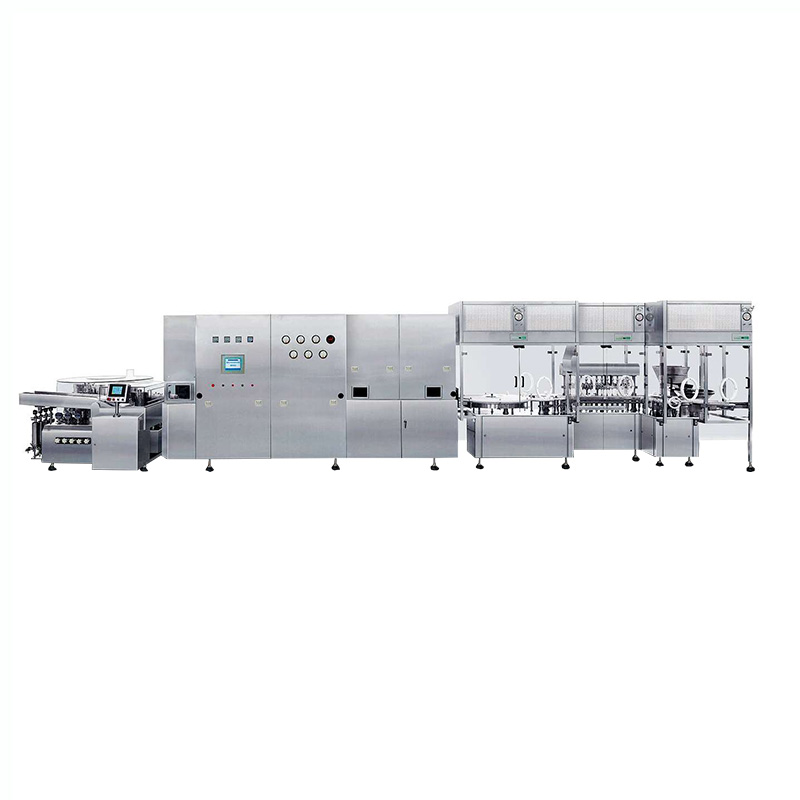

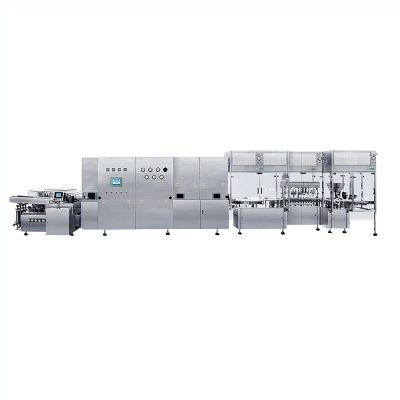

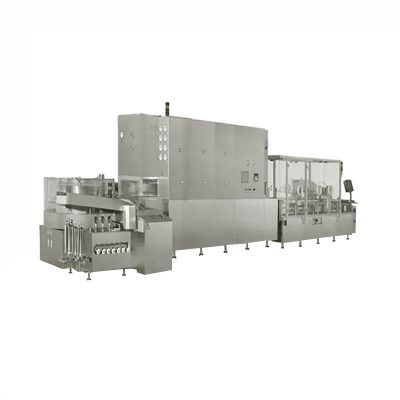

High Output Aseptic Liquid Vial Production Line

AIPAK Engineering liquid vial production line is composed of ultrasonic bottle washing machine, dryer sterilizer, filling stoppering machine, and capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, heat source removing, cooling, bottle unscrambling, (nitrogen pre-filling), filling, (nitrogen post-filling), stopper unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process. Each machine can be used separately, or in linkage line. The whole line is mainly used for filling of vial liquid injections and freeze-dried powder injections in pharmaceutical factories, it can also be applied to production of antibiotics, bio-pharmaceuticals, chemical pharmaceuticals, blood products etc.

Vial liquid example:

Vial Automatic ultrasonic washing machine

Automatic washing machine consist of infeeding section, ultrasonic treatment section and final washing section, the containers are going through those sections for completion of the whole washing processing by Ultrasonic treatment, prewashing and final washing steps, the cleaning quality of the container washed meets any Pharmacopoeia and being able to validate.

Sterilizing Tunnel machine

Vial powder filling and stoppering machine

High Output Aseptic Liquid Vial Production Line Features:

- The whole line meets the requirements of the new version of GMP, and the cleaning effect meets the new standards and requirements of the Pharmacopoeia.

- The whole line can adopt either straight-line layout or wall-to-wall L-shaped layout to reduce risk of drug cross-contamination and provide aseptic protection level.

- Applicable specification: 1ml-100ml vial (as per user's requirement)

- Production Capacity: 1000-36000BPH

- The number of filling head: 1-20, to be selected according to output

- Filling Accuracy: ≤ ±1% (according to drug characteristics)

- Choice of various filling pumps: glass pump, metal pump, peristaltic pump, ceramic pump;

- The pass rate of capping: ≥99.9%

- Compact and simple structure, small occupied area;

- Stable product performance, easy and reliable operation, beautiful appearance;

- High degree of automation, few operators;

- The filling way can be in single row or double row;

- Real-time display and printing system of sterilization temperature are configurable;

- The heat source of tunnel hot air circulation oven is evenly distributed, and the heat removal effect is good.

- The online sterilization function of the cooling section of tunnel hot air circulation oven can be configured.

- Open-RABS isolation protection system and 100-level air purification laminar flow system are configurable;

- Can be equipped with high-performance stop filling without bottle, non-stopper without bottle, stop capping without bottle, linkage bottle extrusion stop function;

- The capping machine can be equipped with dust exhaust device, which can absorb aluminum scraps produced during capping and reduce environmental risk.

- The whole line can be equipped with online monitoring system to monitor key factors that affect product quality (such as dust part, planktonic air dust bacteria, wind speed, wind pressure, etc.).

- Have the function of full-line linkage control;

- To realize fully automatic control and monitor of production process, high

precision color touch screen operation monitoring, PLC automatic control, automatic protection, host frequency conversion speed regulation and other control technology are be used.

- A wide range of bottle specifications, and easy to replace mould.

- The products can be customized according to actual demand of customers.

High Output Aseptic Liquid Vial Production Line Technical Specification:

| Model | APE4 | APE6 | APE8 | APE10 | APE12 | KGF20 | KGF24 |

| Applicable specifications | 2~30ml vial bottles | ||||||

| Filling heads | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Production capacity | 50-100bts/min | 80-150bts/min | 100-200bts/min | 150-300bts/min | 200-400bts/min | 250-500bts/min | 300-600bts/min |

| Stoppling qualification rate | >=99% | ||||||

| Laminar air cleanliness | 100 grade | ||||||

| Vacuum pumping speed | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Power consumption | 5kw | ||||||

| Power supply | 380V 50Hz | ||||||

High Output Aseptic Liquid Vial Production Line Related Products