Your Premier Small Bottle Filling Machine Supplier

- Highest process reliability

- Compact design with little space requirement

- Low product loss during filling and format change

AIPAK Engineering Other Liquid Solutions

AIPAK Engineering other liquid solutions focus on proving you with various small bottle liquid filling machines,including eye drop filling machine,E-liquid filling machine,essential oil filling machine,spray filling machine,perfume filling machine,nail polish filling machine,biochemistry reagent filling machine and pre-filled syringe filling machine.If you’re looking for exceptional accuracy and efficiency from small filling equipment,AIPAK Engineering will your best choice.All AIPAK Engineering small bottle liquid filling machines have high accuracy and customized cleaning programs,which will waste very little product due to overfilling.Additionally, our machinery’s relatively small footprint and flexible layout configurations enable it to fit into existing operations.

Eye Drop Filling Machine

Automatic High Accuracy Plastic Bottle Eye Drop Filling Machine

AIPAK Engineering Eye drop filling machine can complete the dropper bottle unscrambling, conveying, aseptic purified air bottle washing, filling, dropper tip feeding, dropper tip cap screwing, lamp inspection, labeling, cartoning, weighing and detecting, film wrapping, case packing and palletizing. The entire filling production process is completed under the 100-grade laminar flow protection and aseptic isolation systems. With isolation protection of each area ensures the aseptic production of eye drop products. While the eye drop filling machine is also conformed to the most up-to-date GMP requirements.

Easy to operate, safe, and reliable

Touch screen operation platform, PLC control

Variable frequency speed control.

E-Liquid Filling Machine

High-speed Cigarette Making Machine E-Liquid Filling Machine

AIPAK Engineering E-liquid filling machine is stable in operation, simple and safe. It is usually used to fill small (round, square) bottles, especially used to fill e-liquid, e-juice, and other small dose products. The material of main parts is 304 stainless steel, meeting GMP requirement.E-liquid filling machines are essential machinery used in a broad range of industries.These machines allow liquid contents to be packed into separated containers without wastage. Current E-liquid filling machines are advancing, providing companies with the most efficient packaging methods.

Precise filling for specific sizes

Auto-feeding technology

Easy and fast settings

Essential Oil Filling Machine

Automatic High Quality Cosmetic Cream Essential Oil Filling Machine

AIPAK Engineering Essential oil filling machine is widely used for filling and capping for small volume liquid filling, plugging and capping, such as vial essential oil, E-liquid, anti-biotic, eye drops and so on. All contact parts is made of stainless steel, its capacity can reach 3000 bottles per hour, can match most requirement.You can use a completely customized configuration of essential oil filling machinery, with many size and shape options to meet your actual space requirements.

Requiring less frequent maintenance

Low noise, low loss, and no air pollution

High Filling Accuracy

Spray Filling Machine

High accuracy spray pump automatic spray filling machine

AIPAK Engineering Spray filling machine is used in all kind liquids with high filling speed and high filling precision to ensure the bottles and filling nozzles are in the correct position.This automatic spray filling machine contains cap unscrambler,liquid fillers,sealer,gas inflator(1 capping head and 3 or 4 gas inflating heads),mark printer,screw ring presser and swing vibration machine and so on.Full automatic valve feeding equipment,full automatic big cap presser,full automatic weighting machine can be selected optionally.This machine is easy to operate and with high security and measuring accuracy.

Easy operation and maintenance

PLC and touch screen

Piston/gear/ Peristaltic pump filling system

Customization high accuracy automatic aerosol filling machine for small plastic bottle

AIPAK Engineering aerosol filling machine is excellent for small or medium-sized aerosol manufacturing,it can make many aerosol products.Less work is needed to keep the aerosol filling machine running.And it is also self-operating and doesn’t need to be watched or controlled all the time.You will be quickly change the filling container height or size.The machine also has safety door for safety production and can work well with other equipment.

Simple in structure and easy to operate

High stability&reliable performance

Suitable for the experimental room and medium-sized and small-scare company

Perfume Filling Machine

Automatic High Quality Cosmetic Perfume Filling Machine

AIPAK Engineering automatic cosmetic perfume filling machine is suitable for all shapes of bottles and special purpose for filling perfume spray bottle. It is available for series of round and flat perfume bottles. And it adopts stainless piston measuring pump for vacuum filling, pneumatic capping, and rising-and-falling screwing.All AIPAK Engineering perfume filling machine enjoy advantages of accurate measurement, stable screwing and easy operation, widely used in Aiapk Engineering and cosmetics industry.

Good brand PLC control system and color touch screen

Stainless steel piston pump quantitative filling

Pneumatic adding cap and elevating screw capping

Nail Polish Filling Machine

High accuracy Automatic Small Bottle Liquid Filling Nail Polish Filling Machine

AIPAK Engineering Nail polish filling machine is simple to adjust, can fill any kind of the liquid in the different bottles with the similar level of water.The nail polish filling machine is designed with the low voltage that avoids the sparks. It is convenient to move from one place to another place easily. The installation process of AIPAK Engineering nail polish filling machine is simple. The machine through the cam drive, positioning accuracy, stable transmission. PLC automatic control filling, internal tamponade, capping the whole process. Automatic injection molding machine can be formulated by blowing directly into the filling system, to prevent cross-infection, the entire process is completed under sterile conditions.

simple operation, accurate filling

Simple equipment cleaning and maintenance

Easy to adjust the filling volume

Biochemistry Reagent Filling Machine

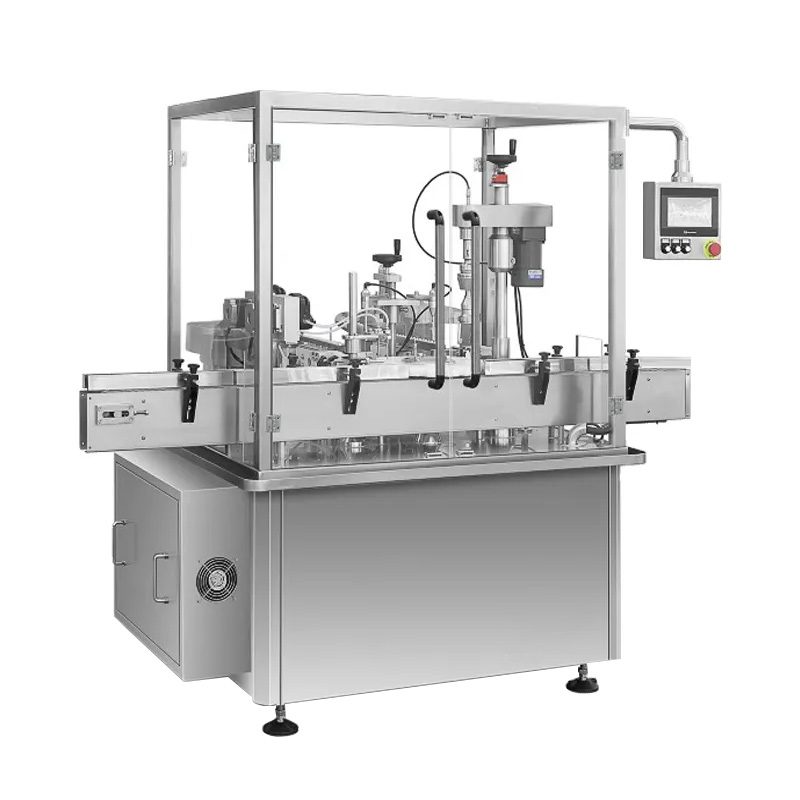

Fully Automated Biochemistry Reagent Filling Machine Small Bottle Filling And Capping Machine

AIPAK Engineering biochemistry reagent filling machine can be used for various types of diagnostic reagent bottle filling and capping and can be used stand-alone or it can be connected with the labeler machine .It can finish all works of bottle feeding, filling, putting inner plug if there is and capping outer covers automatically. The bottle holders is designed for different shapes of bottle.The main body of machine is made of SUS 304 stainless steel and aluminum alloy etc. ,and the designing is complied with GMP.

No liquid dripping in filling station

Alarm for the trouble of machine warning

Reliably and stably cap on and capping station

Prefill Gel Syringe Filling Machine

High Speed Automatic Pre fill gel syringe filling machine Disposable Syringe Filling And Capping Machine

AIPAK Engineering Prefill syringe filling machine is specially designed by our company for the filling of prefilled plastic syringes. It is an automatic packaging equipment for aseptic and efficient filling of syringes. The equipment runs smoothly, is simple to operate, and is equipped with intelligent detection devices. It has high automation, high work efficiency and easy maintenance. It is an ideal equipment for filling and capping prefilled plastic syringes.

Modular design, easy to locate, easy to expand

Human-computer interaction interface monitors

Higher filling accuracy of ±1% in single dosing

Aseptic Filling Machine For Anesthetic

Fully Automatic Aseptic Filling Machine For Anesthetic Liquid Bottle Filling Capping And Labeling Packing Line

AIPAK ENGINEERING Aseptic filling machine for anesthetic adopts aseptic isolation technology to ensure the sterilization of filling materials, packaging environment and packaging containers. Sterilize the bottle and cap by soaking in disinfectant to ensure the sterility of the packaging container. The internal and external surfaces of the equipment are cleaned and sterilized by the SOP method, and the filling environment is kept at positive pressure by using sterile air to achieve a 100-level clean environment.

Fully enclosed filling design

Ceramic pump filling

Anti dripping needle, lock the needle after filling, completely solve the dripping problem