Oral Liquid Filling Machine: The Complete FAQ Guide In 2025

From cough syrup to liquid suspension, oral liquids are becoming our key partners for a healthy life. Thus, their manufacturing and processing is carried out on large scale. However, the most tricky thing about oral liquids is to accurately fill them into containers which vary from one type of liquid solution to another. Hence, an Oral Liquid Filling Machine is designed to end these intricacies.

This equipment can help you uplift the level of filling precision, efficiency, and production with its advanced technology. The high level automation make it more favorable for the rapidly changing industrial requirements. With simple structure, working mechanism, and convenient handling, an Oral Liquid Filling Machine is the best machine to be discovered. So, be ready to deep delve into this FAQ guide!

1.What Is Meant By Oral Liquid?

Woman taking syrup- Picture Courtesy: thestatesman.com

Oral liquid is a term commonly used in pharmaceutical industry to indicate all the liquid medications which can be taken by mouth such as syrups, drops, and suspension etc. Unlike solid dosage form like tablets and capsules, oral liquids are instantly digestible and suitable for kids and geriatric patients with difficulty in swallowing pills.

Similarly, these liquids require entirely different way of packaging for preservation by preventing leaks. For this purpose, oral liquids are stored in small to large bottles or containers which are precisely filled with the help of an oral liquid filling machine.

2.Define An Oral Liquid Filling Machine?

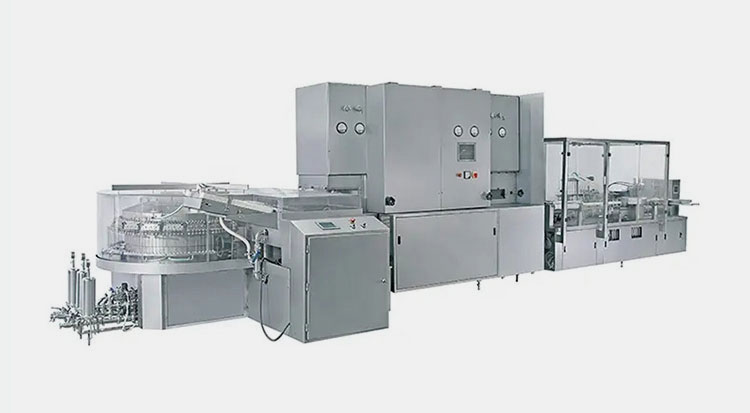

AIPAK ENGINEERING- Oral liquid filling machine

Oral liquid filling machine is a high-tech machine designed with advanced features to fill pharmaceutical liquids into bottles and containers. The machine is made up of stainless steel body along with other components to carry out the function of oral liquid filling.

It is automatic and support independent operation to precisely weigh the liquid and fill it into passing containers. Similarly, it can deal with range of free flowing and viscous liquids which are otherwise difficult to process. Hence, oral liquid filling machine is perfectly applicable in eclectic fields with its versatile performance, customization and high accuracy in terms of filling.

3.Enlist The Benefits Of An Oral Liquid Filling Machine?

Well, an oral liquid filling machine do offers various benefits which are all associated with its latest technology and sophisticated structure which together enable it to fulfill the complex requirements of oral liquid processing industries. So, let's enumerate few of the prominent ones!

Robust Structure

AIPAK ENGINEERING- Robust oral liquid filling line

An oral liquid filling machine is a manifestation of robust structure with corrosion resistant durable stainless steel as a major material for main frame. Similarly, the conveyor belts, stands, transparent window and other parts further strengthen its body which is both easy to adjust and mobilize.

Improved Efficiency

Oral liquid filling into bottles- Picture Courtesy: assetpackaging.com.au

With growing production needs, it becomes important for a machine to have greater filling capacity in less time. This feature can be easily found in an oral liquid filling machine which has improved efficiency level with filling capacity of up to 2000-24000 bottles per hour.

Maintain Consistency

Liquid filled bottles with consistent fill level- Picture Courtesy: Freepik

Maintaining accuracy and consistency during liquid filling is the key for successful packaging. An oral liquid filling machine can better play this significant role by avoiding over and underfilling.

Reduce Waste

As the machine is following automatic principle of no bottle no filling, it can end the waste of material to a greater extent and thus provide you with safe filling of various liquids.

Easy Operation

Operator observing machine setting- Picture Courtesy: emi-wissler.com

Oral liquid filling machine comes with an intuitive control panel with touch screen display which allows you to conveniently set your desired parameters in the machine. These commands will be followed by machine without asking your constant engagement.

High Versatility

It is the dream of every manufacturer to have the machine which is as versatile as possible. So, an oral liquid filling machine is simply one of them which can fill small to large size of bottles with different types such as plastic bottles, glass bottles, and vials.

4.Why An Oral Liquid Filling Machine Is Considered Important In Pharmaceutical Industry?

Various forms of drugs- Picture Courtesy: knnindia.co.in

Pharmaceutical industry is a sector where minor irresponsibility can cause huge losses to manufacturers as well as patients. Thus, there is no room for error and that's the reason why an oral liquid filling machine is considered inevitable equipment in this field.

As oral liquid is popular dosage form used for the people of all ages in all forms whether drops, syrups, suspension, or emulsion, it is eminent to pack these liquids in hygienic environment for which this machine is best qualified.

Moreover, maintaining dosage accuracy is also very important which is not possible manually. Thus, the fulfillment of these requirements makes the use of an oral liquid filling machine pivotal in pharmaceutical industry.

5.What Type Of Containers CanBe Handled By An Oral Liquid Filling Machine?

Depending on the type of machine being used, an oral liquid filling machine can handle different sizes and shapes of containers. The underlying examples will help you get the answer:

Plastic Bottles

Plastic syrup bottles- Picture Courtesy: laiyangpackaging.com

Plastic bottles are commonly used for oral liquids due to their flexibility and cost-effectiveness which make them suitable for safe handling of liquids. These bottles vary in shape and size thereby offers versatility to store small to large amount of oral liquids. These plastic bottles can be easily filled by using an oral liquid filling machine.

Glass Bottles

Various sizes of glass bottles- Picture Courtesy: justdial.com

Glass bottles are highly hygienic and protected against bacteria due to which sensitive oral liquids are often preserved by using these bottles. Hence, an oral liquid filling machine can be employed to safely fill glass bottles.

Vials

Glass vials- Picture Courtesy: cmo.fresenius-kabi.com

Vials are type of glass containers with usually a small body. These vials are frequently used for storing injection water, vaccines as well as oral liquids. Similarly, an oral liquid filling machine can be utilized to process vials.

6.Explain The Working Principles Of An Oral Liquid Filling Machine?

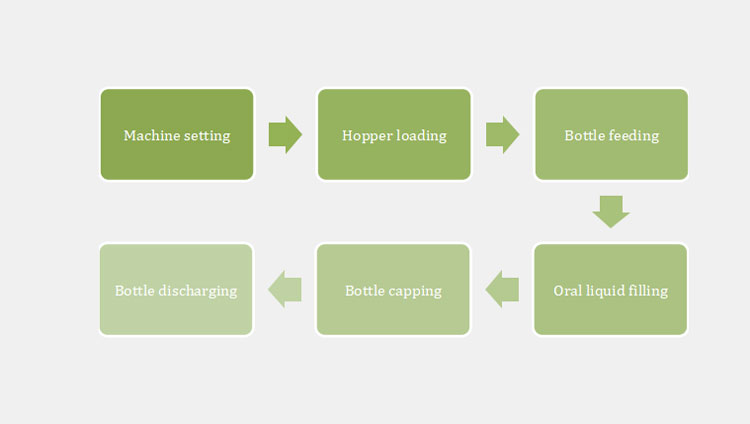

Understanding the working principles of an oral liquid filling machine is pretty easy. You just need to consider it as a liquid filling machine which is specifically used for filling oral liquid. Let's view some essential steps which are part of the machine operation!

Machine Setting

First, the machine needs to be settled properly. This setting is done on two levels: structural adjustment of the tools before starting machine and fixing the parameters for operation such as amount of liquid to be filled and speed of conveyor etc.

Hopper Loading

Now, the second step is to load hopper of the machine with bulk of desired oral liquid. It simply allows the machine to keep running and supply adequate liquid for filling.

Bottle Feeding

Bottles loading- Picture Courtesy: maharshi.com

Along with hopper loading, it is important to feed the machine with empty bottles for smooth functioning. Similarly, as the oral liquid filling machine is powered on, these empty bottles start moving forward towards the machine via conveyor belt.

Oral Liquid Filling

Oral liquid filling into bottles- Picture Courtesy: maharshi.com

With the help of detection system, machine stop the conveyor when bottles reach under the filling heads. Afterwards, the desired volume of oral liquid is weighed by the machine and precisely fill it into awaiting bottles through filling nozzles.

Bottle Capping

Bottle capping- Picture Courtesy: maharshi.com

The filled bottles are then moved ahead for capping. Usually, capping section is integrated into an oral filling machine or can be separately attached. After their transmission from filling unit to capping unit, bottles are supplied with caps and tightly sealed around their necks.

Bottle Discharging

Bottle discharging- Picture Courtesy: maharshi.com

Finally, the capped bottles are ready for outlet. They are mobilized for further packaging such as labeling and cartoning etc.

7.Describe The Structure Of An Oral Liquid Filling Machine?

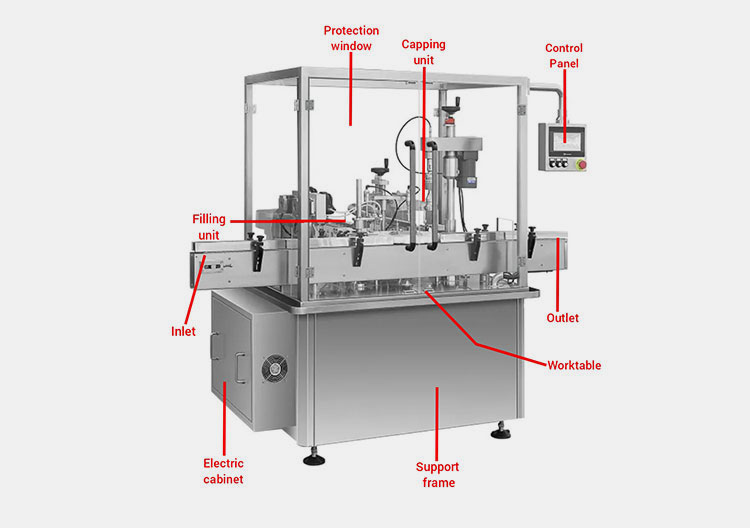

The structure of an oral liquid filling machine is precise with several components constituting its body. These parts along with their functions are described below:

AIPAK ENGINEERING- Structure of an oral liquid filling machine

Protection Window

The machine has transparent protection window around the worktable to provide safe environment for oral liquid filling into containers. Along with that, it allows operator to keep monitoring the operation without intervention.

Capping Unit

Capping unit is another part of an oral liquid filling machine which perform the function of applying caps over filled containers. It is composed of a cap elevator, hopper, cap feeding chute, and a cap application device.

Control Panel

Control panel is another significant part of the machine which is characterized by an intuitive touch screen and certain knobs. Together they are used to control the functioning of machine by adjusting its parameters such as fill volume, filling speed, and capping speed etc.

Filling Unit

Filling unit is considered the core component of an oral liquid filling machine which consists of pump, filling nozzles, and a hopper. The hopper helps in the supply of liquid

Inlet

Inlet refers to the bottle entrance place from where containers are entered into the machine for filling. These bottles are simply conveyed through a conveyor belt.

Electric Cabinet

Oral liquid filling machine has an electric enclosure which encases all the electrical components including wires, fuses, and switches inside for safety. This unit is called electric cabinet.

Support Frame

Support frame constitute the overall body of machine which is made up of stainless steel.

Outlet

It is the end point of conveyor which is used to discharge the finished bottles.

Worktable

Worktable refers to the central part of machine over which filling section, capping section, and conveyor belt are placed. Together, these tools help in performing operation.

8.Are There Any Types Of An Oral Liquid Filling Machine?

There are multiple types of oral liquid filling machine you can found in market. These machines vary from one another on certain basis. Let's know them in a bit detail!

Fully Automatic Oral Liquid Filling Machine

Fully automatic oral liquid filling machine is a superior machine with high automation to perform oral liquid filling. Such machine is highly adaptable to process various sizes and shapes of containers. With sophisticated structure and automatic operation, it can be easily integrated with other machines to enhance production efficiency. Moreover, it is available in 4 to 12 heads to give you desired output. Thus, fully automatic oral liquid filling machine is suitable for large scale industries.

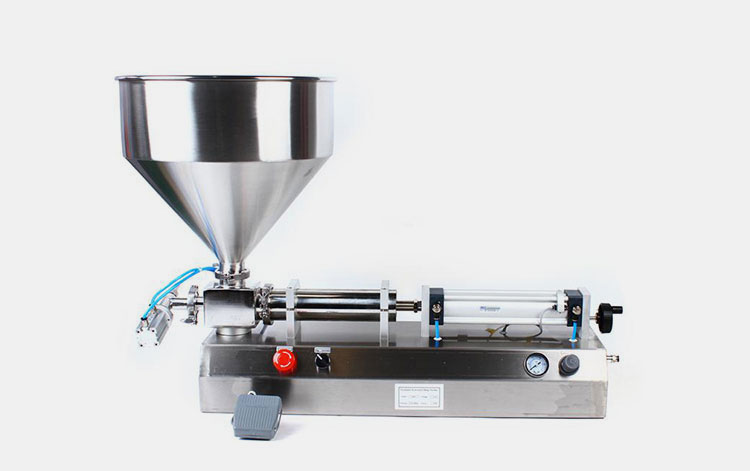

Semi-Automatic Oral Liquid Filling Machine

Semi-automatic liquid syrup filling machine- Picture Courtesy: Allpack

Semi-automatic oral liquid filling machine is another type of machine utilized for filling various oral liquids into bottles and containers including syrups, pastes, and mouthwash etc. It has precise structure with few components which is why you can find it cost-effective.

In addition to it, the machine is simple to operate and can easily deal with range of containers. Thus, you can simply operate it by manually placing and discharging containers under the filling heads. The machine is suitable for small to medium scale production.

Manual Oral Liquid Filling Machine

A03 Manual paste liquid filling machine- Picture Courtesy: Allpack

Manual oral liquid filling machine is pretty simple machine with small footprint and convenient way for operation. It mainly consists of a hopper, handle, filling nozzle, and a base. For operation, you just need to push the handle and it will dispense liquid into underlying bottle. This machine is suitable for home based businesses, however, hygiene should be well maintained as this manual way may cause cross-contamination.

9.What Are The Uses Of An Oral Liquid Filling Machine?

Oral liquid filling machine is applicable to every industry where there is any kind of oral liquid processing. Some of the notable uses of an oral liquid filling machine are as follows:

Pharmaceutical Industry

Cough syrup- Picture Courtesy: samipharmapk.com

Pharmaceutical industry is an area that is constantly engaged in producing various types of medicines. For this purpose, convenient ways for drug delivery are the first priority of pharmacists. Here is where they find oral liquids as the easiest and most simple way for taking therapeutic drugs by adding flavors. Hence, to securely pack these oral liquids into bottles and vials, an oral liquid filling machine is always employed.

Nutraceutical Industry

Drop extraction from leave into bottle- Picture Courtesy: flavourtech.com

With emerging technologies, now it is a common practice that essential vitamins and nutrients are extracted from natural sources and preserved in liquid form. These nutraceutical oral liquids are then used to strengthen immunity and boost energy. Since, the consumers are so many and spread around the globe, so, a machine like oral liquid filling machine is used to safely process them.

Veterinary Industry

Pet syrup bottle

Conducting medical treatment for pets and animals is one of the difficult tasks to do. Well, this is now resolved with the manufacturing of oral liquids which can be simply given to animals as it is or mixing in food so they won't be able to resist. That's where we found another application of an oral liquid filling machine which is appreciated for its efficient filling of oral liquids in veterinary industry.

Food Industry

Bottles filled with sauces- Picture Courtesy: Freepik

Beverages, seasoning, and sauces are some of the examples of liquids which are produced in food industry. Similar to other types of oral liquids, they are often delivered in flexible to rigid containers like bottles. In this way, an oral liquid filling machine is frequently used in food industry to precisely fill these free flowing and viscous fluids into packages.

Chemical Industry

Various liquid chemicals bottles & containers- Picture Courtesy: WebstaurantStore

Liquid chemicals require safe and enclosed environment for their packaging to avoid hazard to environment as well as handle the solutions. These all requirements are simply fulfilled by an oral liquid filling machine which is made up of corrosion resistant stainless steel. Thus, its use us also prevalent in chemical industry.

10.What Manufacturing Standards Should An Oral Liquid Filling Machine Meet With?

Oral liquid filling machine is an equipment designed to process edible oral liquids in pharmaceutical and other fields. Similarly, it must adhere to certain manufacturing standards which are recognized on global level. So, make sure your oral liquid filling machine is complying with the following quality standards:

Checklist icon for manufacturing standards- Picture Courtesy: mrpeasy.com

ISO:International Organization for Standardization is the largest regulatory body being established for the certification of quality products and the machines used for their manufacturing.

GMP:Good Manufacturing Practices is another such standard with primary focus on the quality of structural material used in oral liquid filling machine like 304 stainless steel for corrosion resistant operation.

CE:Conformate European is the European Union collective regulatory authority whose compliance is obligatory for machines used and produced there.

FDA:Food and Drugs Administration is among the important agencies working to ensure public health by issuing quality certifications to goods and equipment adhering to safety standards.

11.What Is The Production Line For An Oral Liquid Filling Machine?

Meeting with production on large and extra large level is not possible with a single machine, rather it ask for employing a full fledged production line. Thus, you can see that now production line for oral liquid filling machine is also there to facilitate you in accomplishing your manufacturing targets. Let's know this comprehensive solution in a bit detail!

Automatic Glass Bottle Syrup Filling Production

Bottle Unscrambler

Bottle unscrambler constitute the first unit of the production line for an oral liquid filling machine. It is used to feed the bottles into line for nonstop working. It composed of a turntable, main frame, and mechanical tools. Together, these parts enable the machine to unscramble randomly positioned bottles and align them for entering the production line.

Bottle Washing Machine

Bottle washing machine is another significant equipment that can be attached to the oral liquid filling machine. It consists of several units including ultrasonic chamber, water system, flushing system, and electric unit. It simply takes the empty bottles by gripping in clamps and then pass these bottles through continuous water flushing for proper washing.

Tunnel Sterilization Oven

Mere washing bottles may not be enough to decontaminate the containers from substances like pyrogens. Thus, tunnel sterilization oven is a must have equipment in the oral liquid filling machine production line. It is used to sterilize the washed bottles by passing them through excessive heat, so, the possible bacteria will be destroyed. Simultaneously, it cools down the temperature to prevent damage t bottles.

Liquid Filling Machine

Liquid filling machine is the central equipment used in production line for ultimate task of filling oral liquids into bottles. It is fully automatic in technology and undertake independent weighing and filling of the desired oral liquid. The structure of machine is enclosed with various components including a stainless steel body, protection window, filling heads, weighing pump, and transmission mechanism.

Capping Machine

Capping machine is also a significant part of the production line for an oral liquid filling machine which can be directly integrated to the main machine. It is composed of a cap feeder, cap supply chute, torque applicator, and conveyor etc. The main task of capping machine is to supply the filled bottles with cap and tightly seal them around the bottles neck.

Labeling Machine

Labeling machine is the last unit of production line for oral liquid filling machine. Its use is as important as other machines because it helps you in letting your finished products recognized in the vast market. The machine is beautifully structured with film roll, film unwinding wheels, label applicator, fur brush, conveyor belt, and support frame. It labels the bottles by unwinding film, splitting it, applying around the bottles, and using a fur brush to get the label stick around them.

12.How To Clean And Maintain An Oral Liquid Filling Machine?

Similar to other machines, an oral liquid filling machine also require proper cleaning and maintenance to avoid sudden breakdown and manage parts wear and tear. So, make sure you are taking the right step to keep your machine at its optimum condition. For this, underlying tips can be helpful:

Engineering maintaining machine- Picture Courtesy: randollindustrial.co.uk

Cleaning:

Conduct regular cleaning for your oral liquid filling machine to remove out debris and lumps.

For cleaning, disassemble the machine by separating the washable parts like hopper, pipes, and filling nozzles.

After disassembling, use recommended cleaning agent along with brush or soft cloth to clean these parts.

For other parts, use a damp cloth and wipe their surface such as protection window, control panel, and main frame.

Once cleaning is done, assemble the parts to their exact location.

Make sure all the parts are dry before you operate machine.

Maintenance:

During operation, keep monitoring the working of machine for noticing any kind of abnormality.

In case of noise, try to identify the place and take relevant steps for troubleshooting.

Maintain the structural integrity of your oral liquid filling machine by tightening the screws and placing parts of their right location.

Keep updating the parameters setting and softwares in control system for accurate functioning of the machine.

Lubricate the movable parts and change the lubrication oil to reduce friction.

In case of parts damage, replace them immediately with new ones.

13.How To Troubleshoot An Oral Liquid Filling Machine?

While operating an oral liquid filling machine, you may encounter sudden problems which can be easily tackled if you have proper knowledge about the key issue and causes behind. So, let's understand some of the common issues along with their solutions!

| i. Liquid foaming after filling | ||

Highlighting liquid foaming during filling- Picture Courtesy: maharshi.com |

Cause:

Excessive filling speed may result in the creation of bubbles which get out of the bottles and result in spilling. The type of filling heads may not be suitable for type of liquid. |

Solution:

Reduce the filling speed to get the liquid settle down in bottles properly. Use appropriate filling nozzles in accordance with the type of liquid like diving nozzles for foamy liquids and narrow nozzles for free flowing fluids. |

| ii. Inconsistent Filling | ||

Inconsistently filled bottles |

Cause:

The nozzles may be blocked which restrict the free flow of liquid. The setting of fill volume may not be adjusted. The machine is placed on uneven surface. The hopper may have shortage of material. |

Solution:

Check the nozzles for blockage and adjust for correction. Adjust the fill volume via control panel. Make sure to place the machine on flat and even surface to avoid shaking during operation. Supply adequate liquid volume to reservoir. |

| iii. Nozzle blockage | ||

Highlighting blocked filling nozzles- Picture Courtesy: maharshi.com |

Cause:

Impurities in the filling material. The debris may be accumulated in nozzles. The filling nozzles are misaligned. The throttle valves are closed. |

Solution:

Check the nozzles and remove out impurities before filling. Keep cleaning the nozzles Adjust the spacing and height of nozzles. Check and open the throttle valves. |

| iv. Bottle transportation issue | ||

Displaying bottles transportation issue- Picture Courtesy: maharshi.con |

Cause:

The speed of conveyor belt is unsuitable. There is issue in spacing of bottle guide rails on conveyor. |

Solution:

Modify the speed of conveyor by using control board. Adjust the spacing of bottles each time when using different sizes bottles. |

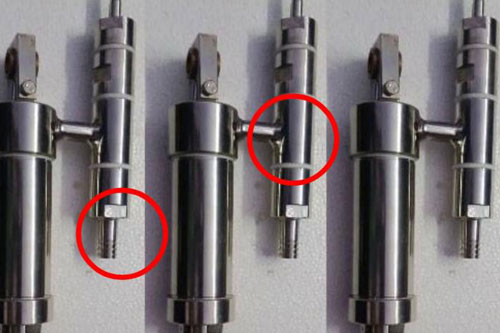

| v. Cylinder is not working | ||

Marked cylinder for oral liquid filling machine- Picture Courtesy: deepujpharmamachinery.com |

Cause:

Pressure gauge is not working. The fuse may be blown down Check if emergency button is pressed down. The piston may be stuck. |

Solution:

Connect the air source for pressure gauge working. Change the blown fuse with new functioning one. Release the button by twisting. Check and reinstall the piston. |

14.Factors To Consider For Selecting The Best Oral Liquid Filling Machine?

Whenever you intend to buy an oral liquid filling machine just take a pause for a while and ponder what type of machine will be best suitable for you. In your consideration, we are here to help you by presenting some of the essential factors including:

Type of Material

Free flowing & viscous syrups

First, you need to understand the nature of liquids you want to fill. For instance, are they free flowing, viscous, or holding particulates? Knowing this will help you scrutinize the specifications of an oral liquid filling machine such as piston filling technique, gravity filling mechanism, volumetric filling technique etc.

Expected Efficiency

Efficiency level icon- Picture Courtesy: musatotech.co.za

Another thing to look for is the level of efficiency you expect from your machine. For example, do you want to operate it for low or medium level production or want to employ it for large production scale. You can simply determine it by reviewing your current manufacturing level and checking the speed of machine production per minute and per hour.

Cost

Cost presentation idea- Picture Courtesy: sagacitysolutions.co.uk

Estimating the overall cost for an oral liquid filling machine is also very significant. It will include the exact price of machine along with its installation, operation, and maintenance cost. In case you find it expensive to purchase new machine, then you may opt for secondhand machine from reputable supplier.

Auxiliary Machines

You may also need auxiliary machines for your oral liquid filling machine like bottle unscrambler and capping machine. So, check for these equipment and try to get them for your convenience.

15.Why Choose Aipak Engineering As Your Oral Liquid Filling Machine Supplier?

Aipak Engineering is a professional Chinese company constantly engaged in the manufacturing and supplying advanced pharmaceutical machines for over 15 years. You might be wondering what benefits you can get by becoming over valuable customer. So, have a look towards our expertise!

AIPAK ENGINEERING logo

Extensive Experience

For over 15 years, Aipak Engineering is working in the field and now its presence can be seen in over 60 countries including Turkey, Russia, Iraq, and Indonesia.

Quality Certification

Certified by international quality standards, EU GMP/US FDA GMP, WHO GMP, PIC/S GMP, all our equipment are made up of quality materials. You will also get the important documents including DQ, IQ, PQ, OQ, FAT, SAT, operation manual, maintenance instruction, and layout drawing etc.

Customer Service

We offer comprehensive customer service including pre-sale and after-sale guide, training, installation and maintenance facility. You can also get remote support any time upon contact.

Wide Variety

Aipak Engineering offers you wide variety of standalone and production line solutions for different types of liquids handling.

Available Customization

The best thing about oral liquid filling machine is the high level of customization and scaling which it supports. With Aipak Engineering solutions, you will have the option to design your own machine the way you want.

Conclusion

Let's move towards the bottom line which emphasizes the importance of an Oral Liquid Filling Machine in medical fields followed by food and non food sectors engaged in liquid production. Dealing with sensitive edible liquids is a critical task for which not only an efficient and enclosed machine is required but also a hygienic one like an oral liquid filling machine. This equipment can end your bother by its user-friendly design, operation procedure, and simple maintenance schedule. So, don't make further delay as you have got all the necessary information. Just click on the given link and be the user of an oral liquid filling machine!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours