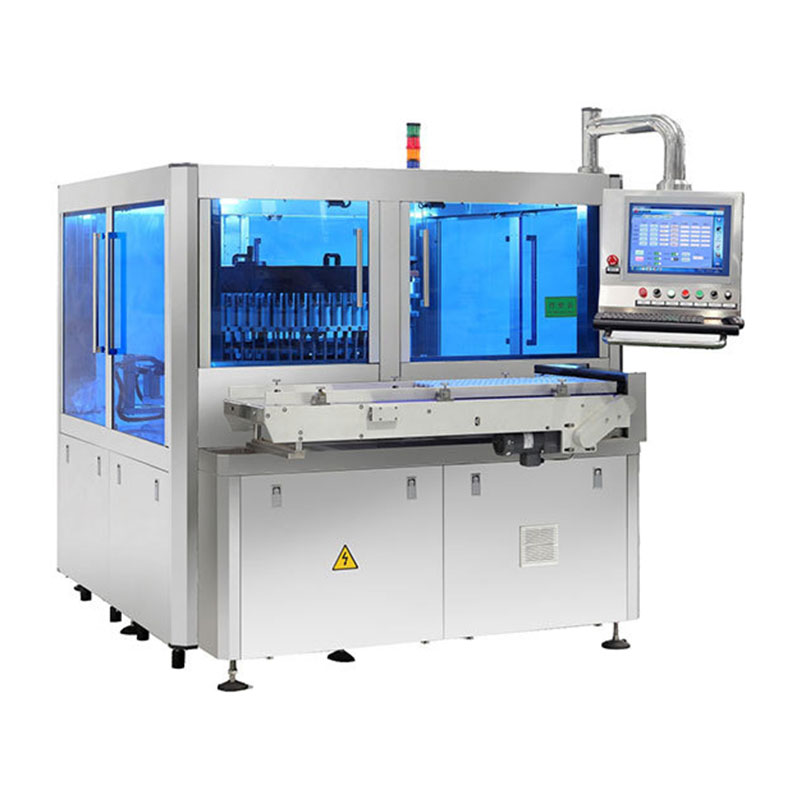

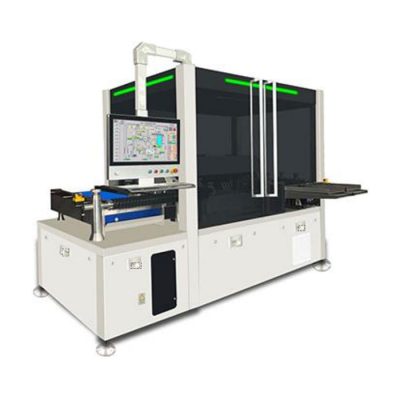

Automatic Visual Inspection Machine for Lyophilized Vials

AIPAK ENGINEERING Automatic visual inspection machine is specially designed for the inspection of lyophilized injectable vials in pharmaceutical production. It provides accurate detection of visible foreign particles, cosmetic defects, and sealing flaws in both molded and tubular vials, ensuring compliance with GMP standards and reliable product quality.

Working Principle:

The system includes an infeed conveyor, star wheel separation mechanism, rotary inspection turntable, camera and lighting tracking unit, outfeed star wheel, servo motor control, and safety enclosure.

Vials are fed through the conveyor and evenly spaced by the infeed wheel before entering the rotary inspection zone. Each vial is clamped by a corresponding head, forming an independent inspection unit that rotates uniformly.

High-speed cameras capture multiple frames at six synchronized inspection stations as the vial rotates more than one full turn. Any defect is automatically identified through image comparison. After inspection, the system releases and sorts qualified and unqualified products automatically.

Inspection Items

The inspection includes product defect detection, container appearance inspection, and seal integrity inspection. The main inspection items are as follows:

1.Cap Inspection: Check whether the aluminum or composite cap is complete and whether the crimping is uniform and visually acceptable (detecting defects such as misaligned, uneven, or wrinkled seals).

2.Neck Area: Inspect whether a rubber stopper is properly inserted and positioned.

3.Upper Body: Check the transparent upper section of the vial for any freeze-dried spots or product splashes formed during filling or lyophilization.

4.Lower Body (Lyophilized Section): Ensure the lyophilized cake is uniform, without missing areas, and free from visible foreign particles on the surface.

5.Bottom Section: Verify the uniformity of the lyophilized product at the bottom and check for missing portions or visible foreign particles.

6.Inside the Vial: Detect any visible foreign particles within the lyophilized drug layer.

7.Container Integrity: Inspect the vial body and bottom for visible cracks or fractures.

8.Filling Level: Detect overfilled, underfilled, or empty vials.

Operating Environment:

Suitable for operation in standard cleanroom environments.

Automatic Visual Inspection Machine for Lyophilized Vials Machine Features:

1.The inspection precision can be adjusted to meet the specific detection requirements of different inspection items.

2.The patented conveying mechanism (refer to the "Manufacturing & Quality" → "Patented Technology" section on the company website) ensures smooth and stable vial transfer during inspection.

3.Multiple stations are equipped with servo motor drives instead of traditional mechanical transmission, enabling full synchronization between motion control and inspection software for improved detection accuracy.

4.Equipped with quick-positioning pins for format parts, allowing for simple changeover and easy adjustment between different vial sizes.

5.Utilizes imported industrial cameras with up to 50× magnification and direct lighting on the inspected objects, providing superior defect visibility and higher inspection accuracy compared to manual inspection.

6.Up to six inspection stations can simultaneously detect all types of product and container defects.

7.Key machine components are processed on precision CNC equipment to ensure dimensional accuracy and mechanical stability.

8.The overall machine structure is elegant and robust, with panels and base plates treated by a special anti-corrosion powder coating process for long-lasting protection.

Automatic Visual Inspection Machine for Lyophilized Vials Technical Specification:

Applicable Range:

Suitable for molded or tubular lyophilized injection vials, 2–25 mL.

Inspection Speed:

400 bottles per minute ±5%.

Motor and Power:

Servo motors: 11 units, total power 0.4–2 kW each.

Power Supply:

9 kW, 380 V ±5%, three-phase AC, 50 Hz.

Working Table Height:

900 mm.

Overall Dimensions (L×W×H):

3620 × 1810 × 2000 mm.

Net Weight:

Approximately 2600 kg.

Vial Filling Line Related Products