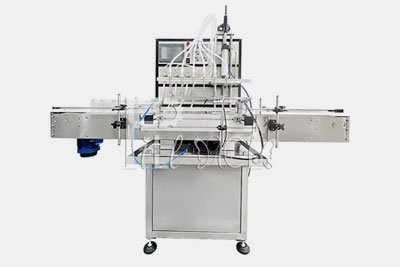

Automatic cosmetic Perfume filling machine

AIPAK Engineering automatic cosmetic perfume filling machine is mainly suitable for filling 10ml glass bottle or plastic bottle E-liquid,essential oil,perfume,syrup,tincture, alcohol,wine and other liquid.It includes the filling-caps feeder-mechanical arm that can suck caps automatically.The part which contact liquid is made of SUS316L stainless steel,the machine frame is made of SUS304 stainless steel.It can work alone or connect with other machine,like the bottle unscrambler,labeling machine to form a complete liquid packing line.The US316L stainless steel piston pump, UK Watson Marlow peristaltic pump and ceramic pump are optional.

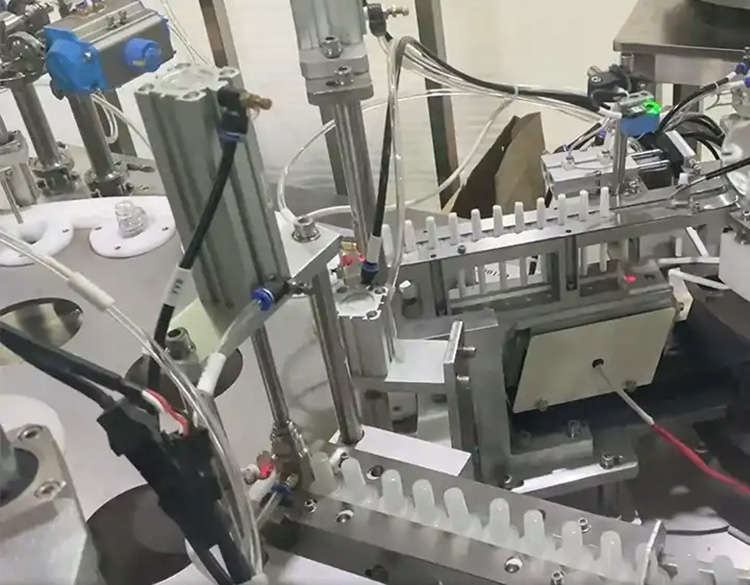

AIPAK Engineering Perfume Filling Machine Sample Display:

AIPAK Engineering Automatic Cosmetic Perfume Filling Machine Features:

1.CE marks and cGMP guidelines

2.Automatic pick and place plugging station

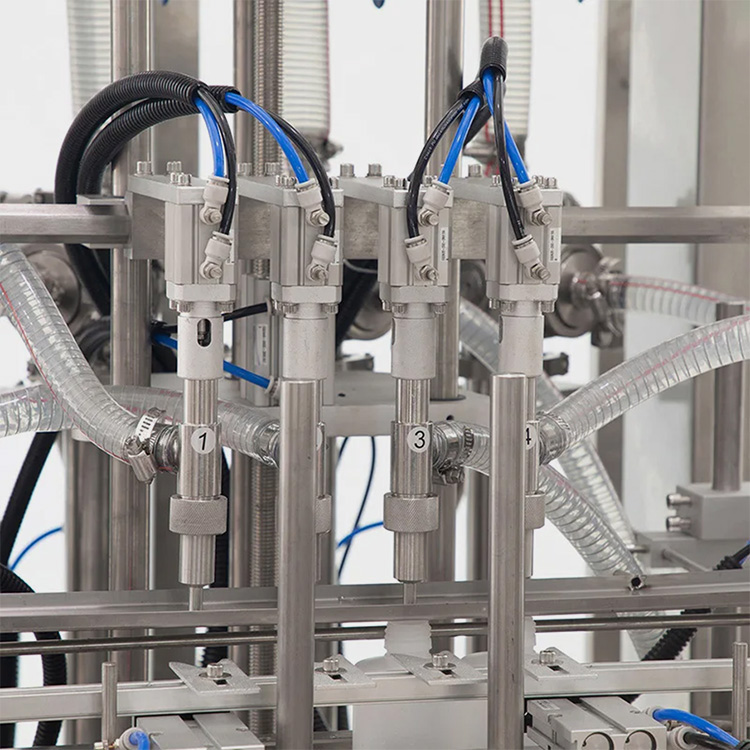

3.Filling needles anti-drip design

4.Mechanical arm pick plug and caps

5.Diving nozzle for an optimized filing cycle

6.Servo system control No bottles No filling(optional)

7.Siemens HMI for easy adjust filling volume(optional)

8.Final caps torque control for each bottle(optional)

9.Precise filling application based on unique star wheel design

AIPAK Engineering Automatic Cosmetic Perfume Filling Machine Technical Specification:

| Machine Speed | 20-40b/m |

| Applied Bottle | 5-30ML |

| Filling Nozzles | 2 Nozzles |

| Filling Accuracy | ±1% |

| Vibrators | Tips Vibrator & Caps Vibrator |

| Capping Nozzle | 1 Nozzle |

| Capping Accuracy | ≥99% |

| Compressor Air Supply | 0.3-0.4kfg/cm2 |

| Air Consumption | 10-15m3/h |

| Whole Machines Size | 4800*1350*1500mm |

| Power/Voltage | AC 380V 50HZ Three Phase (Can be customized) |

The Buyer's Guide

Perfume Filling Machine: The Complete Buying Guide in 2025

Did you know perfume filling is an old technique used for centuries by perfumers and fragrance enthusiasts?

Yes, in those days perfume filling task mostly took place in ornate bottles, porcelain cups, terracotta bowls and crystal flacons that have been transformed into new fashion containers with more eye-catching display.

In order to understand the filling experience, you just need to know the innovative perfume filling machine which is capable of doing this job to preserve your fragrances using state of art methods.

Tracing from history benefits, applications, parts, and so much more, we have brought this article full of extensive information that you will love to read. Let’s go through it now!

1.What Is a Perfume Filling Machine?

Perfume Filling Machine- Picture Courtesy: TraGate

This is a specialized and an advanced method which is developed in modern sciences era for efficient and accurate filling of perfumes and other relevant products into containers.

You must have seen this machine in certain industries such as cosmetics and beauty products manufacturing sectors. But this robust device is hooked to various other departments as well that we’ll discuss later.

The machine is very promising to their customers in the term of speed, consistency, and amazing price ranges.

Due to its unlimited benefits and lowest downtime and high profitability; you can trust on it while adding into your business as an assistant tool.

This machine is very flexible in order to carry important tasks in a diverse way that’s why perfume industry is incomplete without addition of perfume filling machine.

2.When Perfume Filling Machine Originated?

A revolutionary history of perfume filling machine- Picture Courtesy:scentlodge

The history of perfume itself is very broad and vast that began with 600BC where ancient Egyptian used perfume vase to preserve fragrance. Modern perfumes in your hands are rooted from very old ancient civilization where of course entire procedure till storage in different containers were carried out manually.

The early development of the automatic perfume filling machine was traced back in the late 18th century where industrialization was in demand and modern techniques were introduced in the various processes i.e. making, filling, and storage.

Nothing to confuse that a Stephen M. Rust was the first who introduced the first filling machine in 1850 as an automatic filling machine which was able to fill, perfumes, sodas, waters and other products as well; his great invention took taken attention of everyone across the globe and his milestone was further polished that has subsequently changed into today’s advancement in perfumery industries.

3.How Perfume Filling Machine Beneficial?

The perfume filling machine is offering you several benefits in order to improve your productivity and business. What are those benefits? Let’s see below:

Accurate Measurement

Promising Measurement of Formulation

Indeed, this is the most significant criteria that every manufacturer must taken into account to ensure that the filled perfume or material is correct in quantity as subjected on its labeling.

This precision can be carried out perfectly when using a perfume filling machine which complies not only with international quality standards but design in a way that offers 100% accuracy to your end-user.

So your customers will believe in your products and gives you five star rating only if you take help from a correct perfume filling machine.

Stable Screwing

No chances of Product Wastage

You cannot handle sensitive and delicate bottles with hands for twisting caps and inserting lids. This is because of some reasons such as spillage, cross-contamination, evaporation and other. A perfume filling machine is highly consistent and a fast solution that hardly takes time to lid and cap number of bottles in each minute. Isn’t fantastic job?

You can obtain a stable screwing and promising fastening without risk of any loosing or product’s error. So this machine is contributing number of reliable benefits to offering you a finished product.

Easy Operation

User Friendly Perfume Filling Machine

Clicking on PLC screen and a professional working by an automatic machine starts working is now possible with a perfume filling machine. you know that machine itself looks complex, but we promise its operation and user handling is extremely easy. This machine is designed with user friendly parameter so a technician can easily troubleshoot, operate, manage memory, data and much more with smoother filling process.

Increased Productivity

Say Welcome to High Profitability with Perfume Filling Machine

Do you know that a perfume filling machine is incredibly fast and accurate which will directly improve your productivity and offering you a high success rate? Yes, a perfume filling machine is featured with high output keys, and designed in a way that helps in maintaining a target goal in no time so you can easily cope up with current market demands.

Reduced Error Rates

Offering Quality Product Outcomes

Using a perfume filling machine will automatically minimizes the risk of committing errors. Now you must be relaxed when relying on this robust solution as machine itself detects, fills, crimps, screws, and memorise and run your manufacturing processes.

So, what are you worried about? This perfume filling machine is right here to fulfil your dream of filling consistently satisfying batches of your product.

Cost-Effectiveness

A Highly Cost-economical Solution

After reading about so many benefits, you might be wondering about rates of perfume-filling machine. you must be surprised to know that this reliable one stop solution is highly pocket-friendly. So you can add this machine to your production line which is likely to minimize production downtime, training cost, installation, and others.

4.How does the perfume filling machine work?

The perfume filling machine working is very simple and is divided into the following steps for your understanding. Mentioned below discussion is about each step with appropriate illustrations involved in each step of the filling procedure. So, let’s get into it!

| Bottle Positioning

|

This is the first step where filling bottles in an upright position enter the machine with the help of a conveyor as a stable transporter. This process takes place with a highly qualified perfume filling machine so delicate bottles are no longer at risk to be falling down or any product wastage. |

| Filling

|

Bottles are now subjected to the volumetric nozzles where an exact and accurate level of the perfume is effectively filled into each container and moves toward the next station.

The presence of a vacuum level ensures the removal of air bubbles present in the perfume by sucking oxygen molecules. Hence, the level of the product would be consistent with no chance of spillage. |

| Lid Insertion & Crimping

|

The crimping which is commonly known as a sealing takes place over the perfume bottles using the same machine. Once the perfume is filled the gripper via auto-sensor fixes the lid onto each bottle followed by pre-pneumatic crimping which is the partial closing of the bottles. The final crimping takes place after pre-pneumatic crimping for the firm and strong closing of the bottles. |

| Discharging

|

Once the bottles are filled and crimped they’re moved to the next machine for the process of final packaging such as capping, labeling, and secondary packaging procedures |

5.What are the applications of perfume filling machine?

The perfume filling machine is a versatile solution in the era of productivity and modern formulation where presentation and good marketing is the prime success tool behind every prominent industry.

Due to various unlimited benefits, everyone is more concerned about adding this machine to their lines. This is because this machine is ideal for employed functions in various industrial sectors. What are those that can be known by reading ahead!

Pharmaceutical Industry

Uses of perfume filling machine in pharma

Manufacturing, filling, and packaging of products like liquid preparations involving topical, inhalation, as well as injectables such as antibiotics, antiallergy, and painkillers, can be filled using a perfume filling machine. This machine is popular among pharmaceutical manufacturing companies as it works non-stop while offering filling tasks error-free which will directly improve user satisfaction and more market value.

Cosmetics Industry

Cosmetics Sprays & Perfumes

Cosmetic industry is the leading place where a perfume filling machine plays a significant role in the filling of various top-notch products including facial serum, fragrances, facial treatments, eye creams, hand creams, foot creams and so much more. A perfume filling machine is a single unit which is responsible for bringing these tasks and making high profit to your industry by effectively.

Food and Beverage

A perfume filling utilization in food industry

You might be wondering about knowing the role of perfume filling machine for food and beverage industry, hold your horses as this robust solution offers high quality responsibilities to meet consumer needs. This includes filling of food colors, food flavors, various condiments, sauces, dips, and other relevant formulations.

Chemicals and Lubricants

Perfume Filling Machine application in Chemical Industry – Picture Courtesy: Gardener Path

Chemical industry is a sensitive section of production where almost every product is quite aggressive in the term of interactive with your physical system as well as causing harm. Therefore, a perfume filling machine is considered as a safeguard that is offering high shielding effect when filling chemicals like synthetic and natural formulation such as analytes, acidic or basic products etc.,

Personal Care Products

Perfume Machine uses in Personal Care- Picture Courtesy: One Fine Secret

There are various products including in personal care industry that needs a perfume filling machine in its manufacturing and filling.

These include cologne, body cleaners, sprays, hair perfume, hair serum, hair removals, deodorants, and various other product that are accurately and professionally filled by perfume filling machine.

Household Industry

Perfume Filling Machine in Household Industry- Picture Courtesy: Indoor Plant

This industry demanded a perfume filling machine for filling of products that you always need in your homes for cleaning and decorating purposes. Such as glass shiners, thinners, room fresheners, grease removal perfume, mold removal perfume, dust and dirt removal perfume, tile shiners, and so much more. Indeed, their preparatory job would be difficult without a perfume filling machine.

Laboratories & Research

A perfume filling machine Application in R&D

Do you know a perfume filling machine is a worthwhile equipment when bringing it into your research facility. As various research based sample are very much sensitive; as it can changes it values upon reactive with external or internal changes including temperature, lights, and moisture as well as handling. Therefore, a perfume filling machine is amazing solution to bring them in safe containers with minimum contact and more accurately.

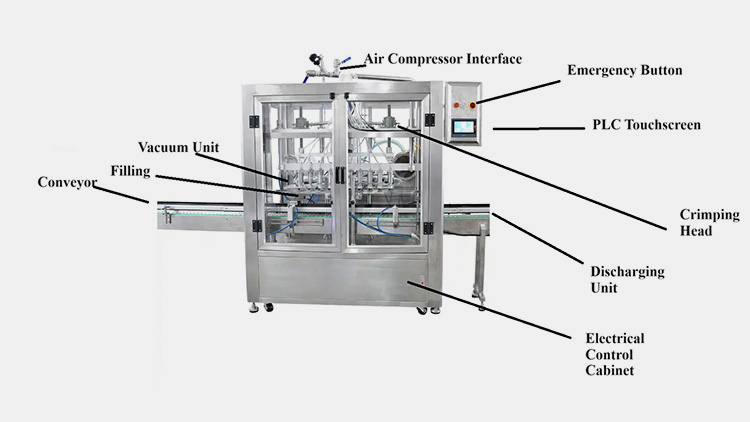

6.Do you know Parts of perfume filling machine?

To understand the basic about the machine you must know what important and essential components it is composed of. That’s why we have specially talked about parts of perfume filling machine. please check below illustration to understand about the machine.

The parts of perfume filling machine

| Air Compressor Interface | If you see the working of perfume filling machine; you may observe several pneumatic movements of the units such as filling, pre-crimping, crimping, etc.,

This entire mechanism of the units is controlled by an air compressor interface which is located just above the machine’s surface. This unit is responsible for pneumatic workflow of various units which is essentially driven by compressed air. |

| Emergency Button | In case of bottle falling, perfume spillage, fire, blockage, or any mishap; the manufacturer has given an easy option to press emergency button which is situated just front position of the machine.

This button is very important as it ensure that you’re 100% safe and you can prevent your working environment as well as your product just by pressing a single button during accident so all movement would be stop immediately. |

| PLC Touchscreen | This is known as a Programmable Logic Controller (PLC) touchscreen which is a leader of the machine that is responsible for controlling, memorizing, and running the operation by simply in feeding the data or process keys by technician.

Once you execute the required protocol inside the machine the signal is transferred to the system and various parts of the machine starts working. It includes, volume of perfume, flow rate, total working capacity, correcting and sensing of bottles and filling of products etc., |

| Conveyor | This is a mechanical and transporting unit which is responsible for introducing and discharging of bottles before and after filling of perfume products. The conveyor ensures you a smooth and stable movement of the containers in a continuous fashion. |

| Filling Nozzle | This is the major unit of the perfume filling machine where a filling nozzle is responsible to bring perfume filling task via adding a defined concentration of perfume into each container. A PLC is sending signal to various units for dispensing the product which include pump, air compressor and then final dispensing of the product filling take place. |

| Vacuum Unit | To bring uniform and consistent leveling in each perfume bottle, a vacuum unit play significant role as it helps in removing or sucking air bubbles in filled container and ensuring accurate leveling of the bottle for promising quality product. |

| Crimping Head | This unit works by pneumatic force which helps in pre-and final sealing of the perfume bottle by setting lids and caps on it. This crimping head picks the lid and auto-sensor helps in the proper fixation of the pump over each container followed by strong closing. |

| Discharging Unit | Like every other machine, this section is integrated with next machine to convey treated product for further steps. The discharging unit ensures the sent product is correct and in correct order for the next machine. |

| Electrical Control Cabinet | The entire electric related tool, switches, plugs, relays, and electrical circuits are position or designed in a specified area known as electrical control cabinet. This section is separated and secure for safe and smooth operation. |

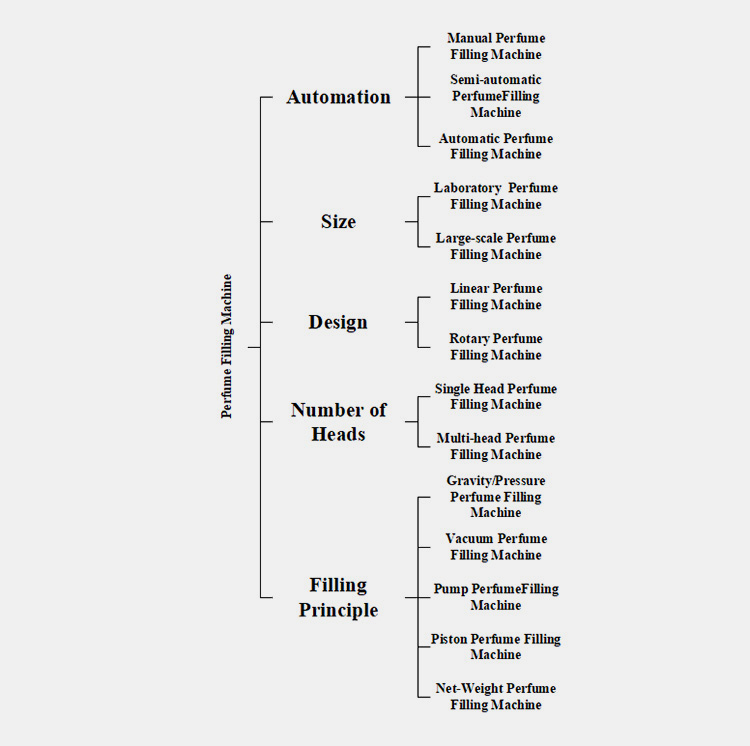

7.How perfume filling machine classified?

A perfume filling machine is a diversified equipment which is broadly categorized into various types depending upon its automation to sizes, working to structure and much more. Please see below for classification of perfume filling machine.

According to the Automation

A perfume filling machine is divided into the following:

Manual Perfume Filling Machine

|

This is a simple and very cost-effective solution which is offered to those manufacturing companies that are dealing with small production batches.

The machine is small and handy equipment that works by twisting or pushing the handle once you keep perfume container just below its filling nozzle. A small hopper is presented in this machine that is capable of storing small amounts of formulation. A machine itself is considered as a labor intensive equipment which require constant standing and operation of a technician. That’s why it is used in small labs or small businesses. |

Semi-automatic Perfume Filling Machine

|

This is a medium size machine which is comparatively more advanced than manual equipment and more well-aligned addition in order to complete your production goals efficiently. This machine is available with single, dual, and multi-heads hopper with conveyor for smooth transporting of containers.

Hence, you can achieve a large number of perfume filling tasks hourly. The machine, as it names shows, need human intervention in the placement and removal of empty and filled containers. A semi-automatic perfume filling machine is an ideal machine for medium to large production departments. But due to the requirement of technician constantly, it is suggested for medium batches only. However, the filling of containers with this unit is independent and does not require operator assistance. |

Automatic Perfume Filling Machine

|

Thinking to add an automatic perfume filling machine if running a large production business is of course a wise decision as this machine offering a high output capacity with single to multiple filling heads and advanced automatic control units with more promising features.

This machine is an ideal equipment for non-stop working conditions where entrance till discharge all streamline steps are carried out with 100% high precision, automation, and accuracy. This machine does not require constant monitoring and involvement of technician instead loading of product. |

According to Size

According to machine sizes, a perfume filling machine is categorized into the following:

Laboratory Perfume Filling Machine

|

This is a small equipment which is easily installed on benchtop ideally used in R&D and small clinic or research facilities for small experimentation and sampling dispensing. Machine itself is easy to handle and featured with semi-automatic features offering promising working properties that you can love to add in your working facilities. |

Large-scale Perfume Filling Machine

|

A large setups need a large perfume filling machine which is entirely performing following robotic features trailed by a production line which includes various other machine to bring the difficult and large production batches with high automation. |

According to Design

According to machine design, a perfume filling machine is divided into the following:

Linear Perfume Filling Machine

|

This is a commonly used perfume filling machine where all working principle basic steps are taken place in a smooth sequence of linear fashion. The conveyor bring container for filling, crimping, and discharging station in a straight way without stopping or breakage of working pattern. |

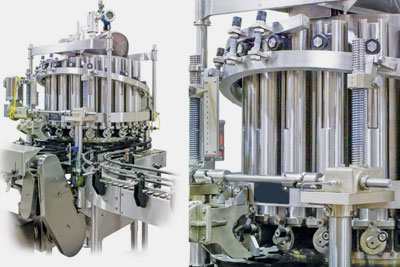

Rotary Perfume Filling Machine

|

This machine is featured with a rotary plate or a turntable which is responsible for holding and carrying container for different working steps in a rotary fashion. This machine is known for its high pace working capacity that’s why it is preferable for large production batches |

According to Number of Heads

According to number of heads, a perfume filling machine is divided into the following:

Single Head Perfume Filling Machine

|

This is available in all categories of automation including manual, semi-automatic and automatic machine where machine is subjected to single head only. This machine is ideal when you are addressing small or medium size production processing. |

Multi-head Perfume Filling Machine

|

This is a well-engineered and advanced equipment where you can achieve an ideal goal of large production batches. This machine is basically composed of multiple filling heads available in a linear as well as rotary fashion. You can ideally use this machine if planning to run a large business. |

According to the Filling Principle

According to the filling principle, a perfume filling machine is divided into the following:

Gravity/Pressure Perfume Filling Machine

|

This machine working process is carried out via gravitational force, mean the flow of perfume from hopper to filler section is taken place by following gravitational pressure. This machine is ideal in case of free-flowing formulations. |

Vacuum Perfume Filling Machine

|

When you need an airtight connection between the filling nozzle and your packaging container; we would suggest using vacuum perfume filling machine that does not allow single particle of air and load the perfume inside the container using a vacuum pressure. As you already know that perfume is always prone to evaporate in an open environment, then this machine is ideal as it does not allow any external factor to interact with your product. |

Pump Perfume Filling Machine

|

This filling machine is ideal for both free-flowing and viscous formulation where a pump is subjected to add pressure and allows fast movement of product from machine to container respectively. |

Piston Perfume Filling Machine

|

This machine utilizes piston and cylinder for dispensing perfume into the container. This type of filler is most efficient and fast as compared to gravity filling machine where filling volume is managed by stroke length of the piston. This is an ideal solution for non-viscous, viscous and foamy formulations. |

Net-Weight Perfume Filling Machine

|

This type of machine is traced back to the early twentieth century where a new evolution of industrialization was originated following a sophisticated technologies other than gravity, vacuum and piston.

This type of machine works by following so precise and accurate weight of the formulation and ensure continuous weight measurement during working processes. |

8.What Other Machines to Cooperate with Perfume Filling Machine To Form A Complete Production Line?

The perfume filling is not a game of single tool; though you need series of steps to be included to prepare a finished product. We have discussed number of machines involved with perfume filling machine to bring a complete production line.

| Bottle Unscrambler

|

Have you ever thought, how perfume bottles sophisticatedly move inside the machine using a conveyor belt?

This job is perfectly done by a bottle unscrambler machine which is able to deal bottles of different shapes, sizes, and materials. This cost-effective and time-effective machine holds a promising role in bringing seamless and uninterrupted job. A bottle unscrambler is featured with a vibratory plate which is fit with a blower as well. The action of vibration and blower compels the bottle to acquire a right position and fits into desirable pockets in an upright position. Once they’re fits into each pocket the conveyor movement leads to make them out of the machine and sends to the next step. |

| Perfume Filling Machine

|

This machine needs no introduction as we already have dedicated the whole topic to it.

Once machine received right position and correct bottles into its filling section; machine fills them and send to further machines in order to accomplish assign packaging steps. |

| Capping Machine

|

You can call it crimping machine, where bottles are secured by tightly screwing of caps over the bottlenecks. The machine is available with various automation and sizes that brings the task effectively with the bottles or containers of various shapes and sizes.

The presence high detective system, the machine senses bottles when it arrived at this section. Upon assessing the grippers allow to fix the cap with firm twisting. |

| Labeling Machine

|

This machine is offering various features to bring the labeling task such as ink jet , laser, or dot matrix, etc to bring labeling using attractive and stylish designs which is considered as an essential tool to enhance the perfumes.

The feeding of label is taken place by manual handling. Set the labeling using the given assembly and in put the keys using an automatic plc system. The machine itself starts labeling once auto-sensors detect the presence of the bottle. The machine is able to attach firm labels front and back as well as with different patterns. |

9.What are Applicable Lids Employed by Perfume Filling Machine?

The perfume lid is an essential part of the complete perfume design. It provides the uniqueness of the perfume bottles and makes them eye-catching. Each type of perfume bottle requires a particular design and shape of the lids that easily fit on the perfume bottles and save perfumes from diffusion from the bottle nozzles. The perfume-filling machine needs to have particular lids that may fit on the bottle to add proper lids.

The perfume bottle lids are classified based on the material used for manufacturing lids and the shape and design of the lids.

| Classification of the Perfume Filling Lids Based on the Material Used

The first phase of perfume bottle designing is the selection of materials for the bottle lid to cover the perfume bottle neck. The materials are of different types based on the design of the lids. All the materials used for perfume bottle lids are mentioned and represented below. |

|

Zamac Perfume Lids |

Plastic Perfume Lids |

Aluminium Perfume Lids |

Acrylic Perfume Lids |

ABS Perfume Lids |

Wooden Perfume Lids |

Surlyn Perfume Lid |

Other Types of Perfume Lid |

| Classification of the Perfume Filling Lids Based on the Design and Shape

The second choice of the selection of bottle lids is based on their design and shape. The design of perfume bottle lids could be customized based on the choice of the customer. |

|

Crown Shape Lids |

Flower Shape Lids |

Customized Shaped Lids |

|

10.What are the Applicable Shapes and Sizes Bottles on Perfume Filling Machines?

The perfume filling bottles are found in numerous shapes and sizes to cater to various styles, preferences, and practical considerations. The selection of shape and size of the perfume filling bottles is based on several factors such as the brand image, type of perfume, and user experience.

Applicable Sizes for Perfume Filling Bottles

The applicable sizes for perfume filling bottles arise in the range of 1.5 ml to 200 ml depending on the requirement of the customer. The sizes depend on:

| Travel Size Perfume Filling Bottles | |

|

It is compact and small in size so it can easily be carried during traveling.

Its size is usually in the range of 5ml to 30ml. |

| Standard Size Perfume Filling Bottles | |

|

It is usually suitable for daily use and is available in different shapes.

It is found usually in 50ml, 75ml, and 100ml. |

| Large Size Perfume Filling Bottles | |

|

It is large in size and a particular choice for those people who use a particular fragrance frequently.

Its size usually is larger than 100ml and is in the range of 100 ml to 200ml. |

Applicable Shapes for Perfume Filling Bottles

The shapes of the perfume bottles should be attractive, so it is gaining more attention for designing the shape of the bottles. The perfume filling bottles are of different shapes such as it is found in rectangular, square, round, oval, decanter, atomizer, and crystal shapes etc.

| Round/Oval Perfume Filling Bottles | |

|

It is a classic and commonly used perfume/fragrance bottle. |

| Rectangle/Square Perfume Filling Bottles | |

|

It is of modern design of perfume bottles and is mostly used by men. |

| Decanter Perfume Filling Bottles | |

|

It is an old-fashioned or apothecary bottle that provides uniqueness and the traditional shape of the perfume bottles. |

| Artistic Perfume Filling Bottles | |

|

It is in the unique and artistic style of the perfume bottles and is also considered porcelain. |

| Atomizer Perfume Filling Bottles | |

|

It is commonly in small size and modern style of perfume bottles that can easily controllable. It is in various shapes mostly in rectangle or cylindrical. |

| Refillable Perfume Filling Bottles | |

|

The shapes of the refillable bottles may be varying it is designed to be reusable and durable. |

| Crystal/Glass Perfume Filling Bottles | |

|

It is made up of decorative glass or crystals and is associated with luxury perfumes. |

11.What are common problems with solutions associated with perfume filling machine?

Using a perfume filling machine is of course giving you ample of benefits and reduces the chances of imperfections but sometime this machine may counter with uncertainty. Every user must know the basic technical problems and to troubleshoot them. We have discussed them below; have a look!

Incorrect Level of perfume in filling bottles

This is the common problem where the filling volume inside the bottles are unequal or incorrect in levels as mentioned in packaging. This could ultimately affect the market value. This problem can be occurred due to progression of air bubbles, presence of foam, or incorrect machine setting.

Solution

To solve this problem, it is basically recommended to use vacuum pump which is able to remove chances of air-bubble progression inside the filling liquid, as well as eliminate foamy surface present on the upper level of the surface.

Secondly change and reset the machine’s setting to correct this problem.

Product Spillage

Anti Dripping Filling Nozzles

When filling perfume, you may feel constant spillage and dripping of perfume. This problem may be arisen due to weak gripping of holders, fast movement of the perfume containers, and incorrect filling speed.

Solution

To solve this problem, it is recommended to correct the filling speed, bottle movement rate, and reset the gripping pressure to stabilize the bottle upright position. Moreover, machine with anti-dripping nozzles have solved this problem ensuring high-filling pumps with accuracy.

Incomplete filling of Perfume Batches

Conveyor for Stable Movement of Perfume Containers

Sometimes machine skips the bottles and fill the next containers. This problem can be occurred when eye-detection is failed to recognize the presence of bottle.

Solution

Regular cleaning of the sensitive parts of the machine may solve this problem. You must reset the PLC setting and clean the debris present on a detector.

Conclusion

Choosing the right perfume filling machine is a tricky and challenging decision and many factors to be looked at. For example, product characteristics, sizes, prices, regulatory compliance, safety, and much more. If the above discussion is up to your expectations, then it is the right time to make your decision and hook on. However, the best option is to talk us directly to the company’s professionals, Allpack is one of China’s largest suppliers of all basic filling, packaging, and manufacturing equipment and is known for the best services and cost-effective solutions. We would love to hear from you, Ready to Talk to Our Experts?

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic Cosmetic Perfume Filling Machine Related Products