Pre fill gel syringe filling machine for pharmaceutical

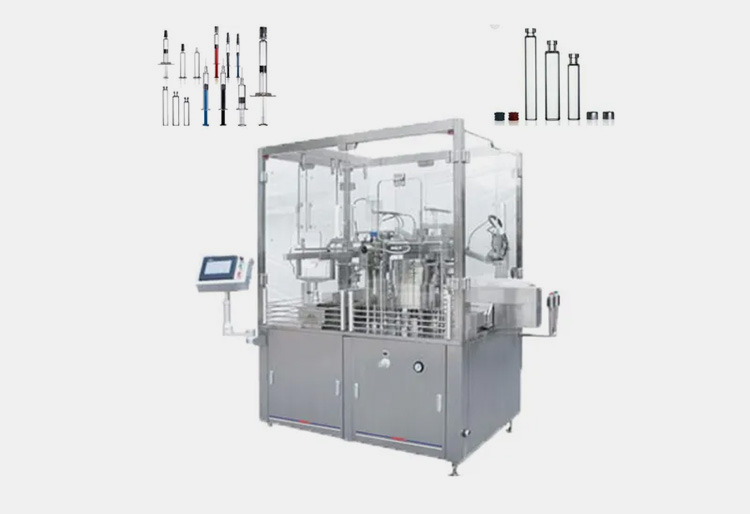

AIPAK Engineering Prefill syringe filling machines are automated systems used to fill pre-sterilized syringes with liquid pharmaceuticals. They are designed to fill the syringes with accurate and precise volumes of the drug.

The prefill syringe filling machine consists of several subsystems, including syringe loading, filling, stoppering, capping, and labeling. The syringes are typically loaded into the filling system using a conveyor or feeding system. The syringes are then filled with the liquid pharmaceutical using a volumetric or peristaltic pump. Once filled, the stopper is inserted into the top of the syringe. The syringe is then capped and labeled before being discharged from the system.

All AIPAK Engineering prefilled syringe-filling machines are widely used in the pharmaceutical industry for the production of vaccines, antibiotics, and other liquid drugs. These machines offer many advantages over manual filling, including increased speed, accuracy, and consistency. They also reduce the risk of contamination, which is a critical factor in the production of sterile pharmaceutical products.

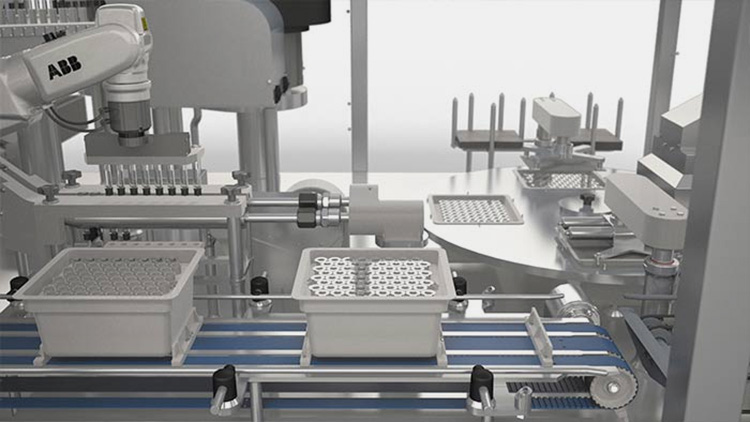

AIPAK Engineering Prefill Syringe Filling Machine Sample Display:

AIPAK Engineering Prefill Syringe Filling Machine Features:

1.Material contact surface: SUS316L.

2.Main structure: Stainless Steel. Frame: Transparent PC. Working platform: SUS304.

3.Servo driven system is used to control the filling volume and accuracy, parameters setting and adjustment freely

4.Single or Double filling lines work independently to increase production speed.

5.Use friendly PLC and HMI interface

6.Use single and double speed adjustable 1.8m PU conveyor, driven by frequency motor.

7.Use photoelectric control for bottle absence. No bottle, no filling.

8.Easy to disassemble the material contact parts for cleaning.

AIPAK Engineering Prefill Syringe Filling Machine Technical Specification:

| Model | APK-005 |

| Filling size | 1 - 10ml |

| Capacity | 1500 - 3600 jars/hour |

| Qualified for cap place on | ≥99% |

| Qualified for cap closing | ≥99% |

| Power | 2.5 KW 220V /110 V single phase |

| Pressure | 0.4 ~ 0.7MPa |

| Air Supply | 0.6kg/cm2,10m3/h |

| Gross weight | 750 KG |

| Dimension | 2500 x 1300 x 1800mm |

The Buyer's Guide

Prefilled Syringe Filling Machine: The Complete Buying Guide in 2025

Self-administration of pre-filled syringes has been on the rise due to the higher incidence of chronic diseases which has led to the growth of prefilled syringe market. The demand for pre-filled syringes is directly co-related to the higher demand for the pre-filled syringe filling machine.

It is the prime concern to achieve efficiency in filling, hence, pharmaceutical and other consumer industries use pre-filled syringe filling machines. It also protects drugs and the workforce during dosing and closing. This machine process and pack parenteral and infusion drugs in syringes with utmost care to prevent drug dosing inaccuracies and to ensure patient health safety.

Different advanced fillers like pumps and pistons improve process sterility.

Without further ado, read this informative guide to discover all the ins and outs of a prefilled syringe filling machine, this knowledge will aid you in buying a subpar machine for your business.

1.What is Prefilled Syringe Filling Machine?

Prefilled Syringe Filling Machine

It is a specialized piece of equipment featuring high-tech gadgets and technology to allow accurate and precise dosing of parenteral and infusion drugs into small and large syringe devices.

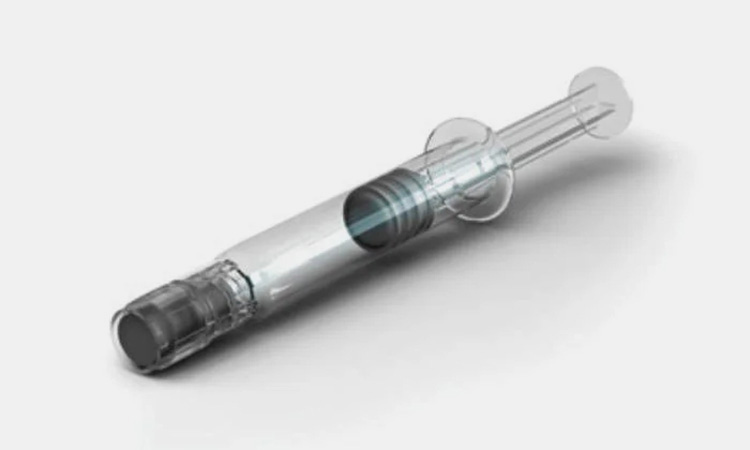

This machine plays a significant part in loading syringes for self-administration at homes. These syringes consist of needles, rods, glass containers, and a plunger.

A prefilled syringe filling machine is a compact instrument offering high automation, quick pace, and aseptic and sterile filling of syringes. Whether small, intermediate, or large-sized processing lines, it creates a safe production environment and is paramount in preserving product standards.

2.What Advantages Prefilled Syringe Filling Machine Offers to Businesses?

A prefilled syringe filling machine is a turnkey solution found in all pharmaceutical and biologics industries. Its efficiency and consistency make it an ideal equipment for drug formulation industries.

The advantages of the prefilled syringe filling machine are discussed below for your understanding:

Automation

Automation with Prefilled Syringe Filling Machine- Picture Courtesy: OPTIMA Packaging

The prefilled syringe filling machine is one of the most innovative technologies that is designed with advanced computerized and mechanical systems that automate every step of syringe filling. Moreover, with the HMI touchscreen, different process parameters are pre-saved offering rapid changeovers. This automation lowers the workload on operators saving labor wages and boosting productivity.

Consistency in Syringe Filling

Consistency in Syringe Filling- Picture Courtesy: Marchesini Group

In the pharmaceutical and other health sectors, it is essential to maintain fixed doses in drug delivery vehicles. To achieve consistency in every batch of syringe filling, prefilled syringe filling machine is employed in businesses. It is equipped with weight-filling systems and sensitive sensors that detect minute changes in filling volume to provide precision in syringe filling.

Safety and Hygiene

Safety and Hygiene- Picture Courtesy: Dara Pharma

The prefilled syringe filling machine is integrated with barrier and isolator systems that provide hygienic filling. Safe interfaces between operator and dosing stations minimize the risk of contamination, keeping both operators and drug products safe.

No Product Wastage

No Product Wastage- Picture Courtesy: Cytiva

Parenteral and infusion drugs are fairly expensive, loss of even a minute quantity could significant production loss. These systems are designed in such a way that they control formulation fill. Robotic controls and intelligent technology prevent formulation leakage and spillage, resulting in zero wastage.

Flexibility in Syringe Processing

Flexibility in Syringe Processing- Picture Courtesy: Dara Pharma

This machine can be customized to process diverse syringe sizes and designs, and that ensures equipment can accommodate future syringe designs. These features also increase the value of the prefilled syringe filling machine in businesses handling and dosing different volumes of drug formulation in the syringes.

3.In What Industrial Sectors a Prefilled Syringe Filling Machine Used?

This machine is routinely used in industries that dose premeasured volumes of medications in the syringes. It is employed for filling sensitive and delicate drug preparations. Here is the list of industries that employ this machine.

Pharmaceutical Industry

Prefilled Syringes in Pharmaceutical Industry: Picture Courtesy: Biopharm International

First and foremost, the pharmaceutical industry is the major user of this machine. Important medications that usually require intravenous and intramuscular delivery are prefilled in syringes by this equipment. This drug dosing offers convenience to both patients and treating staff. Its aseptic filling is paramount in the pharmaceutical industry.

Bioengineering Industry

Prefilled Syringes in Bioengineering Industry: Picture Courtesy: The Hill Times

This industry routinely processes different kinds of biologics, for instance, biopharmaceuticals, insulin, vaccines, recombinant drugs, and anti-cancerous drugs that require absolute sterility and hygiene for filling in drug delivery vehicles.

This industry is where the prefilled syringe filling machine cautiously fills highly potent formulations in syringes without compromising their integrity and effectiveness.

Healthcare Industry

Prefilled Syringes in Healthcare Industry: Picture Courtesy: OPTIMA Packaging

This machine is found in the healthcare industry and hospitals for compounding different medications in syringes. The most popular application of this machine in hospital sectors is the filling of anesthesia medications for prompt administration.

Pet Care Industry

Prefilled Syringes in Pet Care Industry: Picture Courtesy: Nordson

This machine is a prime component of the pet care industry, as it pre-formulates vaccines and other infusion drugs in syringes for the treatment of pets and other animals. It loads the correct amount of pet medication in syringes.

Cosmetic Industry

Prefilled Syringes in Cosmetic Industry: Picture Courtesy: OPTIMA Packaging

Yes, due to high beauty standards, this equipment is regularly utilized in the cosmetic industry for filling fillers, Botox, skin skin-whitening injectables in syringes. Its accuracy makes it an integral component of the aesthetic industry.

Research and Development

Prefilled Syringes in Research and Development: Picture Courtesy: Homeland Preparedness News

Many research laboratories and other drug development sectors use this machine for measuring the effectiveness of experimental and trial drugs on different animal models and human subjects.

4.What are the Primary Components of a Prefilled Syringe Filling Machine?

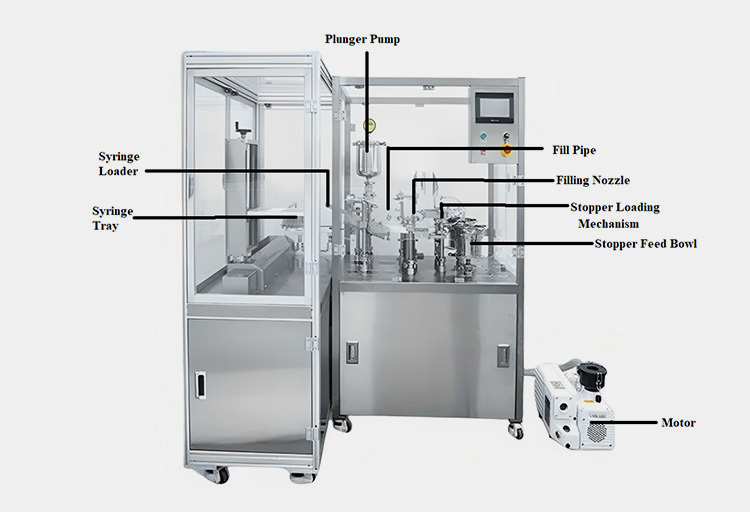

Different parts in the prefilled syringe filling machine carry out a particular function, contributing to the highly safe and aseptic filling of drug formulation. The primary components of this machine are:

Parts of Prefilled Syringe Filling Machine

| Safety Glass | It is a clear shield made with plexiglass that fully separates the syringe processing and filling area from the operator. It is one of the essential features that provide a barrier for decontaminated filling. |

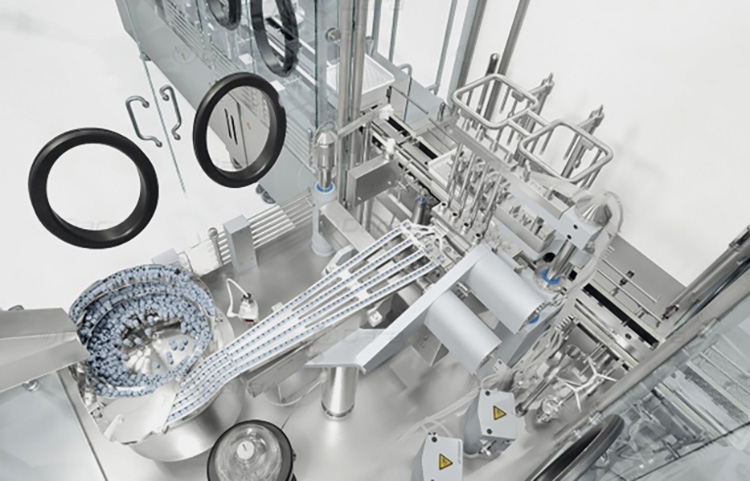

| Stopper Vibratory Bowl | This machine is designed with two vibratory bowls that sort and convey rubber plugs to the stopper loading mechanism through vibration. It is manufactured using high-quality stainless steel and does not contain any dead corners ensuring the safety of plugs. |

| HMI | An interactive and smart screen found in a semi-automatic and automatic prefilled syringe filling machine for smooth adjustment of work settings. Data recipes are saved in this touch screen that allows for swift format change. |

| Operator Interaction Area | Some types of prefilled syringe filling machines have two windows in the safety glass door through which operators with the help of gloves remove the cover from the tray containing empty syringes. |

| Tray Loading Conveyor | It is a long roller type of conveyor found in the prefilled syringe filling machine for the transport of empty syringe trays. |

| Syringe Loader | It is a narrow passageway in which syringes are loaded consecutively by the robotic arm. |

| Syringe Tray | It is a mechanical part that carries syringes to the syringe loading area. |

| Plunger Pump | It is a pump system that aids in the quantitative filling of the drug formulation. It consists of hoppers and hose pipes and is made with ceramics that are temperature and chemical-resistant. |

| Fill Pipe | These structures connect the hopper to the filling nozzles. |

| Filling Nozzle | These are small narrow tubes that fill the drug substances in the empty syringe. |

| Stopper Loading Mechanism | The rubber plugs are dropped down from the vibratory bowl and these are picked by the stopper loading mechanism. These parts deposit the rubber stoppers on the filled syringes. |

| Motor | These are electric powerhouses of the system providing mechanical energy to all mobile components of the prefilled syringe filling machine for their working. |

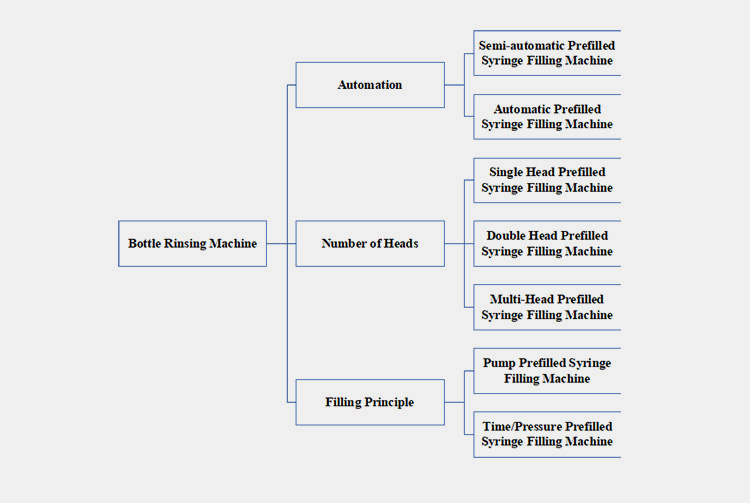

5.How are Prefilled Syringe Filling Machines Classified?

There are different models of prefilled syringe filling machines that are optimised to satisfy evolving production demands. These machines are operated as a standalone or are integrated with other equipment for efficient syringe packaging.

These different classes of prefilled syringe filling machines are discussed below:

Classification According to Automation Level

Semi-automatic Prefilled Syringe Filling Machine

Semi-automatic Prefilled Syringe Filling Machine

It is a small compact system typically operated using a pneumatic system. This cost-cutting machine runs without electricity, contributing to lower utility bills. Hence, it is suited for small and medium-sized businesses. It has limited processivity because it fills one syringe in one cycle. The operators feed and remove syringes manually from the system.

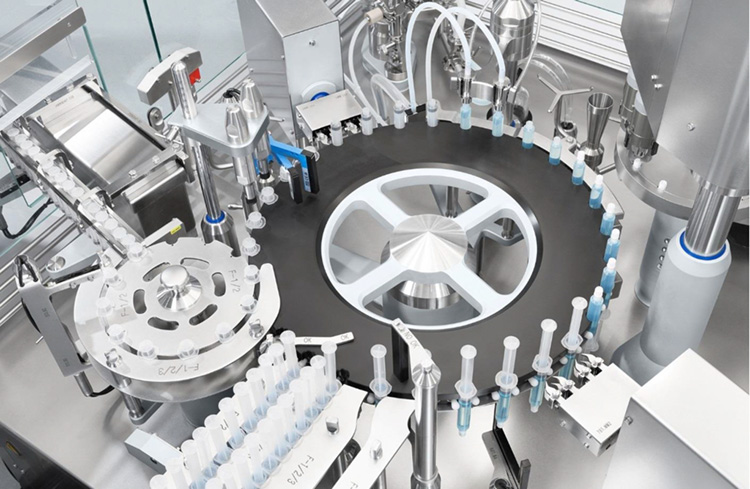

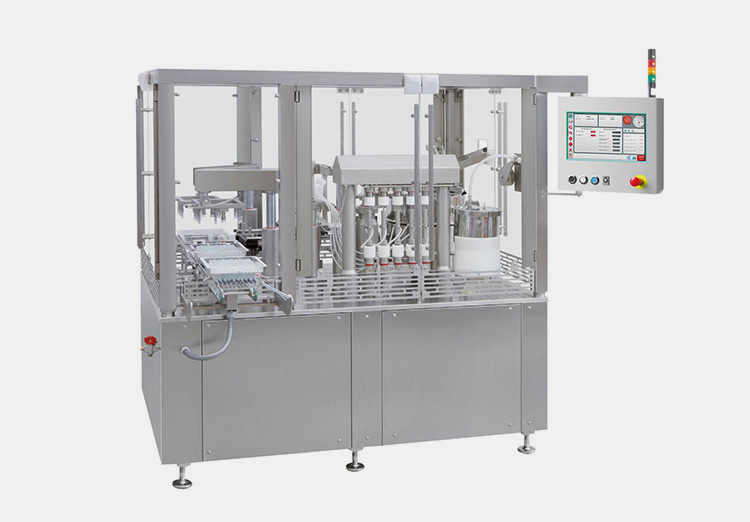

Automatic Prefilled Syringe Filling Machine

Automaic Prefilled Syringe Filling Machine- Picture Courtesy: Marchesini Group

It is a gigantic sized machine requiring larger room for its setup and operation. The automatic prefilled syringe filling machine is fabricated with high-tech synchronized robotic systems and stands that perform the loading and unloading of syringes without needing human operators. Moreover, PLC control systems regulate the working of every component to ensure accuracy in packing syringes.

Classification According to Number of Heads

Single Head Prefilled Syringe Filling Machine

Single Head Prefilled Syringe Filling Machine

This machine is designed with just one filling head so this machine is ideal for small and medium processivity as one syringe is filled in one setting. Due to this characteristic, this machine has a smaller filling range. This machine has both semi-automatic and automatic modes of operation.

Double Head Prefilled Syringe Filling Machine

Double Head Prefilled Syringe Filling Machine- Picture Courtesy: IVEN

Two filling heads in this system, allow it to fill twice as many syringes as its single-head counterpart. Syringe loader two syringes in two holders and two filling nozzles dose two empty syringes with preparation. Therefore, it is preferred in many settings due to its higher filling capacity.

Multi-Head Prefilled Syringe Filling Machine

Multi-Head Prefilled Syringe Filling Machine- Picture Courtesy: Marchesini Group

This machine is equipped with 10 filling heads which allows it to meet higher processing demands. Robotic stands load and load 100 syringes from the tray in this system and these are filled in 10 cycles one after another, achieving high speed and swift results.

Classification According to the Filling Principle

Pump Prefilled Syringe Filling Machine

Pump Prefilled Syringe Filling Machine- Picture Courtesy: IMA Srl

This machine has efficient pumps for filling syringes. Different pumps, for instance, peristaltic, metal, and, ceramic are controlled with servo-driven motors to carry out accurate volumetric filling of the syringes. The rotation of pumps governs the dispensing of formulation in the fill nozzles and then syringes.

Time/Pressure Prefilled Syringe Filling Machine

Time/Pressure Prefilled Syringe Filling Machine- Picture Courtesy: Syntegon

In this type of prefilled syringe filling machine, the filling duration is determined by the time adjusted on HMI. The filling operation and fluidity of liquids are achieved either by natural gravitational force or by creating artificial pressure on the liquid holding tank. It offers versatility when it comes to liquid viscosity.

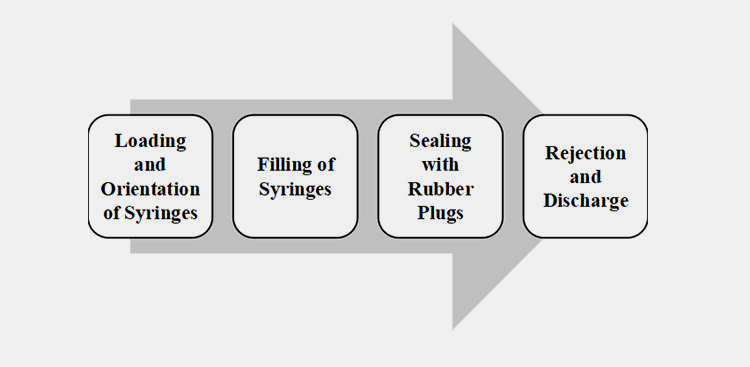

6.What is the Working Principle of a Prefilled Syringe Filling Machine?

A prefilled syringe filling machine is a sophisticated unit in which different computerized systems precisely control each step for uniform and smooth syringe filling operation. The order of these working stages is discussed below for your information:

Loading and Orientation of Syringes

Generally, at the beginning of the prefilled syringe filling operator, the tray containing 100 or so empty syringes with cover is placed on the rolling conveyor. After the initiation of the fill cycle, the conveyors start moving and operators remove the cover from the tray. This stand is picked up by the robotic arm.

The mechanical stand feeds 10 syringes at a time to the syringe loader. These empty syringes are oriented one by one in the holders.

Filling of Syringes

Filling of Syringes- Picture Courtesy: Cytiva

The filling systems are programmed to dispense an accurate volume of formulation in the syringe. The PLC unit of the machine controls the filling speed and duration of each syringe fill. The formulation is fluidized from the hopper into the filling nozzles via volumetric and peristaltic pumps.

The filling nozzle is the main part that feeds the liquid or semi-liquid preparation into the empty syringes.

Sealing with Rubber Plugs

Sealing with Rubber Plugs- Picture Courtesy: www.tofflon.com

The filled syringes are introduced to the stopper loading station. The stoppers or rubber plugs are fed from the vibratory bowl to the rubber plugs pickup stand. This stand deposits these stoppers onto the loading mechanism.

Finally, these stoppers are fixed onto the filled syringes under the vacuum condition by the stopper loading mechanism.

Rejection and Discharge

Rejection and Discharge of Syringes- Picture Courtesy: Cytiva

After stoppering, the quality of filled syringes is ensured using camera vision or weight-checking systems to ascertain that each syringe fulfils stringent quality tests. During these tests, if a defect is found in the syringes then these are rejected and removed from subsequent processing.

Syringes in perfect condition are removed from systems and transported to the primary packaging area.

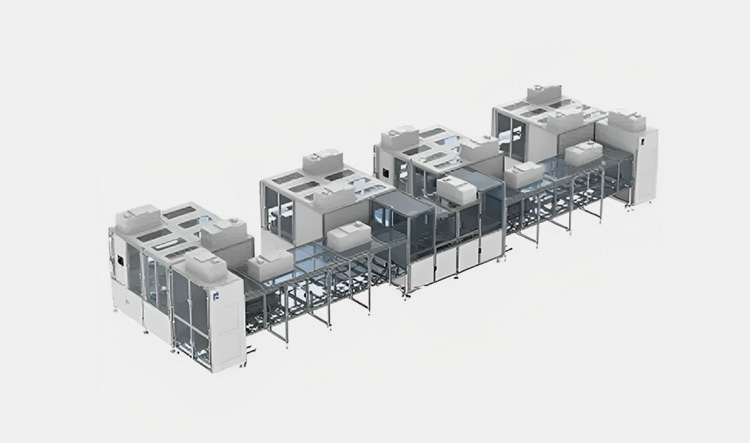

7.What Other Machines Cooperate with a Pre-Filled Syringe Filling Machine to Form a Complete Production Line?

A variety of machines are integrated into the prefilled syringe filling machine production line for seamless and continuous handling and packaging of syringes. Some of these machines are detailed below:

| Machine | Image |

| Syringe Upstream Handling Systems

The empty syringes typically come in bags or large tubes, consequently, automatic bag opening (ABO) systems are the main fixture in the syringe upstream processing line. These systems have specialized units that remove the syringe tubs from their packaging containers safely and securely |

Syringe Upstream Handling Systems- Picture Courtesy: Syntegon |

| De-nesting Systems

These machines are dedicated upstream handling systems for syringes as they adopt exclusive and sterilised solutions to efficiently and safely remove syringes from their nests and then syringes are positioned on the conveyors for downstream filling. |

De-nesting Systems- Picture Courtesy: Radiant Industries |

| Prefilled Syringe Filling Machine

This machine features particular pumps like peristaltic, smart, rolling, and piston pumps for precise loading of biopharmaceutical products in the syringes. It is equipped with RABS or isolator for aseptic dosing of drugs and improving sterility of the process. |

Prefilled Syringe Filling Machine |

| Rod Insertion and Labeling Machine

This machine is essential in sealing the syringe by introducing the rod inside it. Moreover, it marks the syringe with discernable labels for product identification. |

Rod Insertion and Labeling Machine- Picture Courtesy: Packaging Digest |

| Inspection Machine

To achieve high safety standards, an inspection machine is utilized in prefilled syringe filling machines that identify visual defects and leaks in the syringes. Camera and light-based systems detect closure integrity and stopper positioning. |

Inspection Machine- Picture Courtesy: Marchesini Group |

| Sterilizing Machines

Sterility is important in keeping patients safe and it is accomplished by different sterilizing machines that adopt vacuum, steam, or hot water to disinfect syringes and inhibit the reproduction and survival of pathogens. |

Syringe Sterilizing Machine- Picture Courtesy: Sada Medical |

| Syringe Packaging Machine

High-quality syringes are packed in different containers, for instance, thermoforming trays and blisters by the packaging machine. It secures syringes for shipment. |

Syringe Packaging Machine- Picture Courtesy: Making.com |

8.What Syringe Formats Are Handled by Prefilled Syringe Filling Machine?

This machine is configured to handle a variety of different syringe formats, for example”

Standard Luer-Lock Syringes

Standard Luer-Lock Syringes- Picture Courtesy: Maxill

It has a luer fitting tip that has numerous threads on its exterior. The needle of this syringe also has aligning threads that allow it to fit inside the tip.

Luer-Slip Syringes

Luer-slip syringes- Picture Courtesy: DS Medical

It is a commonly utilized syringe loaded by a prefilled syringe filling machine. This syringe has a smooth surface devoid of threads and does not feature any collar. Its needle is introduced into the tip by slipping or pushing.

Safety syringes

Safety syringes- Picture Courtesy: ONE-CARE®

The prefilled syringe filling machine is customized by changing parts to fill safety syringes. These syringes are designed with built-in needles that avert the risk of pathogen transmission and prevent needle-piercing injuries.

Auto-Disable Syringes

Auto-disable syringes- Picture Courtesy: The Kare Lab

As the name suggests, these syringes are only utilized for one time due to their safety mechanism that prevents the movement of the plunger once it jeopardizes the safety of end-users. It is yet another type of prefilled syringe loaded by this machine.

Staked needle syringes

Staked needle syringes- Picture Courtesy: Terumo Europe

The prefilled syringe filling machine is designed to fill stacked needle syringes. This type of prefilled syringe has a hypodermic needle fitted into the syringe nozzle by the glue.

Dual-Chamber Syringes

Dual-Chamber Syringes- Picture Courtesy: Dara Pharma

A specialized type of prefilled syringe filling machine is meant for packing dual-chamber syringes. This syringe has two compartments for storing different medications which are mixed before administration.

9.How To Troubleshoot Important Problems in Prefilled Syringe Filling Machine?

Sometimes unexpected problems in the prefilled syringe filling machine could be the source of distress and nuisance, creating production disarray and processivity interruption. But these problems are easily resolved with some tact and skill. Some problems are their solutions in prefilled syringe filling machines are:

| Cause | Remedy | Image |

| Over or Under Filling of Drug Formulation | ||

| Viscosity differences in the drug formulation could cause inaccuracies

Defective work setting of filling systems Old and damaged filling nozzles Formation of bubble during filling |

Minimize the viscosity variations

Calibrate the filling devices Replace old and damaged filling nozzles Examine for air leakage in the pipes and other delivery systems |

Over or Under Filling of Drug Formulation- Picture Courtesy: groninger |

| Contamination of Drug Preparation During Filling | ||

| Poor aseptic conditions during formulation loading

Unclean machine surfaces and filling systems |

Adhere to aseptic protocols during filling

Clean and wipe the exterior and interior of the equipment |

Contamination of Drug Preparation During Filling- Picture Courtesy: NJM Packaging |

| Leakage in the Filling Systems | ||

| Loose hose and pipe connections

Dented, broken, and faulty O-rings and gaskets of filling system Debris accumulation in the dosing system

|

Tighten every pipe connection

Replace or repair faulty O-rings and gaskets Clear the debris buildup in the delivery component |

Leakage in the Filling Systems- Picture Courtesy: Syntegon |

| Formation of Air Bubbles in the Syringe | ||

| Leakage in the fill pipes

Presence of gaseous substance in the formulation Inaccuracy in fill speed could lead to an air trap. |

Fix the leakage in the fill pipes

Degass formulation before fill Alter the dosing speed to reduce air entrapment. |

Formation of Air Bubbles in the Syringe- Picture Courtesy: excel-medical.com |

10.What are the Future Trends of a Prefilled Syringe Filling Machine?

Future Trends of a Prefilled Syringe Filling Machine- Picture Courtesy: ACIC Machinery

The market of prefilled syringe filling machines is expected to witness high growth with a CAGR of 9% during the years 2021-2016. Expansion in the market is because of increased utilization of prefilled syringes for dosing vaccines and insulin.

Engineers and scientists are fabricating new designs of prefilled syringe filling machines with the latest technology to boost performance efficiency and product filling rate.

It is anticipated that future prefilled syringe filling machines will be manufactured using protocols of Industry 4.0, consequently providing better data analysis, connectivity with the system, and optimization of filling process control.

Furthermore, the upcoming prefilled syringe filling machine will be equipped with robotic systems for loading, processing, filling, tracking, labelling, and unloading syringes. The different real-time scrutinizing sensors will be adopted in the futuristic machine for inspecting the quality of filled syringes.

It is anticipated that this modern machine will have stringent barriers and isolator systems to enhance the hygiene and sterility of the syringe filling process.

11.What are the Basic Factors To Keep in Mind for Purchasing a Prefilled Syringe Filling Machine?

Choosing the right type of prefilled syringe filling machine that is well aligned with the characteristics of formulation and syringe type allows businesses to acquire maximum profit from the investment.

Here is a list of factors that will aid you in narrowing down your options:

Production Volume

Production Volume- Picture Courtesy: Simplest syringe

It is an essential factor that will help you in selecting a type of machine based on automation as well as the number of filling heads. Production volume is determined by the number of filled syringes needed per hour.

The prefilled syringe filling machine with the highest level of automation and more filling heads works at a higher speed, consequently allowing production to handle batches with more syringes.

Integration with Other Machines

Integration with Other Machines- Picture Courtesy: DirectIndustry

A prefilled syringe filling machine with more adaptability is easily integrated into an already existing setup, offering convenience and saving expenses that are otherwise needed to customize and adapt the machine for adding to the existing productions.

Durability

Durability of Prefilled Syringe Filling Machine- Picture Courtesy: Cozzoli Machine Company

Although adding a prefilled syringe filling machine is a one-time investment, it should not come at the price of substandard goods. Go for the machine that is made with superior-grade materials because they will last longer and have lower failure frequency. It will in turn save your wallet repair costs and purchasing new parts for the machine.

Convenient Usage

Convenient Usage- Picture Courtesy: Comecer

It is yet another factor to consider when going into the market to purchase a prefilled syringe filling machine. The system with simple controls, advanced technology, and easier disassembly runs without needing skilled operators and is much more convenient to clean and maintain, consequently offering fast format change.

Reputed Manufacturer

Reputed Manufacturer

It is important to look for a reputed manufacturer when short-listing potential prefilled syringe filling machines. The level of support from the manufacturer, such as prompt and long-term customer service, their large in-stock part inventory and the long warranty period helps save you from the hustle in the long term.

Conclusion

A prefilled syringe filling machine is the up-to-the-minute solution providing accurate and secure means for filling syringes. Different high-tech gears like precise filling pumps and advanced barrier systems are devised in this machine for clean and meticulous dosing of biologics and other drug formulations. Looking for an upgrade to an existing solution or are trying to buy a new instrument, then contact our Aiapk Engineering professional specialists for the best recommendations and counsel.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Prefill Syringe Filling Machine Related Products