Vial Filling Line: The Complete FAQ Guide In 2025

How do sterility and hygiene are maintained during vial filling? Vials are small vessels, manufactured from plastic or glass and have cylindrical flat bottoms. They are not only used for storing pharmaceutical formulations but are also pivotal in research and analysis purposes. They are used for their clarity, inertness, thermal resistance, and sealing.

But how are they filled? How is automation in vial filling achieved? The answer to all those questions is by vial filling line. This filling line is ideal for attaining faster filling rates and sterility in the filling process. Its instant and seamless filling and sealing are integral in boosting its popularity in the medical and research sectors.

This guide on “Vial Filling Line: The Complete FAQ Guide In 2025” is filled with different thought-provoking and informative facts about a vial filling line. By reading this article, you will be able to operate your filling line skillfully. Now, let’s get your reading glasses for learning knowledgeable info.

1.How to define a vial filling line?

AIPAK Engineering Vial Filling Line

Have you ever wondered how pharmaceutical vials are filled when you buy them from the market? There are distinct kinds of liquid filling machines and out of them a vial filling line is considered as the best engineering marvel.

Its main function is to dispense large varieties of liquids and powders differing in their traits and properties. You can easily load your watery, sticky, viscous, powdered, oily, or lyophilized products with this filling line in no time.

You can also achieve sterility and purity of filled preparation without any type of contamination-whether biological, physical, or chemical. The applications of vial filling lines are unlimited, as it is used for loading life-saving, disease-treating, nutraceutical, and, other biological preparations.

Besides filling, manufacturers also favor this line for its vial closing purposes. You can have completely secured and sealed vials with a vial filling line because it fixes and fits leakproof and sturdy rubber stoppers and other closures.

2.Why is a vial filling line crucial in several industries?

Do you know that vials are the one of main vessels for packing parenteral formulations? Because of the popularity of vials, pharmaceutical manufacturers make it their job to set up a vial filling line in their facilities. Why is that? It is because this filling line has evolved into a much-appreciated arrangement for flawless packing vials. Here we are going to look at diverse reasons why a vial filling line is needed in every healthcare manufacturing unit.

Absolutely No Chance of Error

Error-Free Filling- Picture Courtesy: Steriline

Do you know that error-free filling is a major pro of a vial filling line? This is certainly correct with a wide array of filling technologies; you can get precise control over filling outcomes. This means there are no fill differences in product batches. You can offer dose accuracy and patient safety using cutting-edge sensors and weight-checking systems.

Sterility in Every Fill

Sterility in Every Fill- Picture Courtesy: Environment Express

Are you looking for ways to accomplish fill sterility, Then, a vial filling line is indeed an optimized solution. This line purifies your vials with heat treatment before dosing the product. You can hygienically load lyophilized and liquid preparation sanitary environments or aseptic conditions using such a line. Without fail, you are assured of the safety of every batch and better well-being outcomes for patients.

Improved Throughput and Better Outcomes

Improved Throughput and Better Outcomes- Picture Courtesy: Groninger

The vial filling line is mainly offered with automated solutions, which are filling pumps, sensors, filling nozzles, etc. With so many features, you are promised speed and efficient filling times. Consequently, you can easily process bulk volumes of vials in high-capacity productions. So, due to its increased throughput, pharmaceutical developers rapidly introduce large doses of vaccines and other biologics during the pandemic.

Satisfying Regulatory Guidelines

Satisfying Regulatory Guidelines- Picture Courtesy: Watson Marlow Fluid Technology Solutions

Fulfilling regulatory guidelines imposed by the FDA, EMA, and, WHO are a must for product approval and marketing. But how can the installation of a vial filling line will lead to regulatory compliance? Well, it is quite simple with its top-notch sterility standards, clean design, and aseptic operation.

Diversity in Applications

Diversity in Applications- Picture Courtesy: MH Multipack

Are you processing a wide range of vials differing in their sizes and shapes? Then you can think about adding a vial filling line in your productions. It can easily process vials having versatile sizes and shapes with its quick changeable parts. Moreover, it can easily accommodate diverse products- ranging from thick to thicker consistencies.

Quality Inspection Process

Quality Inspection Process- Picture Courtesy: IMA-Pharma

When you are using a vial filling line, you can have better control over the quality of packed vials. This is because a vial filling line is devised with contemporary inspection units for quality control rationales. They can aid you in scrutinizing shortcomings and blemishes, for instance, erroneous fill levels, impurities, or poor seals. By this, you can also lower the probability of product recalls and other fiasco.

3.What is the step-by-step working of the vial filling line?

The working stages in a vial filling line are structured and coordinated to accomplish immediate and accurate filling rates. Let us explain every step in a vial filling line in a concise way:

Vial Feeding

Vial Feeding- Picture Courtesy: Comecer

In the first step, vials are manually or automatically positioned on the conveyor system by operators or automatic vial feeding machines. These containers are evenly spaced and placed in an upright configuration on a conveyor to move them through subsequent packaging steps.

Vial Washing

Washing of Vials- Picture Courtesy: Groninger

After loading, vials are transferred to the vial washing system and are cleaned both on the interior and exterior using efficient washing systems like water spray systems and air jets. These systems are devised to remove and eliminate various types of particulates, impurities, dust, etc. from the vials.

Sterilization

Sterilization of Vials- Picture Courtesy: Groninger

The vials are moved to a sterilization machine after washing to ensure there is no microbial presence in and out of the vials. This sterilization is also called depyrogenation, as in this process extreme temperatures of about typically 200–400°C are employed to thoroughly displace microbes, especially pyrogens from vials. This step guarantees safe and sterile vials for the filling step.

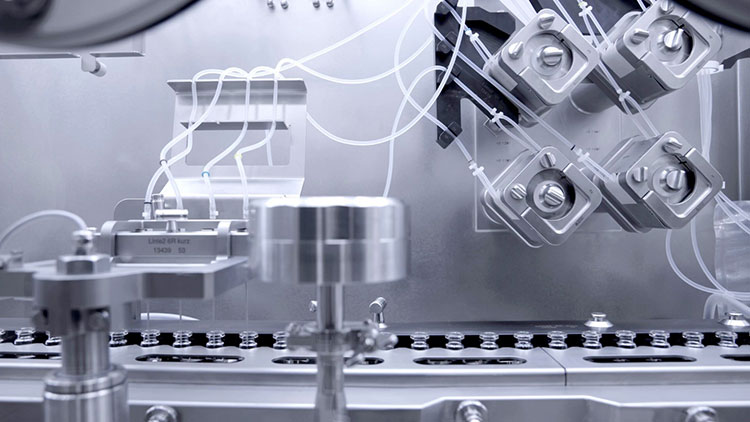

Filling

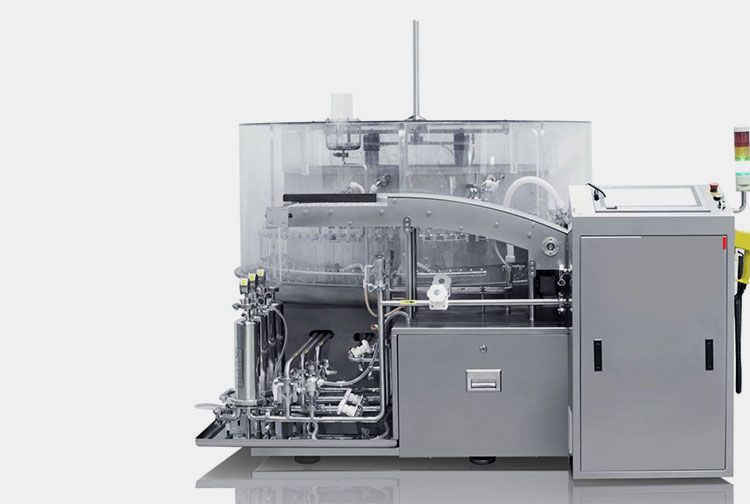

Filling of Vials- Picture Courtesy: Comecer

This is the core step in a vial filling line and occurs with the transport of vials to the filling system. You can refine dosing correctness via filling systems- installed in a vial filling line. This component is equipped with precise sensors and sophisticated filling nozzles to fill a multitude of medications- whether parental or non-parenteral- in an antiseptic way.

Stoppering

Stoppering of Vials- Picture Courtesy: Groninger

You always see the vials with rubber stoppers or other closures. But how vials are stoppered? A simple step is conducted in a vial filling line to deposit and fix stoppers into the openings of vials. The sorting and feeding systems furnished in the stoppering machine- operate for mechanically putting stoppers on vials.

Sometimes, for closing sensitive products, the headspace of vials is gassed to minimize the amount of remaining oxygen to less than 1%.

Freeze-Drying (Optional)

Lyophilization of Vials- Picture Courtesy: Groninger

Indeed, you can lyophilize or freeze-dry your drug preparation by relocating partly stoppered vials to a lyophilizer. With this machine, you can solidify your formulation dry in vacuum conditions. It helps in upholding the stability of sensitive products and prolonging the lifespan of liquid drugs by safeguarding the conformation of active ingredients.

Sealing

Sealing of Vials- Picture Courtesy: Groninger

Sealing of vials is carried out via a capping station. It is offered with different capping systems that insert or twist aluminum or plastic caps on the vials. You can get efficient vial securing and have no chance of product leakage with this step. Also, you can apply tamper-evident or tear-off seals on vials to lower the frequency of illegal vial opening.

Inspection and Labeling

Inspection and Labeling- Picture Courtesy: EMP Tech Group

Multiple types of advanced inspection systems are found in a vial filling line to ensure customers and regulatory authorities, alike that vials have no physical or internal defects. Are you curious as to how inspection systems detect imperfections? They have efficient sensors or cameras to check and locate the type of ineptitude in vials.

In the last step, you can label, code, or engrave your vials with the help of an inkjet printer, labeling head, or, laser system to easily track and trace your products. You can easily include different product facts, for example, lot number, medication name, manufacturing and expiry dates, warnings, and ingredient list.

4.What are the industrial applications of a vial filling line?

The vial filling line is an exceptional unit, steadfast in its state-of-the-art filling of miscellaneous volumes of liquid preparations. It is significantly popular in far and wide industries because of its distinct advantages. Let’s have an insight into the industrial application of a vail filling line:

Pharmaceutical Industry

Pharmaceutical Vials- Picture Courtesy: MIRAI Index

The pharmaceutical industry and a vial filling line go hand-in-hand. Hygiene and precision are two pillars of the pharmaceutical industry and both are upheld by this line. It is habitually employed for stock life-saving medications, infusions, orphan drugs, and other parenteral formulations in glass and plastic containers. It is a promising solution because it guarantees the long-lasting therapeutic life of medicines and their effectiveness.

Biopharmaceutical Industry

Biopharmaceutical Vials- Picture Courtesy: ComplianceQuest

Without it, they are ineffective in treating the illness they were developed for. Therefore, the vial filling line is an indispensable unit in the biopharmaceutical industry because it guarantees the purity of biologics and does not in any way or form interfere with, the properties of these agents. You can achieve successful filling of preparation, such as vaccines, monoclonal antibodies, gene therapies, proteins, hormones, enzymes, stem cells, and blood products.

Biotechnology Industry

Biotechnology Vials- Picture Courtesy: CNBC

No biotechnology industry is complete without a vial filling line. It is gaining a strong footing in the biotechnology facilities to rapidly and hygienically load diverse kinds of clinical testing reagents, diagnostic liquids, buffers, and chemicals used in molecular biology, serology, and, genetics laboratories in the vials. Why it is considered the absolute best? The answer is simple because it securely and competently packs sensitive biotechnology products.

Veterinary Industry

Veterinary Industry- Picture Courtesy: City Lifestyle

You are reading it right! Parenteral therapies for pets and livestock are in great demand nowadays because people love and care for their animal friends. A diverse range of vet treatment solutions, for instance, antibiotics, antiparasitics, nutritional supplements, and fluid therapies are successfully dispensed in clean vials in this sector. So, to carefully load these remedies in vials, a vial filling line is a remarkable solution present in this industry.

Cosmetic and Personal Care Industry

Cosmetic Vials- Picture Courtesy: POPSUGAR

These days, you can buy various cosmetic, dermal, and personal care products in vial packaging. The vial filling line is a great addition to the cosmetic industry to hygienically load and seal multitudes of products- differing in their consistency like serums, hyaluronic acids, anti-wrinkling liquids, anti-aging solutions, beauty enhancers, Botox, dermal fillers that are injected subcutaneously or intramuscularly.

5.What machines are involved in the vial filling line?

There are numerous machines incorporated in a vial filling line, each carrying out a particular task to satisfy the filling demands of purity and precision. Some of the important machines generally found in a vial filling line are discussed below for your information:

Vial Washing Machine

AIPAK Engineering Vial Washing Machine

Although it is the first machine in a vial filling line its importance is undeniable. Is it beneficial for production? Absolutely yes! It is fancied for its role of cleaning and washing vials to get rid of chemical impurities, particulate matter, and other foreign agents. It cleans the inner and outer walls of vials with distilled water, cleansing agents, and air sprays.

Depyrogenation Tunnel

AIPAK Engineering Deprogentation Tunnel

Vials are subjected to high temperature in this sterilizing machine to ascertain there is no microbial presence in the interior and on the exterior of vials. It is a hot oven tunnel in which hot air is circulated to achieve faster sterilization.

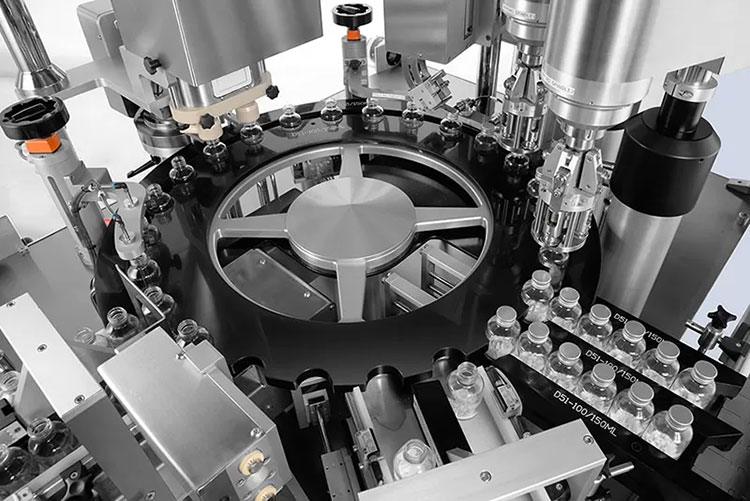

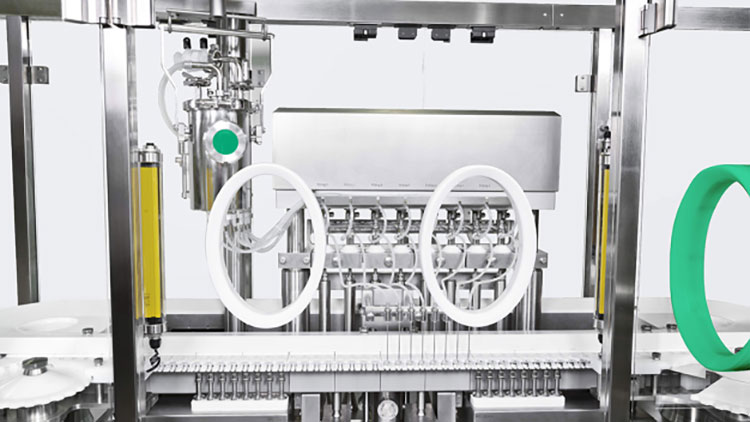

Filling and Stoppering Machine

Vial Filling and Stoppering Machine- Picture Courtesy: Syntegon

This machine is designed for performing both filling and stoppering in one piece of equipment. It introduces precise volumes of formulation into every vial to prevent the likelihood of both underfilling and overfilling. After filling, it also sorts and deposits rubber stoppers using pick and place systems or continuous stoppering systems.

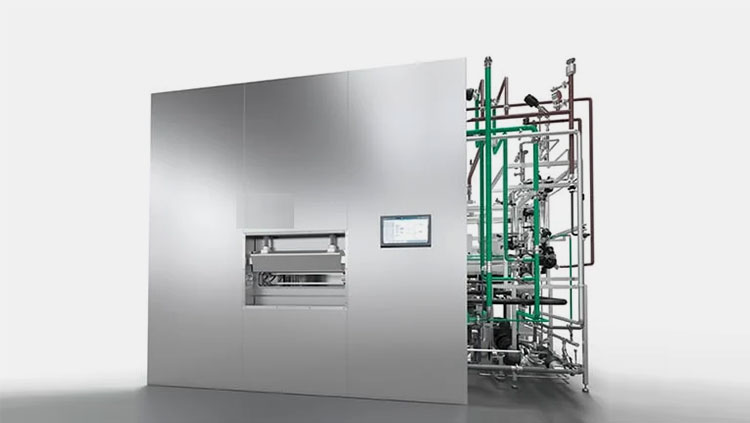

Lyophilizer

Lyophilizer- Picture Courtesy: Syntegon

It is a high-end and optional machine in a vial filling line. But how does it carry out lyophilization? This machine dehydrates high-end and sensitive pharmaceutical remedies and biotherapeutic products. First, the lyophilizer carries out freezing at low temperatures, and then the subzero liquid is promptly changed into a gaseous state by drying at vacuum conditions.

Vial Capping Machine

Vial Capping Machine- Picture Courtesy: Sofinn

Closing of vials is integral to retaining product purity and it is achieved with a vial capping machine. Now you are going to learn about its workings. It sets basic and flip-off plastic or aluminum caps on the vials for their permanent sealing.

First, you place caps in a vibratory bowl of a vial capping machine in which they are oriented in the right position before traveling to the delivery chute. This machine places aluminum caps on the vial through the retaining finger part of the delivery chute. At last, spinning heads rotate to completely secure partly capped vials.

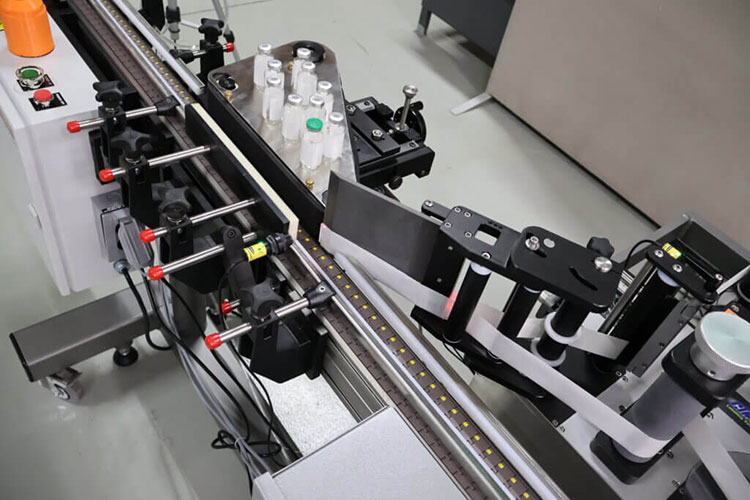

Vial Labeling Machine

Vial Labeling Machine- Picture Courtesy: CVC Technologies Inc.

It is generally the last machine in the vial filling line. As product information plays a pivotal purpose in medication identification by patients and doctors. So, a vial labeling machine helps in content recognition by affixing stickers, hot-glue papers, or wet-glue labels on the central area of the vial. These containers are carried to the labeling module of the machine, where the self-adhesive label from the roll is glued on vials.

6.What type of filling technologies are available in the vial filling line?

Are you curious about filling technologies in the vial filling line? The below-mentioned points will answer your question.

Rotary Piston Pump (RKP)

Rotary Piston Pump (RKP)- Picture Courtesy: OPTIMA Packaging

It is a common category of positive displacement pump and can process a diverse range of preparations, for instance, viscous and sticky fluids and liquids. You can achieve accurate filling rates and high-pressure dosing with this system. It works by simply spinning the piston around a rotor, hence, it imparts suction force to drive formulations across the pump.

Peristaltic Pump (PP)

Peristaltic Pump (PP)- Picture Courtesy: Cytiva

Certainly, it is also a kind of positive displacement pump and works by imitating the natural peristaltic motion of the digestive tract. Are you wondering what is its construction? It is formed from rollers attached to the rotor of the peristaltic pump.

The function of rollers is to rotate, consequently, contracting the pliable tube or hose, generating a vacuum inside the tube to draw the preparation into a tube. You can have a reduced possibility of drug contamination because the liquid is only exposed to the inner side of the hose.

Rolling Diaphragm Pump (RDP)

Rolling Diaphragm Pump (RDP)

It is yet another category of a positive displacement pump and is equipped with a core component- a rolling diaphragm. This pump works by the in and out movement of a flexible diaphragm in the pump device. What does the diaphragm do? It simply enables the drawing of the drug blend through the pump. It also has the pro of preventing contact of pumped liquid with the inner parts of the pump.

Time Pressure Filling Systems (TPF)

Time Pressure Filling Systems (TPF)- Picture Courtesy: Syntegon

It is a kind of liquid filling system, consisting of a pressurized tank in which liquid preparation is housed. The filling process in this dosing technology is grounded on regulating time duration in which pressurized treatment is flowed into filling nozzles, and ultimately into vials. It is equipped with valves that control the fluidity of liquids with their specific timings for opening and closing,

7.What are the kinds of glass vials loaded by the vial filling line?

A vial filling line is very multipurpose dealing with a variety of glass vials- differing based on glass materials, composition, and sizes. All these glass vials filled by the vial filling line are explained below:

Type I Borosilicate Vials

Type I Borosilicate Vials

They have a simple composition- constituting high-quality borosilicate glass that is composed of 80% silica, 10% boric oxide, and trace amounts of compounds, such as sodium oxide and aluminum oxide. Yes, you can frequently use them in pharmaceutical production due to their excellent thermal shock resistance and chemical non-reactivity.

Moreover, you can utilize them for storing acid and neutral formulations and sensitive preparations like vaccines and diagnostic reagents. However, they come with a bigger price tag than other types.

Type II Treated Soda-Lime Vials

Type II Treated Soda-Lime Vials

It is created from soda lime that is treated with sulfur. This surface treatment is vital for boosting chemical tolerability. Now what are the benefits of Type II glass vials? Undoubtedly, they are well-accepted because of their superior acidic, chemical resistance, weather protection, and, hydrolytic resistance.

Type III Soda-Lime Vials

Type III Soda-Lime Vials

Their makeup is identical to Type II glass vials with soda-time usage but with chemical alterations. 75% silica, 15% sodium oxide, and 10% calcium oxide. The remaining 5% of the glass is composed of trace amounts of magnesium, potassium, and aluminum oxides. They are not treated with any chemical.

How this diverse composition helps Type III glass vials. Indeed! It increases flexibility, chemical inertness, and molding at low temperatures. They are increasingly used for packing products-for instance, parenteral liquids, non-parenteral formulations, and aqueous solutions.

Clear (Flint) Glass Vials

Clear (Flint) Glass Vials

Clear vials, as the name shows have no color, therefore, they are the right fit for enclosing non-light-sensitive formulations that do not deteriorate upon light encounter. They are also best for their clarity.

Amber Glass Vials

Amber Glass Vials- Picture Courtesy: SKS Science Products

Borosilicate or soda-lime glass is generally used for making amber glass vials. These vials are unique because of their brown or amber shade. They are regarded as better for light-sensitive substances due to their UV protection features.

8.How is sterility maintained in the vial filling line?

You can decrease the chances of contamination and loss of product safety and potency by keeping your vial filling line sterile. Some basic practices are mentioned below to guide you about different sterility approaches.

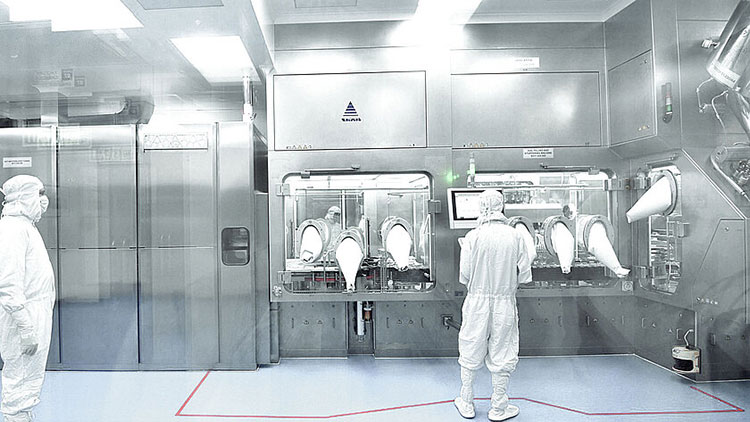

Cleanroom

Cleanroom Environment- Picture Courtesy: Groninger

Cleanrooms are ISO Class 5 (Grade A) or ISO Class 7 (Grade B) certified and they are created to prevent the entry of impurities into vials and destroying their contents. Users also connect cutting-edge HEPA filters in vial-filling rooms to distribute clean and pure air.

Sterilization of Components

Sterilization of Components- Picture Courtesy: Syntegon

Do you usually sterilize your vials, caps, and, stoppers? Recommended sterilization systems, for example, steam sterilization, dry heat sterilization, and gamma irradiation are superior in getting rid of microbial agents. You can also treat your filling system parts, such as tubes, hoses, nozzles, and pumps through autoclaving, hydrogen peroxide sterilization, or Sterilize-in-Place (SIP) system.

Filling Equipment Design

Filling Equipment Design- Picture Courtesy: Syntegon

A vial filling line is normally surrounded by physical blockades, for instance, Isolators and RABS (Restricted Access Barrier Systems) to form a protective enclosure between filling processes and external surroundings. How do operators access the filling line? Well, they can easily and hygienically interact with it through the glove port for product cleanability.

9.What are tips to rectify the problems in the vial filling line?

In a vial filling line, technical problems generally occur because of mechanical defects in its components, poor operational protocols, and, environmental agents. This can significantly impact the quality, efficacy, and, safety of therapeutic products. A systematic approach is needed to rectify these problems.

Hence, for your information, we are writing some useful tips with which you can easily resolve these errors.

Overfilling or Underfilling

Overfilling or Underfilling- Picture Courtesy: Syntegon

The inaccuracy of fill results in overfilling or underfilling.

Solutions

To solve these problems, you should properly and routinely schedule the calibration of filling pumps. There can be a mistake in the settings of the time-pressure filling system, check and fix it. You should carry out regular flow rate checkups. It is best to use automated weighing scales and feedback control loops for unvarying filling results.

Blockage or Leakage of Product

Blockage or Leakage of Product- Picture Courtesy: Syntegon

Have you faced the problem of blockage in filling nozzles? If yes, it could be due to the accumulation of different viscous products inside the nozzles.

Solutions

Keep in mind that filling nozzles have to be inspected, cleaned, washed, or replaced regularly. Also, you should check for wear and tear of O-rings, gasket seals, and valves, and switch them with new ones if necessary.

Inconsistency in Vial Loading and Alignment

Inconsistency in Vial Loading and Alignment- Picture Courtesy: Groninger

Have you ever noticed inconsistent vial feeding on conveyors? If the rate of vial feeding and their alignment is incorrect on conveyors then they lead to several skipped loading and product wastage events.

Solutions

Examining different components of vial loading mechanisms, for example, star wheel, and feeders for physical damage and replacing them can help in managing this issue.

Pay attention to improperly aligned components to right their alignment. You should alter the alignment and leveling of conveyor guides and rails. You must routinely perform the inspection of positioning or optical sensors to ensure accurate vial detection and feeding.

Inadequate Vial Sealing

Inadequate Vial Sealing- Picture Courtesy: Groninger

In some cases, an inspection of vials shows poor vial sealing and cap misplacement. These issues could promote product escape from vials and also impurities could enter the vials.

Solutions

Here are some useful tips for you to solve this problem. You should regularly check the torque and alignment of the capping head to properly secure your vials. Secondly, you should continuously monitor the blocking, jamming, and working of cap feeding and sorting systems. Last but not least, you should check the orientation of caps in the cap feeding systems to properly place them on vials. Sometimes, experts consider it best to install sensors to detect missing or inadequately seated caps, so that you can avoid this issue once and for all.

Air Bubbles in Vials

Air Bubbles in Vials- Picture Courtesy: SaltWire

From time to time, while filling vials air bubbles are formed in the vials, producing serious consequences, for example, a high rate of drug oxidation, impurity, or disparities in dosage.

Solutions

You can easily avoid this unsafe problem by using a bottom-up filling approach, as it will minimize the frequency of foaming or the formation of air bubbles. Some preparations are more predisposed to trap air, so, it is best to decrease filling speed for them. Moreover, venting of the preparation tank also solves the issue of trapping of air.

Conclusion

In summary, filling and sealing of vials are taxing tasks, needing perfection, seamlessness, and sterility at each and every step. So, pharmaceutical establishments have added a cutting-edge system- a vial filling line to conveniently, swiftly, and hygienically implement vial packing vial filling systems. Well, this production line has tons of plus points whether you are looking for comes with various higher productivity rates or reduced set-up times, this line is the right fit for your needs. So, without waiting and delaying come visit our incredible catalogue of our parental filling lines. We, AIPAK ENGINEERING will take you on an undemanding and smooth sailing selection and shipment process.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours