Sore Throat Syrup Manufacturing: The Complete FAQ Guide In 2025

Dealing with liquid suspension like syrups is one of the difficult tasks especially when maintaining quality is a top priority. Similar is the case with Sore Throat Syrup Manufacturing which revolves around several factors that must be paid heed.

In this FAQ guide we will be covering everything related to Sore Throat Syrup Manufacturing from its basics to the ingredients and machines used till the best compatible packaging and necessary quality standards. So, without wasting the time let's delve deep into it!

1.What Is Sore Throat Syrup?

Woman pouring sore throat syrup in cup- Picture Courtesy: shutterstock.com

Sore throat syrup can be simply defined as a liquid medication prepared for treating throat related problems such as throat irritation, discomfort, and pain in the throat lining. It is also used to cure cough and sneezing.

Unlike other liquid medications, sore throat syrup is made up of pure natural and herbal ingredients such as honey, menthol, and glycerol etc. The resultant mixture helps in soothing sore throat. It is best suitable for kids, adults, as well as old people with different dosage.

2.What Do You Know About Sore Throat Syrup Manufacturing?

Sore throat syrup manufacturing on industrial level

After knowing about what sore throat syrup is, now, let's move ahead for its manufacturing. As we know, that manufacturing is an umbrella under which everything related to the product is concerned. Similarly, in case of sore throat syrup manufacturing we mean its production process, the methods adopted, guidelines followed, and equipment used.

It is a production process undertaken on industrial level whether small or large scale. It involves the processing of ingredients and turning into sore throat syrup which is then properly packed into bottles and packages and send for merchandising.

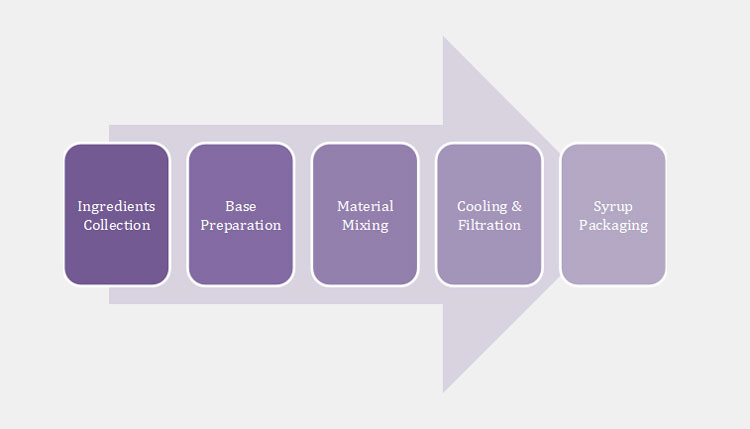

3.Explain The Major Steps Involved In Sore Throat Syrup Manufacturing?

The process of sore throat syrup manufacturing is comprised of several steps through which ingredients are turned into finished sore throat syrup. These phases are sequentially enlisted below in detail to clear your understanding:

Ingredients Collection

Ingredients collection for sore throat syrup manufacturing- Picture Courtesy: ruralsprout.com

Before the process of sore throat syrup manufacturing begins, it is important to collect all the necessary ingredients required for production which include honey, sugar, glycerin, menthol, pain reliever, and flavoring agents. The amount of each ingredient must be properly weighed to ensure accuracy of the intended formula.

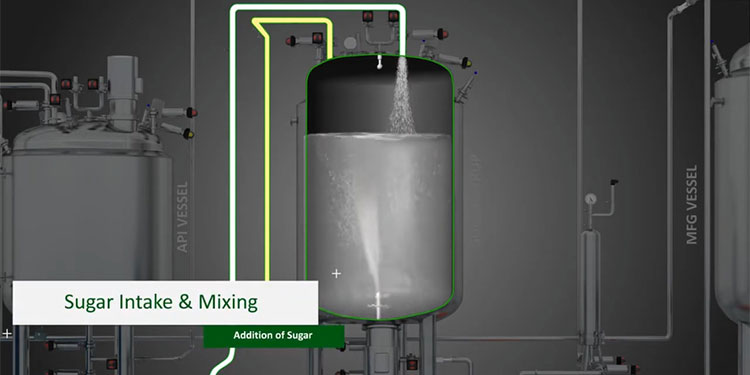

Base Preparation

Sugar intake & mixing for base preparation- Picture Courtesy: Adam Fabriwerk

Now, the first thing essential for sore throat syrup formulation is the preparation of base. For this, sugar is graded, sieved, and then melted in distilled water which forms a homogeneous base for syrup. This sugar base is prepared in a separate melting tank at a suitable temperature.

Purification

Water in a beaker- Picture Courtesy: savethewater.org

After base preparation, the next step is purification of water or liquid solution. In this phase, the mixture is thoroughly cleaned using a water treatment system which helps in the elimination of contamination, bacteria, and microbes.

Material Mixing

Material mixing- Picture Courtesy: Adam Fabriwerk

As soon as the base for syrup is prepared, the next step is mixing. During this phase, the sugar based is transfered to another vessel where mixing with rest of ingredients including active pharmaceutical ingredients like pain relievers, flavors, and honey etc., is done. Under controlled heat, all the substances are dissolved resulting in the creation of thick sore throat syrup.

Cooling and Filtration

Syrup cooling & filtration- Picture Courtesy: Adam Fabriwerk

Proceeding further, the prepared sore throat syrup is then left to cool down at room temperature. Once get cooled, the syrup is passed through filtration step under which impurities and unwanted particulates are separated from syrup. This step is also significant for maintaining the quality control of syrup.

Syrup Packaging

Sore throat syrup bottling- Picture Courtesy: geninox.com

The last step is syrup packaging which must be carried out carefully as the quality of sore throat syrup entirely depends upon how it is stored and kept. For this purpose, glass and plastic bottles are often used to fill syrup. However, now flexible and single serving packaging is also adopted for convenient usage.

4.Enlist The Advantages Of Sore Throat Syrup Manufacturing?

Pharmaceutical businesses are not only in pursuit of earning money and a top presence in the market but also their goal is to create a long list of happy and satisfied customers. For this, they invest in sore throat syrup manufacturing. Because sore throats and coughs are one of the most prevalent problems in all areas of the world.

So, let’s dive deep into the beneficial world of sore throat syrup manufacturing:

Higher Rate of Order Completion

Higher Rate of Order Completion

The demand for sore throat syrup is at an all-time high in every season. But in winter, you see almost every individual in cold climates affected with throat and chest congestion. To meet this sky-high demand, manufacturers take the expertise of sore throat syrup manufacturing. And complete their order mark within a short time.

Easing Symptoms in No Time

Quick Relief- Picture Courtesy: Healthline

Do you know that syrups are one of the simplest means of obtaining quick relief? Isn’t that comforting? Indeed! Sore throat syrup manufacturing produces a large quantity of syrups to offer faster therapeutic comfort to patients. Yes, they have the potential to coat sore and achy areas of the throat, decrease irritation of respiratory surfaces, and alleviate discomfort.

No Fuss No Muss Administration

No Fuss No Muss Administration- Picture Courtesy: Global Risk Community

With this type of manufacturing procedure, developers can develop syrups that are easily given to every patient demographic- whether young or old. Syrup is the most favored way of administering medications to sensitive individuals, who have a fear of ingesting tablets or capsules.

Suitable for Every Market Type

Suitable for Every Market Type- Picture Courtesy: Scinox

One of the biggest advantages of sore throat syrup manufacturing is that the production process is comprised of a limited number of machines. So, can be scaled up and down and reconfigured to cater to the fluctuating demands of both local supply chains as well as international markets.

Efficacy for a Long Period

Efficacy for a Long Period- Picture Courtesy: Daily Mail

Effectiveness is one of the major concerns of every customer. However, pharmaceutical stakeholders easily provide them with peace of mind by properly formulating and executing every step in sore throat syrup manufacturing. With this, the latter not only guarantees the stability of syrups for longer periods but also reduces product wastage frequency and achieves enhanced profit margins.

5.What Is The Production Line For Sore Throat Syrup Manufacturing?

Sore throat syrup manufacturing is a long process which is easily done by various machines. This production line is a comprehensive solution made up of several machines for each step.

Water Treatment Plants

Reverse Osmosis Equipment

AIPAK Engineering- Fully Automatic Stainless Steel RO System For Pharmaceutical Purified Water Treatment

As the name illustrates, this reserve osmosis equipment is employed to deal with the purification of water by applying high pressure force through which water is cleaned. The process takes place when water is passed through a semi-permeable membrane which block all the particles and bacteria including solid substances and microbes etc.

Water Distillation Unit

AIPAK ENGINEERING- Multi-effect Water Distiller

Water distillation is another important machine used in water treatment process during sore throat syrup manufacturing. It works on the principle of evaporation and condensation under which water is boiled in a stainless steel tank. The resultant vapors move towards another tank for cooling where the vapors turned back to water in a purified form.

Water Distribution and Storage Tanks

AIPAK Engineering water tank for purified water storage

Water distribution and storage tanks are essential to safely store purified water under controlled temperature. These tanks are made up of stainless steel which is fully resistant to corrosion and endure temperature. The tanks are also used for distributing stored water to other machine through pipes.

Mixing Unit

AIPAK ENGINEERING- High Speed Pharmaceutical Stainless Steel Liquid Mixing Preparation System

Mixing unit is also called liquid preparation system for the reason that it can mix and heat the liquid with other substances through heat application. The machine is composed of large tanks, control system, electric cabinet, agitators, and lids.

Filtration Unit

Filtration unit

Filtration unit is the final equipment for water treatment of sore throat syrup manufacturing. It has special features of liquid filtration which automatically remove the impurities, unwanted solid particles, and constituents from prepared liquid mixture.

Syrup Bottling Production Line

AIPAK Engineering glass bottle syrup filling production line

Bottle Unscrambler: Bottle unscrambler is the first unit of a production line for sore throat syrup manufacturing. It is used to align the bottles and provide them to the production line through conveyor. The equipment has a simple design with rotary turntable, main frame, inlet, and out feed unit. It is integrated with a bottle washing machine.

Bottle Washing Machine: Bottle washing machines are another important equipment attached to the sore throat syrup manufacturing production line. The machine is highly advanced with an updated system for disinfecting bottles through washing. It consists of a water system, nozzles, bottle holders, and conveyors etc.

Tunnel Sterilization Oven: Sore throat syrup manufacturing production line has another equipment after bottle washing machine which is tunnel sterilization oven. It circulates hot air of around 350°C temperature which is evenly distributed across the tunnel to let the bottles fully free from bacteria and pyrogens.

Liquid Filling Machine: Liquid filling machine is an inevitable part of the production line which is necessary for the dosing of precise sore throat syrup volume into bottles. It has a hopper, weighing system, conveyor, and control system. The machine automatically detect bottles presence and start depositing measured syrup into bottles through nozzles.

Bottle Capping Machine: It is integrated into the production line for airtight closing of sore throat syrup filled bottles. It is high automation advance equipment with sophisticated design that facilitates efficient capping of bottles through electromechanical technology. It consists of a compact structure, hopper, capping plate, and torque pressure etc.

Bottle Labeling Machine: It is the last unit of production line for sore throat syrup manufacturing. Its task is to apply labels around the syrup bottles for recognition and information. The major components include main body, unwinding wheels, label roller, label applicator, and fur brush.

Bottle Labeling Machine: This part of syrup bottling production line is used to label the finished bottles. It is useful to apply sticker labels around sore throat syrup containers for displaying information. It has automatic system for unwinding film, its application around bottles, and then discharging.

6.What Ingredients Are Used In Sore Throat Syrup Manufacturing?

There are several ingredients which are used in sore throat syrup manufacturing. These are listed below:

Ingredients required for making sore throat syrup manufacturing- Picture Courtesy: lifevisionhealthcare.co.in

Honey:Honey is an essential ingredients used in sore throat syrup manufacturing due to its natural sweetness and properties to soothe throat.

Sweeteners:In addition to honey, certain other sweetening agents like glycerol and sugar are also used to enhance the texture of syrup.

Active Ingredients:As sore throat syrup is meant to cure dry cough and throat problems, various substances like active pharmaceutical ingredients are used. These include menthol, expectorants, and paracetamol etc.

Excipients:Excipients are preservatives and stabilizers which helps in improving the texture as well as prolonging the shelf life of sore throat syrup.

Colorants & Flavors:Various colorants and flavors are used to mask the unfavorable taste and enhance the color of sore throat syrup.

7.What Are The Packaging Options For Sore Throat Syrup Manufacturing?

Packaging play essential role in preserving the quality of sore throat. Therefore, it must be chosen wisely. In this way, different types of packaging options are now available in market. Few of them are listed below:

Bottles

Various bottles- Picture Courtesy: vial.company

Bottles of glass and plastic are famously used for the storage of sore throat syrup. Glass bottles are safe against moisture and light, which as, plastic bottles are flexible enough to resist pressure.

Pouches

Maple syrup doypack pouch- Picture Courtesy: mapleroch.com

Apart from rigid packaging like bottles, flexible packaging is now also popularly used for sore throat syrup. These include doypack pouches which have a spout with cap for convenient opening.

Sachets

Cough & cold relief syrup sachet packaging

Sachets are small flat flexible bags which are used for encasing single serving sore throat syrup. Such packaging is highly favored by consumers due to ease of use and ultimately paves the way for better marketing.

Jars & Containers

Syrup jar & bottle- Picture Courtesy: stock.adobe.com

Most of the renowned companies used to pack their produced sore throat syrup into glass jars and containers. It signifies high quality production and adds to the reputation of brands.

8.Where Does The Sore Throat Syrup Manufacturing Take Place?

Sore throat syrup manufacturing on industrial level

Although, sore throat syrup production involves various steps which are carried out at different places such as research laboratories and clinical centers, however, its mass production take place on industrial level.

Where testing and development require specialized fields like pharma and nutraceutical experts, the manufacturing of sore throat can be initiated by any layman as business person. However, it also needs clear understanding of the products, ingredients required, and most importantly the machines used.

9.What Should Be The Labeling Considerations For Sore Throat Syrup Manufacturing?

You certainly would have noticed labeling on syrup bottles. But what is the purpose of labeling? Well, they are included in the syrup containers to educate consumers about potential benefits and ingredient lists of products. This labeling is also a must for regulatory compliance and product differentiation. Now, let’s get into major labeling considerations:

First and Foremost, Regulatory Compliance

Regulatory Compliance- Picture Courtesy: Tasha Rose

Every drug regulatory authority mandates pharmaceutical brands to incorporate the following information on these product labels:

| Drug Name and Classification | Manufacturers must clearly print the drug name, classification, generic formula, etc. on the label. |

| Ingredient Composition | It should mention active as well as inactive ingredients, whether buffers, salts, preservatives, or flavoring agents. For regulatory fulfillment, brands must also state the concentration of ingredients. |

| Dosage and Usage Instruction | How do you know what is the suitable way of taking sore throat syrup? Well, by labeling. You certainly have seen dosing and usage instructions on labels. Like taken on an empty stomach or shaking before use. This dosage is mentioned according to various age groups. |

| Indications | Labels also include the intended application of the product. Such as, it can be used for treating sore throat, and relieving congestion. |

| Dates | Various dates, such as manufacturing and expiry dates are clearly stated on the back of the label. |

| Production Details | Numerous manufacturing details, for instance, producer name, address, tracking codes, and lot number are also incorporated on labels. |

Warning and Precautions

Warning and Precautions

You as a pharmaceutical manufacturer must take care to include warnings and precautions in the sore throat syrup label. For example, keep in mind to incorporate allergen information (honey, artificial dyes, or sweeteners), side effects (drowsiness, dizziness), and overdose guidance. You must also mention drug interactions with sedatives and antihistamines. Moreover, syrup labels should have safety warnings for expecting and breastfeeding mothers.

Product Billboard

Product Branding

While designing labels, you should take into account product visibility and branding. Hence, a label must have a clear bold font, unique coloring, and icons for attention-grabbing and readability. Manufacturers also employ tactics of incorporating flavoring and certification indications to boost product appeal.

10.Factors To Look For Sore Throat Syrup Manufacturing?

If you are intending to begin with sore throat syrup manufacturing then make sure to consider some of the important factors which are mentioned below:

Ingredients

The ingredients you use in making sore throat syrup play essential role in overall manufacturing. So, you need to know about various materials required for manufacturing and their sources for quality purposes.

Machines

Machines for sore throat syrup manufacturing- Picture Courtesy: adinathmachines.com

Without the use of machines, industrial level sore throat syrup manufacturing is quite difficult in modern age. Therefore, you have to list down the equipment required and search for the most sophisticated machines.

Packaging

Cough syrup packaging

Packaging is also very significant step in sore throat syrup manufacturing. Therefore, opt for sustainable packaging with less carbon footprint and use informative labeling for delivery of information.

Regulatory Compliance

Regulatory compliance icon- Picture Courtesy: oneeducation.org.uk

While conducting sore throat syrup manufacturing, it is necessary to comply all the relevant regulatory requirements. These quality standards include FDA, ISO, and GMP etc.

Conclusion

So, we are about to summarize this FAQ guide about Sore Through Syrup Manufacturing with a reminder that modern era is the era of globalization which means you are not bound to pass your trade caravans through the Silk Road. Instead, businesses can be run remotely. However, one thing remains the same which is the onsite production of sore throat syrup that needs proper machinery and must be operated through fixed methods. We hope you have found all these aspects in the guide above. In case you have any query, feel free to contact us through the given link. We will contact you ASAP. Thank you!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours