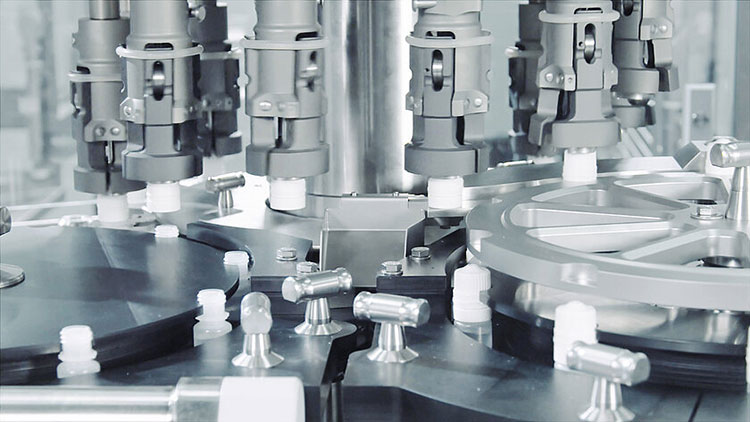

Eye Drop Filling

Eye drop filling into bottle- Picture Courtesy: UPMACH

Proceeding further, the bottles are moved onward into the star wheel. This start wheel takes the bottles and keep rotating clockwise. When the bottles reach under the filling head, the star wheel stopped and precise volume of eye drop liquid is dispensed into it. The cycle is kept continued till desired number of bottles are filled.

Bottles Capping

Bottle capping- Picture Courtesy: UPMACH

Each filled eye drop bottle is then moved for capping where cap is placed over bottle and then with the help of capping head, these caps are screwed to create tight sealing around the bottles neck.

Discharging

Bottles discharging

At the end, filled and capped bottles are guided by the conveyor towards discharging. Upon discharging, they are proceed for further packaging such as labeling and cartoning.

4.Describe The Components Of An Eye Drop Filling And Capping Machine?

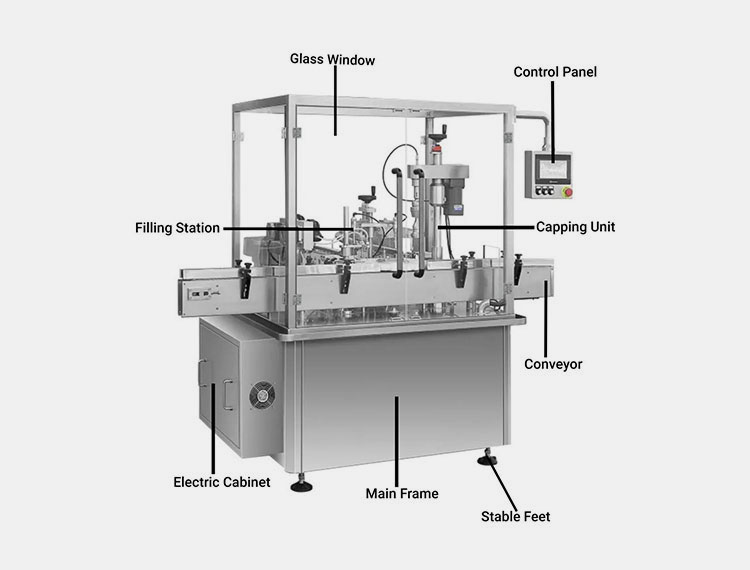

Eye drop filling and capping machine is composed of several components each of them perform specific function in order to make the machine capable of filling and capping. These parts of the machine are described as under:

Components of AIPAK Engineering eye drop filling machine

Filling Station

Filling station is among the core components of an eye drop filling and capping machine. It is itself made up of different parts such as peristaltic pump or ceramic pump filling system, filling nozzle, and the laminar flow system. Overall, the filling station is responsible for carrying out the weighing and filling of liquid solution into bottles.

Glass Window

Another component of the machine is transparent glass windows. These windows help the operator to keep observing the entire operation from outside while also helpful in providing contamination free environment for aseptic packaging.

Control Panel

Control panel is the central part of an eye drop filling and capping machine. It is composed of a touch screen interface, emergency stop, and few other knobs for controlling the machine. By using this device, one can adjust the parameters of the machine.

Capping Unit

This is another unit in the machine that comes after filling station. It consists of a cap supplying hopper, capping head, and torque applicator etc. The main task of this unit is to sort the caps for bottles, place them over bottles, and screw tightly to create sealing.

Conveyor

Conveyor is a mechanical system in the machine that is run by conveyor motor. Its task is to carry the empty bottles from one end and move them towards filling station, capping unit, and ultimately to discharge them. It works automatically to avoid bottles shaking and product wastage.

Electric Cabinet

Electric cabinet refers to an enclosure fitted in the lower body of the machine. It holds inside it the various electrical parts and boxes such as wires, and knobs etc. It protect these components by keeping them in one place together.

Main Frame

The machine has a main frame which is made up of quality stainless steel that is fully resistant to corrosion and bacteria. It provides support to the machine and all other parts are attached to it.

Stable Feet

An eye drop filling and capping machine come with four stable feet. These feet helps in maintaining stability throughout the operation.

5.What are The Applications Of An Eye Drop Filling And Capping Machine?

An eye drop filling and capping machine is an innovative machine which is widely used in different industries for its efficiency, safety, and flexibility. Below you will know about the applications in detail:

Pharmaceutical Industry

Eye drop bottles- Picture Courtesy: Walmart

An eye drop filling and capping machine is an ideal equipment to process pharmaceutical liquids in an hygienic and enclosed environment. Therefore, it is widely used in the field for products such as eye drop, ear drop, and other medications.

Nutraceutical Industry

Various liquid nutraceuticals in bottles- Picture Courtesy: nutraingredients-usa.com

Another application of the machine is nutraceutical industry where the production of herbal and other forms of drugs in liquid form is carried out. These products can be easily made by using this machine.

Veterinary Industry

Pet distress drop bottle

The use of an eye drop filling and capping machine is not only confined to pharmaceutical or nutraceutical industry rather it may also be used in veterinary industry. Many liquid medications for animals are packed in small bottles through this machine.

Food Industry

Various liquid food color bottles

Food industry is an area where there is production of beverages and food colorants on large scale. All these products need to be processed in a well way which can be easily done by using eye drop filling and capping machine that allow for smooth and consistent processing.

Beauty Care Industry

Beauty serum bottles- Picture Courtesy: Mana Beauty Spirit

Serums, vitamin essence, and essential oils are often used for enhancing beauty. For their accurate packaging into small containers, equipment such as eye drop filling and capping machine is best suitable.

6.What Are The Quality Standards Which An Eye Drop Filling And Capping Machine Should Comply?

There are several regulating bodies established on international level to keep checking the quality of goods, products, and equipment. For this reason, an eye drop filling and capping machine must be certified by these quality standards in order to be called as a high quality machine. These include:

![]()

ISO icon- Picture Courtesy: eudaico.com

GMP:GMP stands for Good Manufacturing Practices which is an international quality standard. It ensures the quality of machines that deals with food and medicines. Therefore, an eye drop filling and capping machine must be certified by GMP.

ISO:International Organization for Standardization is another significant standard with global recognition. Companies must adhere to this quality standard especially those manufacturing production and packaging equipment.

FDA:Food and Drugs Administration is established by USA to made stringent safety regulations for machines specifically dealing with food and Drugs such as eye drop filling and capping machine.

CE:It is the quality standard for European Union that is used for all the products which are supposed to be sold there. Hence, every equipment must be certified by CE including eye drop filling and capping machine.

7.What Machines Can Be Integrated With An Eye Drop Filling And Capping Machine To Make Production Line?

In order to make production line for an eye drop filling and capping machine, several equipment can be integrated with it. These machines are described below:

Bottle Unscrambler

Aipak APC-A100 Automatic bottle unscrambler

Bottle unscrambler is one of the important machines which is directly integrated with an eye drop filling and capping machine. It is mainly used for arranging the disoriented bottles and supply them to the main machine via conveyor. It has a compact structure made up of stainless steel body, stable feet, electric cabinet, and unscrambler disk.

Capping Machine

Aipak APC-D903 High Speed Capping machine

Capping machine can also be integrated with an eye drop filling and capping machine. It is used to apply caps or lids over various sizes of bottles. The machine has compact structure with several components including a hopper, control panel, electric enclosure, conveyor, capping head, and pneumatic pressure applicator etc. It works automatically by sorting caps and placing these caps one by one over bottles. Similarly, with the help of torque pressure, caps are tightly sealed around the bottles neck.

Labeling Machine

Aipak APC-T1 Round Bottle Side Face Labeler

Labeling machine is designed for covering the filled and capped bottles with labels. It is necessary for each container of eye drop to be properly labeled. Therefore, labeling machine is attached to an eye drop filling and capping machine. The machine has automated technology for unwinding the labels from roll and applying them to the containers.

Cartoning Machine

Aipak WZH-120 Horizontal Boxes Packaging Cartoning Machine

Cartoning machine is another significant machine which is used alongside an eye drop filling and capping machine. It has horizonal structure made up of stainless steel with other components including conveyor, control panel, carton silo, leaflet holder, flappers folders, coding unit, and sealing device etc.

8.How To Clean And Maintain An Eye Drop Filling And Capping Machine?

In order to keep an eye drop filling and capping machine on the right functioning state, it is crucial to conduct regular maintenance. For this purpose, you need to clean, lubricate, and adjust the machine after few days. Let's go into the explanation for clear understanding!

Operator maintaining machine- Picture Courtesy: SANVO

Cleaning

Cleaning is the first step to maintain hygiene and ensure optimal performance of the machine. It is a multi step process that involves disassembling the machine parts, washing these parts properly with non-acidic water and recommended detergent, letting them get dry and then locating on right place. It ultimately prevent contamination and enhance the working efficiency.

Lubrication

Lubrication is also very important for eye drop filling and capping machine which have some mechanical parts like conveyor. For this reason, high quality food-grade lubricants are used to reduce the friction and risk of wear and tear. It is also useful in ensuring the smooth performance of the movable parts.

Structural Adjustment

Structural adjustment is also very necessary for an eye drop filling and capping machine and us part of regular maintenance. It includes tightening the screws, placing parts in exact location, and parts changeover in case of damaged parts.

9.Explain The Troubleshooting For An Eye Drop Filling And Capping Machine

When operating an eye drop filling and capping machine, there might appear some of the challenges. These challenges or issues can be simply dealt with and solved provided that right action is taken. Thus, in the table below you will know about the troubleshooting of an eye drop filling and capping machine!

| No | Problem | Cause | Solution |

| 1 | Inconsistency in Filling Volumes

Encircled filling nozzles- Picture Courtesy: Pharmec Technologies |

It is the common problem that emerges from the incorrect calibration of the control interface and deteriorated valve components such as wear of the throttle valve. | It can be solved by right calibration of the control interface and adjusting the valves for uniform filling velocity by changing over parts. |

| 2 | Incorrect Capping

Encircled bottle cap- Picture Courtesy UPMACH |

It is caused by various reasons such as misalignment of containers during progression and the inappropriate application of pneumatic pressure to the capping of containers. | The issue may be avoided by ensuring the precision in alignment of containers during capping and the application of uniform pneumatic pressure. |

| 3 | Bottle tipping

Eye drop bottle tipping- Picture Courtesy: iStock |

It is another significant issue that arises from the fluctuations in the speed of conveyor belt and the handling of containers. | The resolution lies in adjusting the velocity of conveyor belt to avoid haphazard and take measures for adept bottle handling. |

10.Factors To Consider When Buying An Eye Drop Filling And Capping Machine?

When you intend to buy an eye drop filling and capping machine, make sure to not avoid considering certain factors. These include production output, the flexibility of the machine and most importantly its quality compliance and cost. Let's uncover these all in the details given below!

Production Output

Eye drop bottles- Picture Courtesy: The Legal Examiner

First, you need to check the production output of the machine with that of your current manufacturing level. For instance, if you are interested in producing large number of products in large scale industry then you must opt for the fully automated machine. However, in case of medium scale production, semi automatic machine is also a suitable choice.

Customization

Eye drop bottles with different cap types- Picture Courtesy: Healthline

You should also check if the machine can support bottles of various sizes and cap types. It is necessary for the reason that in most cases manufacturers use different containers, so, the machine must be flexible enough to undertake the task.

Quality Compliance

Compliance icon- Picture Courtesy: mpeengenharia.com.br

Quality compliance is another crucial factor to be considered. It involves the machine adherence to the principles and guidelines by renowned quality standards on international level. It can be checked by looking into the quality certifications of the machine which often include GPM, ISO, and CE.

Warranty Policy

Warranty icon- Picture Courtesy: kukiringlobal.com

Buying an eye drop filling and capping machine means spending good amount of money. In such case, you must have assurance in form of warranty policy. So, make sure you never overlook this factor.

Cost

A successful businessperson must always be concerned about the money which he spends. The same goes for an eye drop filling and capping machine purchase. Thus, you need to estimate the overall expenditure including machine price along with operation and maintenance cost.

Conclusion

To conclude, an Eye Drop Filling And Capping Machine is an innovative equipment tailored with astonishing features to perform the function of filling and capping small plastic bottles. It has simple operation and maintenance requirements which makes it more reliable for new business startuos. Moreover, it can be widely used in range of industries. However, it is necessary to be mindful of the possible issues and take measures to solve them. If you are also wishing to buy an eye drop filling and capping machine then drop a message and we will contact you ASAP!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours