AIPAK Engineering Vapor Compression Water Distiller

AIPAK Engineering vapor compression water distiller(VCS) is widely used for producing distilled water for injectable use or WFI, which is compliant with the requirements of the International harmacopeias including USP, EP and JP. Water produced by this vapor compression water distiller has very superior quality than waterproduced by other multiple effect distiller. The feed water utilization is up to more than 92%. It is not subjected to pressure vessel rules and ASME pressure vessel supervision. The comprehensive energy saving is up to more than 50% for each unit capacity comparing to multi-effect distiller and waste heat recovery molule energy saving can be up to more than 70%. Adopt system modularization layout, the vapor compression water distiller is convenient for installation and movement.

AIPAK Engineering Vapor Compression Water Distiller Features:

1.The quality of water product is excellent, which is far higher than the domestic standard of multi-effect distilled water machine.Endotoxin can stand for challenge test.

2.lt is free from the supervision regulation on safety technology for stationary pressure vessel and ASME pressure vessel.

3.Raw water utilization up to 92%.

4.Compared with the multi-effect distilledwater machine, the unit output is 50% higher. With the heat recovery module, it can save more than 70% energy.

5.The modular layout of the system isconvenient for installation and relocation.

6.Unigue modular desian complving with latest regulatory reauirement of GAMP.cGMP.FDA etc.Unit is desianed with nodead anales to avoid micro biological contamination.

7.No cooling water consumption, because the whole machine achieves 40°Cwater output in the water production stage.

AIPAK Engineering Vapor Compression Water Distiller Technical Specification:

WFI Parameter

| Unit | CP | USP | EP | Truking Watertown | |

| Conductivity | μs/cm | ≤1.3@25℃ | ≤1.3@25℃ | ≤1.3@25℃ | ≤0.1@25℃ |

| TOC | mg/L | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.05 |

| Microbe limit | CFU/100ml | ≤10 | ≤10 | ≤10 | nil |

| Endotoxin | EU/ml | <0.25 | <0.25 | <0.25 | <0.01 |

Equipment Model

| Model | Cspscity kg/h | Power kw | Plant steam consumption kg/h |

Weight kg | Dimension(L*W*H)mm |

| APK1000-P-F | 600-1000 | 4.6-10.3 | 63-97.7 | 5600 | 2800X2000X2200 |

| APK3000-P-F | 2000-3000 | 11.7-26.4 | 204.2-293.2 | 8000 | 4000X2250X2435 |

| APK5000-P-F | 3300-5000 | 17.5-42.4 | 337.3-488.6 | 9600 | 4500X2500X2435 |

| APK8000-P-F | 5000-8000 | 31.8-85.5 | 503.5-766 | 10860 | 5400X3000X3000 |

| APK12000-P-F | 7000-12000 | 50.1-136.7 | 700.7-1136.1 | 12550 | 5700X3300X3200 |

| APK15000-P-F | 10000-15000 | 60-139 | 1004.6-1442.9 | 16780 | 6400X3600X3400 |

| APK20000-P-F | 17000-20000 | 96-137.2 | 1712.4-1979.9 | 19880 | 7950X3850X4000 |

| APK25000-P-F | 19000-25000 | 122.6-222.9 | 1891.2-2416.1 | 19880 | 7950X3850X4000 |

| APK30000 -P-F | 23000-30000 | 186.1-329.6 | 2243.1-2840.1 | 19880 | 7950X3850X4000 |

The Buyer's Guide

Vapor Compression Water Distiller: The Complete FAQ Guide In 2025

Do you like distilled water? You may find its wide applying in food, medicine and so on. It is the symbol of safety, hygiene and health. If you want to produce distilled water, you may not miss the vapor compression water distiller. This equipment may make the excellent work in producing distilled water.

The better knowing of vapor compression water distiller can make your manufacturing work more. What is distilled water and vapor distilled water from vapor compression water distiller? How about the performance characteristic of vapor compression water distiller? Here comes the comprehensive FAQ guide in 2025.

1.What Is Vapor Compression Water Distiller?

Vapor Compression Water Distiller-Sourced:meco

Vapor compression water distiller is the distilling process which is applied for the water purifying. With the help of centrifugal compression, vapor compression water distiller applied energy to vapor and make the distilled water. The vaporized water will then be compressed to liquid form.

Vapor compression water distiller can make the distilled water with high quality and low efficiency cost. The water for injection produced by the machine is highly pure and safe. For human safety and product quality, there are qualification standard for water like USP, EP. JP and so on. This machine can produce products conform to these standards.

2.What Is The Application Field Of Vapor Compression Water Distiller?

Vapor compressed water distiller is so helpful in producing distilled water. And here are the application fields for vapor compression water distiller.

Food and beverage industry

Food And Beverage Industry-Sourced:logility

In food and beverage industry, you may find the wide applying of vapor compression water distiller. Beer, wine, bottled water, soft drink and many beverage require the great work of vapor compression water distiller. For food like pasta, baked food and so on, it offers high qualified material for your products manufacturing.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:xylem

Injection products, eye drop and many other liquid products in pharmaceutical industry all need distilled water for the proving of its hygiene. Distilled water is the prove of the pharmaceutical products safety and efficiency. Vapor compressed water distiller makes the nice work in serving your pharmaceutical industry.

Cosmetic industry

Cosmetic Industry-Sourced:thewellnessproject

For your various cosmetic products, and for the safety and hygiene of your cosmetic products, you may find the great need for the applying of distilled water. For essence, solution, lotion, facial mask and such cosmetic products manufacturing, it is essential to apply the purified water.

Veterinary industry

Veterinary Industry-Sourced:silverson

Veterinary industry makes the great demand of distilled water from vapor compression water distiller. There are various injection products, oral products and drop products in veterinary industry which need the distilled water from vapor compression water distiller.

3.What Is Distilled Water And Vapor Distilled Water From Vapor Compression Water Distiller?

There are distilled water and vapor distilled water from vapor compression water distiller. Do you know them? Do you know their difference?

Distilled Water And Vapor Distilled Water-Sourced:paradisebottledwater

Distilled water

Distilled water is produced with the simple process by boiling water to make vapor and condensing vapor to liquid water form. You may get the purified water from impurities and minerals. This distilled water is relatively clean and hygienic compared with the the former one.

Vapor distilled water

Vapor distilled water applied a refinement process for the better purifying of your water. There are multiple distillation stages for the purifying process and you may get the purified distilled water with more minerals and impurities removed. And you will find the higher purity level of vapor distilled water compared with the former one.

4.How About The Performance Characteristic Of Vapor Compression Water Distiller?

How about the performance characteristic of vapor compression water distiller. Here you may check the performance characteristic.

High qualified product

High Qualified Product-Sourced:atuman

Vapor compression water distiller produced the superior water which generated quality higher than that of multiple effect. You may apply vapor compression water distiller for the producing of various food products, cosmetic products, pharmaceutical products and so on.

Energy saving

You may have your energy saved with this vapor compression water distiller. The feed water utilization is up to 92% above. And there is no cooling water consumption. The comprehensive energy saving can up to 50% above for each unit capacity which saved 70% above with its waste heat recovery module.

Nice structure design

Nice Structure Design-Sourced:wemacequipment

There is the nice structure design of the vapor compression water distiller. The layout system is convenient for installing and moving. The drain design with no physical structure dead legs can avoid the bacteria growth which makes the cleaning and sterilizing easy and convenient.

High efficient work

The work of vapor compression water distiller is high efficient. The energy analysis modularization is easy for the managing of your products. You may also apply ASME pressure vessel supervision for the smooth and efficient water distilling work of your water products.

5.What Are The Main Parts OfVapor Compression Water Distiller?

What are the main parts of vapor compression water distiller? Here you may check the main parts of it.

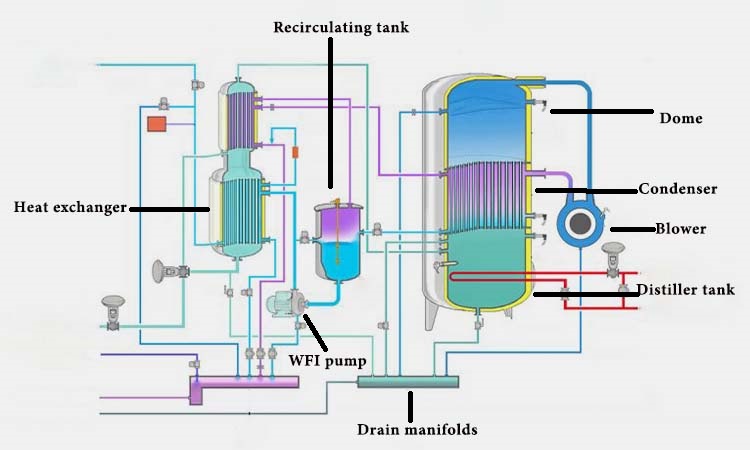

Main Parts Of Vapor Compression Water Distiller-Sourced:vapor-compression-distiller

Heat exchanger

There are two heat exchangers which make the job of feeding water preheating and WFI cooling and incondensable gas condenser. The changing of heat makes the transferring of liquid to vapor to liquid. And it is the important part for vapor compression water distiller.

Distiller tank

Distiller tank is the place where the distilling happened. It is connected with condenser and dome for the distilling work. The water comes in your vapor compression water distiller system and have water distilled and evaporated here.

Condenser

Condenser is the place where apply the low temperature to get the vapor. Your water after distilled will come to condenser for the further compressed. You may have the temperature changed here for the vaporing process.

Dome

Dome is the outer shell round the inner vessel which have water heated and vaporized. The sealed container can then have the vapor connected here for the liquid form. This can apply vaporization and condensation to improve the vapor efficiency.

Blower

Blower is the key elements of the whole vapor compression water distiller. It can drive the whole vapor compression water distilling process and make the water purifying here. It mechanically compress steam to generate compression and machine work.

Recirculating tank

Recirculating tank is applied for the storing of distilled water and it can be pumped back for pre-heating and further distilling. This part can also maintain water quality and de-aerate. This element can be used several times and it is the key element for the proving of product quality.

WFI pump

WFI pump has the full name of water for injection pump. It makes the irreplaceable work in delivering condensed pure water. It makes the further dealing of distilled water from evaporator or condenser.

Drain manifolds

Drain manifolds are the part which drain your wasted water from vapor compression water distiller. It maintains the fluent and smooth manufacturing of your whole vapor compression water distiller process.

6.What Is The Process Of Vapor Compression Water Distilling?

As you known the various parts of vapor compression water distiller. Are you confused about the vapor compression water distilling.

The Process Of Vapor Compression Water Distilling-Sourced:MECOpure

Feed water intake

You should put water in heat exchanger and make the suitable panel setting for your work. Pay attention to the water flow of first phase and the adjusting of WFI temperature. For the second heat exchanger heating, it comes to preheating and you may find some gas generating in the process.

Evaporation

After water heating, water comes to the tank. The water will be heated to the evaporation temperature and the steam generated will come to dome. At this process, managing system will maintain the even pressure for the smooth distilling process. The stable pressure of set value will benefit your managing a lot.

Vapor compression

Your generated pure water will be condensed in the shell which provides energy for the feed-water in condensed pipes. Then it will come to evaporation which provide the pure steam and make the pure steam which is qualified for your various industrial use.

Heat recovery and condensation

After a round of vaporization, there will then come the heat recovery which recycled the released heat in the vapor compressing process. This process makes the environmental friendly work which can reduce energy consume by preheating the new heating water.

Droplet separation

Droplet separation refers to the separating of water droplet which may carried on it. You may find the work of droplet separation made with demister. There are mesh pads and baffles that can be applied for the separating of droplets in your vapor compression water distiller.

Distillate collection

The distillate water after generating will drips down the container tube and gets in the particular collecting cabinet. There may also the pump which can lead the distillate out the vapor compression water distiller. You should prove the hygiene in this process for the proving of your products quality.

Continuous operation

After a round water distilling of vapor compression water distiller, your machine should have the continuous operation. There may get the heat recycling from your distilled water and wastewater steams in your continuous operation which makes the great improving of your energy applying efficiency.

7.What Is The Optional Needs ForVapor Compression Water Distiller?

What is the optional needs for vapor compression water distiller? Here you may get the comprehensive knowing of vapor compression water distiller.

Operating cost

Operating Cost-Sourced:loanbase

Compared with other distilling way, vapor compression water distiller has more efficient cost. For softened feed water, vapor compression water distiller makes the reduced operating costs. The operating cost covers capital, utility, maintenance expense and so on.

Feed water condition

Feed Water Condition-Sourced:sensorex

Feed water condition is also the thing you should consider in your vapor compression water distiller work. Feeding water quality and components can affect your vapor compression water distiller greatly. The suitable feed water condition is the prove of your smooth operating and minimize scale formation.

Utility and infrastructure cost

Vapor compression water distiller has the less footprint and takes less space for the water distilling work. Utility and infrastructure cost concerns a lot to the water distilling quality. You should pay attention to utility consume for the energy and cost saving. For infrastructure equipment, you should apply multimedia filters, softeners, carbon filter and so on.

8.How About The Water Quality Of Vapor Compression Water Distiller?

How about the water quality of vapor compression water distiller? Here are the excellent water quality details.

High purity

High Purity-Sourced:olympianwatertesting

Water from vapor compression water distiller enjoys high purity. From distilling, water boiling and so on, you may have the purity, quality and safety proved here from vapor compression water distiller. And high purity is the important element for quality assessing.

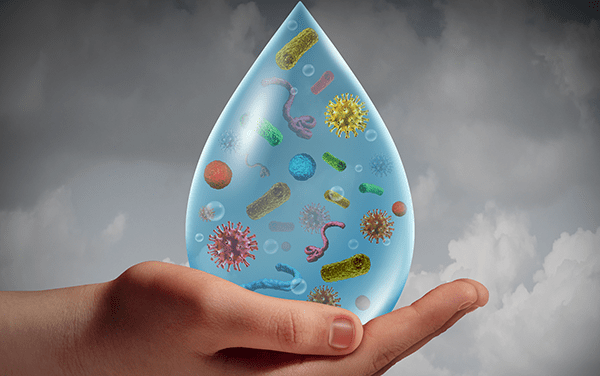

Contaminants removal

Contaminants Removal-Sourced:mypurewater

You may have the various vapor contaminants removed from compression water distiller. Besides the outstanding contaminants, you may also have bacteria, virus, metals and other dissolved solids removed here. This is the prove of your high distilled water.

WFI

WFI has the full name of water for injection. And the water from vapor compression water distiller can make the WFI which can be injected to human body. The requirements on water quality and purity is higher compared with other water for vapor compression water distiller.

9.Are There Other Water Treating Equipment Besides Vapor Compression Water Distiller?

Vapor compression water distiller is the welcomed water treating equipment. And here are the other water treating equipment you may want to know.

Reverse Osmosis Water Filter

Reverse Osmosis Water Filter-Sourced:apecwatersystems

Reverse osmosis system is the water treating equipment which can be applied for the removing of salt and other impurities. It is suitable for various industries. And the small size and high efficient work make it widely applied for family use. Some of it equipped with UV water treatment systems and ultra filter for better filtering work.

Membrane Distillation Water Treating

Membrane Distillation Water Treating-Sourced:link.springer

Membrane distillation system applied a porous membrane which get in vapor and forbid the liquid form. You may find its applying in waste water treating, desalinating and other industrial water treating work. For food processing, you may also find its applying for food extracts concentrating and other solution.

Ozone Water Treatment

Ozone Water Treatment-Sourced:denora

Ozone water treatment applied ozone gas for the purifying of water and oxidizing impurities. It can not only kill contamination like bacteria, virus and so on, and it can also improve your water quality like color, smell and taste. You may find its applying in industrial water treating, well water treating, beverage water treating and so on.

10.Are There Other Distilling System And What Is The Difference OfIt With Vapor Compression Water Distiller?

Are there other distilling system? Of course there are. And here are the difference of the distilling system with vapor compression water distiller.

MED system

MED System-Sourced:veoliawatertechnologies

MED system is the widely used vapor compression water distiller which has the high efficiency in water distilling. It contains multiple boiling and condensing. You may find vacuum distilling, fractional distilling and steam distilling applied for the MED distilling work.

Factional distilling system

Factional Distilling System-Sourced:popeinc

Fractional distilling system can be used to separate the mixture of liquid with different boiling points. This system can make the higher degree of separation as it makes multiple stages of evaporation and condensation. The water of it are greatly evaporated and purified.

Hybrid system

Hybrid System-Sourced:lab1st

Hybrid system makes the great combination of MED system, vapor compression, membrane system and many other technology to make the higher efficiency and lower energy consuming. Hybrid system can be applied for your water distilling of various industries and products.

11.How To Make The Regular Maintenance For Your Vapor Compression Water Distiller?

How to make the regular maintenance for your vapor compression water distiller? The suitable maintaining makes your vapor compression water distiller makes the higher efficiency.

Regular cleaning

You should make the regular maintaining for your vapor compression water distiller. The regular descaling, spray nozzle clearing, heat changer cleaning are the process you should make for your regular cleaning. The regular cleaning is the prove of your hygienic and safe water manufacturing.

Machine check

Machine Check-Sourced:paulmueller

Here are the elements you should check for your products. Heat transfer surfaces, water collection cleanup and sanitation are all the parts you should make the careful check. The daily check can assure the best condition of your vapor compression water distiller which is the premise of your machine smooth manufacturing and the nice products.

Calibrate parameter

Calibrate Parameter-Sourced:anton-paar

You should calibrate your parameter like pressure, temperature, and other controlling system for the pressure of the efficient and smooth flow of your heat, vapor and distilled water. The great maintaining of your vapor compression water distiller contains the strict and accurate calibrating for the parameter.

Conclusion

After the reading of the complete vapor FAQ guide in 2025 about vapor compression water distiller, you may know much about this machine. Do you have any problem or question about vapor compression water distiller? If you have, feel free to contact AIPAK ENGINEERING right now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Pharmaceutical Water System Related Products