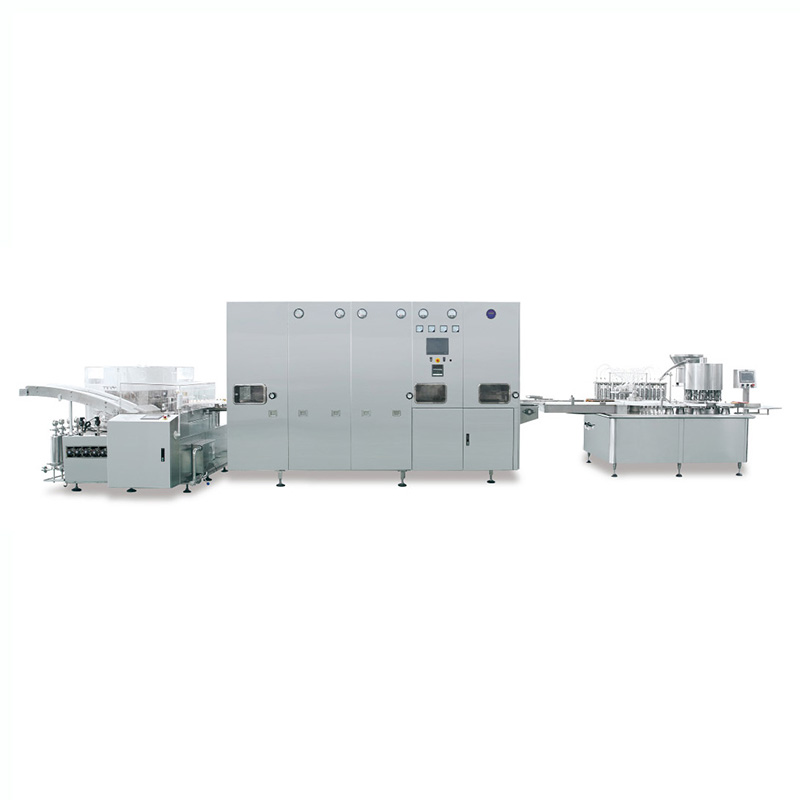

High Filling Accuracy Oral Liquid Production Line

AIPAK Engineering oral liquid production line is composed of three equipment: bottle washing machine, tunnel sterilization oven, and oral liquid filling capping machine. It is divided into three working areas: cleaning, drying and sterilizing, filing and capping. Each machine can be used separately or in linkage line. During linked production, it can automatically complete cleaning, preheating, drying and sterilization, cooling, filling, screw (rolling) capping and is suitable for the production of packaging lines for oral liquid bottles and other small-dose solutions in the pharmaceutical, health care, food and other industries.

Oral liquid example:

High Filling Accuracy Oral Liquid Production Line Features:

1.Outer feature: outer material is stainless steel, dull polished. The whole line is good in appearance, easy to clean. It complies with GMP regulations and can be suitable for several bottle specs.

2.Structure feature: water filling→ultrasonic wave coarsely washing→circulation water→circulation water→compressed air→wfi→compressed air→compressed air→tunnel oven preheating→high temperature drying→cooling→bottle feeding→filling→cap→to the next process.

3.Filling dosage feature: no dripping, no forming, and no spitting.

4.Running feature: stable running, low noise, precise filling, low energy consumption, low bottle breakage ratio, high qualified product ratio.

5.Performance feature: the whole line can single machine control or interlock control. Washing machine 3 water and 3 air ensure washing effect; tunnel oven high temperature ensure drying bottles; piston filling pump ensure filling precision;10 head capping machine ensure sealing effect.

6.Meet with GMP requirement.

High Filling Accuracy Oral Liquid Production Line Technical Specification:

| Product model | HKGL8 | HKGL16 |

| Adaptive Specifications (ml) | 5-30mlOral liquid bottle | |

| Production capacity (pcs/min) | 150-200 | 300-400 |

| Number of filling pins | 8 | 16 |

| Power source | 380V 50Hz | |

| Electrical capacity (kW) | 77 | 88 |

| Total weight (kg) | 7900 | 8500 |

| Overall dimensions (mm) | 8550x2200x2245 | 9200x2200x2245 |

High Filling Accuracy Oral Liquid Production Line Video

High Filling Accuracy Oral Liquid Production Line Related Products