Syrup Manufacturing: The Complete FAQ Guide In 2025

The sugar in syrup can satisfy the customers’ taste buds, so it is widely used in the food industry, such as adding syrup to milk tea. In order to reduce the bitterness of drugs and improve absorption in the body, syrup is also used in the pharmaceutical industry, such as cough syrup.

Do you want to understand the process of syrup manufacturing? In fact, the production of syrup still requires many processes and equipment. Do you still want to know the method of syrup manufacturing and the difference between syrup and suspension? Next, let’s take a look at the complete FAQ guide for syrup together.

1.What Is the Definition of Syrup Manufacturing?

Syrup - Sourced: Adobe Stock

Syrup is a viscous solution containing high concentrations of sugar. Due to its high sugar content, syrup can be stored for a relatively long time in a sealed state without the need for refrigeration. Syrup can be used to prepare beverages or make sweet foods such as bread and cookies. In addition, with good taste and easy to take, syrup is widely used in the pharmaceutical industry.

The syrup manufacturing involves many processes, including mixing, cooling, and filling, etc. The following will introduce the detailed manufacturing process of syrup for you.

2.What Are Main Components of Syrup?

As we all know, syrup is composed of many components, and sugar is just one of them. Do you know any other ingredients?

Sugar

Sugar - Sourced: Taste of Home

Sugar is the basic component in the production of syrup, with a relatively high sugar content that can supplement energy and regulate acid-base balance. Besides, sugar is a key element for syrup viscous.

Purified water

Purified water is an essential component of mixed syrup and requires water treatment before it can be used for syrup production.

In addition, other ingredients can be added according to the product you need. Pharmaceutical syrup also contains medicinal ingredients, such as cough syrup, cough suppressants, expectorants, and auxiliary ingredients.

3.What Are the Main Types of Syrup?

There are actually several types of syrup, and the following briefly introduces the three main types.

Simple syrup

Simple Syrup - Sourced: Empire Wine

This type of syrup has fewer ingredients and generally only contains water and sugar, which can be used as a sweetener. The viscosity of syrup can be adjusted by oneself. The water used to make this syrup needs to undergo water treatment to avoid suspended solids and pollutants in the water that can affect the color and taste of the syrup.

Pharmaceutical syrup

Pharmaceutical Syrup - Sourced: Drugfield Pharmaceuticals Ltd

This pharmaceutical syrup is made easier to take for children through sweetness, with a sugar content of no less than 45%. This syrup contains drugs or extracts of medicinal herbs, which have certain therapeutic effects.

Flavor syrup

Flavor Syrup - Sourced: Amoretti

This type of syrup also contains some aromatic substances or fruit juice, which can be used to enhance the flavor of different foods or drugs, such as as as a liquid flavoring agent.

4.What Are the Application of Syrup?

What syrup have you taken, such as jam for eating bread or cough syrup for catching a cold? Syrups have a wide range of applications, let's take a look at the specific ones.

Pharmaceutical industry

Cough Syrup - Sourced: Amazon

Syrup is used in the pharmaceutical industry to improve drug stability and efficacy. Due to its excellent taste, syrup is highly popular among children. The application of syrup in the pharmaceutical industry includes expectorant and cough suppressant products, gastrointestinal regulation, etc.

Food industry

Fruit Syrup - Sourced: Sara Haas

Syrup can serve as a sweetener, increasing the sweetness and enhancing the taste of food and beverages. During the candy making process, syrup not only provides the candy with a basic sweetness, but also makes the candy taste more delicate and smooth. In addition, syrup can also serve as a coloring agent for candies, making them more colorful and diverse.

Beverage industry

Beverage Syrup Cherry - Sourced: GermanShop24

Whether it’s carbonated drinks, fruit juice drinks, or tea drinks, syrup is an indispensable ingredient. The addition of syrup can not only enhance the taste and flavor of beverages, but also adjust the sweetness of beverages to meet the taste needs of different consumers.

5.What Are the General Methods of Syrup Manufacturing?

There are various production methods for syrup, each with its own characteristics and suitable for different types of syrup.

General Methods of Syrup Manufacturing - Sourced: Herbal Academy

Hot melt method

Adding sugar that meets the production requirements of the final product to an appropriate amount of boiling distilled water, heat and stir to dissolve, then add the required drugs and other materials for dissolution and filtration. This method is suitable for the preparation of thermally stable drugs and colored syrups.

Cold dissolution method

Dissolving sucrose in distilled water or medicated solution to prepare syrup. This method is suitable for the color payment of syrup prepared for thermally unstable or volatile drugs.

Mixingmethod

A mixed method can be used to prepare syrup. Mixing the drug containing solution evenly with a single syrup. Because it is flexible, simple, and can be prepared in large or small quantities, this method can be used for preparing pharmaceutical syrup.

6.What Is the Process of Syrup Manufacturing?

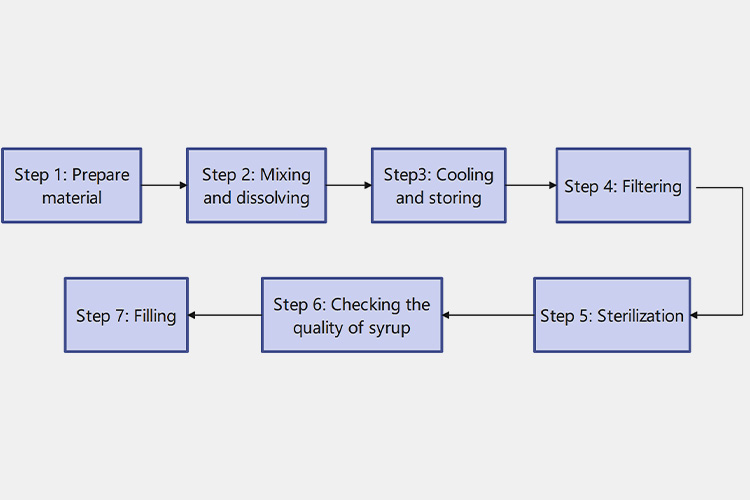

Process of Syrup Manufacturing

Do you have seen how syrup produce? To tell the truth, it involves many process, especially for pharmaceutical syrup.

Prepare material

Prepare Material for Syrup - Sourced: Gallery Png

The components of syrup have been discussed in the question 2, so in the first step of making syrup, you need to prepare the ingredients, which include water and sugar as the basic components, and other pharmaceutical elements. The water used to prepare syrup requires purified water, so the raw water also needs to be treated. Besides, other ingredients can be added according to the desired taste and product type.

Mixing and dissolving

Mixing and Dissolving - Sourced: iStock

After preparing the materials, mixing all the ingredients according to the product formula ratio and add them to the mixer for heating. Boiling the mixture at medium high temperature and stir to dissolve all ingredients. During this process, it is necessary to control the temperature and stirring speed to ensure the stability and uniformity of the solution.

Coolingand storing

After all the material are dissolved, pouring the mixture into a cooling or storage tank for cooling. During the cooling process, the cooling rate and temperature should be controlled to avoid crystallization or deterioration of the sugar solution.

Filtering

In order to remove impurities, the dissolved material need to be filtered. Therefore, special filtering equipment or pure gauze can be used for filtration.

Sterilization

Sterilization - Sourced: RAYPA

Especially for syrup used in pharmaceuticals, sterilization treatment is used to further ensure the hygiene and safety of the product. Sterilization cabinets or high-temperature sterilization methods can be used for treatment.

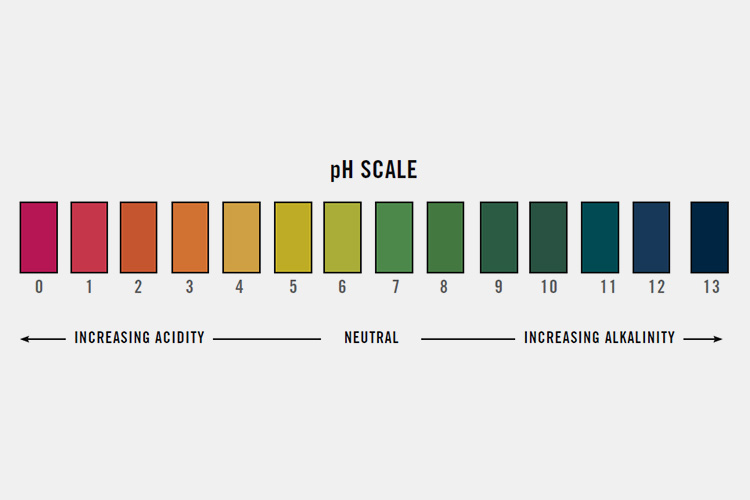

Checking the quality of syrup

In order to ensure that the final syrup meets relevant standards and regulations, you should conduct quality inspection of the produced syrup, mainly including visual inspection, pH value testing, etc. I will provide a detailed introduction to the specific quality testing items in the following text.

Packing for Syrup - Sourced: IBEX Packaging.com

The final step is filling, and the most common packaging for syrup is the bottle. The bottles should meet hygiene standards. We also need to strictly control the hygiene conditions of the packaging environment to avoid secondary pollution.

7.What Equipment Are Used in the Syrup Manufacturing?

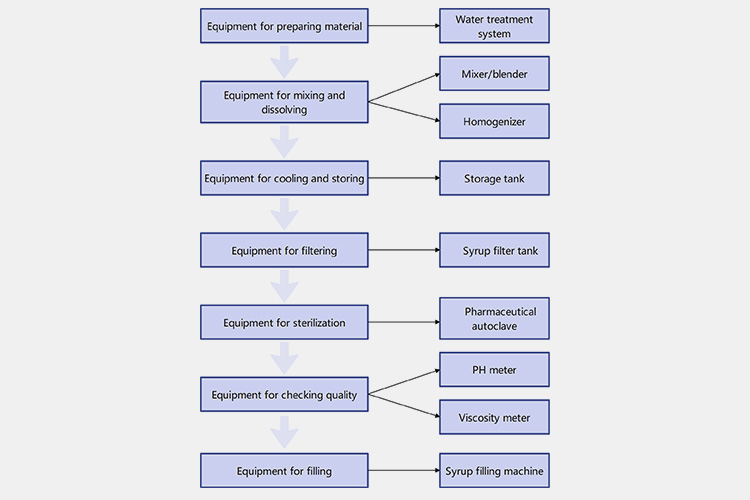

After understanding the syrup production process, do you know what equipment is needed for syrup manufacturing?

Equipment Used in the Syrup Manufacturing

(1)Equipment for preparing material

Water treatment system

AIPAK Engineering Water Treatment System

The production of syrup need purified water. The production of purified water need water treatment of the raw water. The water treatment system usually consists of a series of treatment units, including pretreatment, filtration, disinfection, deep treatment, etc. This system has many benefits, such as high degree of automation, stable operation, low failure rate, and low usage cost

(2)Equipment for mixing and dissolving

Mixer/blender

AIPAK Mixer

When preparing syrup, it is necessary to mix water, syrup, and drug ingredients, so a mixer is needed for thorough mixing. The mixer is capable of efficiently mixing various materials, and the material bin is detachable. This machine can achieve efficient and uniform mixing, allowing materials to dissolve completely.

Homogenizer

AIPAK Homogenizer

In addition to mix material, homogenizer also can improve the uniformity of materials through shearing, impact, etc. This machine compresses the material into small particles through forced flow and shear force, and disperses the material in a liquid medium, thereby achieving homogenization and dispersion of the material.

If producing pharmaceutical syrup, the homogenizer plays a key role in ensuring the uniform distribution of drug ingredients and improving drug efficacy.

(3)Equipment for cooling and storing

Storage tank

Storage Tank - Sourced: Tradeindia

Storage tank can be used for cooling and storing syrup. This tank ensures excellent quality of syrup during storage. Its design features easy cleaning, corrosion resistance, and durability, which can meet long-term usage needs.

This tank is sealed to prevent air and bacteria from entering, thereby extending the shelf life of the syrup. Some high-end syrup storage tanks are equipped with measuring devices that can accurately control the amount of syrup used.

Equipmentfor filtering

Syrup filter tank

Syrup Filter Tank

The syrup filter tank adopts a scraper self-cleaning filter, which uses physical methods to filter out impurities in the syrup. Its main function is to reduce insoluble impurities and turbidity in the syrup, and improve the quality of the syrup. This tank and filter element are usually made of stainless steel material, so it will not undergo chemical reactions with materials and has good durability. .

Equipmentfor sterilization

Pharmaceutical autoclave

AIPAK Engineering Pharmaceutical Autoclave

For pharmaceutical syrup, it is necessary to use a pharmaceutical autoclave for sterilization. This equipment uses high temperature, high pressure, or chemical substances to destroy and kill the growth ability of microorganisms. In addition, it use UV sterilization, which has no significant effect on the chemical composition of the syrup and is easy to operate, effectively eliminating the bacterial community in the syrup.

(4)Equipment for checking quality

PH meter

PH Meter - Sourced: Amazon

By measuring the pH value of syrup, the acidity and alkalinity of syrup can be determined. The pH meter uses a glass electrode and a reference electrode for measurement. When hydrogen ions are present in the measured solution, a potential difference is generated on the electrode surface. By calculating the magnitude of this potential difference, the acidity or alkalinity of the syrup can be determined.

Viscosity meter

Viscosity Meter - Sourced: Amazon

Viscosity meter is used to measure the viscosity of syrup to ensure the stability and effectiveness of drugs. The measurement principle of a viscosity meter is mainly based on the flow resistance generated by a liquid when subjected to external forces. The viscosity meter calculates the viscosity value of the liquid by measuring the flow resistance and combining it with other physical properties of the liquid, such as temperature, pressure, etc.

(6)Equipment for filling

Syrup Filling Machine

After the production of syrup is completed, it needs to be packaged. The syrup filling machine is suitable for filling bottles such as glass bottles, and can achieve quantitative filling, sealing, capping and other operations.

This machine has multiple bidirectional piston filling heads, which can achieve efficient filling. It also can ensure consistent output of each filling volume, reduce syrup waste, and improve product quality.

8.What Factors Will Affect Syrup Quality?

Good quality is necessary to win the favor of customers. Especially for pharmaceutical syrup, it is related to the efficacy of the product, so it is important to understand the factors that affect the quality of syrup.

The moisture content of syrup

The moisture content of syrup is one of the important standards for measuring the quality of syrup, which can directly reflect the cleanliness and purity of syrup. The moisture content of syrup should be within 60-65%, and syrup outside this range has poor quality.

Equipment quality

Equipment Quality - Sourced: Corporate Finance Institute

If the quality of the selected equipment is average or poor, the drug components in the syrup production process may undergo chemical reactions with the equipment, affecting the final efficacy of the syrup.

For example, the equipment that mix and melt require regular maintenance and upkeep. If the maintenance is not thorough or there are defects, it will seriously affect the stable operation of temperature and pressure, leading to problems such as fires and explosions.

Viscosity

If the viscosity of the syrup is not adjusted according to the final production ratio during the mixing and dissolution stage, it will also affect the quality of the final syrup.

9.What Is the Definition of Suspension Manufacturing?

Suspension - Sourced: The Pharma Education

Simply put, suspension is a mixture that contains solid particles and liquid. These solid particles are like sand, they don’t settle obediently, but rather remain suspended in the liquid.

The suspension manufacturing also involves many processes, including material preparation, mixing, filling, etc. If you want to understand the specific production process, you can read this article - Pharmaceutical Suspension Manufacturing The Complete FAQ Guide in 2024.

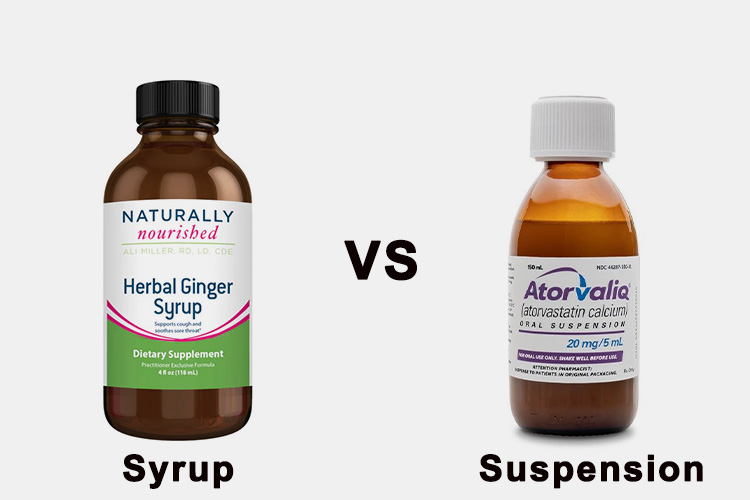

10.What Are the Difference Between Syrup Manufacturing and Suspension Manufacturing?

Difference Between Syrup Manufacturing and Suspension Manufacturing

Syrup and suspension are two types of liquid products that are very similar, but also have differences. Do you know what are the difference between syrup manufacturing and suspension manufacturing?

| Syrup manufacturing | Suspension manufacturing | |

| Particle state | The particles in the syrup completely blend into the solution. | The particles in the suspension have not dissolved into the solution and are in a suspended state. |

| Viscosity | Syrup is thicker and has higher viscosity. | Low viscosity. |

| stability | Due to the dissolution of all drugs in the syrup, it has good stability. | Due to the easy precipitation or aggregation of particles in the suspension, its stability is poor. |

| solubility | The drugs contained in syrup have good solubility, and concentrated sugarcane syrup has been added to suit the taste of children. | The drugs contained in the suspension have poor solubility and are difficult to dissolve, suspended in the form of particles in the solution. |

| production process | The process of making syrup is relatively simple. | Suspension usually need to go through multiple stages, and the production process is relatively complex. |

11.What Are the Main Quality Control Tests for Syrup Manufacturing?

The quality of syrup is related to human safety, so it needs to be strictly controlled. The purpose of quality control test for syrup is to ensure that the product meets relevant standards and regulations.

Viscosity testing

Syrup is a viscous liquid with a viscosity much higher than that of water. Use a viscometer to test the flowability of syrup to ensure that the product texture meets the requirements.

PH testing

pH testing - Sourced: Bradford Derustit

Taking an appropriate amount of syrup sample and use a pH meter to determine if its acidity meets the standard requirements. For example, the pH value of pediatric cough syrup should be between 3.5 and 5.0, which is an important indicator for measuring its acidity and alkalinity, ensuring that it is within the appropriate range to ensure efficacy and safety.

Visual inspection

Visual Inspection - Sourced: Allrecipes

By observing the color and shape of the syrup with the naked eye, it should not contain any impurities or sediment, and should be a transparent or slightly yellowish liquid.

Density detection

Detect the relative density of syrup. Relative density is an indicator of the density of a substance, which is usually measured using the specific gravity method in syrup testing.

12.What Are the Future Development Trends of Syrup Manufacturing?

With the rapid development of technology, there will be more changes in the production of syrup in the future.

Automatic manufacturing

Automatic Manufacturing - Sourced: OptiProERP

At present, the machines used for syrup production can all be automated, and in the future, more precise measurement and filling will be achieved. Products that do not meet the requirements will be automatically detected and removed. These machines can accurately control parameters such as temperature and humidity during the syrup manufacturing by using intelligent control technology and sensor technology, ensuring stable product quality.

Intelligent packaging

Intelligent Packaging - Sourced: Behance

The filling machine and labeling machine for the subsequent syrup production will add sensors and RFID tags to achieve real-time tracking of the syrup. Consumers only need to scan the labels on the packaging with their smartphones to obtain detailed information such as the source, production date, and transportation process of the syrup.

Green and environmentally friendly

With the continuous improvement of environmental awareness, the green environmental requirements for syrup production lines will also become increasingly high. Enterprises need to adopt more environmentally friendly materials and processes to reduce the discharge of waste and pollutants, in order to meet market demand and regulatory requirements.

Conclusion

Syrup can be used for manufacturing food. In addition, syrup is a type of oral liquid that is favored by many patients due to its ease of use and good taste, and it has a promising market prospect. The production of syrup involves many processes and equipment. Are you interested in syrup manufacturing? If you have any questions about syrup manufacturing, you can always contact AIPAK Engineering

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours