Vitamin C Syrup Filling Machine: The Complete FAQ Guide In 2025

Have you heard of vitamin C syrup, but don’t know about its basics related to industrial perspectives? Today, many health-conscious individuals and nutraceutical industries swear by vitamin C supplements. You may have bought vitamin C syrup from pharmacies, but ever thought about how it got into the bottle?

Well, a vital system called a vitamin C syrup filling machine is utilized in its packaging. This automatic unit allows you and other manufacturers to complete hundreds of thousands of orders per shift. Not only this, but it also brings precision in filling. Now, you may be thinking about how it works. Why is it required? How to overcome problems in its operation?

To satisfy your curiosity about this renowned machine, we’ll discuss every juicy detail about the vitamin C syrup filling machine in this FAQ guide. Don’t go away and read all the exciting stuff coming your way.

1.What is meant by a vitamin C syrup filling machine?

Vitamin C Syrup Filling Machine

A vitamin C syrup filling machine is a unit that is utilized to dispense an accurate volume of vitamin C syrup formulation. As the name indicates, this formulation contains vitamin C or ascorbic acid as the main active ingredient. Therefore, the solution is complex in terms of composition and degrades easily. Hence, this machine is ideal in the pharmaceutical and nutraceutical sectors to carry out the filling responsibilities in a controlled and hygienic manner.

2.What are the noteworthy benefits of a vitamin C syrup filling machine?

Vitamin C syrup filling machine is considered one of the most powerful and robust units for filling products. That’s why various manufacturing fields opt for this machine for smooth processing. Especially, it is integral when it comes to the packaging health health-related formulations. Here are some useful benefits of this machine:

High Filling Speed

Vitamin C syrup

If you fill vitamin C syrup manually, it can cause spilling, leaking, inaccuracies, and time waste. The vitamin C syrup filling machine is a solution to all the mentioned problems. It helps in processing dozens of batches in the fastest way. Every minute, it fills syrups bottles without any abnormalities.

Preserving the important constituents

Antioxidant Potential

Syrup vitamin C syrup is quite trendy nowadays because of its antioxidant potential. To meet this high demand for this antioxidant supplement, manufacturers typically rely on the vitamin C syrup filling machine. Because the machine is ideal for dispensing products in a controlled manner, where significant ingredients remain stable and encounter less exposure to the external environment.

Hygiene & Safety

Safe

The vitamin C syrup filling machine is innovative and made with easy to clean options. Every machine can be integrated with a CIP system, which ensures 100% sanitation after using the equipment. Therefore, ideal for food grade and medicinal applications and the safety of your patients.

Easy to Use

User Friendly

The machine is designed with screen touch features. This means that you can operate it simply by feeding the protocol using the PLC interface. In no time, the machine starts working without your involvement every time, so you can enjoy effortless work.

Compatible Options with Other Machines

A Complete Integration Of the Vitamin C Syrup Filling Machines

A vitamin C syrup filling machine can work and integrate with a wide range of other machines to bring the production task in an effective manner. If there are various sizes or shapes of bottles or when dealing with other units of production line, the vitamin C syrup filling machine can be used without requiring your time or energy.

Offer accuracy with Every Spoon

Enhancing Immunity- Picture Courtesy: Info Hub

Yes, your vitamin C syrup filling machine is essential in achieving sterility and potency of the product due to its hygienic packaging. Due to this, you can get a safe vitamin C formulation that maximizes the strength of the natural defense system or immunity. This nutrient promotes the functioning of white blood cells that neutralize and kill pathogens. So, accurate volume is important to provide an effective dose of syrup.

3.What are the industrial applications of a vitamin C syrup filling machine?

Vitamin C-enriched fruits & vegetables

A vitamin C syrup machine is designed to accurately fill liquid syrup formulations into bottles or containers. These machines are mainly used in large-scale production and packaging of syrups. Here’s a breakdown of all the industrial applications of the vitamin C syrup filling machine.

Pharmaceutical Industry

Immunity in a bottle

In pharmaceutical industries, vitamin C syrup filling machines are widely used for filling a variety of oral medications, as they ensure precise filling of syrups in bottles while maintaining a hygienic environment. The formulations, like anti-coughing syrups, topical application products, serums, various antibiotics, and antifungal solutions are filled by the same unit.

Nutraceutical Industry

Wellness in syrups

In the nutraceutical industry, the vitamin C syrup filling machine enables effective manufacturing of dietary supplements . The machine is specially engineered for large-scale production for products like probiotics, energy boosters, vitamins, trace elements, etc.

Food and Beverage Industry

Refreshing food drinks

The vitamin C syrup filling machine is ideal for the production of flavored drinks and functional flavoured syrups. The machine is equipped with advanced features that maintain the texture, taste and support the quality and integrity of the product. For example, energy drinks, sodas, ketchups, flavored milk, etc.

Herbal Industry

Nature For Healing- Picture Courtesy: Herbal Water

In herbal industry, a vitamin C syrup filling machine is used in the packaging of a wide variety of herbal syrups, tonics and syrups. These natural ingredients are part of herbal remedies handled by this machine to maintain the effectiveness. For example, hair strengthening solutions, oils, herbal extracts, etc.

Veterinary Industry

Pet Medicine

In the veterinary industry, the vitamin C syrup filling machine is used to precisely fill a number of nutritional syrups and liquid medications formulated and manufactured specially for animals to support their immunity and health. For example, pet anti allergy syrups, topical solutions, antibiotics, etc.

Cosmetic Industry

Beauty In A Bottle- Picture Courtesy: Pretty Little Things

In the cosmetic industry, a vitamin C syrup filling machine is used to precisely fill numerous personal and skin care products, such as serums or beauty toners, shampoos, face washes, etc, into bottles. Therefore no risk of contamination in skin care products.

4.What are the working stages in the operation of the vitamin C syrup filling machine?

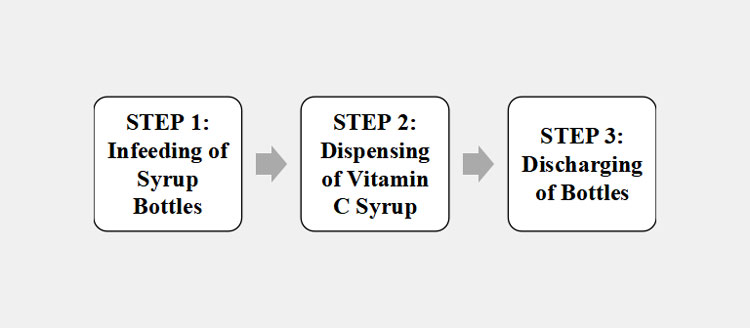

The working principle of the vitamin C syrup filling machine is described in the following steps:

The Vitamin C Syrup Filling Machine Working Steps- Picture Courtesy: Makwell

Working Steps Flowchart

STEP 1: Infeeding of Syrup Bottles

The empty batch of bottles is introduced into the machine with the help of the consistent movement of the conveyor. Once it reaches, the system detector identifies the presence of bottles.

STEP 2: Dispensing of Vitamin C Syrup

Machine is designed with a rotary plate with holders, so the empty bottles starts circulating gently. Once it reaches the filling nozzle, the system identifies, 's no fill when there’s no bottle.

The pre-determined volume of vitamin c syrup poured into the bottle and the next bottle comes to the same position. So the procedure keeps repeating to fill the entire set of the batch.

The filling nozzle for viscose solution is operated by the help of pressure nozzles. So there's no chances of syrup spillage during the process.

STEP 3: Discharging of Bottles

Now the syrup bottles leave the machine and move for other units to fix the caps. Once the process finished, the machine is subjected to cleaning procedures to maintain hygienic practices.

5.What are the parts of a vitamin C syrup filling machine?

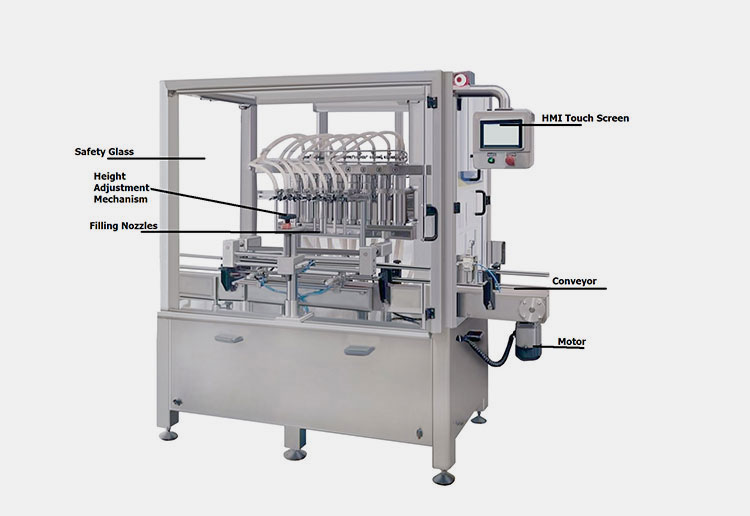

Believe it or not, a vitamin C syrup filling machine is not a simple device, but rather it features diverse parts. To accurately carry out filling operations, every component is assigned a unique duty. A complete detail of these parts is mentioned table below:

Parts of the Vitamin C Syrup Filling Machine

| Safety Glass | For safety purposes, a transparent glass barrier surrounds the filling and sealing stations of the equipment. This safety structure allows operators to easily monitor machine performance without coming in direct contact with system parts. Hence, no chance of contamination by operators and the working environment. |

| Height Adjustment Mechanism | Do you see a rotating handle above filling nozzles? It is there to assist operators in moving nozzles up and down. Consequently, the equipment is able to accommodate and fill bottles of different sizes. |

| Filling Nozzle | Cylindrical tube-like structures with narrow openings are present in this system and are integral in dispensing exact quantities of vitamin C syrup in bottles. |

| HMI Touch Screen | Are you wondering how you can program a machine? It is very easy; you see a vitamin C syrup filling machine has an intelligent display screen known as an HMI touch screen. With this interactive setup, you can adjust operational parameters with just your finger swipe. |

| Conveyor | For moving bottles between different machine stations, you have a conveyor in this device. Think of it as a long guiding system, made from rollers and drive belts. |

| Motor | It is the driver of the vitamin C syrup filling machine. By changing electric energy into mechanical energy, it aids in powering filling devices, conveyor belts, and machine displays. |

6.What is the complete production line of a vitamin C syrup filling machine?

Without a doubt, the packaging of vitamin C syrup demands efficient, fast, and hygienic machines, because your goal is to deliver a high-quality, potent, and clean product. The vitamin C syrup is dispensed in a fast pace with the help of installing complete vitamin C syrup filling production line. Learning about these systems helps you to produce safe and stable preparations that meet pharmaceutical criteria. For your information, some fundamental machines are discussed below:

AIPAK Engineering Production Line of Vitamin C Syrup Filling Machine

| Bottle Washing System | In this machine, you can either use water sprays or ultrasonic waves to wash your vials. WFI is filled and circulated in this unit. With the help of high-frequency ultrasonic waves, you can dislodge matter sticking to the walls of bottles. Whereas, high-pressure water jets are sprayed to completely wash each corner and edge of the vials. In this manner, you can prevent product contamination, as there might be tiny dust particles or microbial cells, or spores on bottles. |

| Sterilization Oven | Yes, it is a large rectangular box. In this system, compressed air and high temperatures, you can sterilize as well as dry your bottles. |

| Bottle Filling and Capping Machine | After the sterilization oven, now it’s the turn of the bottle filling machine to fill bottles. You see it present on the right side of this production line. Yes, has a central place in vitamin C syrup filling because this unit smoothly and safely loads your product into containers. Also, after filling, the capping unit, integrated with screw cap rollers that affix caps on the bottles by applying torque. This ensures the safety of your syrups. |

7.Do you know the strength of a product packed by a vitamin C filling machine?

The typical strength of vitamin C syrup packaged by a vitamin C syrup filling machine varies depending on the target users, the form of vitamin C deficiency they may have, or the kind of disorder doctors aim to treat by recommending vitamin C syrup to their patients.

| 50 ml |  |

| 60 ml |  |

| 100 ml |  |

| 120 ml |  |

| 200 ml |  |

For example, physicians normally recommend a dose of 100 mg for supplementing vitamin C, whereas adults are prescribed a syrup with 500mg strength. For treating severe vitamin C deficiency, the average dose of vitamin C syrup ranges from 300 mg to 1000 mg.

Therefore, they are mainly available in different doses such as 50 ml, 100 ml, 120ml to 200 ml. The machine’s filling capacities also vary depending on the requirements.

8.How can you store a product processed by a vitamin C syrup filling machine?

Storage

You are probably familiar with the fact that a vitamin C syrup filling machine handles a very delicate product that is likely to degrade if exposed to high temperature, UV light, and oxygen. This will change its composition, and may form byproducts harmful to human health. Hence, it is pivotal to store its container properly.

| Light Protection

You should have seen vitamin C in ambered-colored containers. Why is that? Well, dark glass blocks damaging UV and visible light waves. These rays could promote the degradation of vitamin C if they passed through glass. So, always keep this product in its original container and in its original carton until its use. |

Storing Temperature

Keep your vitamin C syrup at a room temperature of about 15°C to 25°C (59°F to 77°F). Don’t freeze this product, as it may affect the potency of the formulation or the integrity of the container. |

| Air Fortification

Hermetic seals are always present on vitamin C packaging to prevent its contact with oxygen. However, once you access the containers, immediately use the formulation. Any leftover solution in a single-use vial or ampoule must be discarded instantly. |

Humidity Control

It is a general rule of thumb that medications, for example, syrup vitamin C, must be stored in dry places, as damp areas may promote mold growth on packaging. Moreover, moisture can indirectly lead to product degradation. Hence, it is best to store this solution in a controlled humidity environment. |

9.What are the ways to solve various technical issues in a vitamin C syrup filling machine?

Are you getting technical glitches when operating the vitamin C syrup filling machine? Indeed, these problems could decrease your output capacity. What to do in this case? Well, to rectify these issues, read the following suggestions:

Inconsistencies in Fill Volumes

Inconsistencies of syrup in bottles

Of course, it is one of the major issues when you’re delivering products in the markets. Variation in vitamin C syrup filling could happen due to a number of reasons, for example, defects in the pump system, variations in air pressure, and incorrect machine inputs.

Remedy

To overcome this challenge, you first need to check the appearance and working status of filling systems, in case of damage, repair or replace them. Secondly, ensure there are no air bubbles and leaks in the pumps. Also, keep your air pressure within the specified range. Assess the machine input and correct fill parameters.

Decrease Vitamin Syrup Flow

Reduced Flow Of Syrup From Nozzles

Definitely, a lower flow rate of vitamin C syrup from the machine nozzle is directly linked to reduced filling speed. This issue stems from the blockage of the pipeline or clogging of nozzles.

Remedy

You can easily resolve this problem by examining your pipes and nozzles for blockage and then cleaning them thoroughly. If your pipeline parts are prone to habitual jamming or if they’re extremely damaged, it is best to replace them. Furthermore, proactively flushing machine hoses and pipes effectively cleans blockages.

Misaligned Bottles on Conveyor

Irregularly Positioned Bottles- Picture courtesy: Wellvalens

Sometimes, you may’ve noticed that bottles are incorrectly positioned on your vitamin C syrup filling machine’s conveyor. This leads to bottles falling on the conveyor, reduced filling output, and waste of expensive product.

Remedy

Some simple measures to fix this matter are, check the alignment of bottle guide and configure them correctly if found misaligned. This allows you to attain right orientation of bottles. Similarly, assess settings of positioning sensors and calibrate them.

Syrup Dripping

Syrup dripping problem

Have you ever observed syrup leak or drip from nozzles? Well, you’re not alone in facing this difficulty, as it is a frequent trouble caused by defective or old seals on nozzles, their incorrect alignment, incorrect liquid pressure, or lack of anti-drip systems.

Remedy

Here is what you can do to troubleshoot this problem. Replace the seals and valves on your nozzles if they’re too worn-out or damaged. Properly align the nozzles and use wider ones if your syrup is more viscous. Fine-tune your filling pressure, and install anti-drip systems, like shut-off nozzles or snuff-back mechanisms.

Conclusion

Due to rising global demand for nutraceutical oral liquid formulations, the vitamin C syrup filling machine is gaining traction across the industry. This highly automated system requires simple programming, and then it works independently with zero hassle and maximum proficiency. By integrating this system into your productions, you can unlock higher financial gains and high product inventory. So, are you ready to choose the perfect vitamin C syrup filling machine for your production? Get in touch with us today. AIPAK ENGINEERING is a dedicated machine manufacturer that offers a wide array of high-quality solutions customized to fulfill the evolving needs of modern manufacturing units.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours