Lyophilizer Machine:What Do You Know?

The world is now experiencing a revolution in "freeze drying" technology. It can preserve extremely perishable materials by "freeze drying". This technological innovation incorporates the power of biology and life sciences. The invention of the lyophilizer can greatly help the storage of precious materials.

Whether it is the pharmaceutical, biotechnology or food industry, lyophilizer machine have a wide range of applications. Being able to choose the right type can greatly improve efficiency and reduce costs. Through this post, let's take a brief look at the lyophilizer machine introduction!

1.What Is Lyophilizer Machine?

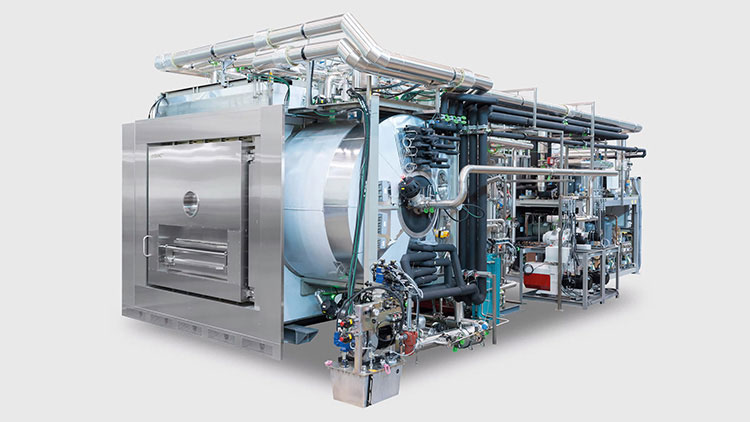

Lyophilizer Machine-sourced: gea

Lyophilizer machine, also called as lyophilizer or freeze dryer. It is a kind of equipment that is specially used to freeze-dry various perishable materials to prolong the shelf life of the materials. The freeze-dried materials are easy to package and store, and convenient for later transportation. This equipment and technology are increasingly widely used in various industries, especially in the pharmaceutical, cosmetic and food industries.

2.How Does Lyophilizer Machine Work?

Working Process of Lyophilizer Machine-sourced: bionetwork

The core technology of lyophilizer machine is dehydration and then drying. By removing the water from the materials, they are more stable and durable in later storage. Its core steps are to freeze the materials, then reduce the pressure around them, and finally heat them to make the frozen water sublime directly from solid to gas. It directly skips the liquid step. By avoiding the liquefaction process, the integrity and activity of the product are lost.

3.What Are The Three Main Stages For LyophilizerMachine?

The work of lyophilizer machine is mainly divided into three stages:

Freezing stage

Freezing stage-sourced: sproutliving

First, you need to put the freeze-dried material into lyophilizer machine or freezing tank. It can quickly freeze the product through rapid low-temperature technology. This step can well ensure the physical form and structure of the product. It allows them to continue to maintain a good shape and bright color. If this step is too slow, ice crystals will form on the surface of the product. This ice crystal is not conducive to the subsequent solid sublimation. Therefore, in the freezing stage, the material needs to be rapidly frozen in a shorter time.

Primary drying

Primary drying-sourced: trailcooking

Primary drying is mainly to reduce the pressure around the product and heat it to sublimate the water. This part avoids the failure of freeze drying due to liquefaction of the water in the material. The freeze dryer is equipped with a condenser. It can provide a surface for water vapor to adhere to, so that the vacuum pump is not affected by water vapor. At this stage, 95% of the water in the material will be directly sublimated. However, the temperature and pressure must be controlled in this part. Too high a temperature will cause the structure of the material to change.

Secondary drying

Secondary drying-sourced: healthline

Secondary drying is the last step of freeze drying. By raising the temperature above the primary drying stage, the moisture in the material is directly sublimated. This step does not destroy the surface structure and physical properties of the material. It can largely retain the shape and color of the material. Most freeze dryers can control the moisture content of the material to about 1%~5%.

4.What Are The Problems You Need To Avoid When Using A Lyophilizer Machine?

Problems You Need To Avoid When Using A Lyophilizer Machine-sourced: zonesun

When using the lyophilizer machine, you need to pay attention to the following:

| Improper temperature control | Too high a temperature will cause the material to liquefy directly, thus destroying the surface structure of the material, resulting in no shape or loss of color. |

| Too much water vapor | If there is too much water vapor, it will cause the condenser to fail or overload. And if there is too much water vapor, the contact surface area of the material surface will be too large, so the integrity of the material cannot be preserved. |

| Insufficient refrigeration | If there is insufficient refrigeration, the surface structure or moisture of the material cannot be completely dried, so there is no way to proceed to the next step of drying, resulting in the failure of freeze-drying the product. |

5.What Are The Important Lyophilizer Machine Terms?

Here are some important terms related to freeze dryers, including:

| Eutectic point or eutectic temperature

Eutectic point or eutectic temperature-sourced: pharm-int |

Eutectic point refers to a crystallization point in the solid state of a product. It also represents the low melting temperature of the product. Not all products will have a eutectic point when freeze-dried, and not all products have no eutectic point. Some products may have multiple eutectic points. |

| Critical temperature | Critical temperature refers to the temperature at which the product quality decreases due to remelting or collapse. If this temperature is exceeded, the quality and stability of the product cannot be guaranteed, so the temperature should be set below the critical temperature during the freeze-drying process. |

| Crystalline

Crystalline-sourced: americanlaboratory |

Crystalline refers to the crystallization caused by the rapid freeze-drying of the surface and internal moisture of the product after freeze-drying. This crystallization is a normal phenomenon. |

| Amorphous

Amorphous-sourced: leinco |

Amorphous means that some materials or mixtures do not crystallize or have no eutectic point. Such materials are not suitable for freeze-drying. |

| Collapse

Collapse-sourced: samsungbiologics |

Collapse means that the product cannot be freeze-dried and is not easy to form. Whether it is dried once or twice, there is no way to stabilize its shape or stabilize its physical form. |

Conclusion:

Today's freeze dryers are becoming more and more advanced. In addition to being used in a wider range of products and industries, they can provide you with higher efficiency, optimal humidity, temperature and pressure control. Finally, they can provide you with the best freeze-dried product quality. If there are more you want to know, contact AIPAK ENGINEERING now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours