Liquid Grape Seed Extract Manufacturing: The Complete FAQ Guide In 2025

How do you get nature’s gift of liquid grape seed in a bottle? That’s possible with liquid grape seed extract manufacturing! Nevertheless, grapes are everyone's favorite with delicious taste and a bunch of benefits. Also, liquid grape seed extract manufacturing happens every year and gives large quantities of products and supplies worldwide.

This FAQ guide is all about liquid grape seed extract manufacturing. After reading the blog, you will be able to distinguish between the right selection of machines ideal for your production workflow. Moreover, we will be discussing manufacturing principles, ingredients, troubleshooting and so much more. So, guys, let's join us!

1.What is liquid grape seed extract?

Liquid Grape Seed Extract – Picture Courtesy: SULU Organic

The liquid grape seed extract which has the Latin name Vitis vinifera helps in the making of wine. The purpose of extracting is to obtain the beneficial properties of grape seed which is challenging to eat as a raw form. It has a weird taste, and you cannot consume it in a large or desirable quantity to get good beneficial effects.

That is why research and trial studies have found the manufacturing solution of liquid grape seed extract to give the final product. Therefore, this is a popular health treasure that provides a supplement with multiple positive effects.

2.What is liquid grape seed extract manufacturing?

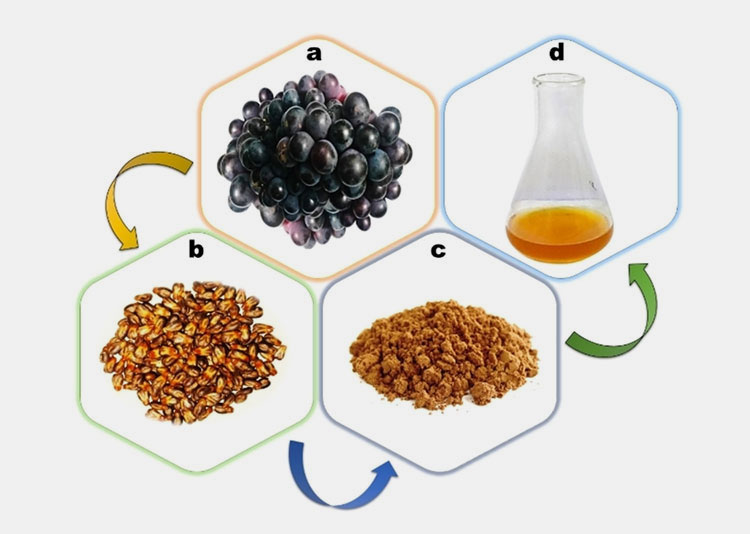

Liquid Grape Seed Extract Manufacturing – Picture Courtesy: ALVINESA

Liquid grape seed extract manufacturing is the method of extracting a pure, accurate, and ideal quantity of grape seed elements with the help of involved stages including harvesting till its final packaging which makes it easier for you to grab prepared product from the shelves of markets.

This entire series of methods is not associated with simple principles rather it is composed of various steps and several sets of production lines. Consequently, the manufactured formulation is promising enough to offer you therapeutic effects.

3.Why is liquid grape seed extract manufacturing required?

There are so many reasons behind liquid grape seed extract manufacturing:

Therapeutic Benefits

Therapeutic benefits

This is a health treasure in a bottle that is enriched with antioxidants; which means 80% of disease states as well as prophylactic actions can be taken from it. Therefore, liquid grape seed extract manufacturing is an absolute solution that offers a complete package without any hassle.

Accurate Dosage

Accurate dose

You can’t make your exact doses yourself, nor any domestic source. However, liquid grape seed extract manufacturing is an essential pathway that offers solution with active constituents with the right number of elements. The mentioned dose and your requirement are mentioned in the packaging as well as your prescriber's advice to enjoy the functional properties of the liquid grape seed extracts.

Diverse Applications

Broad application

Liquid grape seed extract manufacturing is required to produce versatile formulations. Whether it is topical application, oral administration, or required for food and beverage, just unpack the product and use it easily.

Large production in no time

Large production in no time

Just imagine, you are cultivating, harvesting, cleaning, and so many steps all alone to get the liquid grape seed extract. Of course, this is not possible in anyone’s wildest dream. Liquid grape seed extract manufacturing is a highly specialized process that gives you large concentrations of product in a shorter time with more reliability. The process offers you a consistent outcome that is suitable for meeting the consumer’s demand.

The affordable mean of Formulation

Affordable and pure- Picture courtesy: Native Seed

The comparison analysis of liquid grape seed extract manufacturing with another mode of preparation can cause you lesser expenditure. The series of extraction procedures finally gives you a large yield in a cost-effective way and more and more consumer trust in your brand.

Potent and Effective Shelf Life

Highly potent

The liquid grape seed extract manufacturing process aims to produce a formulation with consistent potency and efficacy for a longer short period of time. This is possible when it is prepared in a stringent work environment and protocol. Thus, your product is effectively potent till the timeline claimed by the manufacturer.

4.What are the industrial applications of liquid grape seed extract manufacturing?

Liquid grape seed extract manufacturing is broadly applied in the production sector of various industries. For example:

Applications

| Pharmaceutical Industry

|

The pharmaceutical and medicinal industry gives heavy revenue per year as it fulfills medicinal needs every year.

Liquid grape seed extract manufacturing is required as almost a major portion of medicines works by inhibiting anti-inflammatory mediators. For example: heart problems, painkillers, various other diseases such as arthritis, itches, allergies, and so on are treated with drugs that are enriched with proanthocyanidins which is an active substance of liquid grape seed extract. |

| Cosmetic Industry

|

A fast-growing industry with a high business profit requires liquid grapes seed extract manufacturing to formulate a cosmetic and skin-related product that mainly soothes the topical layer.

There are various products such as lotions, serums, hair-related formulations, perfumeries, creams, foundation, sun protection, etc require liquid grape seed to improve anti-inflammatory, anti-aging, soothing, calming, and antioxidant properties. |

| Food Industry

|

In the food industry, liquid grape seed extract manufacturing is needed for the production of edible oils, drinks, sauces, and condiments, to enhance the formulation efficacy and taste.

Moreover, in the preparation of confectioneries items such as cakes, pastries, candies, gummies, etc, also made up with the incorporation of liquid grape seed extracts for various purposes. |

| Nutraceutical Industry

|

The nutraceutical industry has had a great influence on everyone’s life due to providing beneficial effects in the form of supplements.

Liquid grape seed extract manufacturing has mainly occurred in this area to either be used individually or with a combination of various dietary supplements like vitamins, proteins, solid dosage, liquid dosage, powder formulation, etc. Such medications are already available as over the counter and offer little to no side effects. |

| Fabric Dye Industry

|

Liquid grape seed extract manufacturing also takes place in fabric dyes as a functional finishing entity. They are mainly used as an essential compound for lining shirts including night wares and bed sheets.

The following constituents offer dying as well as anti-bacterial properties making the fabric more comfortable and physiologically friendly. |

| Biotechnology and Research

|

This is a major field where it was assessed and suggested with various benefits of liquid grape seed extract.

Because, here testing, analysis studies, and trials are conducted on the sample and entail the specific benefits and side effects of the constituents. It is involved with in vitro and in vivo studies etc during research activities. |

| Chemical Industry | The primary composition of grape seed extract has proanthocyanidins, flavonoids, tannins, etc.

Liquid grape seed extract manufacturing is required in the chemical industry for the manufacturing of various synthetic chemicals involved in invitro studies as well as for the formulation of antioxidants, preservatives, buffer formulation, etc. |

| Agriculture Industry | Liquid grape seed extract manufacturing is an important production sector of agriculture-related products such as pesticides, herbicides, plant supplements, etc. thus, giving improved crops and cultivations. |

5.What are the ingredients of liquid grape seed extract manufacturing?

In the process of liquid grape seed extract manufacturing, the required ingredients are not too much. You can simply incorporate a few sets of things to start the process. Check it below:

Grape Seeds

Ingredients of liquid grape seed extract- Picture courtesy: Poultry world

Indeed, the process begins with the primary ingredient which is grape seed. They must be cleaned and dried to ensure the process is pure without any dirt or unwanted particles as it has to be consumed by you. Therefore, manufacturers deem for super hygienic practices.

Solvents

Solvents

Any extraction process for pharmaceuticals or related products needs solvents. The purpose of using them is to draw possible valuable constituents embedded inside the seed. In this matter, you will be requiring purified water, or in combination with any organic solvent. However, the direct involvement of solvents included soaking and relevant methods.

Ethanol, methanol, isopropanol, vegetable solvents such as glycerine, etc are the significant substances required in the extraction and associated process.

Preservatives & Stabilizing Agent

Preservatives & Stabilizing Agent

The liquid grape seed extract manufacturing final product is intricate and obtained from complex procedures. Therefore, you must be curious about its stability and long shelf life. For this reason, many manufacturers opt for adding preservatives to maintain the stability of the formulation. For example, potassium sorbate, benzoic acids, phenols, antioxidants, etc.

Flavoring Agent

Flavoring agent

We all know that grapes taste sweet and good but not their seeds. Therefore, to improve taste and consumer compliance, flavoring agents are used to make it acceptable and make you feel good. The commonly used flavor in this case is of course grapes, or any citrus fruits.

6.How does liquid grape seed extract manufacturing take place?

The liquid grape seed extract manufacturing process takes place in the following major steps. For example:

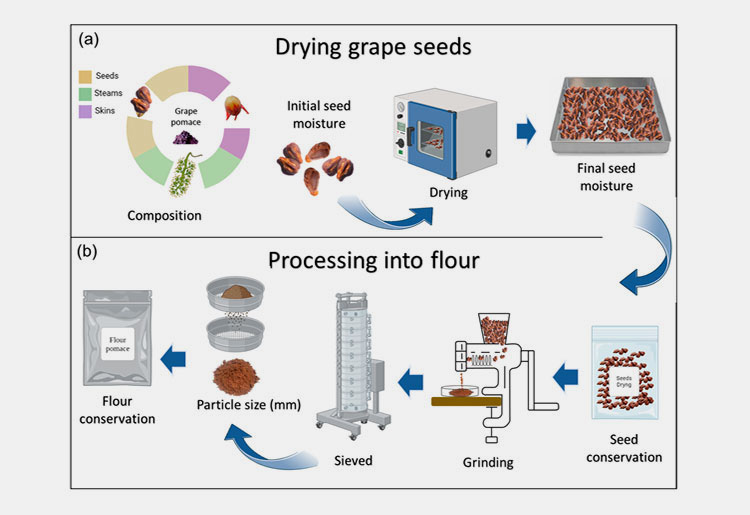

Step 1: Drying & Grinding of Grape Seeds

Drying & Grinding of Grape Seeds

You can’t skip drying and grinding of grape seed whenever opt for the extraction process. There are some steps associated with this method.

Drying

Drying

The washed and cleaned grape seeds are provided with drying time under the optimized temperature of 40 to 50 °C to evaporate the moisture content and keep the therapeutic activity stable by preserving antioxidant constituents. Now, the seeds are stored at room temperature for further dehydration. You can conserve the seeds in vacuum-sealed bags for further processes.

Grinding & Sieving

Grinding and Sieving

This is well sure if the particle size is lesser, more will be chances of obtaining valuable yield. The recommended size of particles is from 0.75 to 0.41 mm for oil extraction. In this matter, a milling machine is used for the safe grinding of the seeds. The next step is to sift the material to get the desirable size of particles with proper uniformity.

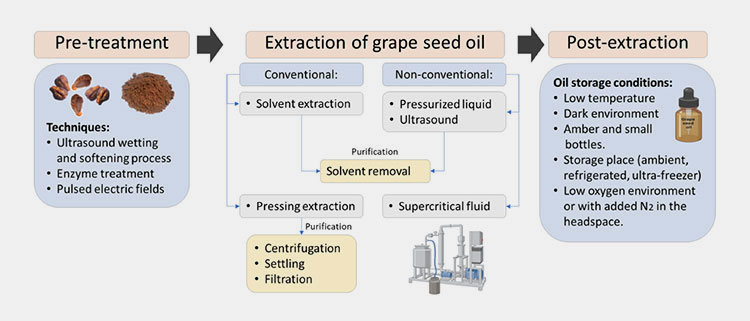

STEP 2: Pre-treatment of Liquid Grape Seed

Grape Seed Oil Extraction Process- Picture courtesy: Researchgate

To get a high yield of valuable constituents; the pre-treatment of grape seeds is done. This can be simply depicted as you soak rice for a few minutes before cooking. In the same way, industrial manufacturing of liquid grape seed must be passed through pre-treatment therefore components like phenols, flavonoids, resveratrol, etc can be extracted as much as possible. The steps involved are as:

| Ultrasound wetting & softening process

|

In this method, grape seeds are subjected to an ultrasonic bath in an immersed polyethylene pack at the temperature of 30 °C for half an hour. Therefore, it catalyzes the generation of α-tocopherol in a large quantity. |

| Enzyme treatment

|

To get a good concentration of oils, the enzymatic treatment is done where enzymes such as protease, hemicellulose, and related are used to improve the getting up of oils and greater antioxidant constituents. |

| Pulse Electric Field

|

This is a modern technique where high-pressure electric impulses are spread inside the grape seed cell membrane for the extraction of internal components. This is done by the formation of temporary pores known as electroporation. The fast-acting process gives more yield in a lesser time. As compared to a conventional method, this is the modern and advanced method with high outcomes. |

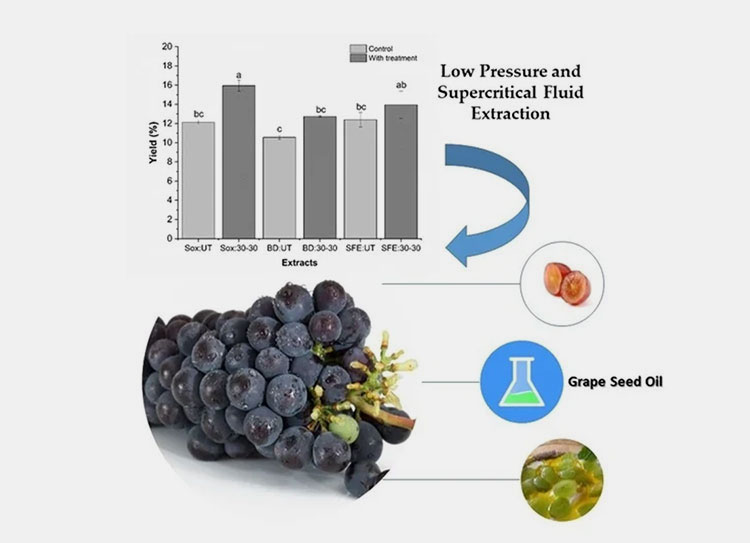

STEP 3: Liquid Grape Seed Extraction Process

Extraction process

This is the major method of obtaining the right concentration of extract present in grape seeds as a whole. It can occur either by directly pressing the seeds or from seeds flour.

Conventionally, it was obtained using pressing and solvent extraction methods but with the advent of modern techniques, the principle of extraction has changed toward more advanced methods. We have described the extraction process method just right below:

Conventional Liquid Grape Seed Extraction Process

This is the oldest method with a lot of benefits. However, when it comes to drawing out the components of the grape seed.

Pressing Extraction

Pressing Extraction- Picture courtesy: Celignis

These methods are mainly used to extract oil from the grape seed flour. The conventional methods included as:

| Screw Press

|

The screw press technique is used for oil extraction where the design of the screw is meant to induce friction and pressure to squeeze the grape seeds upon rotation. The method gives a low concentration of extract, but it is known for its high reliability which is why preferred and still used. |

| Hydraulic Piston Press

|

This technique is involved with crushing or milling of the seed by utilizing the hydraulic piston under the influence of high pressure and mild heat. The combination of factors allows oil to come out of the seeds or from the flour. |

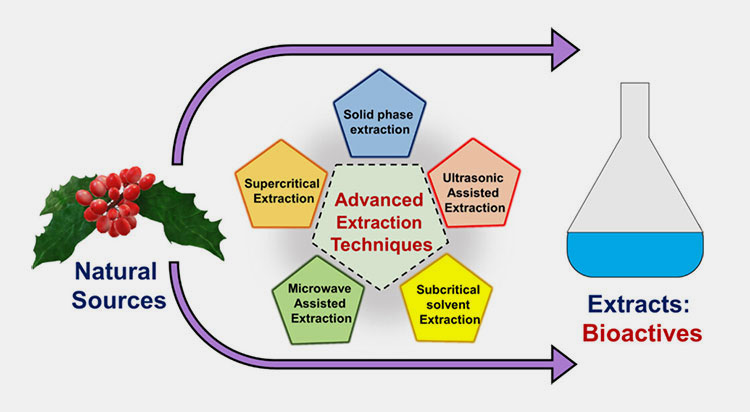

Advanced Liquid Grape Seed Extraction Process

Advanced technique- Picture courtesy: ACS Publication

This is the modern technique involved with the below-mentioned methods.

Solvent Extraction

Solvent extraction

This is an affordable method with a higher popularity than other extracting ways. The working is mainly based on greater contact of grape seed with solvents, so it helps in the drawing out of components easily. However, due to the involvement of organic solvents, the purification and remaining process can be expensive. The main solvent used in this process is ethanol as it is best known for being safe and can be used for food-related products than other solvents.

| Ultrasound-Assisted Extraction Method

|

This is a quick and effective method that is based on the cavitation that breaks the bubbles of food matric and degrades the cell membrane thus ensuring fast extraction of compounds by using organic solvents. |

| Pressured Liquid Extraction Method

|

In this method, the utilization of solvents with various temperatures and pressures is employed to enhance the process of extraction. This method is considered as effective than pressing or solvent extraction as liquids do not tend to be involved with components thus offering a considerably safe and fast way for extracting vitamin E from grape seed. |

| Supercritical Fluid Extraction Method

|

The process involves subjecting solid material to supercritical fluid till you get the desirable extract. In this method, carbon dioxide is used as it is economical and allows easy elimination with no side effects. The following process is mainly used to get high antioxidant components under-maintained parameters such as 400 bar pressure and 41 °C. |

STEP 3: Post Extraction

Post Extraction- Picture courtesy: ResearchGate

To preserve the advantageous elements of liquid grape seed extract, the manufacturing process is further involved with post-extraction. For example,

Purification

Purification

To prevent the inclusion of unwanted particles or materials and provide safe products. The following post-treatment steps are carried out.

Centrifugation

This process is used in small and large manufacturing sectors to separate the layer of juice and seed particles with the help of intense centrifugal force which is a thousand times more than gravitational force. The end results of centrifugation help in the elimination of solid unwanted sediments and allow the taking of clarified liquid grape seed extracts.

Filtration

The final prepared batch of liquid grape seed extract is now subjected to the last step of manufacturing which is filtration. The ultrafiltration technique is used to obtain purified extract for commercial packaging.

Filling & Packaging

The final process is involved with two basic methods:

Filling

Filling

Once the liquid formulation is ready, the accurate volume is filled using amber colors packaging material. The purpose of using these colors is to prevent the formulation from degrading from light and other factors. The airtight sealing is also done to keep the product away from air and moisture. The filling machines are used for fast and desirable filling needs.

Labeling

Labeling- Picture courtesy: BRM Chemical

The prepared packaging material is now subject to a labeling machine to apply the label with desirable information related to the product, uses, and marketing formalities.

7.What are the possible machines used in liquid grape seed extract manufacturing?

The number of machines used in the process of liquid grape extract manufacturing is quite extensive than their ingredients. This is because each step has to be carried out with promising outcomes and a good final objective.

Vibratory Sifter

AIPAK Vibratory Sifter

The grape seeds as a raw form may contain debris, dust, ruptured skin, etc. Therefore, cleaning is done and for this purpose, a vibratory sifter is used. The machine works by continuous shaking of the designed sieving trays. By this, you can get particular and desirable materials by eliminating unwanted dirt and materials that can impact negatively.

Grinding or Milling Machine

AIPAK Pulverizing Machine

Grinding and milling machines are mandatory installation options for crushing and reducing the sizes of grape seed thus facilitating an easy and fast extraction process of liquid. The purpose of these machines is to increase the surface area and to get more and more active ingredients in further processing without damaging them. In this matter, pulverizer machines, and milling machines like hammer mills, and pin and ball mills can be used.

Extraction Machine

AIPAK HB121-50-02 Supercritical CO2 Extraction Machine

The machine is useful in the isolation and purification of active and useful constituents present in the grape seed. The process takes place by simple methods, but types of machinery operating skills and knowledge must be sufficient enough to bring excellent results. The commonly used extraction machines in this matter involved solvent extraction units, supercritical CO2 units, ultrasonic extraction machines, and others.

Centrifugation Machine

Centrifugation Machine- Picture Courtesy: Cence Centrifuge

For more purity and to avoid unwanted solid particles present in the extract, the centrifugation machine is used. In this machine, you can load the sample and allow high acceleration of centrifugation force that mainly works by following 1000 to 5000 revolutions per minute or more. Therefore, the solid particle gets settled in the bottom and you can easily use the upper cleared layer of required extract.

Mixing Machine

AIPAK Mixing Machine

Once you get the desired concentration of extract, you will need a mixing machine. The required machine helps in the blending of liquid grape seed extract with other ingredients such as water, preservatives, flavoring agents, or sweetening agents. In this case, there are several machines available to do this task effectively. For example, a high-shear mixer, an emulsifying mixer, etc.

Liquid Grape Seed Extract Filling Line

AIPAK ENGINEERING liquid grape seed extract filling line

Once you’re done with the complete formulation of liquid grape seed extract, the next step is to fill and pack the product. This is mainly done with liquid grape seed extract filling line in a safe and effective manner.

It is composed of a set of units which helps in bringing the process in no time and without so many technicians. The arrangement includes a bottle washing machine, where a fast and intense shower of water strikes every corner of the bottle or packaging material to wash the bottle.

The unscrambler machine is the next unit that aligns the random bottles and sends them to the sterilization tunnel. Here, hot air leads to dry and sterile the bottle.

The filling machine is integrated which accurately fills the bottle with the help of piston nozzles. The unit identifies the presence of the bottle and then allows the proper dispensing of the extract.

The bottles or packaging material is secured by screwing of caps. For this purpose, a capping machine is used. Several grippers pick up the cap and twist around the neck of the bottle to create an airtight seal.

Labeling Machine

AIPAK Labeling Machine

To convey the right information and handling of products, labeling is required and is done by a labeling machine. The machine is also integrated with the production line thus bringing the entire manufacturing process in alignment without interrupting the workflow. The label is adjusted manually but the remaining process is mostly done automatically based on sensors and applicators.

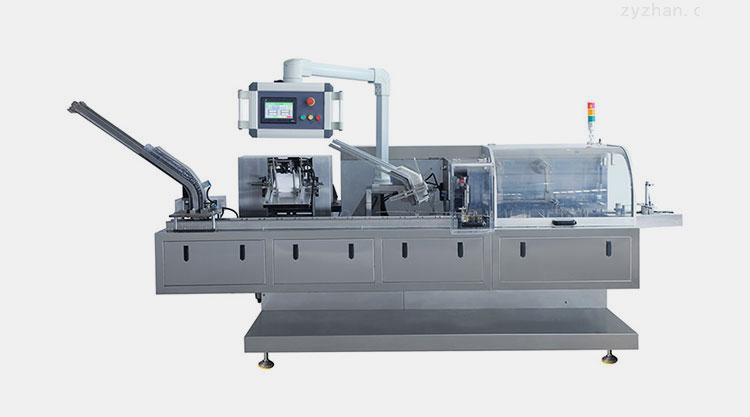

Cartoning Machine

AIPAK Cartoning Machine

The final packaging is done by using a cartoning machine that helps in the securing product and ensuring the tamper-evident feature of your product. The machine helps in the folding and sealing of the carton with the automatic placement of liquid grape seed extract bottles inside. Thus, all involved machines are discussed with their significant responsibility.

8.What are the packaging materials required for liquid grape seed extract manufacturing?

Liquid grape seed extract manufacturing product packaging can take place in versatile types. For example:

Vials

Vials

This is a mainly used and popular option of storage. Vials are capable of accumulating a specified portion of extract and with the help of a dropper, you can pick the liquid grape seed extract as suggested by your prescriber or physician. They’re mainly used in pharma, food, and cosmetics formulations.

Bottles

Bottles

Small, average, and large-size bottles are used for the storage and packaging of the liquid grape seed extract. They can be either glass material or plastic, with various options such as amber colored mainly. The purpose of this is to preserve the properties and protect the antioxidant constituents.

Drums and Gallons

Drums and Gallons

For distribution, commercial applications, and research purposes, the liquid grape seed extract is mainly filled and stored in large containers such as drums and gallons. The material storage is capable of storing hundreds to thousands of liters of liquid grape seed extracts.

Conclusion

After reading the blog on liquid grape seed extract manufacturing, you will be pretty sure about the series of mandatory steps involved and the types of machinery. Indeed, good quality and materials of the equipment with advanced features meant a lot for good manufacturing. This will ultimately boost our business as you can generate more capacity and excellent formulation. If you’re planning to start a new business, AIPAK ENGINEERING is a friendly and expert center in offers innovative & affordable machines used in the process. Don’t hesitate to contact us for queries and equipment information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours