Water For Injection: The Complete FAQ Guide In 2025

Is preparing medication without water possible? Just like your life, cells, and body functions, medication existence is not possible without the involvement of water.

Along with the building block of life, it is also one of the significant pillars of medicine. Whether it comes to diluting the medicine, mixing, or administration, water is required. Do you use tap or general water for pharmaceutical preparation? No, for this purpose you can use home-based tap water rather than using a specialized water known as water for injection.

This is the safest way for medication preparation and is used for various medical-related applications. In this blog, Water for Injection: The Complete FAQ Guide In 2025, you will find key knowledge about the subject related to uses, types, differences, preparation, etc. Read to explore more.

1.What do you know about water for injection?

Water for injection- Picture courtesy: American Regent

Water for injection is commonly termed as WFI in the pharmaceutical terminology. It is mainly used for the preparation of pharmaceutical-based products as it provides pure quality water.

For parenteral preparations such as intramuscular injections, intravenous injections, intrathecal, etc, WFI is used as a vehicle for dissolving and carrying the active pharmaceutical ingredients.

For administration of parenteral drugs inside the skin, blood circulatory system, or muscles, the vehicle must be ultra clean and pure, for this reason, water for injection is used as it assures water is prepared by passing through multiple processes that are ruled by international standard programs such as United States Pharmacopeia or USP as well as European Pharmacopoeia or EP.

Therefore, it is used where sterility and hygiene are essential. The following vehicle is significant in terms of being free from microbes and unwanted elements (inorganic contaminants).

2.Why do you need water for injection?

In the preparation of formulation, you always seek a high level of purity. In this way, you can achieve the desirable goals for the product’s manufacturing. The need for water for injection is described in the below content:

Concept of purity

Concept of purity- Picture courtesy: Pual Muller Company

You might be wondering why tap water is not required for pharmaceutical or sterile preparations. This is all because of the high degree of purity that you need for medicinal products. In tap water, you might be not sure if it is 99.99% pure.

It may be composed of several undesirable components such as microbes, inorganic and organic trace metals, minerals, etc. The following composition may affect the properties of medicines and make them non-potent as you promise. The water for injection in this way is free from all the above factors making medicine pretty safe and has non-reactive effects on the APIs.

No medium for contamination

No medium for contamination- Picture courtesy: Wellcome collection

Water for injection is transparent and cleared medium. It gives no way for growing microbial organisms. Microbial contamination may be possible if there’s presence of elements like salts, minerals, or components favors the growth. However, lacking nutritional medium can be an excellent medium to make your formulation quite stable and make no possibility for unwanted microbial invasion.

Sterile vehicle for parenteral medicines

Sterile vehicle for parenteral medicines- Picture courtesy: WJLA

Just think about the parenteral medicines, they’re directly administered into your bloodstream. Moreover, they rapidly reach the vital organs too. You can’t compromise sterility when it comes to injecting the medicine into your body. Therefore, water for injection is a promising vehicle offering the non-presence of septic components or any harmful particles inside. It is prepared from multiple series of steps to ensure a high level of sterility.

Pyrogen Free water

Pyrogen Free water- Picture courtesy: Edward Elmhurst health

The water for injection is generated from either distillation, reverse osmosis, or other way. The purpose of such types is to attain water that is free from endotoxins, or bacterial infections. The following infection reacts inside the body cell and the immune system produces a response in the form of fever. Therefore, water for injection is used when diluting the parenteral or already in formulation to avoid such unwanted circumstances.

Safety for all age groups of patients

Safety for all age groups patients- Picture courtesy: University of Queensland

Whether you’re suffering from mild disease or chronic. Either the individual is immunocompromised or suffering from a life-threatening disease. Their medications must be very safe so as to provide calming and therapeutic effects. The water for injection in a way acts as a safety barrier that helps in the carrying of medicine inside your body in a non-reactive manner.

3.How many types of water for injection are there?

Water for injection is mainly prepared for reconstituting the formulations. Also, it has broad applicability in pharmaceuticals and various other industries that we have talked about in a further section of this blog post. There are various other types of water for injection used for specific uses. Have a look at them to learn more.

USP water for injection

USP water for injection- Picture courtesy: Technical safety service

The United States Pharmacopeia water for injection is a highly sterile category of water that is best known for its greater nonpyrogenic properties. This is mainly available and packed in a single-dose ampoules or vials for parenteral purposes. The suitable pH of USP water for injection is observed between 5 to 7. In this type of water, there’s no possibility for microbial growth or unwanted foreign particles.

Bacteriostatic water for injection

Bacteriostatic water for injection

The type of water for injection which is designed for parenteral uses only. It can be either used alone or other drugs can be dissolved as it offers an aqueous medium to the drug. Bacteriostatic water for injection is not recommended when it comes to diluting the medicine used for neonates.

This is also the type of USP water for injection which is not only nonpyrogenic but also contains benzyl alcohol with 0.9% or 9 grams/mL. This is the reason the water is known as bacteriostatic as it is incorporated preservative in it. This is also available and packed in multi-dose vials or ampoules or in bulk where you need repeated uses. The recorded pH range of bacteriostatic water for injection is between 4.5 to 7.

The general application of bacteriostatic water for injection does not impact on body’s physiology. But it can exert more effects in disturbing the fluid balance of neonates that’s why it is not recommended for small babies. Moreover, it should also not be used for fluid replacement of the body as well as for epidural or spinal anesthesia.

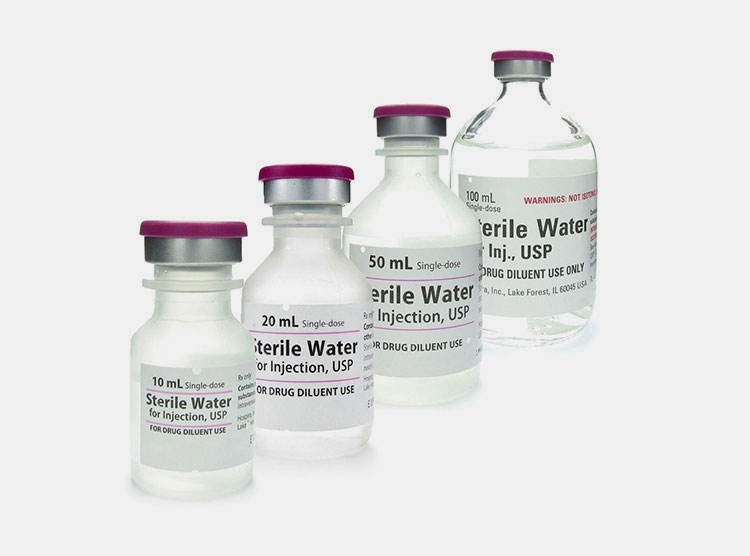

Sterile water for injection

Sterile water for injection- Picture courtesy: BBraunUSA

When it comes to subjecting the body to fluid replacement, sterile water for injection USP is used. It is suitable for administration once it is balanced with the required isotonicity, as it can be a hemolytic agent that can aggravate the hypotonicity in your body. It is used for mixing antiseptic medications and is recommended for intravenous routes. The isotonicity can be balanced upon the addition of suitable solute in the vehicle.

4.What are the general uses of water for injection?

Water for injection has so many uses in various fields of formulation, packaging, testing, etc. We have talked about primary yet the major uses just right below:

IV Administration

IV administration- Picture courtesy: Wise tech

Whether you’re administering nutritional supplements, minerals, antibiotics, etc using an intravenous route, the water for injection is an absolute choice to mix with the medication to be administered. It is used for reconstitution, and you can relaxingly infuse it into the IV system without risk for safety issues.

IM administration

IM Administration- Picture courtesy: medicine learning program

Water for injection is not only confined to IV, but you can also used to dilute the medication for intramuscular administration. Certain drugs such as painkillers, anti-allergy, vaccinations, etc are mainly subjected to IM administration and also require water for injection for mixing of medicines.

Ophthalmic Formulation

Ophthalmic solution- Picture courtesy: CNN

There are various ophthalmic preparations such as normal saline eye drops, tear solution, antibiotics, or irrigation formulations; in this case, water for injection is used as a main medium to dissolve the active and inactive components ensuring the entire preparation is met with high sterility.

Nebulizers & inhalers

Nebulizers and inhalers- Picture courtesy: Care+ pediatrics urgent

Whether you’re manufacturing formulation for oral or inhalational, or for nebulizers, the water for injection is always used as an essential vehicle for making the formulation pretty clear and safe. This is the paramount medium that has to carry the essential therapeutic agents directly to your vital organs such as the lungs and overall respiratory system effectively.

Irrigation of body wounds and cuts

Wounds and cut- Picture courtesy: Royal Life Saving WA

This is a normal practice to clean the portion of our body if it is damaged or has gone through treatments like operations or surgeries. The cuts and wounds are mostly irrigated with water for injection to subject the sterile vehicle to the sensitive portion. Water for injection in this way ensures the cleaning without risk of contamination to the specific region.

Dialysis solution

Dialysis solutions- Picture courtesy: RENOLIT

When the patient goes under dialysis, body fluid replacement and related processes are taking place. During means protocol, water for injection is the primary carrier way that significantly promises that the fluid infused in your body is pure and sterile to keep the patient safe.

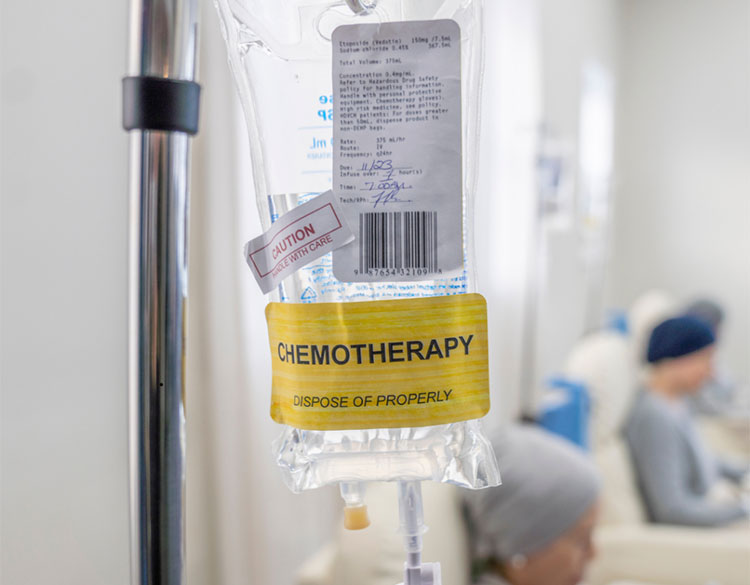

Cancer and critical care patient therapies

Cancer and critical care patient therapies- Picture courtesy: Calmare NJ

This is pretty common that cancer patients are mainly treated with a specific regimen of chemotherapies. Moreover, patients in unconscious states or critically ill or injured are nourished with the administration of parenteral nutrition such as total parenteral nutrition (TPN) and peripheral parenteral nutrition (PPN). Water for injection is used as

Rinsing & cleaning of critical tools and units

Rinsing & cleaning of critical tools and units- Picture courtesy: Blue Thunder Technology

For the preparation of medicines, compounding, tissue culturing, working in biosafety hoods, doing bio-assessments, etc. You first clean the surface by spraying the alcohol (70% diluted in water for injection) followed by water for injection spraying or pouring by wiping with a dry cloth. Side by side, various surgical instruments are also rinsed and cleaned using the same vehicle ensuring high-quality handling.

5.Where is water for injection required?

Beyond medicinal applications, water for injection is used in various places due to offering advantageous requirements. We have described the major industries and sectors that require water for injection for formulation or production workflow. Have a look at below discussion:

Pharmaceutical industry

Pharmaceutical industry- Picture courtesy: Pitcher partner

The requirement of water for injection in pharmaceutical preparation is very clear and essential. Whether it is vaccinations, antiviral therapies, chemotherapies, nutritional requirements, intravenous, intrathecal, intraperitoneal, etc all medication needs vehicle as water for injection as it is pure and pharmaceutical grade agent free from contamination.

Biotechnology Industry

Biotechnology industry- Picture courtesy: surf search

This mainly signifies knowledge related to life. New advancements related to tissues, cells, plasma, recombination of DNA, RNA, macromolecular studies, micro-molecular studies, tissue culture, cell culture so on procedures are carried out in biotechnology industries. Water for injection is a sterile medium that is used as a critical and mandatory medium during the processing of the following assays.

Nutraceutical Industry

Nutraceutical Industry- Picture courtesy: MDbio

The nutraceutical industry in today’s world is responsible for providing essential health-related supplements that are mainly obtained from natural sources. The primary aim of nutraceutical products is to maintain your well-being and quality of life. There are various nutraceutical formulations such as minerals, trace elements, multivitamins, probiotics, iron supplements, enzymes, antioxidant therapies, etc infusions are mainly diluted in water for injection as an inert medium.

Hospitals, clinics, pharmacies

Hospitals, clinics, pharmacies- Picture courtesy: Nurse now

For general practice for various parenteral preparations, water for injection is required for the reconstitution of the dosages in hospitals and clinics. Additionally, in pharmacies, water for injection is used as a primary agent for compounding formulations in general as well as in sterile areas.

Veterinary industry

Veterinary industry- Picture courtesy: Vetwest Animal Hospital

The life of your pet is always valuable. For pet medicines, the administration of vaccinations, painkillers, antibiotics, and various infusions required water for injection as a supporting medium to carry the active pharmaceutical ingredients.

Laboratory and diagnostic sectors

Laboratory and diagnostic- Picture courtesy: Augusta

Water for injection is required in lab-related procedures and tests. Such as testing blood levels, fasting blood glucose, urine samples, etc mainly assessed by using laboratory techniques. For dilutions or making volume before the process, the water for injection is used to get an accurate result without interruption of real laboratory tests.

6.How do you prepare water for injection?

To prepare water for injection, there are following main procedures are used in the production units. Have a look at them:

Pre-treatment

Pretreatment- Picture courtesy: Praj Hipurity system

The pre-treatment method is a procedure that has to be carried out before the processing of water for injection. The objective to perform the step is to prepare pure water which is free from unwanted components such as solid particles, ionic or organic substances. That’s why various filtration steps are taken place which alters the nature and quality of water by filtering the suspended particles, hardness, and disinfectants such as chlorine or chloramines.

Distillation

AIPAK ENGINEERING water distiller

This is the process that helps in the production of sanitized and pure water which is recovered from liquid to gas then liquid phase. The process of distillation can be carried out by two important methods.

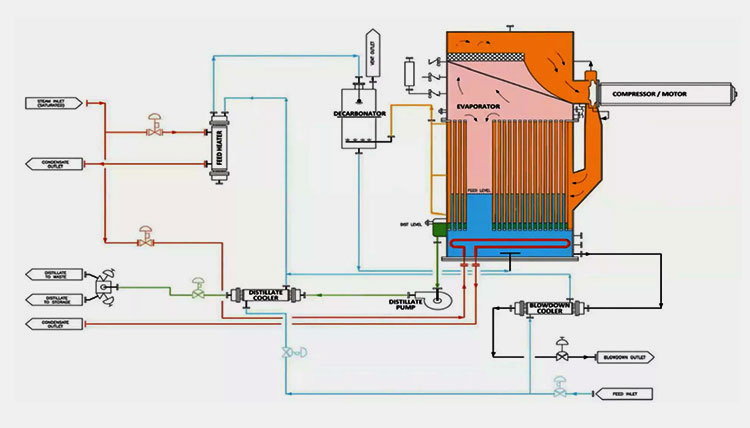

Vapor compression distillation

Vapor compression distillation

This is a commonly used method for the preparation of water for injection. It is also known as ‘thermal compression, or mechanical vapor compression. This procedure requires a relatively low temperature such as 80 degrees to develop the steam. The process can be induced by either steam energy or electric energy.

This is called compression distillation as it implies compressors for compressing the steam and keeping induction of pressure and temperatures.

In this system, the initial heating phase helps in the elimination of oxygen carbon dioxides, and related gases from the water. By implementation of the pressure of 3 ½ psi and steam of 80 degrees inside the evaporating tubes, the process takes place. The water starts to transform steam which is picked within tubes.

Moreover, the vapor condensation helps in the collection of water in the bottom which is taken up by a distillate pump which makes them cool by passing them from the cooler or chiller. However, the water for injection is produced by using both hot as well as ambient temperatures without requiring a chiller.

Multi-effects distillation

AIPAK ENGINEERING Multiple Effect (ME) Distillation

As its name shows, the water is passed through a series of multiple units to obtain purified water. This is first introduced with plant steam just like tube heat exchangers. The water circulation results in steam by using pressure of 60-80 psi.

The action of heat transfer and pressure simultaneously gives more steam. The condensation column helps in the condensation and cooling of the water for injection.

The unit works at comparatively more high pressure and temperature than vapor compression. The resulting outcome ensures that water is purest as meeting the regulatory requirements.

Reverse Osmosis

AIPAK ENGINEERING Reverse Osmosis

This unit is designed to pass water from the RO membrane which is a semi-permeable thin sheet that eliminates the components and disinfects the water. It also ensures the water hardness is removed and dichlorination is achieved.

Through this process, the pressure is applied to water to cross the membrane that captures molecules like organic, solid particulates, microbes, and dissolved ions present in the water is removed by deionization.

This mainly takes place by following three steps, in the first step, pre-treatment, large molecules are removed. In the second step, reverse osmosis takes place which significantly reduces salts and organic matter. In the third step, water is collected.

7.What other machines are required to obtain water for injection?

To obtain water for injection, along with preparatory machines, other machines are also required for various purposes. For example:

Clean Steam Generator for SIP Process

AIPAK ENGINEERING PLC Clean Steam Generator For SIP Process

Machines that are used to get water for injection must be cleaned and sterilized. Manually cleaning is of course not possible; if you can attempt to do so, it will give you a compromised outcome with more labor. The steam generator is a mainly used unit that is integrated into the machines for ensuring high-level cleaning and making your machine ideal for further production of water for injection.

This unit is critical and mandatory if you are working in medicinal, laboratory, or health-related fields. The machine flows high-heated water for rinsing the tubing, the high steam offers an ultra-cleaning. It promises you to maintain your machine and keep it away from microbial invasion or colonization.

Water Tank for Purified Water Storage

AIPAK ENGINEERING Water Tank For Purified Water Storage

These are large tanks made up of food-grade materials ideal for use in health sectors. The obtained water for injection is mainly used in these stainless-steel storage tanks in a bulk volume that ensures the quality of water remains intact for a long time.

The machine is connected to another unit with the help of pipelines and the entire system is enclosed with sealing lids, and valves to ensure no interaction of external factors and contaminants. This system is essential to install as it offers a stand-by water supply required anytime during the production process in your working environment.

Water circulation system

AIPAK ENGINEERING water distribution system

An innovative and mandatory unit is required to supply the water for injection towards the specific destination. This machine minimizes the chances of external exposure yet makes the water distribution very promising by circulating in sealed pipelines. The machine works automatically with designed pressure valves and a PLC system where you can put the pressure, level of water, and volume of water supply hourly or depending on your requirements.

8.Is water for injection similar to purified water?

The major differences between water for injection and purified water are discussed below:

Water for injection and purified water- Picture courtesy: INOXPA USA

| Points | Description |

| Expenditure | As compared to purified water, the water for injection is a more expensive mode of water. |

| Process unit | Purified water can be obtained by various units such as RO, ion exchange, and distillation.

Whereas the water for injection can be obtained from distillation or RO. |

| Uses | Purified water is used to clean and rinse the units and tools in pharmaceuticals.

Whereas water for injection is used to make small volume parenteral as well as for large volume parenteral. The purified water can be used for non-sterile preparations and can be consumed orally. Moreover, it is healthy water, you can drink as it is pure water that doesn’t harm you. On the other hand, water for injection is also the type of purified water but it is prepared from more astringent principles. It is mainly prepared for directly administering them for parenteral uses. |

| Distribution | The distribution of purified water mainly occurs in a circulation loop that mainly functions in cold to normal temperature ranges of 15 and 25°C. Whereas the water for injection requires at least 80°C in its circulation loops. |

9.What are the main packaging types of water for injection?

According to the need of your patient's treatments, there are several packaging types introduced. For example:

Ampoule

Water for injection ampoule

In ampoules, water for injection is filled and sealed for single-time applications. It is the popular packaging type that allows small volumes of water. The prime purpose of ampoule filling is to dilute the medicine which is needed to be dissolved in a small volume of water such as 2 ml, 10 ml, or 25 ml.

Vial

Water for injection vials

For irrigation, flushing, dilutions, mixing, etc, water for injection vials is available with broad volume storage ranges. For example, 10 ml, 20 ml, 25 ml, 100 ml, etc. It is recommended to use the vial for a one-time application. The remaining water should be discarded.

Bottles

Water for injection bottles

The sterile water for injection in a large volume is required for IV infusions, diluting the powders, making chemotherapeutic preparations, nutritional formulation, etc. This type of packaging is not only handy and economical but also offers a high level of safety for material storage.

Prefilled medicines syringes

Prefilled medicines syringes- Picture courtesy: McKesson

A time-saving packaging type where you can get benefits as a ready-to-use syringe. It is directly used to mix your drug or can be used as a flushing source in your circulatory system. They are available in small volumes such as 3 ml, 5 ml, or 10 ml prefilled syringes.

Water for injection infusion bags

Water for injection infusion bags

These are large-volume parenteral vehicles, which are available in 100 ml, 200 ml, 500 ml, 1000 ml, and 2000 ml of water for injection. The uses for an IV infusion bag are the same as the above description, except it is also used to clean or wash surgical cuts or wounds involving a large section. These are properly sealed bags providing sterility throughout the application process.

10.Can you drink water for injection?

Water for injection- Picture courtesy: Pharmco

Drinking water is generally composed of minerals, ions, and trace elements and is considered to be necessary for your physiological system.

Besides this, the water for injection is highly purified and sterilized water with many eliminations of various ions that may impart the potency of the medication that you intend to dilute.

Therefore, if you drink water for injection apart from formulation or specific needs, it may not be beneficial rather impacting negative effects on your body in the form of kidney problems.

Water for injection is mainly intended for the administration of parenteral formulation and is safe for inside infusion. In some cases, if you’re supposed to take water for injection then it is necessary to have guidance from a doctor or prescriber.

11.What are the complexities of water for injection manufacturing processes?

To manufacture water for injection, there are complex series of steps that occur in the process. Not only one piece of equipment is responsible for this task rather you will need many production units to bring the water for injection as it is required.

It is involved with the right machine, right calculation, right timings and so other factors. Therefore, any slight error or problem can interrupt the procedure. We have talked about the basic complexities of the procedure below:

Contamination

Contamination- Picture courtesy: HRS Heat exchange

Machineries used during the production of water for injection are more prone to progress with microbial progression such as algae, accumulation of metals in its filtration system or membranes, and corrosion in pipelines. Remember, if you neglect any small issues can result in a big loss when it comes to talking about pharmaceutical preparations.

To rectify the problem, you will need to have strict checkups and monitoring of the whole system. Immediately, replace the worn-out parts of the machine with new ones. Keep cleaning the units by using an SIP washing and sterilizing system which ensures the system is well-maintained and sterilized.

Water for injection distribution

Water for injection distribution- Picture courtesy: Ovivo water

When manufacturing water for injection, you may face issues in the transferring of prepared sterile water toward the required units. The manual transferring in some areas compromised the quality of water. But when it comes to talking about medicines, you will need a promising system.

To solve the problem, you need to set the distribution setup which offers high-pressure circulation of water towards different units. In this way, you can witness the sterile process, save energy, and reduce water wastage.

Water wastage

Water for injection- Picture courtesy: TSA process

During the procedure, most often sufficient volume of water is also prone to waste. Simply discarding water is not an ideal option which can cause water shortage as well as pollution. To solve this problem, when the unit keeps discharging residual water from valves, it can be recirculated into machines like autoclaves, ion exchangers, and relevant units to treat the wastewater. Once the water is obtained, it can be used for other purposes in pharmaceuticals, chemical fields, and others.

Conclusion

The water for injection is a sterile and quality vehicle used for pharmaceuticals and health-associated regions to attain quality formulation and practices. The purpose of attaining and maintaining the quality of water is to provide a good standard medium that is free from pyrogen, microbes, impurities, etc. It is a complex and hectic process but thanks to AIPAK ENGINEERING for offering an excellent series of water treatment units with stringent international quality standards. Now you can protect your formulation, distribute potent medications, and manufacture promising water for injection with eco-friendly processing machines. Contact our expert to learn more about water for injection production units.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours