Oxymetazoline Hydrochloride Nasal Spray Manufacturing: The Complete FAQ Guide In 2025

Do you know how nasal spray is therapeutically helpful? This is the common and new method of treatment which is non-invasive. The medication has the ability to reach the target sites and activate the particular receptors involved in decongestion ailment. The oxymetazoline hydrochloride nasal spray is an affordable and acceptable solution worldwide. For manufacturing the spray, we have created this article for you. The topic is composed of the following points related to its ingredients, preparation, machines, handling, its packaging. The purpose of this article is to provide you with the significant and essential information required in order to oxymetazoline hydrochloride nasal spray manufacturing. Keep reading!

1.What is oxymetazoline hydrochloride nasal spray?

Oxymetazoline hydrochloride nasal spray - Picture courtesy: Cleveland clinic

An oxymetazoline hydrochloride nasal spray is a therapeutic medicine that you use to relieve nasal decongestion. It is composed of an active pharmaceutical ingredient’ oxymetazoline hydrochloride, which belongs to an alpha-adrenergic agonist.

It mainly stimulates the alpha 1 receptor and partially activates the alpha 2 receptor. The activation of this receptor is mainly used as a therapeutic target that ensures constriction of blood vessels. That’s why it is a suitable drug for treating conditions like sinus, nasal congestion, and flu or cold-like symptoms.

This is a topically used spray that you administer into the nasal passage, and it limits the congestion rapidly and allows clear breathing soon after puffing the spray. The time observed in its working ranges from a few minutes and the therapeutic action lasts for hours (for example, 10 to 12 hours).

2.What is oxymetazoline hydrochloride nasal spray manufacturing?

Oxymetazoline hydrochloride nasal spray manufacturing- Picture courtesy: advacare

This is a process that helps in the manufacturing of the unit dose or multi-dose oxymetazoline hydrochloride nasal spray. The preparation allows an effective nasal drug delivery without requiring the involvement of the user’s dose-making. You just need to pick the bottle and spray it by following the recommended ways.

The process is involved with dose calculation, compounding, filling, and packaging. Additionally, the state-of-the-art machines involved in the manufacturing process include water treatment plants, mixing and emulsification units, filling machines, etc.

Therefore, the list or number of ingredients that you design prior manufacturing process can be properly treated. Remember, this is a sterile process, where the end product must be very pure and clear. That’s why the process must be carried out in a sterile work section that is regulated by the US and FDA-approved guidelines.

3.What is the reason for oxymetazoline hydrochloride nasal spray manufacturing?

Reason for manufacturing oxymetazoline hydrochloride nasal spray- Picture courtesy: mucinex

You might be wondering why it's manufacturing important for you. If you’re a newbie or regular production person, the following points related to the significance of oxymetazoline hydrochloride manufacturing would be surprising and helpful.

To offer fast action against nasal blockade

Fast relieving action

You must understand the pathology of nasal blockade. This actually happens when you suffer from cold, flu, asthma, or allergic problems. Therefore, your physiology responds in a way that starts swelling the vessels of the nose or respiratory tract.

Also, the extra mucus secretion leads to nasal blockade by disturbing the normal airflow that you breathe. That’s why breathing problems arise.

The manufacturing of oxymetazoline hydrochloride nasal spray acts much faster than oral medication by constricting the swelling and secretion of the nose and allowing the reliving effects by opening the airflow or breath.

Safe and hygienic formulation

Safe and hygienic- Picture courtesy: Record searchlight

To provide a safe and sterile product for individuals, oxymetazoline hydrochloride nasal spray manufacturing is done. The process itself takes place in a strict hygienic work environment. Therefore, entire steps assure you that the formulation is 99.99% safe to use.

Formulation with local application

Specific local application

The prime reason behind the formulation of oxymetazoline hydrochloride manufacturing is that the product is capable enough to produce a local therapeutic effect.

As compared to local decongestants, such as Zyrtec, Claritin, or medication like pseudoephedrine, which can exert more profound side effects. For example, modulation in your BP, irregularity in the heart rate, or some central nervous system problems like dizziness or insomnia in some cases. Therefore, when you use oxymetazoline spray it is least likely to produce any adverse effect rather it is ideal to get an immediate and low-risk effect as it uses nasal passage as a primary therapeutic site.

Easy to use

Easy to use- Picture courtesy: Allergy and anaphylaxis

Oxymetazoline hydrochloride nasal spray manufacturing is required as it offers an easy and flexible way of medication for nasal blockade.

When you take tablets or any oral medication for relieving nasal elements, it may not be convenient for some patients with swallowing problems. So the nasal spray is more effective in that it can be used anywhere and anytime.

Its application is so easy; you just have to position the spray bottle directed toward your nose for puff and that’s it! Therefore, oxymetazoline nasal spray manufacturing is considered to be a beneficial mode of medicine with a fast and immediate response to handle your symptoms.

To meet the production demand

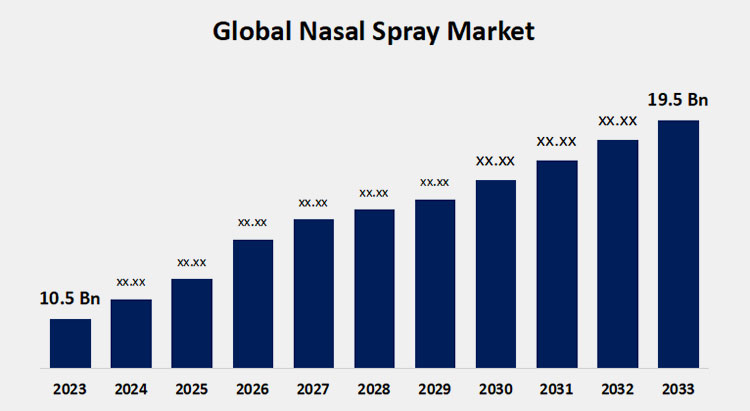

Global demand- Picture courtesy: Spherical inside

Businesses or the corporate world, always look to bring solutions based on what customers demand. When you see the present demand for oxymetazoline hydrochloride nasal spray manufacturing, the market is strongly growing and expected to grow from $15.7 billion in 2024 to 16.61 billion $ in 2025 with a CAGR of 5.8%. This tremendous increase in the demand for decongestant spreads is the main factor behind its manufacturing.

Accurate dose delivery

Accurate dose- Picture courtesy: Dick smith

The oxymetazoline hydrochloride nasal spray manufacturing main objective is to offer accurate drug delivery. In this case, you don’t need any practitioner support dose estimation, etc. The nasal spray bottle is already available in reconstituted form therefore when you spray in each nostril, you will be receiving the local effects by a required concentration for relieving the symptoms.

4.What is the composition of oxymetazoline hydrochloride nasal spray manufacturing?

The oxymetazoline nasal spray manufacturing is composed of the various ingredients to form a stable preparation. For example:

Active ingredients

The active pharmaceutical ingredients used in the nasal spray manufacturing is discussed below:

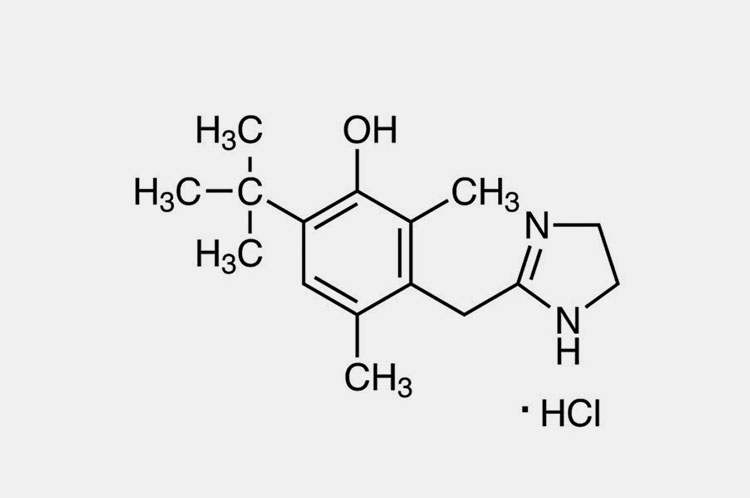

Oxymetazoline hydrochloride

Oxymetazoline hydrochloride

This is an active ingredient which is acting as the major contributor to the nasal spray. The concentration of oxymetazoline hydrochloride used in the spray is typically available in 0.5 mg/mL, 0.5 mg/mL, and 1 mg/mL (nasal spray as well as drops). This is considered an effective percentage to stimulate nasal vasoconstriction and results in minimizing the symptoms.

Inactive ingredients

To support the oxymetazoline hydrochloride nasal spray solution, there are some inactive ingredients are added to get a stable effect without interfering with the pharmaceutical properties of the active compound.

Solvent

Solvents

Every solid particle needs a medium to dissolve in it. The solvents are used in the formulation to support the mixing or emulsification of the ingredients needed to make suitable concentrations.

There is the following list of vehicles or solvents that are mainly used as a mixing medium. For example:

Purified or sterile water

Purified water

To ensure the water is free from unwanted microbial contamination or suspended particles. The purified water is used. This is mainly achieved after dealing with water treatment plants, which provide you water free from impurities and microbes.

Buffer solutions

Buffer Solutions- Picture Courtesy: Thermos Scientific

To maintain the pH of the solution, the typical concentration of buffer solution is also added to the formulation. The usual buffer solution used is either phosphate buffer or citrate buffer. The reason behind its utility is to resist pH changes even after spraying in the nasal pathway.

Propylene glycol

Glycerine- Picture courtesy: News-medical

This is the solvent medium which acts as a moisturizing agent in the solution. The oxymetazoline hydrochloride sprays allow you to maintain nasal moisturization. That’s why it is also used to treat nasal dryness. Also, it acts as a thicker in your product.

Glycerine

Glycerine

This is another moisturization agent added to the oxymetazoline hydrochloride nasal spray that works by relieving the feeling of crankiness within the nasal wall. Also, it helps in the fast dissolution of the oxymetazoline hydrochloride.

Surfactants

Surfactant- Picture courtesy: Gantrade

The surface tension or cohesive force of the solution is mainly balanced by the incorporation of ethanol or polysorbate 80, etc. Apart from offering an effective dissolution rate, it is also providing you with some anti-microbial properties to the formulation.

Preservatives

preservative

Every formulation is prone to invaded from microbial progression after some time. The use of preservatives can halt the process by resisting the microbial progression. Therefore, the formulation is considered as safe if the preservatives are added inside it. The commonly used preservatives are benzalkonium chloride, and benzyl alcohol, whereas in some formulation potassium sorbate, or sodium benzoate is also used.

Chelating agent

Chelating agent- Picture courtesy: AVVALE

In some formulations, the stability of ingredients can be provided with the incorporation of chelating agents such as EDTA. It has the capability to firmly bind with metal ions and is mainly used to protect the formulation from oxidation, thus offering a good shelf life.

5.What is the handling of oxymetazoline hydrochloride nasal spray manufacturing?

The oxymetazoline hydrochloride nasal spray manufacturing is not a simple or single-step process. There are sequences of several major steps to make a complete product. Remember, each step plays an important role, therefore, an error at any point can disturb the whole batch. The following number of process steps are described below:

Ingredients gathering and measuring

Ingredients gathering and measuring- picture courtesy: Technology network

There are active and inactive ingredients involved in the manufacturing process. Therefore, weighing and measuring all ingredients are taken into account prior to beginning the process.

Combination & Homogenization

Mixing- Picture courtesy: Silverson

In a mixer tank, you need to incorporate the ingredients. First, you can add the solvents and ensure that mixing is properly distributing all the components very well. In the case of viscosity agents or adding ingredients with suspended particles, we would recommend using high-shear mixers. In this way, the number of particle sizes gets fully minimized and dissolved with high-speed mixing process. At the same time, you will observe the uniformity of formulation is getting ideal.

Purification

Sterilization of solution- Picture courtesy: Steelco

Although, the added ingredients and solvents are cleaned and high purity range substances. But to assure ourselves that they are compliant with high-quality standards, the purification is carried out. In this process, the solution is passed through the filtration plant. The presence of any residue or large-sized particle of more than 10 micrometers can be removed. After this process, the sterilization takes place under a high temperature. This step ensures that solution is free from microbes and 99.99% cleared.

Filling & sealing

Filling and sealing- Picture courtesy: Groninger

The solution is now subjected to the filling and sealing step. Here the sterilized solution is filled inside the packaging materials. The solution filled is already up to the required volume. The automatic plants are capable of identifying the exact volume by interpreting the settings. The sealing of bottles takes place by placing metering spray nozzles.

Packaging

Final product

Once the solution is filled in the spray bottles, they are packed into assigned cartons.

6.Where does oxymetazoline hydrochloride nasal spray manufacturing mainly occur?

When it comes to talking about the industrial applications of oxymetazoline hydrochloride nasal spray manufacturing, it is hooked to many regions and fields. Along with healthcare fields, its manufacturing is also taking place in various other regions. Let's have a look at the manufacturing sectors of oxymetazoline hydrochloride nasal spray manufacturing.

Pharmaceutical Industry

Pharmaceutical industry – Picture courtesy: Emerj

This is the central area where medications related to nasal decongestants are manufactured. The pharmaceutical industry is mainly facilitated by sterile manufacturing machines and world-class research to bring the accurate dose as well as quality formulation of oxymetazoline hydrochloride nasal sprays. Therefore, the day and night production batches strive best to meet the requirements or demand across the globe.

Research and development

Research and development- Picture courtesy: AAPS

This is the primary department that ensures the formulation and formation of oxymetazoline hydrochloride nasal spray. The clinical studies, and drug indications, detailing the toxic effects, side effects, therapeutic effects, dosage, etc are assessed and verified related to oxymetazoline hydrochloride nasal spray manufacturing in the R&D sector.

Veterinary Medicine

Veterinary industry- Picture courtesy: Blue Cross

Flu and colds are also very common in pets or animals just like us. The oxymetazoline hydrochloride nasal spray activated the blood vessels of the animals upon application of the spray. This ultimately minimizes the symptoms of nasal secretion by constricting the blood vessels and inhibiting the mucus secretion. In the veterinary industry, the formulation is manufactured and prescribed under physician supervision. This form of medication is allowed as OTC formulation shouldn’t be given without consultation.

Hospital compounding

Hospital pharmacies- Picture courtesy: Perth compounding

In hospitals, clinics, or pharmacies, the pharmacist is the prime body who has the expertise to compound the formulation of oxymetazoline hydrochloride nasal spray. Side by side, the active ingredient can also be used to form a topical gel or solution. The inside setup ensures that optimized concentrations of oxymetazoline hydrochloride are diluted with sterile water to form a nasal spray. This is a commonly used sector where sterile preparation is carried out to meet the in-patient and out-patient demands for the product.

7.What is the list of equipment required for oxymetazoline hydrochloride nasal spray manufacturing?

For oxymetazoline hydrochloride nasal spray manufacturing, there are the lists of equipment required. For example:

Water treatment plants

The journey of exploring machines starts with water treatment plants. There are the following types of water treatments takes place required for the formulation and manufacturing of pharmaceuticals based, and associated products.

Reverse osmosis unit

AIPAK ENGINEERING RO plant

This is the first step where the machine is facilitated with a semi-permeable membrane which obstructs the entry of microorganisms and large particles. Thus, the water provided is contaminant-free and compliant with pharma and food grade standards.

Water distillation plant

AIPAK ENGINEERING distillation plant

Water is further provided by using a distillation machine. This is a significant unit that provides you with safe and hygienic water for nasal spray. The main working principle of this plant is based on high steam and thermal energy. By utilizing the heat, the water content transforms into vapors.

Once they turned to this state, lowering of temperature brings them back to liquid form. By this method, you can get purified water without risk for contamination or microbial involvement. Therefore, transformation helps to attain water that is free from impurities.

Water storage and distribution tanks

AIPAK ENGINEERING storage and distribution tanks

The treated water is collected in storage tanks that facilitate turbulent flow toward the required machine with the help of integrated pressure circulatory pipes. The machine pressure is always maintained during the flow of water and allows an enclosed system to be installed at various sections of the oxymetazoline hydrochloride nasal spray manufacturing setup.

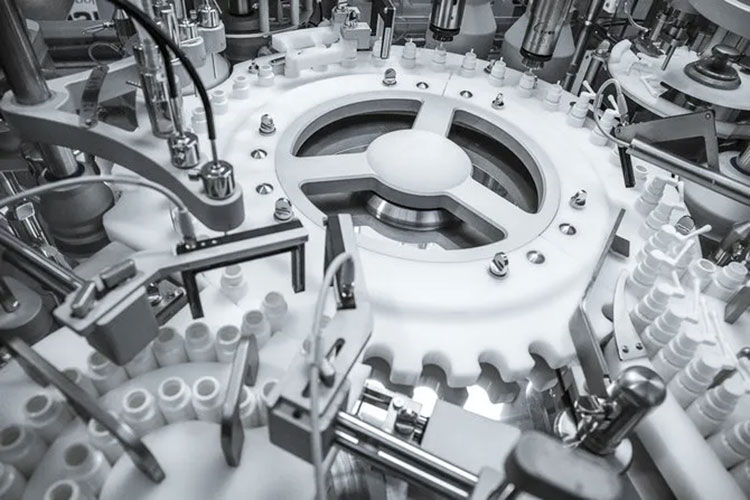

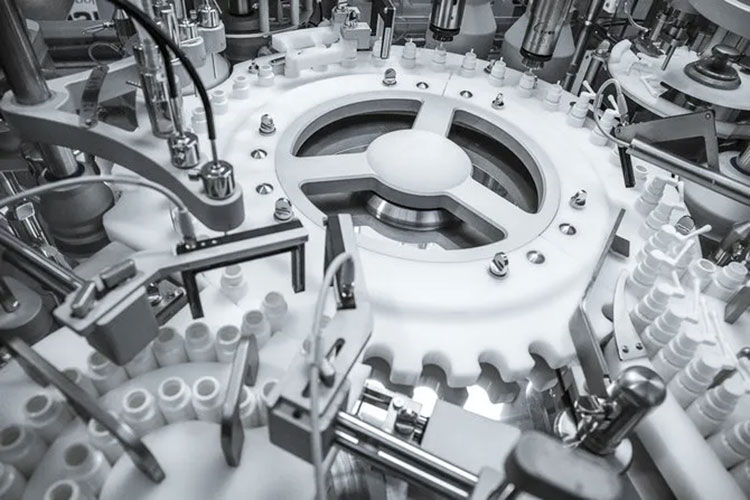

Mixing Unit

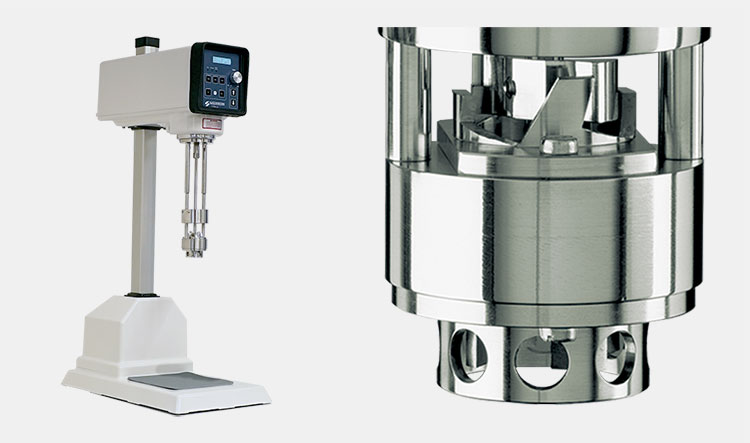

AIPAK Vacuum emulsifying mixer

The vacuum emulsifying mixer is the main unit that helps in the combination of various ingredients and solvents. The machine is capable of producing high-speed mixing under the influence of vacuum pressure which is an ideal property for sensitive materials uniform mixing. The particle sizes are ideally minimized by using the machine up to your required procedure.

Filtration unit

Filtration unit- Picture courtesy: Pharma lab

The prepared oxymetazoline hydrochloride nasal spray solution is now subjected to the filtration machine to capture unwanted or oversized particles. The filtrate solution is now cleared and ready to fill in the bottles.

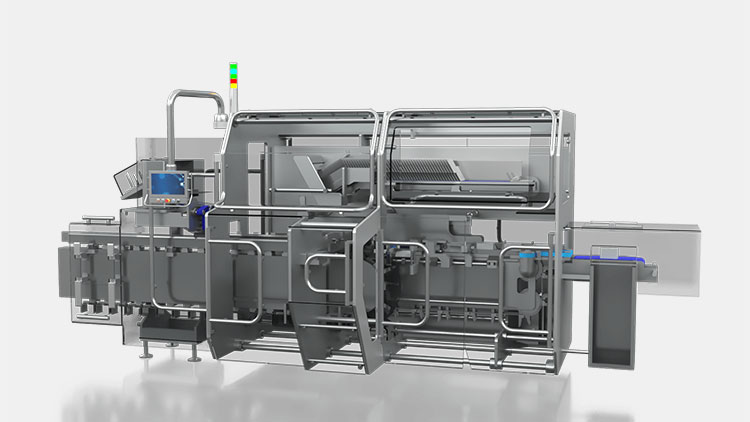

Filling line

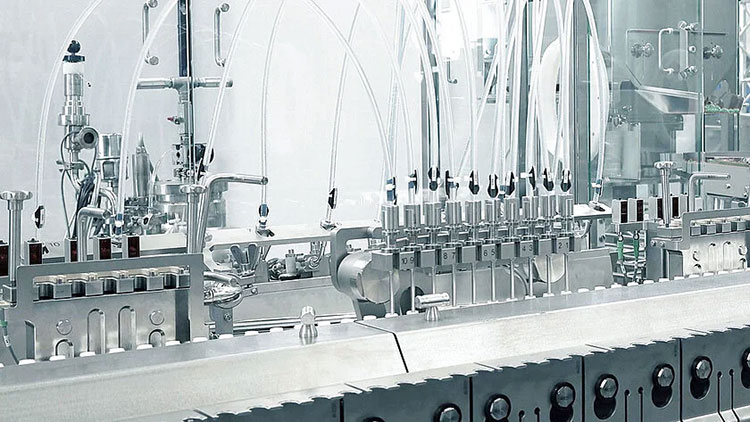

Oxymetazoline hydrochloride nasal spray filling line

The filling line is composed of three chief sections including the washing, and drying of nasal spray bottles, the sterilization unit that is required to sterile the packaging material entirely, and the filling machine.

The spray filling machine is mainly used for dispensing oxymetazoline hydrochloride solution with high speed with maintained accuracy. Moreover, it is composed of multiple features such as unscrambling of spray bottle nozzles and caps, filling of the solution, and sealing.

Labeling machine

Round bottle labeling machine

The oxymetazoline hydrochloride nasal spray bottles are now subjected to the labeling machine for the application of labels all around the surface. The applied label is an essential step in manufacturing as it provides necessary information related to the medicine, i.e. dosage, precautions, about the brand, etc.,

Carton machine

Cartoning machine- Picture courtesy: Universal Pack

This machine is mainly used in the last step, the flat cartons inside the machine can be placed which is transformed into the required cartons automatically. The conveyor supplies the filled bottles that are positioned and packed by the machine by using robotic grippers.

8.What are the parameters that must be monitored for oxymetazoline hydrochloride nasal spray manufacturing?

Certain factors impact the formulation as well as spraying aerosol. You must know these important considerations and should implement the proper steps during the manufacturing process for a good quality product with optimized characteristics.

Oxymetazoline hydrochloride nasal spray manufacturing- Picture courtesy: scientific product

|

Viscosity

|

You should know the knowledge about viscosity ratio of the formulation and the planning design. Remember if your formulation is composed of higher viscosity agents or the percentage, it can affect the atomizing effects of the spray.

The material can be difficult to spray or move forward if it is more viscous. Moreover, if the size of the droplet is bigger and the spray plume is shorter, it directly impacts the nasal spray delivery. Hence your formulation viscosity percentage should be optimized to allow an easy facilitation of the formulation whenever you require to administer it inside your nostril. |

| Surface tension

|

If your formulation is with lesser surface tension, then it becomes easier for you to spray and atomize the product. It means that if the size of the droplet of oxymetazoline hydrochloride nasal spray is smaller, it allows the easier flow with expanded spray pressure.

You need to remember that your droplet size should not be higher than 10 µm. For that, various solvents and co-solvents are used but you need to monitor the balance ratio among density and viscosity. |

| Density

|

The density which is defined as mass per unit volume, also has a similar effect to viscosity and surface tension.

If the density of the formulation or the product you are designing is higher it will make your preparation difficult to move out or it affects the atomizing effect of the spray. So, it should be less so that effects on the spray and their circulation inside the body would be better. |

| Particles

|

The particle size also has a direct relationship with the atomizing property of the oxymetazoline hydrochloride nasal spray.

Therefore, every manufacturer must be keeping account that the particle size of the solution must be smaller. For this purpose, further milling and micronization of the ingredients must be carried out. |

9.What is the difference between oxymetazoline hydrochloride nasal spray manufacturing and regular nasal spray manufacturing?

You might have thought about why it’s needed to use oxymetazoline hydrochloride nasal spray when regular nasal spray is available. This is all because of getting specific therapeutic effects i.e. nasal decongestion. When it comes to manufacturing, there are slight variations between oxymetazoline hydrochloride nasal spray manufacturing and regular nasal spray manufacturing. Have a look at them below:

Oxymetazoline hydrochloride VS regular nasal spray manufacturing

| Active ingredient | The oxymetazoline hydrochloride is the main APIs used in the spray to induce vasoconstrictive effects and nasal relieving effects. Whereas the regular sprays might be used with either normal saline as a main ingredient, anti-allergic compounds, phenylephrine, glucocorticoids, etc. |

| Dosage | the oxymetazoline hydrochloride nasal spray manufacturing product is only allowed to be used for three days. Whereas there are no restrictions for products of regular nasal spray manufacturing. |

| Preservatives | Oxymetazoline hydrochloride nasal spray manufacturing needs preservatives as an essential ingredient. On the other side, regular nasal spray manufacturing may be formulated with either a mild concentration of preservatives or without the inclusion of it. |

| Preparatory limitation | You can compound the oxymetazoline hydrochloride nasal spray with strict limitations by the FDA. The entire work protocol must be carried out in a controlled environment and critical dosage monitoring. The regular nasal spray can be compounded with flexible rules and working protocols, which vary in pharmacies, labs, and industries. |

10.What are the key considerations for successful oxymetazoline hydrochloride nasal spray manufacturing?

Things to consider for oxymetazoline hydrochloride nasal spray- Picture courtesy: Complete care pharmacy

Whenever you are planning to set up oxymetazoline hydrochloride nasal spray manufacturing, you should properly understand the basic aspects that can bring your business to the peak of success. For example:

| Understanding the formulation design

|

In the case of nasal spray, you should properly understand the concentration of active pharmaceutical ingredients, its dosage for each group, side effects, etc. Also, their understanding of the excipient must not ignored. By working on this, you can get an effective formulation that will increase the trust level of your customers in your company. |

| Maintaining the level of sterility

|

Nevertheless, oxymetazoline hydrochloride nasal spray is introduced into your blood circulation via nasal passage. Therefore your company workflow structure should be maintained with sterility and hygiene from scratch till the end of the formulation. |

| Reliable machineries

|

For oxymetazoline hydrochloride nasal spray manufacturing, each successful step is based on a reliable machine. If any of the machines get faulty, the entire work process will be disturbed. Subsequently, you must plan and purchase the machine from a manufacturer that is associated with a good track record as well as offering you excellent customer services. |

| Your production facility size

|

The oxymetazoline hydrochloride nasal spray manufacturing requires a series of machines to be installed. Therefore, you must estimate the size of the area for their fixation. Also, your manufacturer also provides help in providing the right type of machine that has to be integrated into the supporting portion. |

| Your affordability

|

This is the main factor over which the entire planning depends on. Your budget and the estimation must be determined before planning to start the business. This is included with expenses on the ingredients, type of machinery, packaging types, etc. Therefore, it will ensure easy decision-making for procurement equipment as well as related parameters involved in manufacturing. |

11.What are the basic challenges you meet during oxymetazoline hydrochloride nasal spray manufacturing?

When you attempt oxymetazoline hydrochloride nasal spray manufacturing, you may suffer from some technical issues. There are some important points that you mostly face with their solutions.

Inaccurate dispensing of nasal spray solution

Inaccurate filling- Picture courtesy: liquid filling machine

This is a quite significant problem in that machines do not pour the exact amount of nasal spray solution into each dispensing bottle. The following issue may result in ineffective medication as the spray amount that reaches your systemic circulation is not the required concentration to give therapeutic responses.

Solution

To check the issue, check the filling and capping machine’s settings. There might be problems with its calibration. It is always recommended that your unit calibration should be maintained regularly. Moreover, check and correct the obstruction with the filling nozzle. To keep an accurate filling, check the viscosity level of the solution and the type of filling method used. For example, use a pump or piston filler if the solution is viscous to avoid variations.

Entrance of foreign particles or chances of cross-contamination

Foreign particles- Picture courtesy: study solution.com

As we mentioned above, oxymetazoline hydrochloride nasal spray manufacturing is a sensitive and critical process; so it requires more strict work environmental conditions. In some cases, the unwanted particle's entrance disturbs the whole batch production or withdrawal of formulations.

Solution

The machines involved in the production line must be cleaned by using the CIP and SIP systems. The following approaches are involved with pre-wash, rinsing, and post-wash with steaming process. That verifies and ensures you that the units are now ready for sterile preparations. You should attempt regular cleaning soon after the management of each batch. In this way, the risk of cross-contamination is almost nullified.

Leaking of the manufactured product

Dripping- Picture courtesy: Cleveland Clinic

Apart from types of machinery, you also face problems with oxymetazoline hydrochloride nasal spray bottle dripping. This is a very common problem with filled materials and may result in product loss and may result in unsatisfactory user response.

Solution

The problem can be solved by selecting the anti-drip closure for the bottles. Moreover, the leakage testing after filling and packing the material can alarm you immediately about the batch status. Thirdly, if the bottles are again dripping when you’re administering, then the user must be instructed to use the right direction for its administration. For example, a tilted direction of your head can avoid dripping,

Conclusion

In the future, there is more expectation of greater demand for oxymetazoline hydrochloride nasal spray and more production demand. Therefore, manufacturing companies are making possible ways for you to add more advancement and research. This will ensure to provide better results for the management of nasal decongestion problems most safely and conveniently. In addition, sterile manufacturing is a paramount structure that promises to offer high quality and excellent formulation. If you are planning to contribute to the oxymetazoline hydrochloride manufacturing business, we would love to hear from you. We AIPAK is the team of experts that is hooked up to the field of machinery supply required for manufacturing. Contact us now for more information and an affordable list of equipment.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours