Penicillin Antibiotic Injection: The Complete FAQ Guide In 2025

Have you been prescribed a penicillin antibiotic injection and your mind is full of questions about this antibiotic? Then you’re not alone. Everyone who has ever been recommended an antibiotic in their lives certainly has thought about how this formulation works or what are its benefits and side effects.

As you would likely know from your high school biology penicillin is the original antibiotic and has been in use for several decades because of its quick and effective response. Your doctors often prescribe the penicillin antibiotic injection when oral pills are not working. If the words “antibiotic injection” sounds scary to you, then we’ve got your back.

In this article “Penicillin Antibiotic Injection: The Complete FAQ Guide In 2025” we’ll explain each and every aspect of penicillin antibiotic injection- whether its benefits, production process, doses, side effects, or types. So, let’s get started.

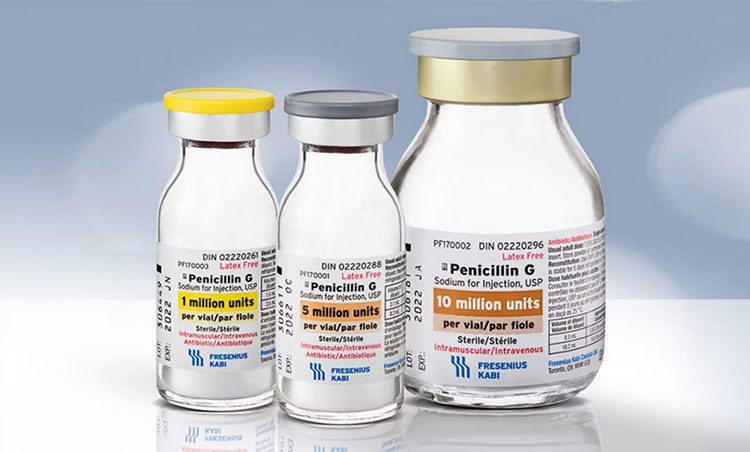

1.What is a penicillin antibiotic injection?

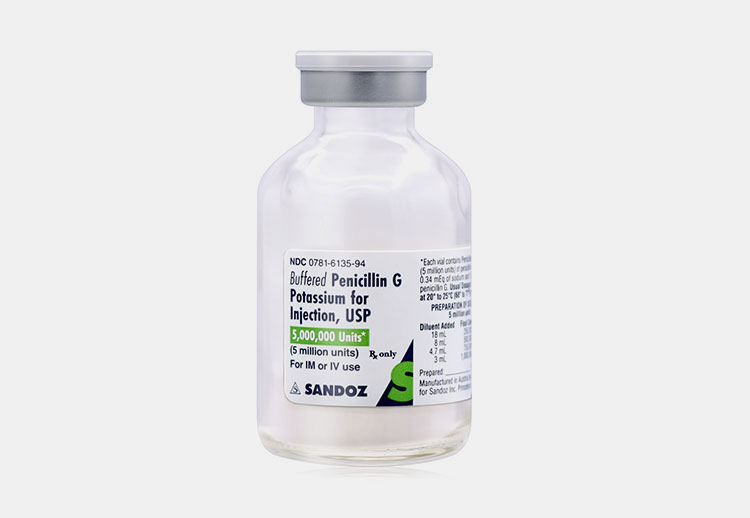

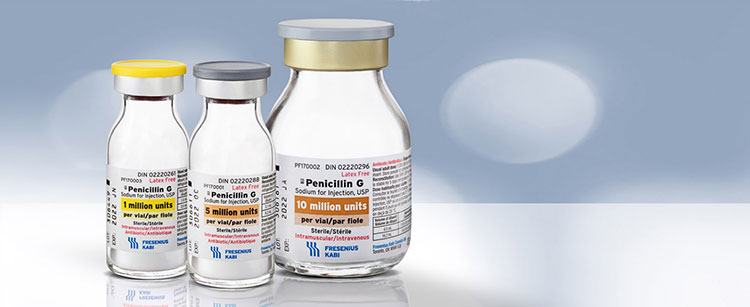

Penicillin Antibiotic Injection – Picture courtesy: Fresenius Kab

Penicillin is the first antibiotic that was discovered by Alexander Fleming in 1928. It is a type of chemical substance made by Penicillium notatum mold that prevents bacteria from growing. Penicillin is a subcategory of beta-lactam antibiotics.

It is available not only as oral medications that can be pill or liquid suspension but also in injection form. Penicillin antibiotic injection is directly injected into the blood via various routes for faster absorption and therapeutic action.

Penicillin antibiotic injection has a simple mechanism of action. It binds to the cell wall of bacteria and destroys it, ultimately killing the bacteria.

2.Why do you need a penicillin antibiotic injection?

Penicillin antibiotic injection has been an effective and trusted treatment option for many decades. It is often recommended when you need a quicker and more reliable treatment approach for bacterial infection. Let’s discuss some major scenarios in which you required penicillin antibiotic injection:

Have Moderate or Severe Bacterial Infection

Moderate or Severe Bacterial Infection- Picture courtesy: Private Medical Clinic

Healthcare providers prescribe it to you to treat moderate or severe forms of bacterial infections, like strep throat, pneumonia, bacterial meningitis, syphilis, septicemia (systemic infection), anthrax, diphtheria, anthrax, gonorrhea, tooth infections, Lyme disease, and UTIs.

Need Swift Therapeutic Relief

Need Swift Therapeutic Relief- Picture courtesy: Te Niwiha

As you probably know penicillin antibiotic injection doesn’t require an oral intake and is administered parenterally. As, the injection route circumvents the digestive tract and liver and avoids first-pass metabolism, subsequently larger concentration of penicillin quickly becomes available in the blood meaning faster treatment relief. This is especially advantageous in case of life-threatening infections like sepsis or meningitis.

Can’t Take Oral Meds

Can’t Take Oral Meds- Picture courtesy: Dailycare

Sometimes patients are severely ill and have constant nausea, vomiting, or gastric discomfort, hence, are unable to take oral medications. So, they are given penicillin antibiotic injection that offers an instant means of delivering penicillin when their gastric system is compromised.

Require One-Time Treatment Regime

Require One-Time Treatment Regime- Picture courtesy: GoodrX

Some types of penicillin are known for their sustained-drug release. This means that after your penicillin antibiotic injection, a steady and potent quantity of the drug is maintained in your blood. This provides relief for days or even weeks. This is quite useful if the penicillin antibiotic injection is administered for prophylaxis or as single-event therapy.

Need a Broad-Spectrum Antibiotic

Need a Broad-Spectrum Antibiotic- Picture courtesy: Drug Discovery World

Yes, you have a higher chance of bacterial resistance if you incorrectly take multiple antibiotics for different infections. However, penicillin has higher effectiveness against various gram-positive bacteria (cocci and rods) and select Gram-negative organisms. Hence, you don’t need different antibacterial as penicillin antibiotic injection is the preferred choice for treating illnesses caused by streptococci, Treponema pallidum (syphilis), and Clostridium species.

Improved Patient Adherence

Improved Patient Adherence- Picture courtesy: research Outreach

A one-time penicillin antibiotic injection is appropriate for you if you’re one of those people who forget or skip pills. This injection minimizes the need to take frequent doses of the pill because the former offers full-course therapy.

3.What are the critical components used in penicillin antibiotic injection?

Like other medicine formulations, penicillin antibiotic injection doesn’t consist of a single component. Instead, many ingredients (excipients) are incorporated during its preparation to generate a stable and potent antibiotic medication.

For your information critical components used in penicillin antibiotic injection are detailed in the following section:

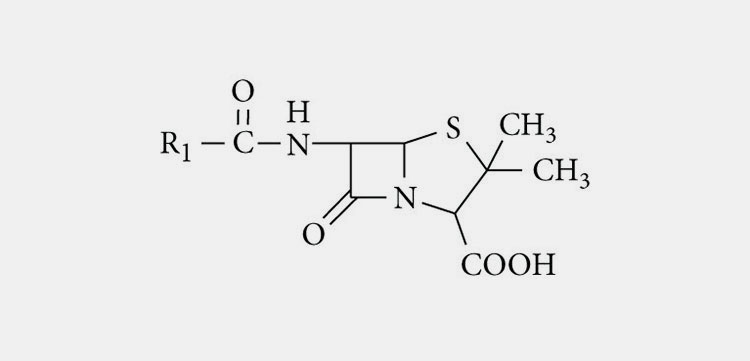

Active Ingredient

Penicillin- Picture courtesy: ResearchGate

It is quite obvious that penicillin is the active ingredient in the penicillin antibiotic injection. However, you’ll find it in its salt form in the injection combined with sodium, potassium, benzathine, or procaine. The delivery method, time of working, and duration are depended upon the form of penicillin.

Solvent

Solvent- Picture courtesy: Medisa

It’s a given that penicillin antibiotic injection has water as a solvent. However, it’s not simple water but sterile water for injection that is free of any impurity or contaminant of any sort. Sometimes, you’ll see normal saline on the ingredient list of this antibacterial. These substances aid core ingredients in dissolution or suspension.

These also act like diluents and allow you ease in drug reconstitution and administration.

Buffers

Buffer- Picture courtesy: Technofilter

Penicillin antibiotic injection is quite sensitive to pH fluctuations. Therefore, buffers or pH stabilizers are integral components in the formulation, ensuring protection against pH changes and chemical instability. Additionally, thanks to the buffers, penicillin does not irritate when injected.

Preservatives

Preservatives

Multi-dose penicillin antibiotic injections can’t be formulated without preservatives. These substances, for instance, benzyl alcohol keep this antibiotic safe from microorganisms and disintegration. They increase the shelf-life of medications.

4.What types of penicillin antibiotic injections?

It is natural to be curious about the types of penicillin antibiotic injections and the specific conditions they are utilized to treat. To satisfy your curiosity, here is a detail of the major types of penicillin antibiotic injections:

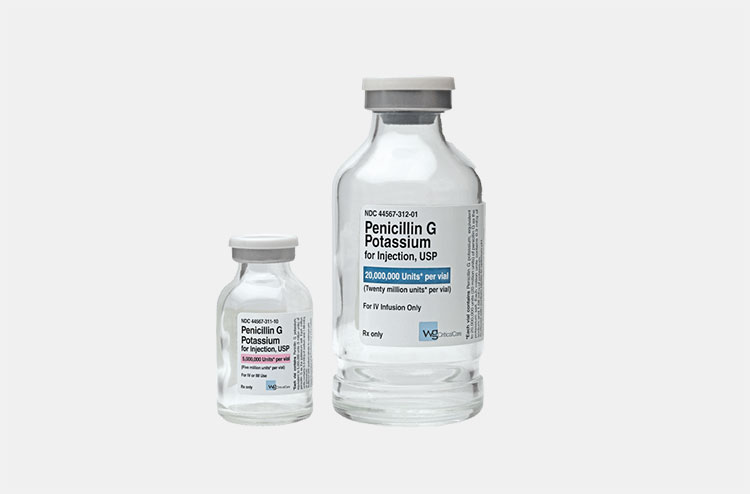

Natural Penicillin

Natural Penicillin- Picture courtesy: WG Critical Care

As the name suggests, these penicillin antibiotics occur naturally in nature and are not created by people. It is purified or isolated by the scientists from the naturally existing source and is converted into medications.

Penicillin G

It is first isolated by a fungus present in nature. It occurs in two sub-forms- Penicillin G Benzathine and Penicillin G Procaine. They are differentiated based on their duration of action. Penicillin G Benzathine is a combination of penicillin G and benzathine base. It is used for managing syphilis (early and latent) and preventing recurrent rheumatic fever.

Penicillin G Procaine is a combo of penicillin G and procaine. Besides acting as an antibacterial, it also has anesthesia properties due to procaine. So, it also helps in pain control.

Semi-synthetic Penicillin

Semi- Synthetic Penicillin Injection

They are not entirely developed by scientists rather than structure of the natural type of penicillin is altered to create a more effective form of penicillin or to combat bacterial resistance. They include:

| Penicillinase-resistant Penicillin | They are developed to withstand degradation by penicillinase enzymes made by bacteria. This enzyme is the cause of resistance in bacteria as it inactivates some form of penicillin. Their examples are nafcillin,

Oxacillin and methicillin (rarely utilized now). |

| Aminopenicillins | They have additional amino groups in addition to their β-lactam ring and this allows them to easily breach the outer membrane of gram-negative organisms. Hence, they are a broad spectrum of action. Ampicillin is the best-known example of aminopenicillin. |

| Extended-spectrum Penicillin | It has a broader spectrum and is quite valuable in managing difficult-to-teat bacteria, such as Pseudomonas aeruginosa. Its common examples are Piperacillin and Ticarcillin/Clavulanate. |

5.How is penicillin antibiotic injection manufactured?

The manufacturing of penicillin antibiotic injection happens in various stages, each coordinated to develop a pure and high-quality product. The major steps of penicillin antibiotic injection include:

Step 1: Cultivation of Mold

Penicillin Biosynthesis- Picture courtesy: News- Medical

It is one of the most pivotal steps in the development of penicillin antibiotic injection. In this step, a fungus called Penicillium chrysogenum is prorogated in large containers. It is cultured on a nutrient-rich medium. Once, this mold is grown and produced enough penicillin, it is then fermented by separating liquid medium from it.

Step 2: Extraction and Purification

Extraction and Purification- Picture courtesy: University of Oxford

This is based on following steps:

Extraction

After fermentation, the penicillin compound is isolated from the medium (containing both fungus and fermentation liquid) by different techniques, such as filtration and solvent extraction.

First, with filtration, the sedimented fungal debris is removed, and after that penicillin is separated from filtered liquid using solvent extraction. There are three major categories of solvent extraction, including:

| Pressurized Solvent Extraction Method | It is also called the accelerated solvent extraction method. Generally, both elevated temperatures and pressures are combined in this method to improve penicillin extraction. With higher pressure, a solvent is kept in the liquid state even though a high temperature is applied to evaporate it. This improves the solubility of penicillin. |

| Supercritical Solvent Extraction Method | In this process, fermented liquid is subjected to supercritical fluid like carbon dioxide to extract penicillin without damaging its structure. Carbon dioxide gas is pressurized and heated above its critical point, due to which it becomes liquid and aids extraction by dissolving the penicillin compound. |

| Ultrasound-Assisted Extraction Method | As the name indicates, this method uses ultrasonic waves to disturb the cell membrane, which boosts solvent penetration and increases penicillin dissolution in a solvent. |

Purification

Chromatography- Picture courtesy: Metrohm

Finally, purification techniques like chromatography are utilized to acquire highly pure penicillin. These methods remove unwanted particles dissolved debris, impurities, and other contaminants from penicillin.

Step 3: Preparation of Penicillin Formulation

Formulation- Picture courtesy: K Health

Now that you’ve pure penicillin, this compound is then dissolved or suspended in a pure solvent, often sterile water for injection. Different excipients, like stabilizers, buffers, preservations, or chemicals that facilitate solubility are thoroughly mixed with a penicillin-water mixture to create a uniform distribution of particles in antibiotic preparation.

Step 4: Sterile Purification

Sterile Purification- Picture courtesy: Lab Training

Since the prepared penicillin antibiotic injection formulation might have microbial growth, consequently, it is passed through sterile filters or ultrafiltration membranes to completely remove any microbe or its product.

Step 5: Filling and Sealing

Filling And Sealing- Picture Courtesy: Recipharm

Once your sterile penicillin antibiotic injection product is ready, it is transferred to the filling systems. This product is then accurately aseptically dispensed into packaging containers. This process is carried out in cleanrooms (ISO Class 5 or Grade A), where strict hygienic standards are implemented to control particle and microbial contamination.

After that, filled containers are conveyed to the sealing area, where, stoppers or caps are placed on the opening of penicillin antibiotic injection containers to firmly secure them and shield the sealed product from air, moisture, and microbes.

Step 6: Labeling

Labeling

The sealed penicillin antibiotic injection packaging is reallocated to labeling equipment in order to apply labels displaying necessary information regarding the product, manufacturing firm, and uses.

6.What machines will you use for penicillin antibiotic injection?

The production of penicillin antibiotic injection utilizes an extensive list of machines, as each step has to be carefully executed to acquire promising outcomes. So, for your information, the major machines in penicillin antibiotic injection manufacturing are penned below:

Extraction and Purification System

AIPAK ENIGEERING Column Chromatography Extraction and Purification System

Column chromatography extraction and purification system is usually the first in-line machine in penicillin antibiotic injection manufacturing. Typically, it is utilized for to extraction and purification of penicillin from microbial cells and medium components. In this machine, diverse types of solvents are mixed with fermentation broth, which then penetrates the fungal cells to dissolve penicillin.

It has the ability to separate active components of ingredients by utilizing column chromatography and gives out effective substances for penicillin antibiotic injection.

Centrifugation Machine

Penicillin Centrifugation Machine

After the fermentation process, you might employ this system to separate solid residues (biomass) from the fermentation liquid. It gives you a higher yield than simple filtration. Or you might use it after solvent extraction to isolate penicillin from extraction solvents. Furthermore, it also has a task to clear out suspended impurities from the product at any penicillin antibiotic injection manufacturing step.

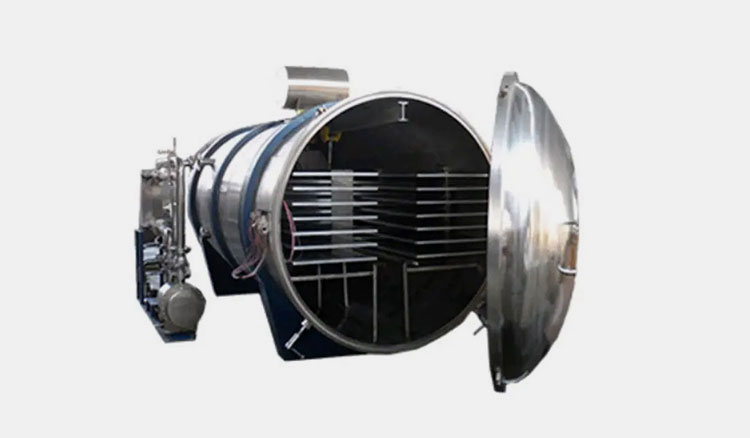

Freeze Dryer

AIPAK Freeze Dryer

An automatic system is an automatic unit required for pharmaceutical antibiotic preparations that dewater the substances by sucking moisture content with the help of sublimation working principles. This means that water is frozen and sublimates directly to gas form under a high vacuum and captured thus giving you a dry granular powder formulation.

Vial Filling Production Line

AIPAK ENGINEERING Vial Filling Line

After you’ve completed preparing the penicillin antibiotic injection, your next step is to load and seal the product which is done by vial filling production line. For this purpose, you use a vial-filling production line. It consists of multiple pieces of equipment that bring the filling operation to completion in no time without requiring much supervision from technicians.

This assembly is comprised of a vial washing device that uses a swift and strong spray of water to hit every nook and cranny of vials in order to fully wash each of their surfaces. The unscrambling device is the next unit, where randomly ordered vials are positioned one after the other in perfect sequence and are then moved to the sterilization tunnel.

In this unit, hot air is blown to dry and sterile every vial. After that, you have a filling machine that dispenses a pre-set volume of penicillin antibiotic injection in vials using piston or pump systems.

Lastly, there are stoppering and sealing systems in which the mouth of vials are stoppered and crimp-sealed to form a leak-proof closure.

Labeling System

AIPAK surface automatic labeling machine

To communicate accurate information to various consumer sectors, you’ll need attractive product labeling and this process is carried out by a labeling system. It seamlessly operates to place a wrinkle-free label on vials, which ensures correct product handling.

Cartoning Machine

AIPAK cartoning machine

Finally, at the end of penicillin antibiotic injection production, you’ll find a cartoning machine. It is required in production lines because it secures products by enclosing them in sturdy boxes. Usually, tamper-evident sealing components, such as tapes or glue are applied to boxes to ensure container closure integrity (CCI).

7.What types of packaging are used for penicillin antibiotic injection?

The purpose of penicillin antibiotic injection is to protect sensitive products, which goes a long way in ensuring the stability of product and patient safety. So, let’s uncover different packaging formats for penicillin antibiotic injection:

Glass Vials

Glass Vials- Picture courtesy: Imres

First and foremost, the most important and most widely utilized packaging is glass vials. It is used for packing both single-dose and multi-dose volumes of penicillin antibiotic injection. It is a known fact that glass vials are mostly manufactured from Type I borosilicate glass.

It can withstand heat as well as chemical reactions. You can seal securely these vials with rubber stoppers and aluminum crimp caps.

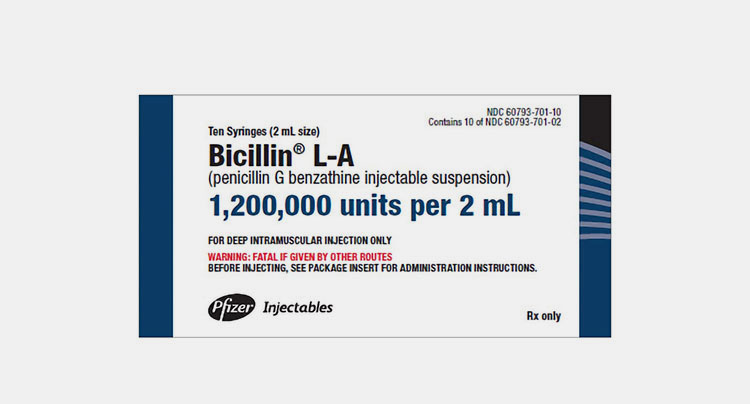

Pre-Filled Syringes

Pre-Filled Syringes- Picture courtesy: McGuff

They are the less common format of penicillin antibiotic injection packaging. They are the latest innovation in medical packaging and consist of sterile syringes that have pre-loaded and fixed volumes of penicillin antibiotic injection. They are advantageous because they minimize dosing errors and save time in case of emergency.

8.What are the doses of penicillin antibiotic injection?

Doses Of Penicillin Antibiotic Injection-Picture courtesy: Nursing Time

The correct doses of penicillin antibiotic injection are very important in offering an accurate therapeutic response. However, is integral to know that the dose of penicillin antibiotic injection is determined based on the age and weight of the patient, the kind and severity of illness, the form of antibiotic, and whether the antibiotic is prescribed for treatment or prophylaxis.

Therefore, in this section, we’re describing the dosing ranges of the most frequently utilized penicillin antibiotic injection:

| Penicillin G Benzathine | Since it is given as a single injection, therefore, adults require 1.2 to 2.4 million units at one time. Whereas, for children, 600,000 to 1.2 million units are utilized. However, its dose in children depends upon their age and weight. |

| Penicillin G Procaine | Its multiple injections are needed for treatment, thus, in adults, 600,000 to 1.2 million units are injected per day for 7-10 days. In children, a daily dose of 50,000 units for every kilogram. This is administered in 1-2 doses. |

9.What are the sites of administration of penicillin antibiotic injection?

When you receive a shot of penicillin antibiotic injection, the location matters, as it ensures an effective therapeutic response. In case you are wondering what are the administration sites for penicillin antibiotic injection, read below to find out the answer:

Intramuscular (IM) Injection

Intramuscular (IM) Injection- Picture courtesy: Medpage Today

This route of administration is used for penicillins that have a slow absorption and provide therapeutic response over a longer period. Usually, Penicillin G Benzathine and Penicillin G Procaine are dispensed as Intramuscular (IM) injections. You typically get this injection in two major muscle groups gluteal muscle (buttocks) or vastus lateralis (thigh).

Intravenous (IV) Injection

Intravenous – Picture courtesy: Nursing Time

This site of administration is commonly used for fast-acting penicillins like Penicillin G Potassium or Sodium. You’ll have it injected directly into your veins or received through a drip or infusion line. With this route, you’ll have quick drug onset and it is especially advantageous for treating critical emergency circumstances, for instance, meningitis or sepsis.

10.How fast does penicillin antibiotic injection show response?

Penicillin Antibiotic Injection- Picture Courtesy: Fortune

You certainly want to know that when the penicillin antibiotic injection you had received, would cure your sore throat. Although, there are a few factors that come into play in determining a response time normally you’ll see treatment working within 24-48 hours.

When penicillin is dispensed intravenously, it is swiftly available in systematic circulation quickly resolves mild infections, and improves symptoms by reducing fever, pain, and inflammation. For more severe infections, such as pneumonia, syphilis, or cellulitis, it might take several days to weeks to completely eradicate infection.

11.Are there any side effects of using penicillin antibiotic injection?

Even though penicillin antibiotic injection is a powerful fighter, it might have some side effects. They can range from mild to serious. Some types of side effects of penicillin antibiotic injection include:

Side Effects of Using Penicillin Antibiotic Injection

| Frequent Side Effects | They are often mild and resolve in some days. They include pain and swelling at the injection region. Fever, mild chills, gastric-related issues (vomiting or diarrhea), and headaches are also some temporary side effects of penicillin antibiotic injection. |

| Allergic Reaction | Some individuals might experience allergic reactions after getting a penicillin antibiotic injection. They might be serious, so it is recommended to always keep the patient in observation. Rash, itching, hives, shortness of breath, squeezing feeling in the chest, or anaphylaxis are a few allergic reactions in response to penicillin. |

| Severe Adverse Events | Although, they are rare but can cause some life-endangering situations, for example, neurotoxicity or kidney damage due to high doses of penicillin antibiotic injection. Besides this, confusion, seizures, hemolytic anemia, and serum sickness are cases of severe side effects because of penicillin antibiotic injection. |

12.What is the shelf-life of penicillin antibiotic injection?

Learning about the self-life of penicillin antibiotic injection is pivotal in obtaining maximum therapeutic outcomes from it. It is a well-established fact that penicillin antibiotic injection like other meds can’t provide the right treatment response if it pasts its shelf-life. So, let’s have a brief overview of the shelf-life of this formulation:

Shelf-Life Of Penicillin Antibiotic Injection – Picture Courtesy: Connecticut Public

Unreconstituted Form

It is a dry powder form of penicillin antibiotic injection produced by freeze-drying or lyophilization technique, which improves its shelf-life. Subsequently, it lasts approximately 18 to 36 months. But you have to store it in sealed vials at temperatures below 25°C (77°F). However, it’s some types need refrigeration at 2-8°C to maintain their effectiveness.

Reconstituted Solution

It is a ready-to-use liquid form of penicillin antibiotic injection. Upon adding diluent, you have to instantly use it or depending upon formulation utilize it within 1-6 hours. Some forms are good for 24 hours if kept in the refrigerator. But keep in mind that you’ll have efficacy loss and propagation of microbes over time.

Long-Acting Suspensions

Some forms of penicillin antibiotic injection, for instance, Benzathine Penicillin are long-acting suspensions. This means that the release of penicillin gradually in blood over time consequently, has an extended therapeutic effect. So, they have a shelf-life of 12-24 hours but you’ve to store them in the fridge and shake well before use.

13.What are the critical problems and solutions when manufacturing the penicillin antibiotic injection?

Problems and Solutions

There is no doubt that penicillin antibiotic injection manufacturing is an extremely high-stake process and a lot can go wrong in this process. These critical problems can seriously impact the overall confidence in the quality and safety of penicillin antibiotic injection.

Let’s explore all these critical problems and their solutions in the manufacturing of penicillin antibiotic injection.

Vial Breakage or Leaks

| Are you having problems related to vial breakage or product leaks? Indeed, sometimes, you’ll see that your glass vials get cracked or a stopper leak, causing product wastage or contamination during shipment. | Solution

To solve this problem, you should take the following steps, for instance, a vial washing machine and siliconizing units should be used before product filling. Secondly, automated capping equipment aids in thoroughly securing packaging. Utilize various types of visual inspection systems or perform manual examination of packaging to discover any crack lines or leaks. |

Degradation of Active Ingredients

| As you probably know penicillin ingredients are very unstable and sensitive and can lose their integrity upon a slight change in heat or pH conditions. | Solution

To address this challenge, you’re required to use jacketed tanks during penicillin antibiotic injection formulation, which will aid you in maintaining a controlled temperature environment. Moreover, if you incorporate pH buffers and stabilizers in preparation, they’ll stabilize the latter. Freeze-dried penicillin antibiotic powders should be opted for if you want to prolong shelf-life. |

Mistakes in Filling volumes

| It is a very significant problem, as even a minor mistake in product loading results in overdosing, underdosing, or expensive product recalls. | Solution

It is suggested by experts to load penicillin antibiotic injection with a piston or peristaltic pump. These systems assist in precise dosing down to the microliter range. To catch filling errors early in production, it is best to integrate weight-checking and vision inspection devices. Besides this, anti-drip nozzles are favored to minimize product wastage. |

Conclusion

Despite innovation in the pharmaceutical sector, penicillin antibiotic injection remains a cornerstone to defend the body against bacteria since its discovery. It provides quick and effective treatment against various bacteria even life-threatening ones. For this reason, it is integral to have a thorough knowledge of how it is manufactured, packed, administered, and stored to guarantee a desirable treatment outcome. Now, if you’re interested in investing machine related to developing penicillin antibiotic injection, then please visit the AIPAK Engineering site at your convenience. We are a leading expert in providing pharmaceutical solutions at budget-friendly prices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours