Sheep Antibiotic Injection: The Complete FAQ Guide in 2025

Are you looking for a way to treat your sheep? Treating sheep is of priority as they form the backbone of your farm. Getting an infection in one sheep, if, not treated timely, and can spread to other sheep, leading to big problems. As a famous proverb is “prevention is better than cure”, so timely treatment is better than dealing with after-effects.

When you try to grip on the infection of sheep but it gets out of hand, sheep antibiotic injection works as magic. It treats and fights off bacterial infection effectively. Preventing and treating infections, sheep antibiotic injection is the best remedy for this.

If you’re new to sheep rearing and veteran shepherd, then you have clicked on the right link. You will know the details about sheep antibiotic injection. Let’s jump right in.

1.What is sheep antibiotic injection?

Sheep antibiotic injection-Picture Courtesy: norbrooklaborotories.com

Sheep antibiotic injection is used to treat bacterial infection in sheep. By targeting pathogens, sheep antibiotic injection releases antibodies in bloodstream to neutralize and fight off bacteria. Frequently address the infections, this reduces the symptoms of infections such as fever, gastrointestinal -related problems and many more. This helps to prevent your existing flock from spreading infection.

2.Do you know the purpose of using sheep antibiotic injection?

Nothing can be used without a purpose and everything we use has purpose. The purpose of sheep antibiotic injection is as follow.

Treating bacterial infections

Bacterial infection

This is used to treat bacterial infections in sheep. By this, it can combat pathogens spreading to another part of body. It promotes quick recovery and reduce the severity of infection.

Support livestock

Livestock

Sheep’s immune system gets weakened when exposed to poor environmental conditions. Sheep antibiotic injection provides support to sheep before infections getting a hold of them support and strengthen livestock and make them strong enough for future infections and ensures antibodies for them are already present in their body.

Reduces symptoms

Symptoms come with infections and these symptoms such as fever, skin infection and breathing problems are minimized and controlled by sheep antibiotic injection.

Prevent spreading

Prevent spreading

Treating one or a few sheep with sheep antibiotic injections can prevent the further spread of infections within your herd. Timely treatment can reduce the risk of outbreak and help to recover the infected sheep.

3.Can you explain the therapeutic uses of sheep antibiotic injection?

Followings are the therapeutic uses of sheep antibiotic injection.

Treatment of:

Gastrointestinal infection

Gastrointestinal infection-Picture Courtesy: NADIS.com

Gastrointestinal infection is caused by bacteria such as salmonella and E. coli. This leads to diarrhea and dehydration. Sheep antibiotic injection targets the responsible bacteria for gastrointestinal infection.

Respiratory infection

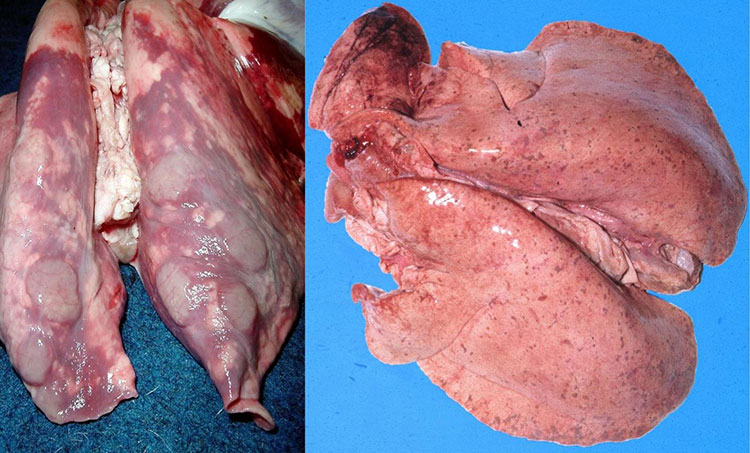

Sheep lungs disease-Picture Courtesy: ecampusontario.com

Due to Pasteurella and mycoplasma(bacteria), sheep are exposed to respiratory infection. They have difficulty in breathing, which also leads to coughing and nasal discharge. This injection targets the causing bacteria and reduces the symptoms by reducing lung inflammation, and preventing pneumonia in sheep.

Skin infection

Skin disease

Rashes, redness, swelling, and softened tissues in sheep are caused by bacteria named Trueperalla pyogenes. Sheep antibiotic injection exposes pathogens to the antibiotic and heals skin.

Foot rot

Foot rot

Fusobacterium necrophorum is responsible for foot rot in sheep. Sheep cannot grow and develop and even difficulty in movement. This injection helps to prevent the bacteria from further spreading and causing infection.

4.What is the composition of sheep antibiotic injection?

The composition of sheep antibiotic injection is different from each other as antibodies for each bacteria causing the infection are different. Here are the common components that are included or used in composition of sheep antibiotic injection.

Antibiotic (Active ingredient)

Oxytetracycline injection-Picture Courtesy: veyong.com

Active ingredient is a commonly used substance that is used almost in every composition. Antibiotics, active ingredients, are different from injection to injection and infection to infection. Some of the antibiotics used in sheep antibiotic injection are:

Tetracycline and Amoxicillin

Respiratory and gastrointestinal diseases are treated by using this antibiotic.

Penicillin

Infections caused by gram-positive bacteria are treated by penicillin.

Florfenicol

Florfenicol treats pneumonia in sheep.

Buffering agent

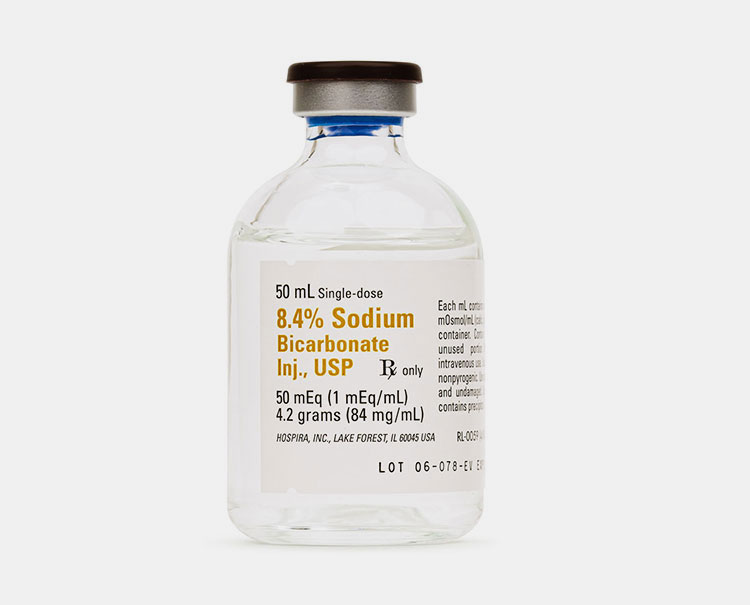

Sodium bicarbonate-Picture Courtesy: empower pharmacy

To maintain the PH of the solution, a buffer agent is used. As the slight increase or decrease in PH can cause problems such as may animal body showing other symptoms or irritation, or solution gets degraded. Common buffer agents such as sodium bicarbonate are used to maintain PH of the solution and ensure proper absorption.

Solvent

Saline water solution-Picture Courtesy: dental sky

Have you ever wondered how the active ingredient dissolves in body? Antibiotics are dissolved in a solvent. It makes sure that antibiotic effectively and efficiently enters the bloodstream. Saline water and glycerin (to make solution viscous) are used as solvent.

Suspending agent

Hydroxypropyl methylcellulose is used as suspending agent in sheep antibiotic injection. Some of the injections do not show response immediately, and slow effects. Suspending agent is used for the same purpose. They slow but have effective and productive response to the infection. It prevents the active ingredients from settling out of solution and stabilizes the suspension.

5.What is the making process of sheep antibiotic injection?

Followings are the steps involved in manufacturing sheep antibiotic injection.

Selection of microbial strains

Microbial strains

The first and important step is to choose the microbial strain. This must be complied with an important consideration. To produce antibiotic, microbes need to consist natural ability to biosynthesize antibiotic. For penicillin, Penicillium and streptomyces for oxytetracycline is used. The strains may be of fungi and bacteria.

Fermentation

Microbial fermentation

After selection of microbial strains, the next step is fermentation. Here, the quantity of selected microbial strain is increased. It is loaded in stainless steel fermenter. A solution of glucose, ammonium salt, vitamins and mineral are provided where there is controlled and growth-maximizing environment.

Temperature is maintained of about 25 to 35 centigrade. In this temperature, no germs are survived so the fermented solution is free of germs. After 2 or 3 days, antibiotic is produced.

Formulation

The purified antibiotic solution is transformed in the injectable product. This is done by mixing many required solutions such as buffer agent, solvent and stabilizer. According to the use, it is intended that way, either move for lyophilization or for filling in injections directly.

Packaging

Packaging

Packaging is the final stage. Here, the formulated antibiotic is filled and package in vials and ampoules. These are washed and sterile, and then filled. After filling, they are moved for sealing and labeling. They are tightly sealed and important information like production date, expiry date and product information are labeled. Finally, vials are cartoned.

6.Do you know about machines involved in manufacturing sheep antibiotic injection?

Sheep antibiotic injections come in market in proper packaging. This is done using different machines in pharmaceutical industries. To make the solution of antibiotic, wide variety of machines are used in each step of manufacturing.

Stay here and let’s get in.

Fermenter

Fermenter

Do you know that antibiotics are made from bacteria to cater another bacterium? Yes, antibiotic is made from some of the bacteria. All this is done by fermenter. It is designed to ferment bacteria by providing an ideal environment such as controlled temperature, oxygen and many more.

To grow microorganisms, the first step is to prepare solution. The environmental conditions equate with growth of microorganism. The desired probe is added to the solution and keep its temperature for around 25 to 35 centigrade. After few days, microbes grow and antibiotic produce that is filtered and purified, onward.

Homogenization machine

Homogenization machine

The antibiotic solution is in highly dissolve form. You cannot see the particles with eyes. This is done with homogenization machine. Homogenizer machine is designed to ensure even mixing of antibiotic solution.

It is used when insoluble materials are to be dissolve in solution or uniform emulsion by breaking down of particles. Now, how insoluble particles are break in uniform particles? High pressure is applied and change them in small particles to ensure a stable suspension.

Centrifugation machine

Centrifugation machine-Picture Courtesy: comi polaris system

There is clean, without any debris or lumps of materials, antibiotic injection. Centrifugation machine is used for this purpose. It separte materials on density base and remove impurities.

It is actually a pre-filtration in which unblended API or other debrises are extracted from suspension. The solution is loaded in rotating chamber which are rotated at high speed. By centrifugal mechanism, low density materials are settled in centre and high density materials are side of centrifuge.

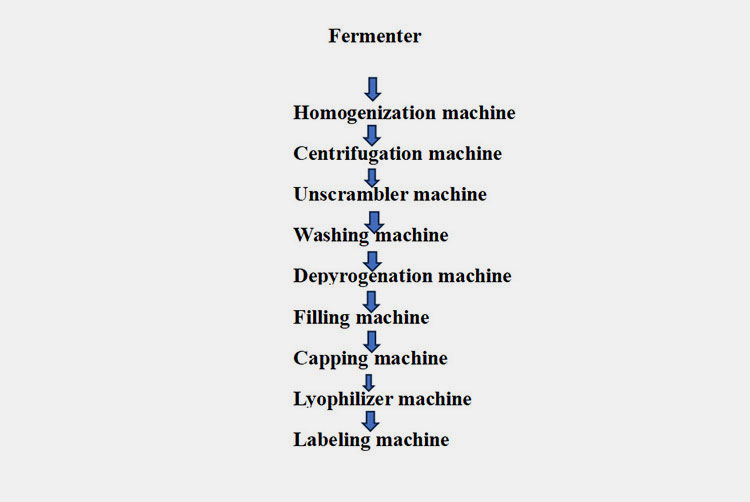

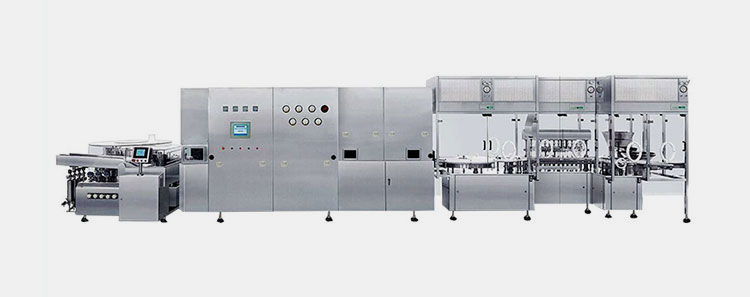

Production line

ALLPACK high ultrasonic vial production line

The above picture of sheep antibiotic injection production line illustrates the stages such as vial washing, depyrogenation of vials, filling and capping. It consists of unscrambler machine, ultrasonic washing machine, dry sterilizer, filling machine, capping machine. You can use the machines separately or in line.

Followings are the machines involved in various stages of manufacturing sheep antibiotic injection.

Unscrambler machine

In machine large quantity of vials are feeded in machine. But place in proper and oriented position is done by unscrambler machine. It uses air jet to position vials. Precise handling is the quality of this machine which helps to prevent damages.

Washing machine

Before filling injection, it is washed to make them clean and sterilize by washing machine. These germs free vials help in effective storing of antibiotic solution. For internal cleaning, vials are turned upside down.

Depyrogenation tunnel

To achieve sterile sheep antibiotic injection, depyrogenation tunnel is used. This machine is designed to make vials free of germs and make it suitable for filling with antibiotic solution. pyrogenation tunnel uses dry heat or hot air to sterilize the vials.

Injection filling machine

It is the important machine in manufacturing sheep antibiotic injection. This helps in filling injection accurately without making fuss of underfilling and overfilling. Injection filling machine use piston to dispense antibiotic in injection.

Capping machine

To protect injections from contamination and waste, capping is done. Here, the automation is done while capping. Capps are loaded in machine hopper then covey to capping station where apps are applied using torque system. Inspection is done to ensure tightened capping. lastly, it goes out from machine through vial discharge.

Lyophilizer

AIPAK vacuum freeze dry machine lyophilizer

This type of machine also uses in manufacturing sheep antibiotic injection. Lyophilization is used to removes water from antibiotic solution. Thus, making antibiotic in dried powdery form. If you are worrying about its storage and needs refrigerator, then you don’t need to be worry as it does not need a refrigerator and can be stored for months and years.

It works by freezing antibiotic solution. Solution is being freeze and then by applying vacuum and the process of sublimation, solid freeze solution change into gaseous state by drying at vacuum condition. Temperature is increased more and more to remove any moisture from the antibiotic solution.

Labeling machine

Injection labeling machine

You might have seen labels on sheep antibiotic injections. These are labeled by labeling machine. It is important to label as doctors and customers will know about the ingredients amount, date of expiration, and how to use.

7.What is the storage requirement for sheep antibiotic injection?

To protect injection from contamination and other environmental factors, it is necessary to store sheep antibiotic injection. Here are the requirements of storing injection.

Protection from light

Protection from light

You might have read labels of antibiotic injections that protect the injection from light. The reason for this is that ingredients in injections are prone to break down when exposed to light, making it less effective.

The solution to this is that sheep antibiotic injection must be placed at a place where there is no strong light and should be stored in opaque bottles or vials.

Using guideline

On most of the injections, the proper usage instruction is written to guide the user. Some of the sheep antibiotics needs to be shaken well before use or some to be stored in a cool place for effective efficiency.

Storage at germs-free place

Storage at germs-free cabinet

Sheep antibiotic injections need to be store at sterile environment. If it gets contaminated and injected in sheep, it will enhance the infection rather than cure it. It must be stored in a cabinet that is only for medications and provides a clean and germs -free environment.

Ideal temperature

Ideal temperature

All antibiotic injections need different temperatures for storage. But sheep antibiotic injection needs a low temperature for storing. The ideal temperature for this is 2 to 8 centigrade. Temperature higher than this will cause ingredients to break because antibiotics like penicillin are highly sensitive to temperature.

Now a question will pop up in your mind do all the sheep antibiotic injection requires low temperatures for storage? No, some of the sheep antibiotic injection needs a temperature of 8 to 15 centigrade but for a short time.

Humidity

Do not use sheep antibiotic injection in high -humidity places. It will deteriorate your appealing packaging of injections along with this, it will encourage the growth of bacteria.

8.What are the available sizes and volumes of sheep antibiotic injection?

Different sizes and volumes of injections-Picture Courtesy: farmacy.com

Sheep antibiotic injection comes in various sizes and shapes depend on type of antibiotic and manufacturer. Let’s have a look at this.

| Volume/size | Explanation |

| Small volume vials | Sheep antibiotic injections come in small volumes vial from 10ml to 50ml. These small vials are enough for small-scale farm and individual sheep at a time. |

| Medium volume vials | Medium size vials are of 100ml to 250ml. these ranges of sheep antibiotic injections are ideal for medium-scale farm. It can accommodate large doses. So, can be use for multiple sheep simultaneously. |

| Large volume vials | 500ml to 1 liter of vials and bottles of sheep antibiotic injections come in market for the large-scale farm such as industrial based farm. These sizes typically are used when infection is of widespread in herd. It is of best use when managing infections that require more doses over time. it is cost-effective. |

| Pre-filled injection | Sheep antibiotic injection comes in a ready-made way. In it, there is no error of overdosing or less-dosing, contains a fixed volume of antibiotic. It is user-friendly. |

9.What is the effect time for sheep antibiotic injection?

The effect time for sheep antibiotic injection is varying. What are you waiting for? Let’s get started.

Depends on infection

Type of infection: Picture Courtesy: diamondhoofcare.com

Minor infection is quickly treated by antibiotic. It effectively holds bacteria spreading. If

there is chronic or severe infection in sheep then sheep antibiotic infection response is slow as compared to mild infection. Because infection entered in bloodstream and affected organs. It takes longer time to show its effectiveness.

Release mechanism

All sheep antibiotic injection does not equal release mechanism because every one of them is designed for different infections. Some have slow-release mechanisms as it has to cure chronic infection that needs a long term treatment.

Fast-release of active ingredients mechanism are often used to treat mild infections such as swelling, fever and redness.

Sheep health

Sheep health-Picture Courtesy: irishfarmersjournal

If sheep have weak immune systems and unfit health, then their response to antibiotic injection might be late. You might has heard that some of sheep antibiotic injection has immunomodulatory effects that strenthen sheep’s immune system to fight off bacterial infection.

Dosage rate

Dosage rate also effect the effective time of sheep antibiotic injection. A minimum dosage is not that much effective compared to maximum dosage. It also depends on antibiotic use in injection and the type of infection being treated.

10.What are the side effects of overuse of sheep antibiotic infection?

To exceed the use of sheep antibiotic injection can cause several side effects. Followings are the side effects of sheep antibiotic injection.

Organ damage

When sheep antibiotic injections are injected by crossing the recommended limit can cause organ failure such as kidney failure and liver damage as it is responsible for metabolizing antibiotic. It can experience toxicity which ended in symptoms like reduce appetite.

Developing other infections

Over-dosing can cause immune system to weak as germs quantity in body get increased and immune system can not handle to fight off them. This results in developing other infections in body.

Antibiotic resistance

Overuse may result in antibiotic resistance bacteria. It becomes difficult to treat the current infection. Even in future, if sheep gets same infection, this resistance bacteria will be activated and will show resistance to the infection treatment.

Allergic reaction

Allergic reaction-Picture Courtesy: Agri Orbit

Sheep body will signal allergic reaction if overdosed. Symptoms such as swelling, skin rashes, and other develop.

Disturbance of gut flora

In the sheep gut, there are beneficial bacteria responsible for digestion. Overuse of sheep antibiotic injection can cause disturbance of digestive system by disturbing gut flora.

11.What role do veterinarian play in guiding the use of sheep antibiotic injection?

To ensure safe and effective treatment, consults veterinarian. They play pivotal role in guiding proper use of sheep antibiotic injection. Here is the role.

Determining infection

Determining infection

To get proper treatment, first thing you need to know the kind of infection, whether bacterial or not. Antibiotics will not be given when infection is viral. Veterinarian will prescribe you with right antibiotic depends on infection and severity.

Prescribe antibiotics

Veterinarian will help you in selecting antibiotic for your sheep. Different infections need specific antibiotic for cure. Veterinarian will help you with this. If sheep’s body does not response to the prescribed antibiotic, he will closely monitor it.

Education

Education-Picture Courtesy: rideau-St. Lawrence

There are special seminars for veterinarian and farmers. In these proper guidelines and information are provided to farmers about the proper use of sheep antibiotic injections, symptoms of infection and side effects of overuse of sheep antibiotic injection.

Conclusion

To conclude the FAQ guide, it is important to note that timely antibiotic injection is essential to protect your sheep and save your herd from future problems. This guide shows you knowledge of side effects of overuse and gives you insight into machines used in production. If you are a vet, farmer or businessman looking for a high-quality machine for injection production, you don’t need to go anywhere else. We provide all kinds of machines- from vial filling to sealing. Stay here and find everything you need.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours