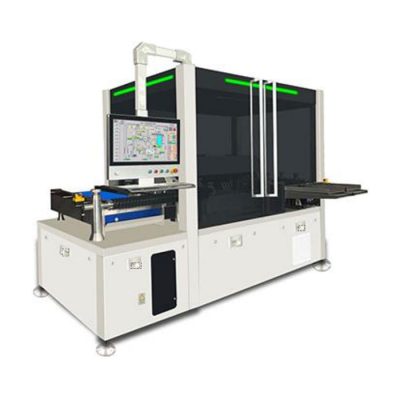

Ampoule/Vial Leak Detection Machine

AIPAK ENGINEERING Ampoule/vial leak detction machine is specially designed for detecting leaks in ampoules, vials, and oral liquid bottles, ensuring product integrity before final packaging. It can precisely identify micro-holes, cracks, or sealing defects on the bottle body, bottom, and neck areas.

Working Principle:

Bottles are conveyed through an infeed belt and evenly separated by a star wheel. They are then guided into a screw conveyor that rotates each container by 90° into a horizontal position. Multiple inspection stations detect leaks at different parts of the container, depending on customer requirements. After inspection, a rejection system automatically separates defective products from qualified ones.

Detection Mechanism:

The system uses a high-frequency, high-voltage electrical detection method. The detection circuit includes two electrodes (transmitting and receiving) and the test solution inside the container. When the container is intact, a weak induced current (I₁) flows through the circuit via capacitive coupling. If the container has a leak, the capacitance between the electrode and the liquid disappears, resulting in a larger induced current (I₂). By comparing these micro-current differences, the system can accurately determine whether a container is leaking.

The ampoule/vial leak detection machine ensures high-speed, non-destructive, and highly sensitive leak detection, making it ideal for pharmaceutical manufacturers seeking reliable in-line quality inspection for ampoule and vial production.

Ampoule/Vial Leak Detection Machine Machine Features:

1.Can operate as a standalone unit or be integrated into a production line for fully automated in-line inspection of each container.

2.Capable of detecting ultra-fine cracks and micro-holes that traditional methods cannot identify.

3.The applied energy on the container is low and of short duration, ensuring that the inspected product remains electrically insulated while passing through the detection zone. This allows non-destructive testing without affecting the liquid inside the container.

4.Detection electrodes do not come into direct contact with the product, preventing any contamination.

5.A single machine can handle multiple container types and sizes by simply changing the molds, including ampoules, antibiotic vials, and oral liquid bottles, improving equipment utilization.

6.User-friendly touch screen interface with comprehensive control, display, data acquisition, and printing functions.

7.Provides a complete set of GMP-compliant validation protocols.

8.The current leak detection product series has received multiple patents.

Ampoule/Vial Leak Detection Machine Technical Specification:

| Item | Specification |

| Model | AJL300 |

| Application | 1–20 ml ampoule, vial, and oral liquid products |

| Capacity | 300–400 bottles/min |

| Power Supply | 2.4 kW, 380 V, 50 Hz |

| Output Voltage Range | 10 kV – 35 kV |

| Output Frequency Range | 500 Hz – 50 kHz |

| Power Channels | Multi-channel high frequency high voltage |

| Weight | Approx. 1000 kg |

| Dimensions (L×W×H) | 3694 mm × 1180 mm × 1364 mm |

Vial Filling Line Related Products