Pharmaceutical Purified Water Treatment System: The Complete FAQ Guide in 2025

Purified water has many uses in the pharmaceutical industry, such as being used as raw materials for drugs, cleaning equipment, etc. Raw water contains many impurities, microorganisms, suspended solids, etc., so it cannot be directly used in the pharmaceutical industry.

Do you know how pharmaceutical purified water is produced? Next, we will take you to learn the most comprehensive knowledge about pharmaceutical purified water treatment system.

1.What is the Production Processof Pharmaceutical Purified Water Treatment System?

Production Process of Pharmaceutical Purified Water System

The pharmaceutical purified water treatment system usually consists of a raw water tank, a raw water pump, pre-treatment equipment (such as multi-media filters, activated carbon filters, and softeners), a reverse osmosis device, a purified water tank, and a purified water pump.

During operation, it is necessary to monitor various parameters of the system in real time, including conductivity, pH value, flow rate, pressure, and temperature, so as to ensure stable operation of the system and compliance with effluent quality standards.

2.What Is the Pre-treatment System of Pharmaceutical Purified Water?

The pre-treatment process of pharmaceutical purified water production involves many equipment, let’s take a look together!

Raw water tank

Raw Water Tank - Sourced: Prefab Tanks

When municipal tap water enters the raw water tank, a certain amount of sodium hypochlorite solution is added to reduce the risk of microbial growth. The concentration is generally controlled at 0.3-0.5mg/L, and residual chlorine in the water can be monitored by a residual chlorine detector or ORP meter.

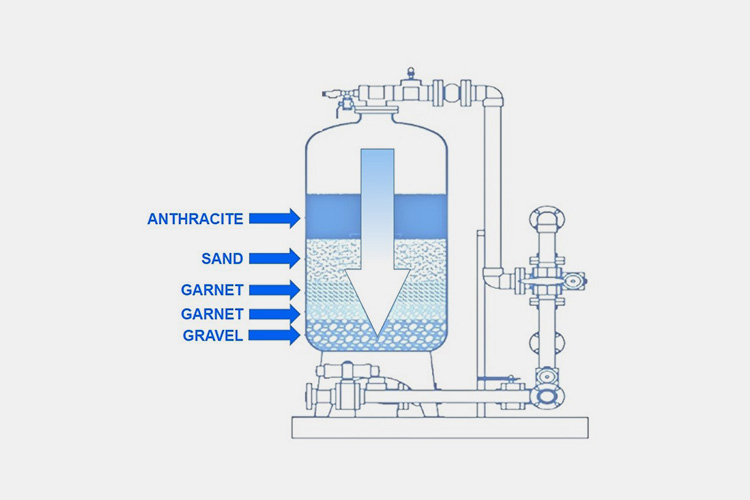

Multi-media filter

Multi-media Filter - Sourced: Osmo Sistemi

The raw water pump pumps cached tap water into a multi-media filter, which is generally composed of filter materials such as anthracite and quartz sand. It is mainly used to filter out impurities such as large particles, suspended solids, colloids, and sediment in the raw water, in order to reduce the impact of raw water turbidity on the membrane system and lower the SDI (pollution index) value.

Dual softener

Dual Softeniner - Sourced: Newater

By using a softener, hardness components such as calcium ions, and magnesium ions in water are removed to prevent these ions from forming scale during subsequent treatment, which can affect equipment performance and effluent quality. Softeners typically use sodium-based softening resins for ion exchange.

Activated carbon filter

Activated Carbon Filter - Sourced: Mars Water Treatment

The filter media is usually composed of a fixed layer of granular activated carbon, which can remove harmful substances such as free chlorine, chromaticity, organic matter, and some heavy metals in water.

3.What Is the Refined TreatmentSystem of Pharmaceutical Purified Water?

In addition to pre-treatment system, pharmaceutical purified water also needs other refined treatments to help better extract purified water. Do you know what refined treatment systems are available?

NaOH dosing device

NaOH Dosing Device - Sourced: IndiaMart

Reverse osmosis membranes cannot remove gases, and carbon dioxide in water can affect conductivity. By adding NaOH to adjust the pH value, dissolved carbon dioxide in water can be converted into bicarbonate ions. Reverse osmosis membranes have a high removal rate, thereby reducing the carbon dioxide in water.

Precision filter

Precision Filter - Sourced: Brother Filtration

Precision filters can trap particles larger than 5 microns in water, preventing them from entering the reverse osmosis membrane. After being accelerated by a high-pressure pump, these particles may penetrate the reverse osmosis membrane components, causing a decrease in desalination rate and potentially scratching the impeller of the high-pressure pump. Therefore, precision filters are also known as security filters.

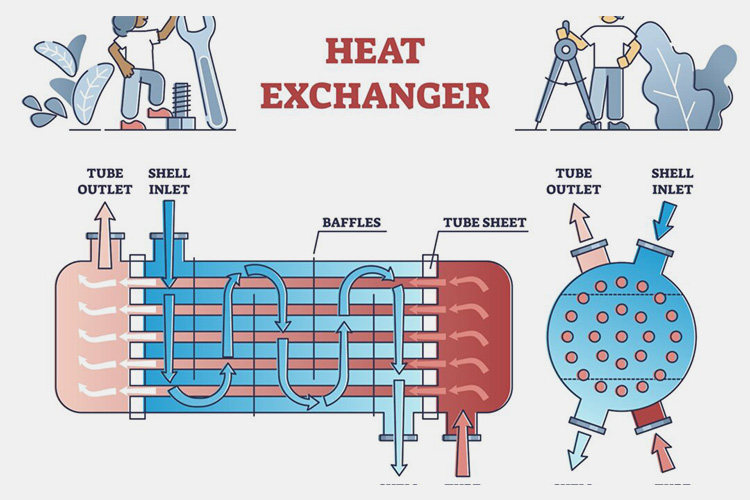

Heat exchanger

Heat Exchanger - Sourced: Patriot Boiler

Heat exchangers are used to maintain the optimal operating temperature of reverse osmosis membranes (20-25℃) and provide a heat source for system disinfection.

Reverse osmosis unit

Reverse Osmosis Unit - Sourced: Crystal Quest Water Filters

Reverse osmosis is driven by a high-pressure pump and uses a reverse osmosis membrane to remove dissolved salts from water, as well as some organic macromolecules and small particles that were not removed in the previous stage. A semi permeable membrane can permeate water but not other substances such as salt, acid, precipitation, alternation, bacteria, and endotoxins.

EDI device

EDI Device - Sourced: Water Treatment Supplier

EDI device, also known as a deionization device, its main function is to further desalinate by using mixed ion exchange values to adsorb cations and anions in water. At the same time, these adsorbed ions are removed through cation exchange membranes under the action of direct current voltage.

EDI devices can further improve the water quality after reverse osmosis. The produced water enters the purified water storage tank and is distributed to various water consumption points through the distribution system.

4.What Daily Inspections Are Required for Pharmaceutical Purified Water Treatment System?

In order to ensure the operation of the pharmaceutical purified water treatment system, it is necessary to conduct daily inspections. Do you know what inspection items are included?

Equipment appearance inspection

Equipment Appearance Inspection

In order to ensure that there is no damage, stains, and cleanliness, you should check the appearance of the equipment daily or regularly, including the casing, control panel, etc.

Pipeline connection inspection

You should check the inlet and outlet pipes, valves, joints and other connecting parts of the equipment every day to ensure that there is no water leakage or seepage. If there is a leak, you should tight or replace the real in a timely manner.

Instrument and meter inspection

Instrument And Meter Inspection

During daily operation of the pharmaceutical purified water system, you should closely monitor the display of pressure gauges, flow meters, thermometers, conductivity meters and other instruments on the equipment to ensure that the data is normal and within the specified range. If any abnormalities are found, they should be calibrated or replaced in a timely manner.

Recordingoperating parameters

Operators should record the operating parameters of the equipment at least once a day, such as inlet pressure, water production flow rate, concentrated water flow rate, water quality indicators, etc.

Analyzingoperational data

By comparing the operating parameters of different time periods, operators should timely detect the changes in equipment performance, so as to take corresponding maintenance measures。

5.How to Clean and Disinfect Pharmaceutical Purified Water Treatment System?

Pharmaceutical purified water must strictly comply with hygiene standards, therefore it needs to be regularly cleaned and disinfected to ensure product safety.

Equipment surface cleaning

Equipment Surface Cleaning - Sourced: Busy Bee Cleaning Service

In order to remove dust, stains, and water stains, operators should use a clean soft or damp cloth to wipe the surface of the equipment. In addition, operators should avoid using corrosive or irritating cleaning agents.

Internal cleaning and disinfection

In order to prevent microbial growth, operators should regularly clean and disinfect salt tanks, medicine tanks, water storage tanks, and purified water tanks. It is recommended to carry out cleaning and disinfection work after monthly or quarterly shutdowns.

6.How to Maintain the Pharmaceutical Purified Water Treatment System?

In addition to cleaning and disinfection, pharmaceutical purified water equipment also needs maintenance to maintain long-term operation.

Maintain the Pharmaceutical Purified Water System- Sourced: Picpedia

Multi-media filter

According to the quality of the raw water, operators should carry out backwash every 5-7 days to remove accumulated impurities and dirt. When the inlet and outlet water pressure difference is too large (usually exceeding 0.1MPa) and cannot be restored to normal after multiple backwashs, the filter media needs to be replaced. The replacement cycle of filter media is generally 1-2 years.

Activated carbon filter

Maintain Activated Carbon Filter - Sourced: Simple Water Softener

Similarly, operators should carry out backwash every 5-7 days to maintain its adsorption performance. And operators should disinfect once every 1-3 months to prevent bacterial growth.

When the inlet and outlet water pressure difference is too large, the residual chlorine value of the water quality is greater than 0.05mg/L, or the service life exceeds 1 year, the activated carbon filter media needs to be replaced.

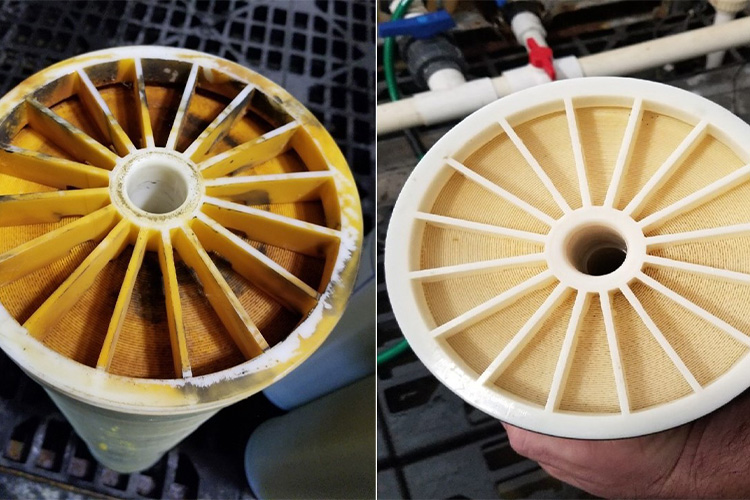

Precision filter

The inlet and outlet pressure difference should be regularly checked. If it is greater than 0.05MPa, the filter element should be replaced in a timely manner to avoid affecting the effluent quality.

Softening resin

Based on the hardness of the raw water and the operation of the equipment, you should regularly regenerate the softening resin. When the inlet and outlet water pressure difference is too large, the hardness of the produced water quality is greater than 0.03mmol/L, and the hardness of the regenerated produced water still does not reach the normal value or the service life exceeds 2 years, the softening resin needs to be replaced.

Reverse osmosis membrane

Matain Reverse Osmosis Membrane - LinkedIn

After a period of operation, pollutants will accumulate on the surface of the reverse osmosis membrane, leading to a decrease in water production or deterioration of water quality. Generally, chemical cleaning is carried out every 3 to 6 months.

At the same time, you should regularly check whether the membrane components are damaged, leaking, etc. If there are any problems, they should be replaced in a timely manner.

Conclusion

The application of purified water in the pharmaceutical industry is becoming increasingly widespread. This article takes you to understand the preparation system of pharmaceutical purified water. Have you gained a comprehensive understanding of its process and daily maintenance? If you have any further questions, feel free to contact AIPAK Engineering at any time

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours