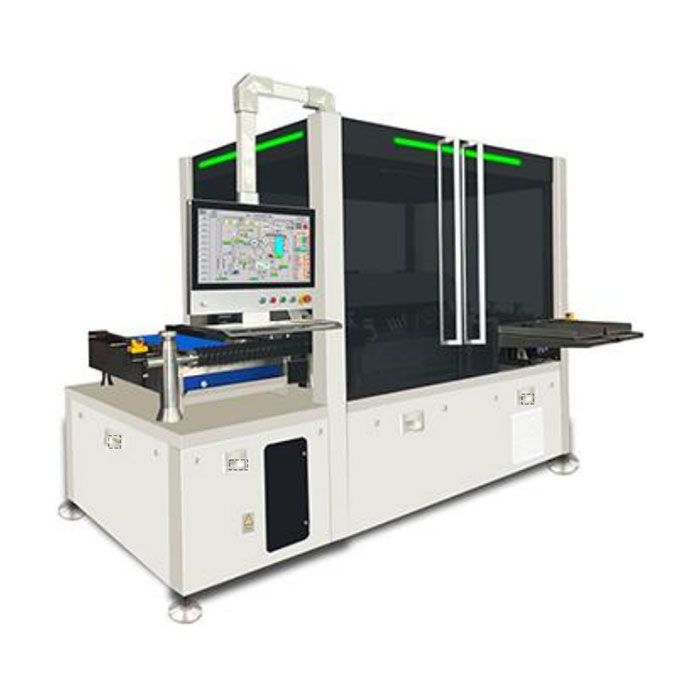

Automatic Visual Inspection Machine for Ampoules

AIPAK ENGINEERING APKDJ-600 full-automatic visual inspection machine for ampoule is a single-machine with double-station structure. With 10ml oral liquid bottles as the reference standard, and the inspection speed per station is up to 600 bottles/minute, which can be connected in parallel according to the production requirements of customers, the product meets the relevant specification requirements of GMP, FDA in the United States, EDQM in the European Union, MHRA in the United Kingdom, PMDA in Japan, TGA in Australia, MFDS in South Korea and MCC bottle outer wall cleaning machine in South Africa.

It is mainly suitable for infrared full-automatic detection of oral liquid, syrup, eye drops, ampoule water needles and other preparation products in the range of 1-100ml in pharmaceutical, chemical, chemical, food, health care, cosmetics and cosmetics. The preparation bottles are orderly arranged on the conveying shaft by the bottle feeding device, then pass through the inspection darkroom and rotate forward, and pass through the infrared light curtain of the concentrated light source in turn. Various visible foreign substances in the preparation bottles (for example: hair spots, large pieces, glass chips, hair, fibers, metal wires, turbidity, smoke-like particle columns, etc.), loading, rubber plugs, aluminum caps (ampoule coke head, carbonization) and cracks in the bottle body are fully reflected through upper and lower mirrors and self-rotation.

Various defects of products can be accurately detected through high-speed industrial cameras and full-automatic image tracking and analysis software, with the help of the equipment automatic control system, qualified products and defective products will automatically enter their respective channels.

Full-automatic light inspection machine Features:

1.The design and manufacture conform to GMP .

2.Friendly operation interface, convenient maintenance, easy to clean.

3.Die replacement is simple and can be quickly replaced without tools.

4.DD motor direct drive technology is adopted to track smoothly without gap error.

5.The clamping position of the product is designed by the clamp type, so that the detection of the product has no dead angle and blind spot, and the clamping force, speed, rotating speed, rotating circle number and rotating time of the clamp can be accurately adjusted.

6.Non-conforming products can be classified and eliminated, which can be used for QA personnel to conduct data analysis and statistics on production conditions.

7.Standard configuration + option configuration, flexible customization of testing items.

8.Detection data and detection process are recorded synchronously, which conforms to GAMP specifications.

Full-automatic light inspection machine Technical Specification:

| Item Name | Technical Parameters | ||

| Model | APKDJ-400 | APKDJ-600 | APKDJ-800 |

| Application Range | 1-500ml | 1-500ml | 1-500ml |

| Inspection Speed | 400bpm | 600bpm | 800bpm |

| Voltage/Power | AC220V/5KW | AC220V/5KW | AC220V/SKW |

| Compressed Air Consumption | 0.6MPa-0.1m3/h | 0.6MPa-0.1m3/h | 0.6MPa-0.1m3/h |

| Dimensions(mm) | L2600×W1000×H1800mm | L2600×W1300×H1800mm | L2600×W1600×H1800mm |

| Weight | 4500Kg | 4500Kg | 4500Kg |

Vial Filling Line Related Products