Your Best Oral Liquid Solution Provider

AIPAK Engineering Oral Liquid Solutions

AIPAK Engineering oral liquid solutions include the syrup filling solution and oral liquid filling solution.All the production lines are made by bottle unscrambler,bottle air /ultrasonic washing,syrup or oral liquid filling ,capping machine and labeling machine.It integrates design, one machine can wash, fill and screw bottle in one machine, reduce investment and production cost. The whole machine is with very compact structure, small occupying area, and less operator. All the filling machines on the production line are very accurate and stable,the filling volume can be directly adjust through HMI,you will get quick changeover time for different container size.With separated pipeline for cleaning medium, there is no cross-contamination, and it is according to GMP requirements.With filling head synchronously tracks filling, there is high filling accuracy.

Oral Filling Production Line

High Filling Accuracy Oral Liquid Production Line

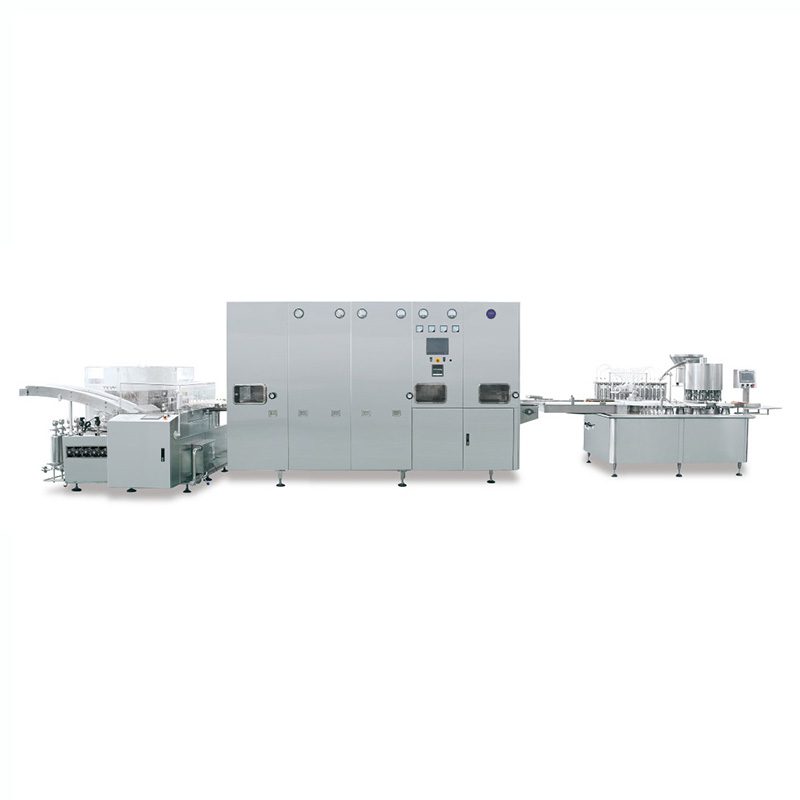

AIPAK Engineering oral liquid production line is composed of three equipment: bottle washing machine, tunnel sterilization oven, and oral liquid filling capping machine. It is divided into three working areas: cleaning, drying and sterilizing, filing and capping. Each machine can be used separately or in linkage line. During linked production, it can automatically complete cleaning, preheating, drying and sterilization, cooling, filling, screw (rolling) capping and is suitable for the production of packaging lines for oral liquid bottles.

Good in appearance, easy to clean

No dripping, no forming, and no spitting

Stable running, low noise, precise filling

Easy-to-fold Plastic Bottle Oral Liquid Production Line

AIPAK Engineering easy-to-fold plastic bottle oral liquid production line conforms to the "CGMP" requirements, applicable to filling and sealing the new easy-folding plastic bottle. Through a series of special process works of automatic bottle supply, bottom filling, automatic capping, hot melt-type bottom sealing, pneumatic fingers clip sending bottles the production line finishes filling and sealing.And the whole production line adopts PLC control, man-machine interface operation, automatic.

Automatic bottle loading, bottom filling, automatic capping

Man-machine interface operation

Not breaking in bottling and transportation

Syrup Filling Production Line

Automatic Glass Bottle Syrup Filling Production Line

AIPAK Engineering glass bottle syrup filling production line is composed of four types of equipment: bottle unscrambler, bottle washing machine, tunnel sterilization oven, and liquid filling and capping machine. Each equipment can also be working independently; It can automatically complete bottle unscrambling, cleaning, pre-heating, sterilization, drying, cooling, filling, screw (rolling) capping, and other processes and is suitable for syrups, tinctures, wines, health products, beverages, sauces and other liquids with different viscosity in the Aiapk Engineering.

High degree of automation and with stable and reliable operation

High-precision color touch screen operation monitoring

High capacity to realizes electromechanical integration

Full Automatic High Precise Plastic Bottle Syrup Filling Production Line

AIPAK Engineering plastic bottle syrup filling production line is composed of four types of equipment: bottle unscrambler, bottle washing machine, tunnel sterilization oven, and liquid filling and capping machine. Each equipment can also be working independently; It can automatically complete bottle unscrambling, cleaning, pre-heating, sterilization, drying, cooling, filling, screw (rolling) capping, and other processes and is suitable for syrups, tinctures, wines, health products, beverages, sauces and other liquids with different viscosity in the Aiapk Engineering.

Easy adjust filling volume and filling speed

High-performance non-bottle no filling, no bottle no capping

Full-line linkage