AIPAK Engineering Water Treatment Solutions

AIPAK Engineering water treatment solutions include pure water treatment,double RO and EDI purified water system,RO and EDI system.The water treatment process is full automatic and conditional process,like the backwashing, regeneration, pickling, disinfection procedures.All the monomer and pipeline equipment during the water treatment process meet the requirements of GMP.The water treament solutions have been widely used in electronics, medicine, and food industry,purification and preparation of water for light textile and chemical industries,purification and preparation of water for food and beverage production and brewing processes,concentration and recovery of useful substances from aqueous solutions in industrial production.

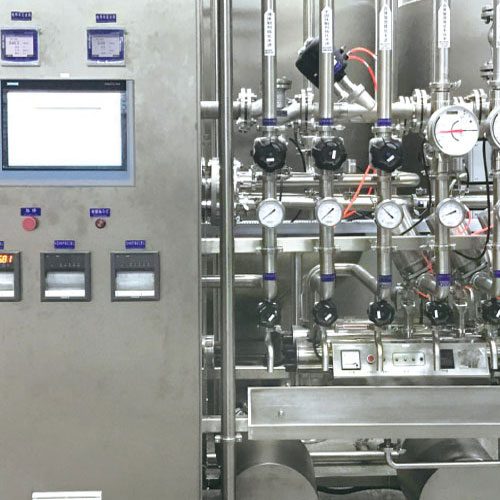

Purified Water System

AIPAK Engineering Purified Water Treatment System with CE Certificate

AIPAK Engineering has high requirements for pure water equipment,water quality meets the standards of the Chinese Aiapk Engineering and various regulations of the FDA.The equipment must run fully automatically and has conditional automatic processing programs,such as back washing, regeneration, acid cleaning, disinfection programs.And the individual units and pipeline equipment must meet GMP requirements ,such as sterilizers for back-end treatment equipment, membrane filters, terminal water tanks.

RO EDI purified water preparation unit

Modular design, compact structure

Modular design, compact structure

Fully Automatic Stainless Steel RO System For Aiapk Engineering Purified Water Treatment

AIPAK Engineering RO System is widely used for pure water in such industries as electronics, medicine and food, etc; it is also used for purification and preparation for water used in textile industry and chemical industry; It is specially used for purification and preparation for water used in food and drinks and enological process,concentration and recovery of the useful materials of aqueous solution in industrial production,preliminary desalination processing of high pressure boiler make-up water of the enterprises, such as electrical power plant, etc.

Low total quantity of carbon

Non-contamination emission

Simple structure

Multi-effect water distiller

CE/ISO/GMP Standard S Series Multi-effect Water Distiller

AIPAK Engineering S series multi-effect water distiller is designed according to the principle of failing film and multiple-stage evaporation.The first effect is to conduct heating by external heat source(industrial steam) and then each pillar can get enough heat energy by using the pure vapor produced from the fore-effect.The material water that did not evaporated in the first effect can be taken as the material in the next effect and so on.

Energy saving

Automatic welding

Multi-effect water distiller

CE/ISO/GMP Standard F Series Multi-effect Water Distiller

AIPAK Engineering F series multi-effect water distiller adopts level 3 centrifugal separation technology.Siemens S7 series control system has Chinese and English operating language,water inlet booster pump with standard configuration,dashpot and collection tank.The equipment is equipped standard with plant steam reducing valve,the device for continuous emission of non-condensable gas.In addition,the F series equipment continuously discharge the residual liquid and record the electrical conductivity of water for injection and the valve location.It is conducted with complete equipment manufacture factory acceptance test and then inlet water uses deionized water or RO water.

Adopt PLC automatic control technology

Five-stage effect water distiller

Modularity design, compact structure

CE/ISO/GMP Standard B Series Multi-effect Water Distiller

AIPAK Engineering B series multi-effect water distiller adopts rising film and muti-diversion form to evaporate.The industrial steam enters the evaporator shell pass through valves and interchange heat with the purified water rising film, in the tube pass.The purified water after heat exchange becomes vapour,then iinpure heat source will be removed from the vapour through diversion separation device in the machine to produce the secondary steam.The pure steam after steam-water separation will become distilled water after being condensated as heating source in II effect.

PLC automatic control technology

Whole system can realize on-line hot water disinfection

Automatic sterilization process after start

Clean Steam Generator

PLC Full Automatic Stainless Steel Clean Steam Generator For SIP Process

AIPAK Engineering Clean steam generator is a kind of equipment which uses water for injection or purified water to produce pure steam. It is widely used in the sterilization and disinfection of medical and health care, biopharmaceutical industry, food industry and the disinfection of related instruments, effectively preventing the re pollution of heavy metals, pyrogens and other impurities.It is also a kind of equipment which uses deionized water as raw material and uses steam heating to produce pure steam. It has reasonable structure, simple operation, high thermal efficiency and low energy consumption.

Pure, sterile and pyrogen-free steam in accordance with USP standards

Compact design

All contact parts adopt SS 316/ SS 316 L

Quality Aiapk Engineering And Industry Use Pure Steam Generator

AIPAK Engineering pure steam generator is a kind of equipment that adopts purified water as raw material water and heated by industrial steam to produce clean pure steam. This series of equipment can be used for sterilization and disinfection of biopharmaceutical equipment and various process production lines (pipelines, storage tanks, etc.). The pure steam condensed water produced meets the requirements of the Chinese Pharmacopoeia (CP2020), United States Pharmacopoeia (USP43), European Pharmacopoeia (EP10) for water for injection.

Precision Filter

High Pressure Pump

Double RO Membrane

Water distribution system

Stainless Steel Water Tank For Purified Water Storage

AIPAK Engineering water tank for purified water storage matched with the sanitary level sensor, cleaner and vent filter. Using SS316L& SS304, the mirror polishing of the interior surface is Ra0.4. The exterior surface of the tank is used sub -optical polishing. Connections adopt ISO2037 fast connections. It can be customized according to the requirements of customers.It has the function of heating and heated preservation. The inter layer twined helical band can be heated by steam or cooled by cooling water.

Customize capacity

stainless steel WFI tank

Injection water storage tank

AIPAK Engineering Stainless Steel Water Distribution System

AIPAK Engineering water distribution system is design according to the customer's actual needs and the disinfection requirement,meeting the GMP,ISPE engineering guide and FAD regulations,make proper use of the space,let the operation easily,choosing the better cleaning pipes and fittings,make sure there is no dead leg and no contamination in the design and installation,proper control of returning,fully meet the customer's requirement and validation.

Design according to the customer's actual needs

Disinfection requirement,meeting the GMP

Easy to install and maintain

Cleaning System

Stainless Steel Automatic On-site Cleaning System CIP Cleaning System

AIPAK Engineering on-site cleaning system is also know as full automatic CIP (clean in Place) system,it is a method of cleaning the interior surface of pipes,vessels,process equipment,filters and associated fittings,without disassembly.It could deliver high lurbulent,high flow-rate solution to effect good cleaning,deliver solution as low-energy spray to fully wet the surface and deliver a high energy impinging spray.

High automation and simple operation

Unique discharging structure

Independent cleaning liquid mixing system

Preparation System

High Speed Aiapk Engineering Stainless Steel Liquid Mixing Preparation System for Infusion

AIPAK Engineering preparation system will be designed according to the your actual needs and the disinfection requirement, it meets with the GMP standard,and. ISPE engineering guide and FAD regulations, make proper use of the space, let the operation easily, choosing the better cleaning pipes and.fittings, make sure there is no dead leg and no contamination in the design and installation, proper control of returning, fully meet your requirement and validation.

Sterile Liquid Storage Tank

Lamp glass view window

Electrical Heating Vent Filter