Manufacturing Of Antibiotics: The Complete FAQ Guide In 2025

How often have antibiotics prevented you from becoming severely ill or helped you to stop infection getting worse? Have you ever be inquisitive about how antibiotics are made? This guide is designed to satisfy all your curiosity about manufacturing of this life saving medication.

What do you need to learn about manufacturing of antibiotics? It’s the basic knowledge that makes you understand the purpose, importance and necessity of manufacturing of antibiotics in our society. Here you will get awareness about benefits, whole operation, packaging containers, machines, considerations and issues of manufacturing of antibiotics.

1.What do you understand by manufacturing of antibiotics?

Manufacturing Of Antibiotics-Picture Courtesy: VeryWell Health

Preparation of antibiotics on a large scale by utilizing specially designed equipment can be called manufacturing of antibiotics. You can observe such preparation in pharmaceutical industry, where every step carries out with great care and efficiency. Here we discuss about production of antibiotics given by parenteral route and it involves particular process to ensure the quality and sterility of the drug product.

Do you know the fundamental steps of making an antibiotic? You can include the fermentation of microorganism to get antibiotic, then purification of extracted antibiotic and last step is to make the final product of antibiotic by adding other ingredients in it.

2.What privileges are earned by manufacturing of antibiotics?

Privileges Of Manufacturing Of Antibiotics

Can you figured out the privileges you earn by manufacturing antibiotics? It’s huge and its impactful role is expanded over different grounds. Let’s explore it!

Treating different diseases:

Treating Different Diseases-Picture Courtesy: Britannica

Either it’s an acute infection or a chronic disease; you always witness the effective role of antibiotics. It is the manufacturing of various antibiotics that transforms the way of treatment, saving people from getting seriously ill or even dying.

You can see often that any disease that spreads so fast is controlled by the use of antibiotics. Many infections that can harm you after any surgical process are handled by administering antibiotics. Now you are well-convinced upon the beneficial role of manufacturing of antibiotics on health system.

Offering innovation in therapeutics:

Offers Innovation In Therapeutics-Picture Courtesy: AAMC

Are you informed about the fact that you can create resistance against antibiotics? Yes it is true and this issue is continuing to be happened since the start. You can sense that the manufacturing of antibiotics brings innovation in therapeutics and you get new different kinds of antibiotic drugs that are proved to be effective against resistant bacteria.

Proving to be a fruitful investment:

Proves To Be A Fruitful Investment-Picture Courtesy: Datex

You are well informed about the vigorous use of antibiotics in our society. Don’t you think it’s a fruitful investment in pharmaceutical industry? By investing in this regard, you and industry both experience prominent benefits.

You can gain profit due to vast production of antibiotics and pharmaceutical industry makes its manufacturing wider and advanced to meet the standards and demands. This thing also contributes in betterment of framework of pharmaceutical production.

Powerful role in protecting animals:

Powerful Role In Protecting Animals-Picture Courtesy: Farmers Weekly

Have you thought that the manufacturing of antibiotics has only benefited humans? No, it has powerful effects on animals. You have seen so many antibiotics product designed to deal with infections related to pets and livestock, resulting in prevention and protection of animals from diseases.

Do you recognize the role of livestock for agriculture? Livestock contributes in agriculture activities and help farmer in different ways, which prove the advantageous impact of antibiotics manufacturing on agriculture.

Establishing economy:

Establishing Economy

Do you have idea in what ways; manufacturing of antibiotics is contributing in growth of economy? You know it very well that antibiotic is the need of everyone, and by producing antibiotics in vast quantities you can export it and cause advantage to finance. This huge production invites many job opportunities for your people that can low the unemployment rate. Due to mentioned benefits, economy flourishes.

Contribution to research & development:

Contribution To Research & Development-Picture Courtesy: ComplianceQuest

Do you sense the favor of manufacturing of antibiotics to research and development? It has countable impact on it, by presenting different new techniques that utilize for making this life-protecting medicine. Research remains continued to formulate more effective antibiotics with fewer side effects and resistance.

3.What forms of antibiotics are prepared by manufacturing of antibiotics?

Do you have idea that antibiotics given by parenteral route are available in two different states? Yes these formulations are available as liquid or powder form and there is a clear reason behind their formulation like that. Let’s discuss!

| Forms of antibiotics prepared | Image |

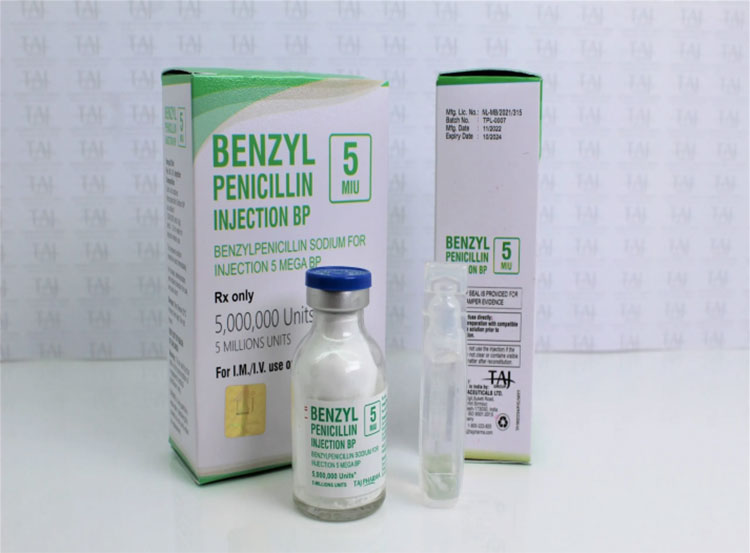

| Powder (lyophilized) form:

You often observe that antibiotics are available in powder form and sterile water is added in it before administration. Can you guess why? These antibiotics are very sensitive and can become unstable in liquid form during shelf life. There is always strong chance of growth of microorganism in liquid state. Such facts convince the formulation of product in lyophilized/ freeze-dried form. Example: penicillin, fosfomycin, etc. |

|

| Liquid form:

Some formulations of antibiotics are produced in liquid state and reasons can be very clear. These antibiotics have capacity to remain stable during shelf life, these are heat-stable and you find them unchangeable even storing in liquid form. Example: Nafcillin |

|

4.Are you known to the classes of antibiotics made from manufacturing of antibiotics?

Classes Of Antibiotics

You are well-aware of the fact that antibiotics are the cure to various infections and they work in different ways to show their dominant effects. Here you get knowledge about available antibiotics manufactured for parenteral route administration.

| Classes of antibiotics | Example | Picture |

| Penicillin:

This class works by inhibiting the cell wall synthesis of bacteria and you find it effective for many infections. Uses: You can use penicillin to treat ear and throat infection, rheumatoid fever, urinary tract infections |

Ampicillin |  |

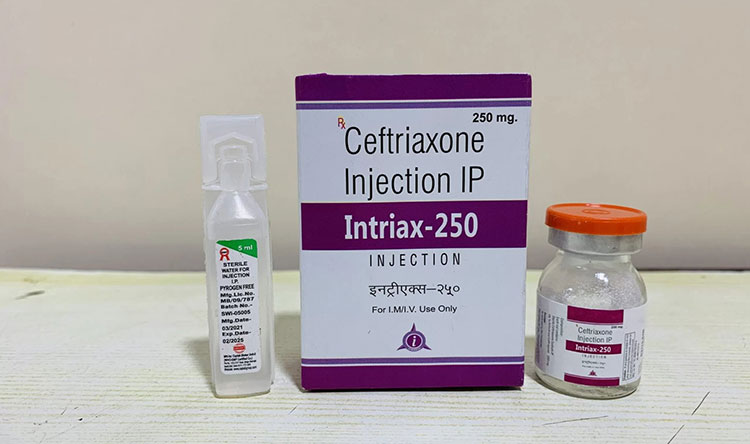

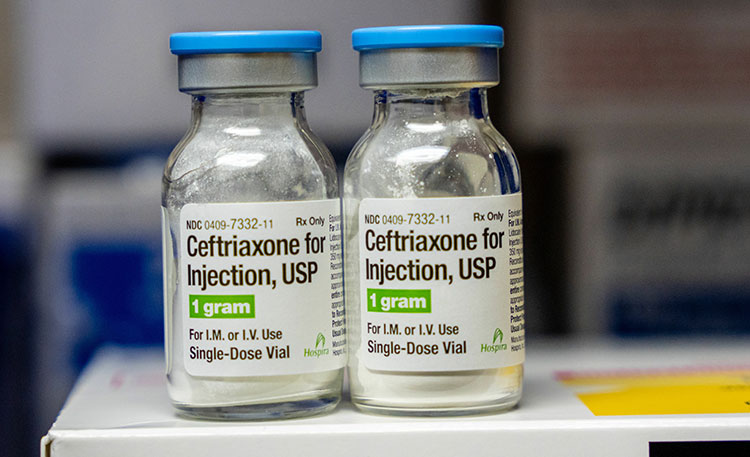

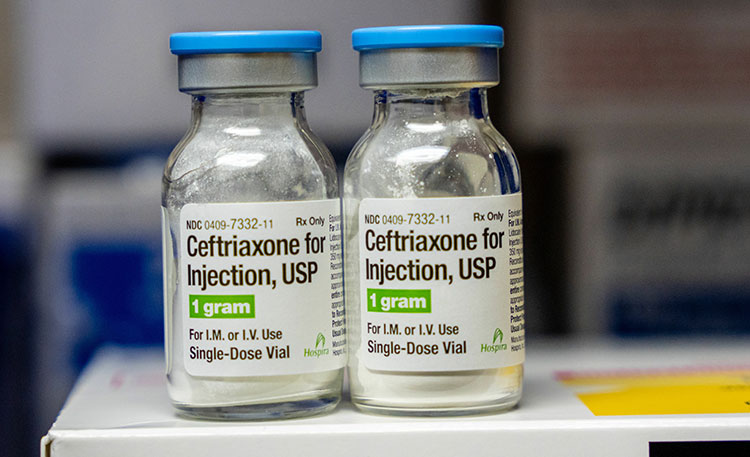

| Cephalosporins:

These antibiotics show their profound effect by interrupting the cell wall synthesis in bacteria. Fragile cell wall eventually leads to death of bacteria. They have wide spectrum and can be used against so many infections. Uses: These are used to cure sexually transmitted diseases like gonorrhea, reproductive system related infections or infection of brain you can called as meningitis. |

Ceftriaxone |  |

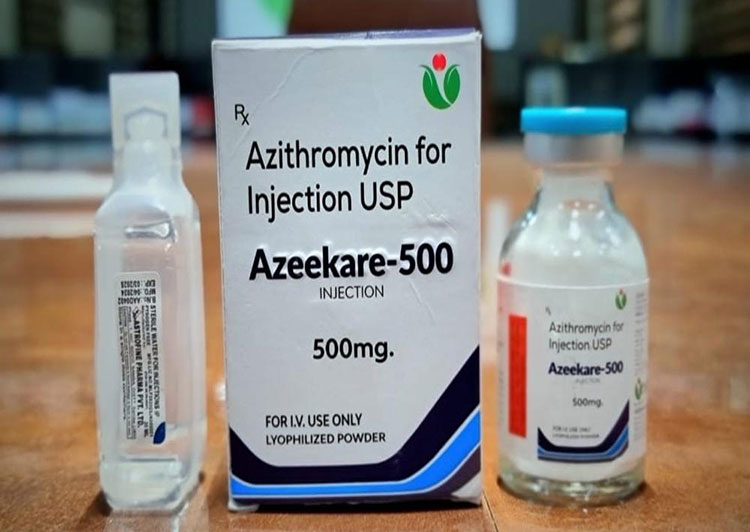

| Macrolides:

Do you know bacteria needs protein to survive? Antibiotics of this class have capacity to inhibit protein synthesis of bacterial cell by attaching to50S ribosomal subunit. Uses: These antibiotics have great ability to fight against respiratory tract infections, infections related to ear, skin and sexually transmitted diseases. |

Azithromycin |  |

| Aminoglycosides:

These antibiotics are capable to stop protein synthesis in bacteria, just by binding to 30S subunit of ribosome. It is being used for many diseases that are caused by gram-negative bacteria. Uses: These are used to treat some important infections like tuberculosis, nosocomial respiratory tract infections, abdominal infections etc. |

Amikacin |  |

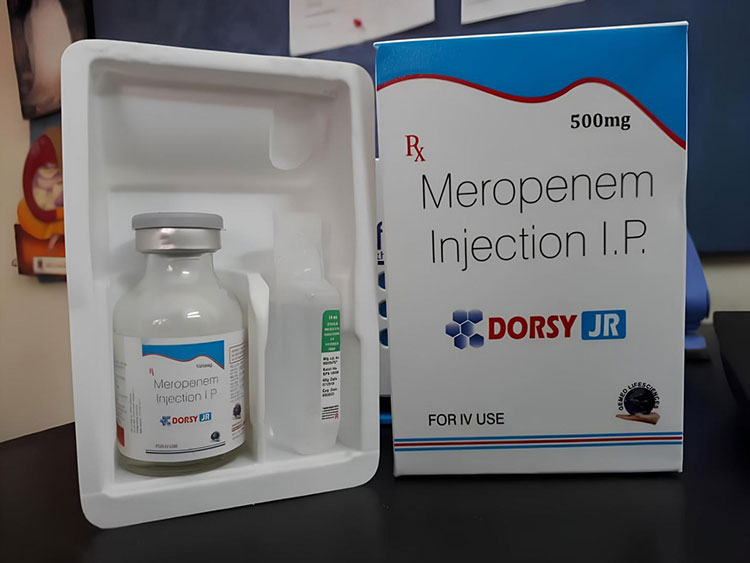

| Carbapenems:

These antibiotics can stop the integration of bacterial cell wall that causes fatality of bacteria. These are considered as broad spectrum and can treat variety of infections. Uses: Carbapenems are often used to manage infections related to respiratory tract, urinary tract, abdomen, skin, pelvic, brain etc. |

Meropenem |  |

| Flouroquinolons:

These antibiotics have great tendency to stop DNA synthesis in bacteria, do you know how? By inactivating two important enzymes that are responsible for DNA production. This class of antibiotics comes under broad spectrum antibiotics, so they are utilized on the basis of their capability to fight different bacteria. Uses: Flouroquinolones are intended to treat pneumonia, sepsis, urinary tract infections, bone infections etc. |

Ciprofloxacin |  |

| Glycopeptides:

Such antibiotics work by limiting the synthesis of cell wall in bacteria. This hindrance can cause death of bacteria. You can often observe the use of these antibiotics to manage infections caused by gram positive bacteria. Uses: Glycopeptides antibiotics are used when other antibiotics have failed to cure serious infections. Do you know why? These antibiotics have ability to treat resistant strain of bacteria. They have been used to treat nosocomial infections, lower respiratory infections, bone infections, skin infections etc. |

Vancomycin |  |

| Nitroimidazole:

Such antibiotics act to affect the DNA and inhibit the synthesis of protein of bacterial cell wall. Uses: These are used to administer after surgery, or to treat serious lesions. |

Metronidazole |  |

5.Do you know about the packaging containers used in manufacturing of antibiotics?

It is somehow an interesting knowledge to know the packaging containers used in manufacturing of antibiotics. These antibiotics are given directly into your blood stream, don’t you think they need such containers that keep their sterility and stability intact.

| Packaging containers: | Information: |

| Vials

|

Do you sense what is the common dispensing container utilized in manufacturing of antibiotics? Its vials, small cylindrical container with aluminum sealing.

You can observe that antibiotics injections are available in vial either single dose or multiple doses. These vials are capable to store antibiotics without affecting their stability or sterility. Vials also offer the ease to draw precise dose and without causing any contamination. Vials follow guidelines given by good manufacturing practices for packaging antibiotics. You can see vials are made of glass or plastics. |

| Ampoules

|

Do you have idea which container is considered as suitable to draw a precise single dose? Its ampoules.

Antibiotics that are intended to be given as single dose as they don’t contain preservatives, you can use ampoules. Ampoules can ensure you proper sterility and stability of product. You don’t expect chemical instability due to packaging in ampoules. Most commonly, you often find glass ampoules for antibiotics packaging. |

| BFS bottle

|

Do you guess what packaging container provides you better sterility of formulation and keep the product contamination-free? Its blow-fill-seal bottles.

You often observe IV antibiotics come in BFS bottles that are mixed with vehicle to form liquid formulation. These are plastic containers that you find convenient to carry and use. Packaging process of packing antibiotics in BFS bottle is so secure that there are minimum chances of contamination in the product. |

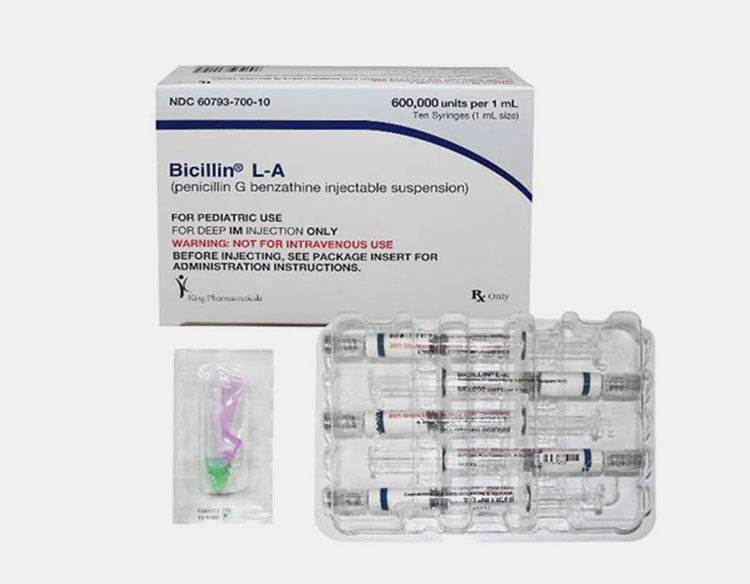

| Pre-filled syringes:

|

Do you know about such dispensing container which conveniently dispense single dose? Yes it is pre-filled syringes, which contains calculated dose of antibiotics.

This container offers the best way to administer sterile and accurate dose of antibiotics. You fill liquid formulation in pre-filled syringes and you don’t need to worry about its stability as you have to follow storage instructions to keep it stable. Do you know about its storage temperature? Pre filled syringes are stored at freezing temperature like -20C to keep them stable for long time. Refrigeration keeps formulation stable for few days. |

6.What are the chief steps of manufacturing of antibiotics?

Chief Steps Of Manufacturing Of Antibiotics-Picture Courtesy: Shutterstock

Have you ever wonder how antibiotics are made? This topic is crafted to increase your knowledge about manufacturing of antibiotics. Whole operation of manufacturing is carried out in aseptic conditions, and following the guidelines proposed by good manufacturing practices (GMP). Every step is narrated in a defined way to extend your interest.

| Chief steps of manufacturing of antibiotics | Information |

| Selection of strain: | You have learnt it before that there are different types of antibiotics made in pharmaceutical industry, have you thought about its source? Do they come from same source?

No it is not like that. First you need to decide which bacteria or fungi you need to source antibiotics from, as every antibiotic comes from distinct source. |

| Fermentation & extraction: | Initially you are required to perform the fermentation process to grow that bacteria or fungi and by which you gain antibiotic as secondary metabolite, is that not so interesting?

For fermentation process, you need three things; high-grade microbial strains, nutrients containing culture to grow the strain and fermentation tanks. These fermentation tanks are specialized equipment that maintains the temperature, pH, and nutrients during growth of microbial strain. You have to wait for three to seven days to complete the fermentation process. After the cultivation of microorganism, you perform the next step to extract the antibiotics. You obtain the broth when fermentation process gets over and you can use Centrifuges to separate cells of microbes from the broth. The portion that is in liquid form, you can find antibiotics over there; you can use different processes like solvent extraction, precipitation or adsorption to extract antibiotics. |

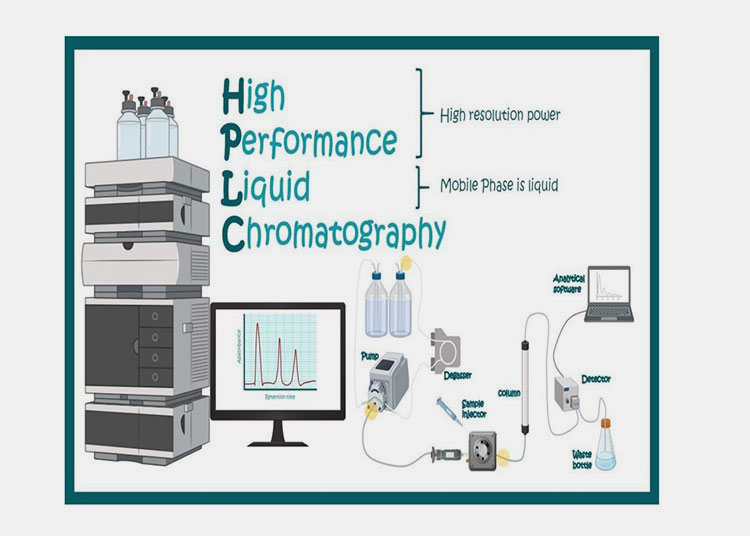

| Purification: | The antibiotic you get after fermentation process, does not meet the regulatory standards. You need antibiotic of high purity and sterility.

For this purpose you perform some methods to get pure form of antibiotics. This antibiotic will be used as active pharmaceutical ingredient to formulate the final product. Purification methods that can be used by you include crystallization, chromatography or filtration by the help of membrane. Crystallization is helpful as you get the purest form of antibiotic in crystallized form, chromatography is a fine method to get the high-grade antibiotic and filtration is carried out by passing antibiotic from membrane to retain endotoxins and unwanted particles. |

| Formulation of antibiotics: | The purest form of antibiotic you obtain is used to formulate the final product.

First you are required active pharmaceutical ingredient, vehicle, stabilizer or preservatives to formulate the antibiotics. Vehicle that is useful for you is sterile water for injection, which you source from water treatment system. Active pharmaceutical ingredient is mixed with sterile water by using a mixing vessel. After that you can add other ingredients. The mixing process will be continued until you obtain a well-mixed solution. This mixing tank has the ability to keep the suitable temperature during the process and stirrer is utilized for proper mixing. |

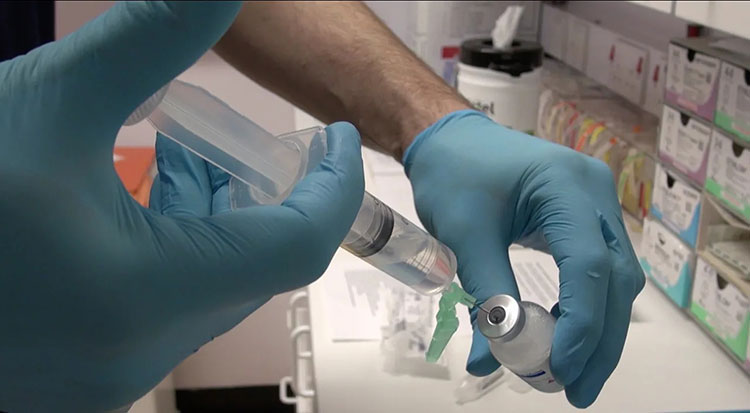

| Sterile filtration: | After the formulation is prepared, you need it to sterilize it for once in order to get rid of impurities or microorganisms. |

| Filling & sealing:

|

Do you know there are many types of filling & sealing machines that are used according to the dispensing container?

You can see that filling and sealing machines works on almost same principle and their goal is to fill and seal antibiotics in specific container with great accuracy. All of these machines are fully automated and capable of maintaining aseptic environment during operation. First you can observe that the packaging containers are washed and sterilized, then subjected to be filled by the help of filling nozzles. After filling, you put the container for sealing. Different containers have their own particular way of sealing like vials are sealed by putting rubber stoppers crimped with aluminum caps. Ampoules are sealed by using flame. Thin top neck of ampoule is melted through heat and gets air-tight seal. BFS bottle is sealed by the aid of heat or mechanical jaws. |

| Lyophilization: | Lyophilization is a common process performed in pharmaceutical production; do you know how does it perform?

Antibiotics that are delicate to store in liquid form, you have to change their form into powder to keep them stable during shelf life. Process of lyophilization is very simple, initially you froze the drug formulation and then apply pressure to remove water content from in int. this method provides you powder form antibiotic directly from frozen state. This powder form can be known as freeze dried powder. Lyophilizers are the part of manufacturing of antibiotics and vials are subjected to lyophiliozers after filling and sealing. |

| Sterilization: | You must be well informed about that the sterilization process is the key step for every formulation especially when you are administering the drug parenterally.

Antibiotics are subjected for final sterilization in autoclaves. |

| Quality control: | Final product of antibiotics is always checked for their quality.

You can assess the quality by performing different tests like potency test, sterility test, purity test etc. |

| Labeling & packaging: | The last step you have to carry out before marketing the final product is labeling and packaging.

You can firstly apply labels by using labeling machine. Labels must be applied with precision, wrong labels can put consumer in serious consequences. Packaging of dispensing container is counted as integral step to keep formulation stable and sterile during storage and distribution. You can utilize cartoning machine for this packaging of containers into appropriate sized boxes. |

7.Can you define equipment take part in manufacturing of antibiotics?

What comes in your mind when you think of equipment used in manufacturing of antibiotics? Equipment involves in manufacturing are very complex and highly maintained. They are compliant to regulatory standards to achieve a high quality product. Here we discuss the main machines that take part in production.

| Equipment | Picture |

| Fermentation tank:

You have understood that the process of manufacturing of antibiotics start with fermentation process, for which you must require fermentation tanks. This tank carries out the process of fermentation efficiently. You can observe that temperature, pH, and nutrients are remained in optimistic level to support the growth of microbes. |

|

| Centrifuge:

Do you know the purpose of centrifuge? This equipment uses centrifugal force to separate particles of a mixture. Liquid that contains antibiotic is made separated by the help of centrifuge. |

|

| High performance liquid chromatography (HPLC):

This equipment is utilized in pharmaceutical industry to purify the substance. Here in this process, you use this technique to purify the extracted antibiotics. |

|

| Water treatment system:

During whole process, you require sterile water. This water is made sterile by the help of water treatment system. This system ensures the purity of water. |

Aipak Water Treatment System |

| Mixing vessel:

All ingredients need to be mixed well, for mixing process, you use mixing tank that contains stirrer and temperature controlling system. |

|

| Sterile filters:

Filtration before filling is quite necessary to secure the sterility of formulation. You can use sterile filter that contains a membrane which retains impurities and microbes and allows only formulation. |

|

| Pre-filled syringe production line:

You find pre-filled syringe production line easy to function as it performs all steps automatically. You can observe that, the process starts when disposable syringes are loaded, then these are made unpacked and torn up to get filled with formulation. After filling syringes are plugged to make them secure and safe. |

Aipak Pre Filled Syringe Production Line |

| Vial filling machine for lyophilized powders:

Vial filling machine for lyophilized powders is designed for precise and aseptic filling and sealing of antibiotics in vials. You find this machine so convenient and efficient to use. This machine comprises of four important parts that are washing unit, sterilization unit, filling and stoppering unit and capping unit. |

Aipak Vial Filling Machine For Lyophilized Powder |

| Vial filling and sealing machine for liquid:

Vial filling machine for liquid machine is fully automated and well equipped machine, that is formed by incorporating four different machines that are Washing machine Sterilizing machine Filling and stoppering machine Capping machine

|

Aipak Vial Filling And Sealing Machine For Liquids |

| Lyophilizer:

Antibiotics that are produced in powder due to instability issues, you require lyophilizer for them. Liquid formulation of antibiotics changes into freeze dried powder form by using lyophilizer. |

|

| Ampoule filling machine:

Ampoule filling machine is fully automated and performs each step efficaciously to fill and seal the ampoules. You can see the machine is comprised of washing and sterilizing unit, filling station and sealing unit. |

Aipak Ampoule Filling And Sealing Machine |

| BFS bottle filling machine:

BFS bottle filling machine functions automatically and with great accuracy. You can see the process starts with formation of plastic bottle, which passes to sterilizing, filling and sealing units one by one. |

Aipak BFS Bottle Filling And Sealing Machine |

| Autoclave:

Autoclave is the convenient mean of sterilizing formulations in pharmaceutical industry. When you fill and seal the antibiotics in dispensing container, you can put the container in autoclave for final sterilization. This machine uses steam to sterilize the formulation and it comes with ability to protect heat-sensitive formulations from getting damaged. |

Aipak Autoclave |

| Labeling machine:

Labels are printed and applied by the help of labeling machine. You can see it utilizes adhesive technique to apply labels on vials. |

Aipak Labeling Machine |

| Cartoning machine:

Cartoning machine has the purpose of packaging final products of antibiotics into boxes. Some boxes have space for single product and some boxes have multiple compartments to package more than one product. |

Aipak Cartoning Machine |

8.How sterility is maintained during manufacturing of antibiotics?

Do you realize the importance of sterility during manufacturing of antibiotics? It is integral to maintain sterilized conditions and for that purpose you carry out some measures.

| Measures to maintain sterility | Image |

| Clean rooms:

You have to perform all functions in a clean room to avoid any contamination. Do you have idea what these clean rooms have? These clean rooms have temperature and humidity in optimized limit and air is unpolluted. Such conditions are maintained by the help of HVAC system. You perform every process by wearing a specialized costume to prevent contamination by human touch. |

|

| HVAC system:

This system is behind the controlled environment of clean room. You can find it working in different ways like, it makes air free from unwanted particles and microbes, maintains temperature and humidity and distributes the filtered air throughout the clean room. |

|

| Restricted access barrier system:

You often look at filling and sealing equipment and found this restricted access barrier system (RABS). This system helps you to prevent contamination during chief process of filling and sealing of antibiotics. |

|

| Clean in place (CIP) or sterilize in place (SIP)system:

You find this system very useful for cleaning or sterilizing any machine without moving it to other place. For example, you can sterilize fermentation tanks by the help of this system. |

|

9.What aspects are considerable in manufacturing of antibiotics?

You have got the better understanding about manufacturing of antibiotics, but have you ponder upon the important aspects that you must consider while producing antibiotics? This topic provides you awareness about those aspects that help you to carry out the operation efficiently by focusing on such aspects. Here is the list prepared for you.

Type of antibiotic:

Type Of Antibiotic

First thing that comes in your mind before stating the process of manufacturing is that which class of antibiotic you are going to make. So antibiotics can be natural, semi- synthetic or synthetic. For natural antibiotics, you can utilize the extracted antibiotic from microbes but for semi- synthetic or synthetic antibiotics, you must need to make alterations in it. These alterations can be made through chemical reactions or structural changes.

Choice of microbial strain:

Choice Of Microbial Strain-Picture Courtesy: Technology Networks

It is another important aspect you can consider in manufacturing of antibiotics. You can select microbial strain that has high-yielding ability and less chances of contamination.

Steps of manufacturing:

Steps Of Manufacturing-Picture Courtesy: CHEManager

You have learnt the steps involved in manufacturing of antibiotics, keep in mind that all steps must be performed with sequence and with efficiency too. You must never skip any step otherwise it affects the product sterility, stability and potency.

Sterility:

Sterility-Picture Courtesy: Meiji Pharma Spain

You are well aware of the importance of sterility in this process of manufacturing. Keep this in your mind that sterility of formulation, containers, and equipment have similar significance and must be maintained by using different means.

Quality of finalized product:

Quality Of Finalized Product

You always must be ensuring about the quality of finalized product and how can this happened? It is very convenient; you just have to carry out some tests that show you the quality standards of your product.

Compliance to regulatory standards:

Compliance To Regulatory Standards

Have you any idea about compliance to regulatory standards? If you want your manufacturing highly efficient and productive, you must make sure that each step must be performed according to good manufacturing practices (GMP) and every machine must functions according to mandatory standards.

10.What issues can be encountered during manufacturing of antibiotics? How they can be solved?

Issues & Their Solution Related To Manufacturing Of Antibiotics

Like any other process, manufacturing of antibiotics can also have some problems and you need to be aware about it. Knowing only about problems does not make any change, that’s the reason, this topic educates you about the solution of that issue that can be happened during antibiotics production.

| Issues encountered during manufacturing | Their solution |

| You may experience contamination by different means and this contamination can cause a huge loss. Contamination in formulation or container or equipment can be occurred. | You should strictly maintain the aseptic conditions; you must check all means that take part in keeping the sterility intact. |

| Sometimes you may not get the antibiotics in great amount because the strain you have used was not high-yielding. | You must check the quality of microbial strain before subjecting it to fermentation and secondly you must maintain the optimistic condition for best growth of microbes. |

| You may also face problem in functioning of different equipment that take part in manufacturing. This is due to many reasons like they are damaged or not lubricated properly of having problems in their electric system. | You need to inspect the equipment and calibrate in quickly. You must repair damages and lubricate if it is required. |

| You may see that the formulation is failing in potency and stability testing. Reason could be low quality active ingredients and excipients. | You must inspect about the quality of ingredients before using them for manufacturing. Always take ingredients from a reliable source and make their storage in optimum conditions. |

| You may observe that the guidelines of GMP are not followed correctly. | You must carry out the internal audit to ensure the strict implementation of rules and regulations. |

Conclusion:

Manufacturing of antibiotics shares an impactful role in wellbeing of society. This process demands high quality ingredients, aseptic conditions, implementation of good manufacturing practices, well equipped machines and well-trained staff to obtain a high quality product. If you are looking for well-defined content related to manufacturing of antibiotics, you will not be disappointed by visiting AIPAK ENGINEERING. For any queries, you can contact us anytime!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours