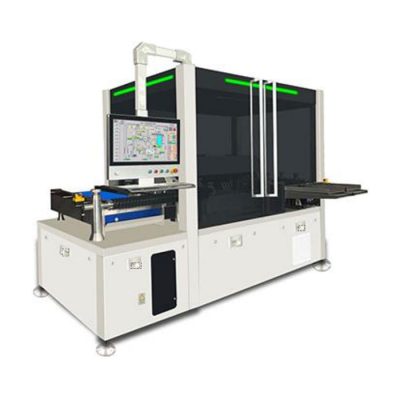

Automatic Visual Inspection Machine for Oral Liquid Bottles

AIPAK ENGINEERING Automatic visual inspection machine is designed for precise detection of visible foreign particles, cosmetic defects, and micro-leaks in pharmaceutical oral liquid bottles. It provides an intelligent, high-speed inspection solution for pharmaceutical oral liquid,standalone bottle filling,ampoule filling,integrated automated packaging production lines.

The system uses high-speed industrial cameras, advanced image tracking software, and dual reflective mirrors to ensure a 360° inspection of each vial. It can accurately detect various defects such as:Glass fragments, metal particles, and fibers, Black or white spots, flakes, or turbidity, Peeling or bubbling in lyophilized products, Underfilled or overfilled vials, Cracked bottles, missing stoppers, or damaged caps. The inspection speed reaches 400–600 bottles per minute, ensuring fast and reliable quality control for large-scale pharmaceutical production.

The integrated vial leak detection system offers unmatched sensitivity — capable of detecting micro-holes as small as 0.1 micron.

Unlike conventional leak detection methods, this system uses low-energy, short-duration signals that ensure no adverse effect on product integrity, making it ideal for sensitive biological formulations such as vaccines or blood products.

Equipped with an intelligent control system, the machine automatically separates defective vials from qualified ones. It supports full online connection with upstream visual inspection systems and downstream labeling or packaging equipment, forming a fully automated inspection line that maximizes productivity and ensures consistent output.

Vials are precisely spaced by an infeed starwheel and guided through a twisting channel for 90° rotation, enabling complete inspection at multiple stations. Each inspection point can be customized according to specific user requirements. After inspection, a rejection mechanism automatically diverts unqualified bottles from the main line.

Automatic Linear light inspection machine Features:

1.High-speed inspection: 400–600 vials/minute

2.Detects particles, cracks, and cosmetic defects

3.Leak detection sensitivity up to 0.1 μm

4.Fully automatic sorting of good and defective vials

5.Compatible with upstream and downstream equipment

6.Suitable for vaccine, injectable, and lyophilized product inspection

Automatic Linear light inspection machine Technical Specification:

| Item Name | Technical Parameters | ||

| Model | APKDJ-400 | APKDJ-600 | APKDJ-800 |

| Application Range | 1-500ml | 1-500ml | 1-500ml |

| Inspection Speed | 400bpm | 600bpm | 800bpm |

| Voltage/Power | AC220V/5KW | AC220V/5KW | AC220V/SKW |

| Compressed Air Consumption | 0.6MPa-0.1m³/h | 0.6MPa-0.1m³/h | 0.6MPa-0.1m³/h |

| Dimensions(mm) | L2600×W1000×H1800mm | L2600×W1300×H1800mm | L2600×W1600×H1800mm |

| Weight | 4500Kg | 4500Kg | 4500Kg |

Vial Filling Line Related Products