APK-XTJ200 Syringe Vertical High Speed Rotary Rod and Labeling Machine

AIPAK Engineering APK-XTJ200 vertical high-speed rotary rod and labeling machine is a device developed by our company for syringes. The equipment can automatically complete a series of actions such as rotary rod labeling, inkjet or laser printing batch number, production date, etc, to realize the rotary rod and labeling of syringes. This equipment has the advantages of compact structure, lightweight, simple operation, reliable, operation, convenient maintenance, stable rotary rod, fast labeling speed, flat and beautiful labeling, strong adaptability, etc, and can adjust the labeling speed according to the fling speed of the previous process. Stepless speed regulation ensures that the machine can be used alone or in line with other machines. It is an ideal choice for syringe rotary rods and labeling.

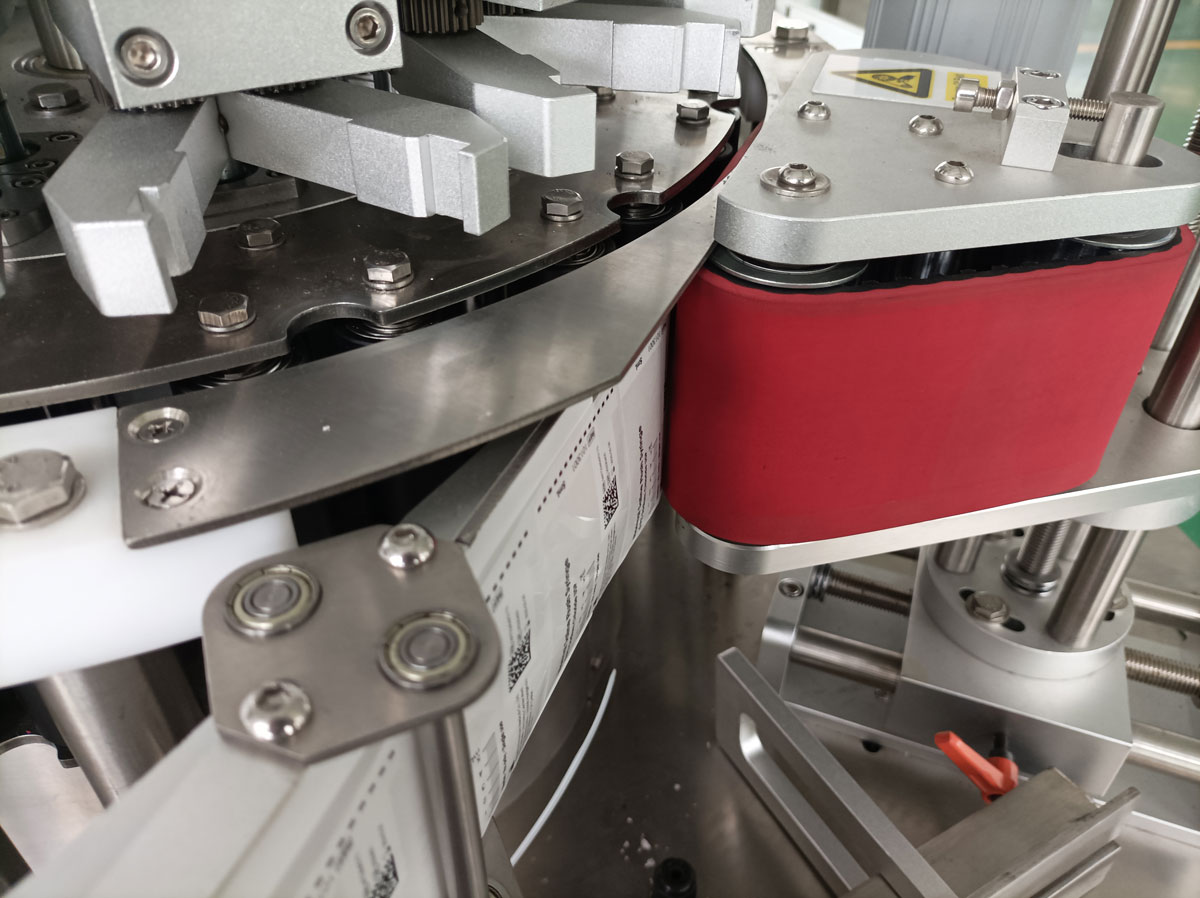

APK-XTJ200 Syringe Vertical High Speed Rotary Rod and Labeling Machine Details:

APK-XTJ200 Syringe Vertical High Speed Rotary Rod and Labeling Machine Features:

1.Intelligent control, automatic photoelectric tracking, with the functions of no object no labeling, no label automatic correction and label automatic detection, to prevent missed labeling and label waste.

2.Flexible application, it can be produced by a single machine or connected to an assembly line. The layout of the production site is simple, and the conveyor belt can be configured to directly connect the rotary rod labeling machine from the clean room through the mouse hole, saving the space in the clean workshop.

3.Adopt internationally renowned electrical components, implement non-interference modular control, all synchronous actions are controlled by servo motors, and implement automatic rotary rod labeling, which is accurate, reliable, and easy to operate.

4.The operation of the motor is controlled by the PLC programming controller, the human-computer interaction interface monitors and displays the working status of each station in real time, and the real-time automatic alarm displays the fault location and fault prompt.

5.Syringes of various specifications can be used universally through molds or adjustment mechanisms.

6.It can be equipped with automatic feeding function. The glass syringe can be fed into the labeling machine by the nesting device, the push rod can be automatically sorted and sent by the vibrating plate or the centrifugal plate, and the prefilled catheter can be fed to the centrifugal plate by the elevator for automatic sorting. Tube, delivery tube, sent to the chute for unloading (combined with product considerations).

7.Optional thermal coding/jet coding function, to realize real-time printing functions such as printing batch number, production date, output counting, etc.

APK-XTJ200 Syringe Vertical High Speed Rotary Rod and Labeling Machine Technical Specification:

| Applicable Packaging Materials | Syringes |

| Applicable Specifications | 1ml long/1-3ml/5ml/10ml/20ml

(Need to replace specifications) |

| Maximum Outer Diameter of Label Roll | Ф320mm(Maximum) |

| Label Core Inner Diameter | Ф76mm(Minimum) |

| Label Specifications | Height 10mm-80mm

Length 20-70mm (Special specifications can be customized) |

| Production Capacity | 120-180 pcs/m

(Depending on product size and label length) |

| Power | 4.5kw |

| Voltage | 380V 50Hz |

| Compressed Air | 0.6-0.7Mpa |

| Dimensions | L1500×W1300×H2000mm |

| Weight | 400kg |

Prefilled Syringe Solutions Related Products