Pharmaceutical Suspension Manufacturing:The Complete FAQ Guide In 2025

Suspension is a common medicine in our life. To tell the truth, not all of them are liquids, but there are particles dispersed in liquid. For the convenience of children and the elderly, many drugs are made in the form of pharmaceutical suspension.

Do you know what features this pharmaceutical suspension has? What production processes are required for its production?

Let’s learn the most comprehensive knowledge about pharmaceutical suspension manufacturing together.

1.What Is Pharmaceutical Suspension?

Pharmaceutical Suspension - Sourced: MK Medicine

Pharmaceutical suspension contains tiny particles or plankton that remain suspended in the medication. For easier ingestion and absorption, pharmaceutical suspensions are usually used for oral liquid drugs, but some are also used for external use.

The suspended particles are fine and uniform, and sink slowly. After sinking, the particles do not clump and can be evenly dispersed with a little shaking.

2.What Are the Key Elements of Pharmaceutical Suspension?

Do you think that suspensions are made by mixing water and other mediation? In fact, pharmaceutical suspension is composed of many components.

Dispersant

Dispersant - Sourced: Azelis Customer Portal

Dispersant is one of the important components in pharmaceutical suspension, which can evenly disperse drugs in liquid media. The common dispersants include sodium carboxymethyl cellulose, hydroxyethyl cellulose, etc.

Stabilizer

A stabilizer is a substance that can prevent the aggregation and sinking of solid particles in a pharmaceutical suspension. The common stabilizers include magnesium silicate, sodium carboxymethyl cellulose, etc.

Water

Water - Sourced: Pexels

The liquid medium in a pharmaceutical suspension mainly refers to the solvent, which is usually a co solvent or a base liquid, such as water. The type of liquid medium also affects the performance of the suspension agent, and water is one of the commonly used liquid media in suspension agents. The main function of water in a suspension agent is to act as a medium, helping particles maintain a stable state.

3.What Are the Advantages of Pharmaceutical Suspension?

Why are more and more drugs in suspension form? The reason is that it has many benefits. Do you know the advantages of it?

Easy to take

Easy to Take - Sourced: VetMedics Compounding Pharmacy

Pharmaceutical suspension is usually administered in liquid form, making them easy to take and more readily accepted by patients, especially for children, the elderly, or those with swallowing difficulties. And the dosage adjustment is convenient, allowing for flexible adjustment of drug dosage according to needs.

Easy to adjust dosage

A small amount of pharmaceutical suspension, with high unit dose and concentration, is usually used for external application. For oral medications, the dosage can be easily adjusted to control the drug dosage and achieve the optimal therapeutic effect.

Improving bioavailability

Improving Bioavailability - Sourced: LoFi Cannabis

Pharmaceutical suspension can suspend solid drugs in liquids. So it makes them easier for the human body to absorb. As as result, it can improve the bioavailability of drugs.

Sustained release effect

The drug prepared by suspension can achieve sustained release effect and prolong the drug’s action time by controlling the particle size and morphology.

Wide adaptability range

Wide Adaptability Range - Sourced: Express Pharma

After the drug is prepared into a suspension, it can be added to oral solutions or applied topically, and the usage is simple. In the following text, we will specifically discuss several suspension agents with different usage methods.

4.What Are the Features of Pharmaceutical Suspension?

The requirement of medicine is high. Do you know what are the features required for pharmaceutical suspension?

Dispersal ability

Dispersal Ability - Sourced: imdip

A good pharmaceutical suspension should be able to evenly disperse particles and avoid particle aggregation. The stronger the dispersal ability, the more transparent the color of the suspension.

Viscosity

A good pharmaceutical suspension should have a moderate viscosity. Excessive viscosity can cause particles to aggregate and not disperse evenly, while low viscosity can lead to unstable particles in the suspension and easy precipitation.

Stability

A good suspension agent should have high stability, that is, it should not produce particle precipitation for a long time, which requires the suspension to resist the effect of gravity, so as to keep the particles suspended in the liquid.

5.What Are the Types of Pharmaceutical Suspension?

You must have taken oral suspensions before, do you know of other types such as externally applied suspensions? According to different classification methods, there are different types of pharmaceutical suspensions.

(1)According to the usage method

Oral suspension

Oral Suspension - Sourced: Tylenol

Oral suspension can improve taste and is easy to swallow, especially suitable for children and adults with swallowing difficulties. It can be taken orally or mixed with a small amount of warm water (not hot water) before taking, avoiding the use of hot water to destroy the drug activity.

Externally applied suspension

Externally Applied Suspension - Sourced: Pharmapproach

External applied suspension is mainly used for surface or local treatment of the skin. You should gently apply with a cotton swab or clean fingers to the affected area to avoid excessive friction.

Parenteral suspension

Parenteral Suspension - Sourced: Medical Supplies

This type is commonly used for subcutaneous, intradermal, intramuscular injection, and intrathecal injection. Before use, it must be thoroughly shaken to prevent drug particles from settling, ensuring even distribution of the drug.

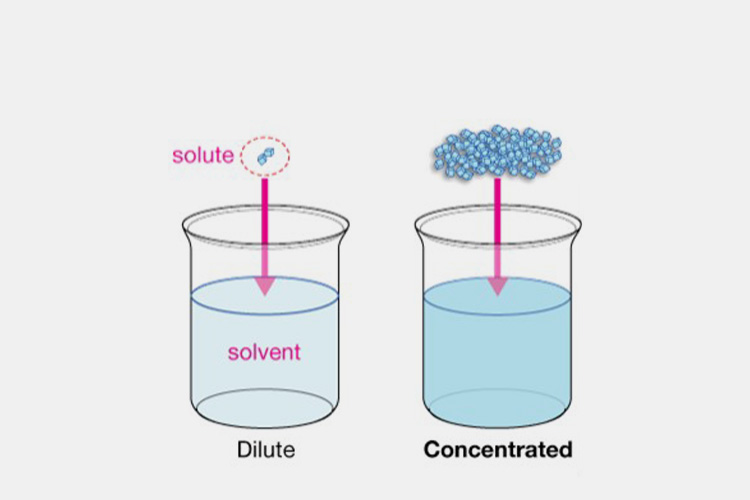

(2)According to concentration

Dilute suspension

Dilution solution is a low concentration suspension used to turn a solution of a certain concentration into a thinner solution. The concentration of diluent depends on the quantity of diluent and the desired target concentration. To obtain accurate concentration, it is necessary to mix the solution and diluent in strict proportions.

Concentrated suspension

Dilute and Concentrated Suspension - Sourced: TEL Gurus

It is a high concentration suspension commonly used to concentrate dilute solutions to the desired concentration. There are many methods for preparing concentrated solutions, among which the most commonly used are evaporation and extraction.

6.What Machines Involved in the Pharmaceutical Suspension Manufacturing?

The production of pharmaceutical suspensions involves many processes and therefore many machines. The target audience for the use of pharmaceutical suspensions is human, so the requirements for machines are also very high.

Water treatment system

AIPAK Engineering Purified Water Treatment System

One of the materials required for pharmaceutical suspension is water, and tap water cannot be used here because there are still many microorganisms, so water treatment system is needed.

Equipped with multiple programs and structures, the AIPAK engineering purified water treatment system is widely used in industries such as pharmaceuticals, biochemistry, chemical engineering, and hospitals. The workflow mainly includes the raw water inlet tank, mechanical filter, activated carbon adsorber, ion exchanger and other links, and the final effluent meets the required water quality requirements.

Mixer/Blender

AIPAK Horizontal Ribbon Mixer

AIPAK horizontal ribbon mixer is a device that processes solid or liquid materials mechanically, physically, and chemically to produce a uniform slurry. The contact surfaces between the machine and the material are made of stainless steel, and sealing devices are installed at both ends of the mixing shaft to prevent material leakage.

Homogenizer

AIPAK Homogenizer Vacuum Emulsifying Mixer

AIPAK homogenizer vacuum emulsifying mixer can also play a mixing role and effectively mix different pharmaceutical suspension, and other liquids, making the mixed substances uniform and free of any lumps. This machine can be heated by electricity or steam and is equipped with a temperature sensor that can detect the temperature of the product.

Mill/Grinder

ALLPACK Colloid Mill

ALLPACK colloid mill is an ultrafine grinding equipment, whose main function is to disperse solid or liquid materials into extremely fine particles, or mix other materials in the liquid to achieve uniform dispersion. The separated colloid mill motor and grinding disc have the characteristics of good stability, easy operation, and long service life of the motor.

Filtration equipment

Rotary Filter - Sourced: Larsson Sweden

Rotary filter is used for solid-liquid separation of various suspension, with relatively high filtration accuracy. The blade rotating filter of this machine can filter impurities and foreign objects within a certain range by continuously rotating the screen and applying pressure, achieving efficient filtering effect.

Vessel (stainless steel tank)

Stainless Steel Tank - Sourced: USA Lab

The stainless steel tank is made of high-quality stainless steel material, which has good corrosion resistance and is suitable for various acidic and alkaline liquids. It is also easy to clean and disinfect, meeting hygiene standards. This tank can temporarily store pharmaceutical suspension and also can be used for stirring.

Sterilizer

AIPAK Engineering Pharmaceutical Autoclave

AIPAK engineering pharmaceutical autoclave uses high-temperature circulating water for sterilization, which can eliminate sedimentation in the suspension. Adopting a PLC control system, it can accurately control temperature, has an independent data recording device, adopts a sliding door design, and is easy to use.

Drying equipment

AIPAK Centrifuge Atomizing Drier

AIPAK centrifuge atomizing drier can evaporate the water in the suspension to obtain solid particles. This machine can maintain the appearance and taste of the raw materials, and has a fast drying speed and high evaporation strength.

Stirring/Agitation Equipment

Agitation Equipment - Sourced: Amazon

A agitation equipment is a mechanical device used for stirring liquids, which mixes materials such as liquids and solid particles evenly through rotating blades or paddles. Suspension is the process of using a agitation equipment to suspend solid particles in a liquid, forming a solid-liquid mixture or suspension.

pH and viscosity control instruments

PH Meter and Viscometer - Sourced: WorldofTest

PH value is an important indicator for measuring the acidity and alkalinity of suspension agents. Importing the pH meter into the suspension sample and wait for the instrument to stabilize before reading the pH value, which can be accurate to 0.1 units. Viscometer does not require personnel to randomly operate, and operators can leave the site after layout to achieve viscosity testing.

Liquid filling machine

AIPAK Liquid Filling Machine

After the suspension is produced, a liquid filling machine is needed to fill the material into bottles. The liquid filling machine can be improved and designed according to different needs, controlled by PLC program to achieve automated filling, suitable for large-scale production lines. And the operation is more convenient and the accuracy is higher. This machine is suitable for pharmaceutical suspension products with various packages and caps .

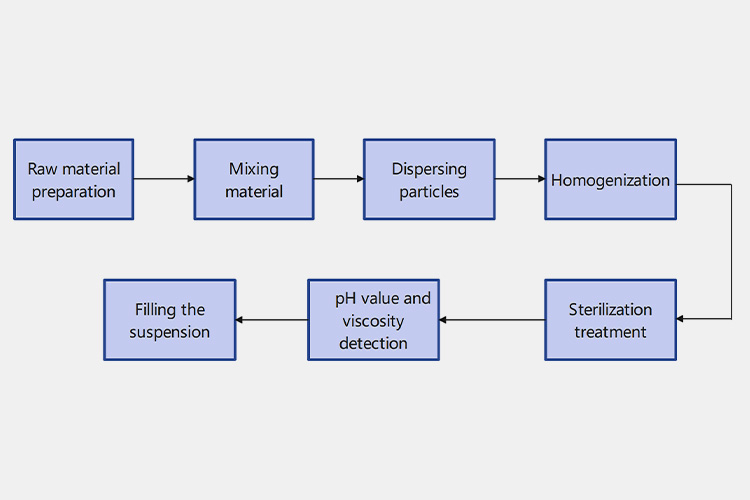

7.What Is the Production Process of Pharmaceutical Suspension?

Are you curious about the production process of pharmaceutical suspensions after learning about the machines used? Do you know any production processes for obtaining pharmaceutical suspensions?

Production Process of Pharmaceutical Suspension

Raw material preparation (water treatment)

Dispersants, stabilizers, and water should be prepared when producing pharmaceutical suspension. Water needs to be treated for raw water. By using methods such as reverse osmosis and activated carbon to treat raw water, impurities and microorganisms in the water are removed, resulting in purified water that can be used for pharmaceutical suspension.

Mixing material

Mixing the suspension material with a certain amount of water to make a suspension. And mixing it with a concentrated solution of wetting agents, and adjusting the stirring time and speed according to the ratio and properties of the raw materials.

Dispersing particles

And then, mixing the dispersant material with a certain amount of water to make a dispersion. Using the agitation equipment to thoroughly mix and stir with the suspension agent. Making it into a slurry. In order to disperse the particles, and further placing the particles into a colloid mill to completely wet each individual particle.

Homogenization

When some formulas and drugs are stirred at high speed, air may enter the formulation, which may affect its stability. Using a homogenizer to reduce the size of dispersed particles and make them evenly dispersed.

Sterilization treatment

After the suspension agent is produced, it needs to undergo quality control treatments such as sterilization to ensure product quality and safety. High temperature and high pressure sterilization, ultraviolet sterilization and other methods can be used for operation.

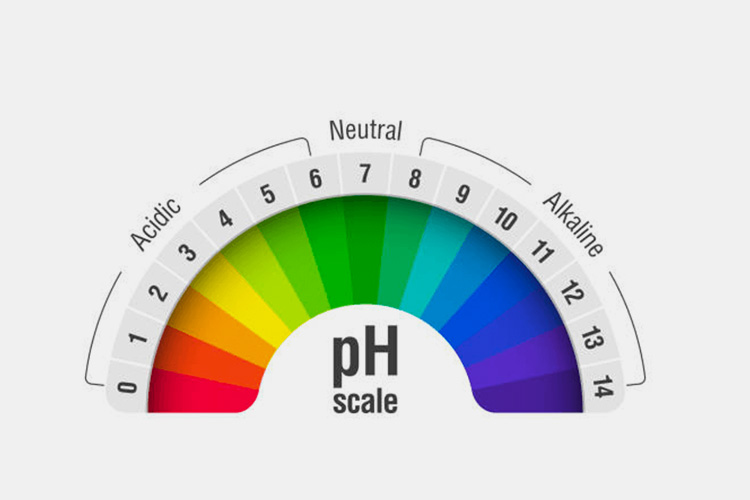

pH value and viscositydetection

The pH value of the pharmaceutical suspension is measured using a pH instrument, which affects the stability and dispersion effect of the suspension. The viscosity of a suspension is an important physical property that plays a crucial role in the stability and efficacy of drugs. Therefore, a viscosity meter is required for testing.

Filling the suspension

After experiencing the pH value and viscosity detection, it is time to fill the pharmaceutical suspension. It can be operated using equipment such as automatic liquid filling machines, or manually operated. During the filling process, it is important to maintain a good hygiene environment to prevent contamination.

8.What Are the Methods of Developing Pharmaceutical Suspension?

Different Methods - Sourced: EvaluATE

Do you know the methods of developing pharmaceutical suspension? The two common methods are as follows:

Dispersion method

Firstly, you should add the soluble components to the diluent, mix them, and disperse them into the carrier. Wetting agents can be used to disperse the carrier. Grinding coarse particles of drugs into suspensions with the required degree of dispersion, and prepare them in a dispersion and medium. The dispersion method is closely related to the hydrophilicity of drugs.

Condensation method

In this method, you should dissolve the drug in a benign solvent to prepare a hot saturated solution, add it to another cooled poor solvent under rapid stirring, and rapidly crystallize the drug to obtain particles below 10 μm (accounting for 80%~90%). Then you can suspend the particles in a dispersion medium to obtain

When preparing, attention should be paid to the conditions for chemical reactions to generate precipitates, in order to obtain uniform and fine new precipitates. Stabilizers such as suspending agents, wetting agents, coagulants, and anti coagulants are often added to prescriptions.

9.What Are the Quality Control Indicators And Measurement Methods For Pharmaceutical Suspension?

In order to control the quality of the final product, it is necessary to perform quality control on the suspension. Do you know which indicators need to be tested?

Appearance

Appearance of Pharmaceutical Suspension - Sourced: AdvaCare Pharma

You need to check the appearance of the pharmaceutical suspension, including color, physical state, and odor. The state of matter is generally a viscous and flowable suspension liquid.

Suspension degree

Suspension degree is one of the key indicators of pharmaceutical suspension, which determines the quality and effectiveness of suspension agents. Generally, methods such as colorimetric method, transmittance method, and Rayleigh scattering method are used to determine the suspension degree.

Stability

Stability - Sourced: Climate Chamber

The stability of a pharmaceutical suspension refers to the interaction force between particles that maintains a uniformly dispersed state of the suspension under certain storage conditions. The factors that affect stability include particle size, shape, volume of surfactant, pH value of suspension, etc. The stability of suspension can be determined by methods such as centrifugation test, precipitation test, and microscopic morphology analysis.

Rheological properties

The rheological properties of suspensions have a significant impact on their wetting, drainage, filtration, and other detailed application performance. Rheology refers to the characteristic of viscosity changing with external stress. The methods for determining rheological properties include rotational viscometer method, tensile viscometer method, etc.

pH value determination

PH Value Determination - Sourced: Career Power

The pH value of pharmaceutical suspensions is generally between 7-9. You need to control the pH value by adding different chemical reagents to ensure the stability of the reselection suspension.

Particle size distribution

The distribution range of suspension particle size has a significant impact on its application performance. A suspension with uniform particle size distribution ensures good stability and filtration rate. The methods for measuring particle size distribution include laser particle size analyzer, haze meter, dynamic light scattering method, etc.

10.How to Ensure the Stability of Pharmaceutical Suspension?

The stability of pharmaceutical suspensions can affect their efficacy, so it is necessary to ensure their stability. Do you know how to ensure the stability of pharmaceutical suspension.

Adding dispersant

Dispersant can form a protective film on the surface of particles, reducing the forces between particles and preventing particle aggregation.

Changing temperature

Changing Temperature - Sourced: Geographic Book

By changing the temperature, the viscosity of the pharmaceutical suspension and the forces between particles can be altered, making the suspension more stable.

Adjusting pH value

By adjusting the pH value of the solution, the particle surface is negatively charged, enhancing the repulsive force between particles and preventing particle aggregation.

Using ultrasonic waves

Using Ultrasonic Waves - Sourced: DKSH

Ultrasonic waves can generate cavitation, causing the surface of particles of pharmaceutical suspension to be impacted and resulting in uniform particle dispersion.

11.What Are the Innovations of Pharmaceutical Suspension?

With the increasing demand from people, suspensions are constantly improving. Do you know any innovations in pharmaceutical suspensions?

Nanosuspension

Nano Suspension - Sourced: IndiaMART

Nano suspension refers to a suspension containing nano particles, where the size of the particles is in the NM range. Nano suspension can help drugs be more easily absorbed by the human body, increase their efficacy, and reduce adverse drug reactions

Taste masked pharmaceutical suspensions

Taste Masked Pharmaceutical Suspensions - Sourced: KTZ Company Limited

In order to improve people’s medication comfort, especially to reduce children's resistance to drugs, taste masked pharmaceutical suspension has been developed. This reagent mainly uses methods such as polymer coating with basic substance to eliminate the unpleasant smell of drugs.

Sustained release suspensions

Sustained Release Suspension - Sourced: Truemeds

This kind of pharmaceutical suspension refers to a drug that has a long-lasting effect and can be slowly and persistently released. Generally, the onset time is relatively long. This sustained release suspension is mainly made by coating it with insoluble polymers.

Conclusion

Suspension is a common medication that is easier to take compared to other drugs. After reading this article, have you gained a deeper understanding of the production process of pharmaceutical suspension? If you have any further questions, please feel free to contact AIPAK Engineering at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours