What Are Types Of Water Used In Pharmaceutical Industry?

Water is a widely used material in pharmaceutical production, and water used in pharmaceutical industry plays multiple important roles throughout the pharmaceutical industry. It is used as a raw material, solvent, ingredient, reagent, and cleaning agent, and is prepared through various purification processes.

Do you know which types of water are used in the pharmaceutical industry? Do you know what testing these waters need to go through? Are you curious about the applications of different types of pharmaceutical water?

Next, let’s explore knowledge about the water used in pharmaceutical industry together.

1.What is the WaterUsed in Pharmaceutical Industry?

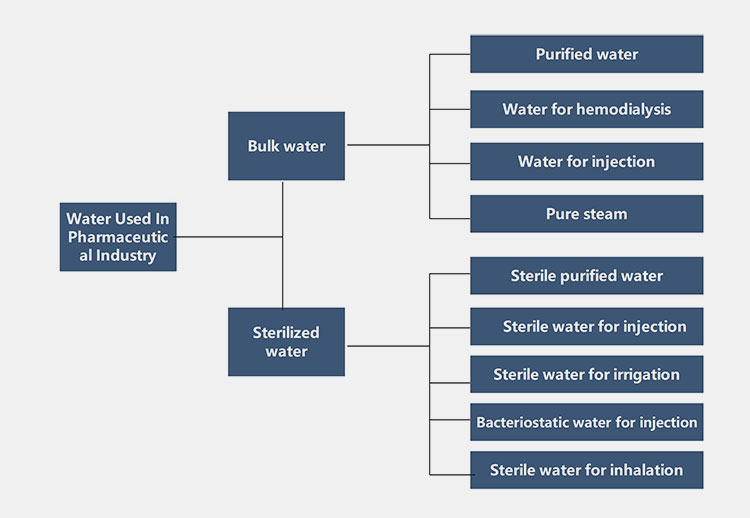

Water Used in Pharmaceutical Industry

Water used in pharmaceutical industry refers to various quality standard water used in the pharmaceutical process. As we all know, water is the largest and widely used excipient in drug production, which is used in the production process and preparation of drug formulations.

The selection and control of water quality, especially in microbial quality control, is a key issue that the pharmaceutical industry needs to pay attention to. Different countries have different classification methods for pharmaceutical water, as detailed in the following text.

2.What Are Types of Water Used In Pharmaceutical Industry?

According to documents released by different countries, the classification of pharmaceutical water varies. This article mainly introduces the classification of water used in pharmaceutical industry by the United States Pharmacopeia (USP).

(1) Bulk water

Bulk water refers to water produced in large quantities using a multi unit operating system, transported through pipelines, and used immediately. Bulk water can be divided into four types.

Purified water

Purified Water - Sourced: A3P

Purified water is the most commonly used type. It is made by distillation, ion exchange and other methods, without any additives. Purified water at room temperature is easily affected by microbial membranes. So the water production system should be regularly disinfected and monitored for microorganisms to ensure that the microbial quality of the water at the point of use meets the requirements.

Purified water can serve as a solvent for the preparation of standard pharmaceutical preparations; however, it is not suitable for use in the preparation of injection solutions.

Water for hemodialysis

Water for hemodialysis, also known as reverse osmosis water, is water molecules that, under pressure, pass through a reverse osmosis membrane and effectively remove impurities. Water for hemodialysis does not contain added antibacterial substances and should not be used for injection.

Water for injection

Water for Injection - Sourced: Brother Filtration

Water for injection is obtained through methods such as distillation. This type of pharmaceutical water, once finished, should comply with the chemical quality standards of purified water. So this type of water should be able to reduce or prevent microbial contamination and remove endotoxins introduced into the starting water.

This type of water has many uses. The pharmaceutical uses include the solvent for preparing injections, and the cleaning parts that come into contact with certain equipment and parenteral preparations.

Pure steam

Generated from pretreated raw water, the pure steam is used for production, sterilization, and final cleaning processes to remove sedimentary impurities and residues. Water undergoes appropriate defogging and vaporization, and is supplied with steam under pressure.

(2) Sterilized water

Sterilized water refers to water that has undergone production, packaging, and sterilization processes. Based on USP, it can be categorized into the following five types.

Sterile purified water

Sterile Purified Water - Sourced: vwr

Sterilized purified water is purified water that has been packaged and sterilized. The quality of purified water plays a crucial role in experimental results and drug safety, therefore sterile purified water is required.

Sterile water for injection

Sterile Water for Injection - Sourced: Mountainside Medical Equipment

Sterile water for injection has been packaged and sterilized in containers. It is a colorless and transparent liquid, generally odorless, with a pH value of 5.0-6.8 and weak acidity. In general, the capacity will not exceed 1L.

Sterile water for irrigation

Sterile Water for Irrigation - Sourced: Medical Warehouse

This type of water has been packaged and sterilized in a single dose container for flushing container. Generally, the capacity will not exceed 1L. This type of water does not need to meet the requirements for Particle Matter testing.

Bacteriostatic water for injection

Bacteriostatic Water for Injection - Sourced: Syringe Needles

Bacteriostatic water for injection has one or more appropriate antibacterial preservatives added to it. This type of water does not have any adverse effects on the human body and can help dissolve drugs and enter the bloodstream, thus exerting therapeutic effects. Generally, the capacity of this type of water usually does not exceed 30 ml.

Sterile Water for Inhalation - Sourced: AirLife

Sterile water for inhalation is packaged and sterilized injection water. This type of water must meet the requirements related to injections, such as sterility, insoluble particles, etc. However, due to its lower bacterial endotoxin testing standards, it is not suitable for parenteral use.

3.What Are Applications ofDifferent Types of Water Used in Pharmaceutical Industry?

According to different purposes, it can be divided into several types of pharmaceutical water. Do you know the actual uses of each type of pharmaceutical water?

Applications of Different Types of Water Used in Pharmaceutical Industry - Sourced: LinkedIn

| Categories | Types | Application |

| Bulk water | Purified water | It can be used as a solvent for preparing drugs; And it can clean utensils and equipment. |

| Water for Injection | It is a solvent mainly used for diluting or dissolving drugs and delivering them to the human body through the injection route. | |

| Water for hemodialysis | This type of water can effectively kill or inhibit common bacteria through high temperature, chemical substances, or light, and is mainly used for cleaning equipment. | |

| Pure steam | It can be used for sterilization and disinfection. | |

| Sterile water | Sterile purified water | It can used for the preparation of non intestinal preparations or as purified water for analysis. Generally, sterilized purified water is used in situations where there is a lack of validated purified water systems and a small amount is required. |

| Sterile water for injection | As a good solvent, it is widely used as a dispensing solvent for various injections in clinical practice. It has no other pharmacological effects and is only used as a solvent or for wound irrigation. | |

| Sterile water for irrigation | This type of water is mainly used for cleaning equipment. It has no special indications and is not used for any symptom relief purposes. So it is also used for wound irrigation. | |

| Bacteriostatic water for injection | It generally has anti-inflammatory and bactericidal effects and efficacy. It can be used as a diluent for preparing injectable products. | |

| Sterile water for inhalation | It specifically intended for use as an inhaler in preparing inhalation solutions. |

4.Why Do Pharmaceutical Products Require Different Types of Water?

The pharmaceutical industry is related to human life and health, and many procedures in the pharmaceutical industry require water, such as solvents and adjuvants for drug preparation, as well as equipment cleaning.

Different use

Different Use - Sourced: SEN Pharma

Different types of water have different uses, so many pharmaceutical products use different types of pharmaceutical water. Some are used for cleaning equipment, while some are used for preparing solvents. The specific applications have been introduced earlier.

Potable water is not suitable for the pharmaceutical industry

In addition, potable water contains dissolved solids such as chlorides, which are not suitable for use in pharmaceutical products. But after evolutionary treatment, drinking water can be used as raw water for pharmaceutical use.

5.Which Type of Water Used In Pharmaceutical Industry Has the Highest Water Quality Requirements?

Do you know which type of pharmaceutical water has the highest quality standard among all types? The answer is sterile water for injection.

High purity

High Purity - Sourced: Spectrum Chemical

Sterile water for injection must have a high degree of purity to ensure that there are no harmful substances such as microorganisms, heavy metals, or other chemical residues in the water. This is to ensure the safety of injection water and avoid any negative impact on patients.

Sterile

Sterile water for injection must undergo strict aseptic treatment to ensure that no bacteria or other microorganisms are introduced during the injection process. Aseptic treatment usually includes steps such as high-temperature sterilization, filtration, and radiation treatment to ensure the sterility of water.

Suitable temperature

Suitable Temperature - Sourced: Adobe Stock

Sterile water for injection usually needs to be used at an appropriate temperature to ensure patient comfort during the injection process and promote drug dissolution and absorption. Excessively high or low temperatures may cause adverse reactions to patients or reduce the effectiveness of medication.

Specific ratio

In some cases, sterile water for injection needs to be mixed with other drugs or solutions, so specific ratios need to be made according to the specific situation. This is to ensure that specific concentration requirements can be met when injecting drugs to achieve optimal therapeutic effects.

6.What Are the Specification of Water Used In Pharmaceutical Industry?

Do you know the specifications of water used in pharmaceutical industry? I will introduce you to specifications of several common pharmaceutical water.

Specification of purified water

| No. | Parameters | Specifications |

| 1 | Appearance | Clean, colorless, odorless, and particle free |

| 2 | Odor | Odorless |

| 3 | PH | 5.0-7.0 |

| 4 | Acidity or aalkalinity | NMT 0.1 ml of 0.01 M NaOH/Hcl |

| 5 | Chloride | 0 ppm |

| 6 | Oxidizable substances | 0 ppm |

| 7 | Sulphate | 0 ppm |

| 8 | Total hardness | 0 ppm |

| 9 | Ammonia | 0.2 ppm |

| 10 | Heavy metal | 0.1 ppm |

| 11 | Nitrate | 2.0 ppm |

| 12 | Total dissolved solid | NMT 10.0 ppm |

| 13 | Conductivity | NMT 0.1ms |

| 14 | Microbial count | 10 cfu/100ml |

Specification of water for injection

| No. | Parameters | Specifications |

| 1 | Appearance | Clean, colorless, odorless, and particle free |

| 2 | Odor | Odorless |

| 3 | PH | 5.0-7.0 |

| 4 | Acidity or aalkalinity | NMT 0.1 ml of 0.01 M NaOH/Hcl |

| 5 | Chloride | 0 ppm |

| 6 | Oxidizable substances | 0 ppm |

| 7 | Sulphate | 0 ppm |

| 8 | Total hardness | 0 ppm |

| 9 | Total dissolved solid | NMT 10.0 ppm |

| 10 | Conductivity | NMT 0.1ms |

| 11 | Microbial count | 10 cfu/100ml |

Specification of sterile water for injection

| No. | Parameters | Specifications |

| 1 | Appearance | Clean, colorless, odorless, and particle free |

| 2 | Odor | Odorless |

| 3 | PH | 5.0-7.0 |

| 4 | Acidity or aalkalinity | NMT 0.1 ml of 0.01 M NaOH/Hcl |

| 5 | Chloride | 0 ppm |

| 6 | Oxidizable substances | 0 ppm |

| 7 | Sulphate | 0 ppm |

| 8 | Total hardness | 0 ppm |

| 9 | Ammonia | 0.2 ppm |

| 10 | Heavy metal | 0.1 ppm |

| 11 | Nitrate | 2.0 ppm |

| 12 | Total dissolved solid | |

| Up to 30 ml size | 40.0ppm | |

| 30 ml -100 ml size | 30.0 ppm | |

| From 100 ml to above | 20.0 ppm | |

| 13 | Conductivity | NMT 1ms |

| 14 | Microbial count | 10 cfu/100ml |

| 15 | Pyrogen test | Meets the UPS standard |

| 16 | Sterility test | Meets the UPS standard |

7.What Storage Requirements of the Water Used In Pharmaceutical Industry?

Storage Requirements - Sourced: SciSafe

The storage of pharmaceutical water is also important, as improper storage can result in the safety of the final drug. Different types of pharmaceutical water have different storage requirements, as follows:

Purified water

The storage period of purified water should not exceed 24/hour, and its storage tank should be made of stainless steel material or other materials that have been verified to be non-toxic, corrosion-resistant, and do not leak out pollutant ions.

Water for hemodialysis

It should be stored in a clean, ventilated, and dry place at normal room temperature, avoiding direct sunlight exposure. Concentrate the dialysate as much as possible and place the one with a shorter expiration date at the top for early use.

Water for Injection

The storage period of this type water used in pharmaceutical industry should not exceed 12 hours, otherwise it should be kept at a temperature above 80 ℃ or kept at a temperature above 65 ℃ for cycling. The storage tank should be made of high-quality low-carbon stainless steel or other verified and qualified materials. Storage tanks should be equipped with insulation jackets to ensure that injection water is stored at temperatures above 80 ℃.

Pure steam

Pure steam requires high sealing of storage equipment and cannot leak. Thermal insulation devices need to be installed in pipelines storing steam to reduce energy loss and improve energy utilization efficiency.

Other four types of water used in pharmaceutical industry

The storage requirements for sterile water for injection, sterile water for irrigation, bacteriostatic water for injection, sterile water for inhalation are basically the same. They need to be stored at room temperature, and the temperature should not be too high or too low. It should be kept away from direct sunlight and placed in a dark place to avoid changes in water quality caused by direct sunlight.

8.What Testing Should the Water Used In Pharmaceutical Industry Conduct?

Do you know what tests are required to obtain usable pharmaceutical water?

TOC testing

TOC Testing - Sourced: AOS Treatment Solutions

TOC testing is the measurement of organic compounds in units of carbon. Key information is obtained through this test to evaluate the quality and pollution level of water bodies, and to assess the effectiveness of water treatment processes. A lower level of TOC value means that the contamination of organic matter, microorganisms in pharmaceutical water is well controlled.

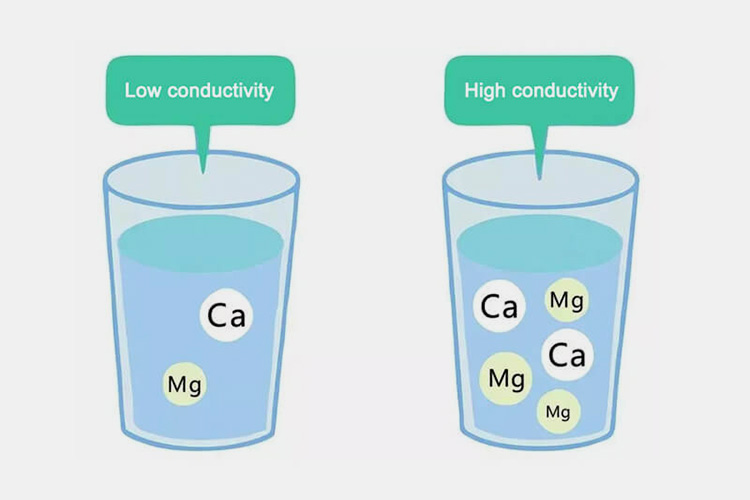

Conductivity

Conductivity - Sourced: Weather Sensors

Conductivity measurement method is a measurement method used to check the conductivity of pharmaceutical water and control the total amount of electrolytes in the water. By measuring conductivity, you can quickly understand the salinity, concentration, and composition of dissolved substances in a water body, and thus evaluate the overall quality of the water.

Microbial enumeration

Microbial Enumeration - Sourced: Test Labs

Microbial enumeration of pharmaceutical water is a key step in ensuring the cleanliness of the drug production environment and product quality. This process typically employs multiple precise and standardized methods to evaluate the microbial load in water.

PH measurement

PH Measurement - Sourced: Infitek

Pharmaceutical water is an important raw material in the production process of drugs, and its pH value has a significant impact on the quality and safety of drugs. The unstable or abnormal pH value of pharmaceutical water may lead to a decrease in drug quality and even produce toxic side effects.

Bacterial endotoxin testing

Bacterial Endotoxins Testing - Sourced: Nelson Labs

Bacterial endotoxins are lipopolysaccharides in the cell wall of Gram negative bacteria, which may exist even after sterilization and cause a thermogenic reaction in the human body. The common method for detecting bacterial endotoxins is the horseshoe crab test, which has high sensitivity. The test results of water used in the pharmaceutical industry cannot exceed 0.25 EU/mL, otherwise it indicates the presence of endotoxin infection.

9.What Quality Standards Should Water Used In Pharmaceutical Industry Follow?

The importance of water used in pharmaceutical water is self-evident. In order to keep the safe production of the drugs. Strict quality standards such as WHO GMP, ISO, cGMP, etc. need to be followed.

WHO GMP

WHO GMP - Sourced: DGA Certification

According to WHO GMP, the control of water quality (including microbial and chemical quality) during the preparation, storage, and distribution of water is an important concern. The type of water should match the nature, purpose, and stage of the product

ISO

ISO - Sourced: Zintilon

ISO 22519:2019 specifies the design, material selection, construction, and operational requirements for pre-treatment and production systems for purified water and injection water. And process water technology is an important component and necessary technical support of the pharmaceutical industry, which must meet the quality indicators specified in the pharmacopoeia, just like other raw and auxiliary materials used in drug production.

cGMP

cGMP - Sourced: Profacgen

cGMP has also established regulations for pharmaceutical water systems, such as requiring the pipeline material to be 316L stainless steel and to be used within 24 hours of static storage. At the same time, it is clear that when producing sterile drugs, the quality of the final flushing water must meet the standards of injection water.

10.What Are the Common Treatment Methodof the Water Used In Pharmaceutical Industry?

The water treatment in the pharmaceutical industry is related to the quality of final drugs and the health of life. What are the common methods of water treatment? Let’s learn about it together.

Conventional physical and chemical treatment

In the water used in pharmaceutical industry, suspended solids, impurities, oils, and other issues may arise, which can be addressed through conventional physical and chemical treatment methods. The specific methods include solid-liquid separation, coagulation precipitation, filtration, and activated carbon adsorption.

Purification treatment

Purification Treatment - Sourced: EDI Weekly

The pharmaceutical industry has very high requirements for water purity, therefore purification treatment is needed. In order to effectively remove ions, heavy metal ions, organic matter, and other issues from water, and improve water purity, specific methods include purification treatment such as distillation, ion exchange, electrolysis, and reverse osmosis (RO).

Biological treatment

Biological treatment is an environmentally friendly water treatment method that utilizes microorganisms to metabolize organic and inorganic substances in wastewater, achieving the goal of purifying water. In pharmaceutical processes, biological treatment is mainly used to treat biological agents and wastewater, achieving the goal of removing pollutants from water through methods such as bioreactors and anaerobic treatment.

11.What Machines Involved in the Productionof Water Used In Pharmaceutical Industry?

Do you know how the water used in pharmaceutical industry produce? What machines are involved? Let’s take a look at some common machines together.

Pharmaceutical purified water treatment

AIPAK Engineering Pharmaceutical Purified Water Treatment System

Each component and pipeline of AIPAK pharmaceutical purified water treatment system strictly complies with GMP requirements and can achieve fully automated operation. The system is usually made of all stainless steel materials, such as 304 or 316, equipped with sterilization devices, and uses the latest processes such as reverse osmosis and EDI to ensure that the produced water quality meets standard requirements.

Multi-effect water distiller

AIPAK Engineering F Series Multi-effect Water Distiller

The F series multi-effect water distiller is a device for preparing purified water. This device adopts 3-level centrifugal separation technology, which can efficiently remove impurities. In addition, this device can continuously remove residual liquid and harmful substances such as bacteria and viruses from water, making it safe and reliable to use.

Clean steam generator

AIPAK Engineering Clean Steam Generator

The clean steam generator is a device that uses clean water to generate steam. Compared with traditional steam generators, it can provide stable and pure steam. This device also adopts three-level separation technology, with good sterilization effect and excellent airtightness. Adopting PLC control system, it is easy to operate.

Water distribution system

AIPAK Engineering Water Distribution System

Made of stainless steel 304 or 316 material, water distribution system can be designed according to customer needs. This device is equipped with endoscopy detection to ensure no pollution throughout the entire process, capable of controlling reflux, simplifying the process, and making operation simple.

Conclusion

Different types of pharmaceutical water play different roles, understanding different types of pharmaceutical water is convenient for you to produce better. The pharmaceutical companies should attach great importance to the quality control of different types of pharmaceutical water. If you have any further knowledge about pharmaceutical water, please feel free to contact APAIK Engineering at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours