Large Volume Parenterals (LVP): The Complete FAQ Guide In 2025

Did you know that large volume parenterals (LVP) are the keystone of modern intravenous therapy? If it is not convenient to administer oral medications, then large volume parenterals (LVP) are utilized.

These therapies are important for patients undergoing surgery, suffering from burns or having fluid imbalance. However, the use of large volume parenterals (LVP) is not limited to the above-mentioned applications.

Picture Courtesy: Healthy Women

Large volume parenterals (LVP) are prepared under strict and rigorous quality control steps. The field of large volume parenterals (LVP) is continuously evolving with a focus on preventing contamination and providing enhanced safety.

In this FAQ blog, we will discuss what makes large volume parenterals (LVP) an innovative procedure. Let’s start.

1.What is Large Volume Parenterals (LVP)?

Large Volume Parenterals (LVP)- Picture Courtesy: Rusoma

Large volume parenterals (LVP) is an effective therapy that is used for replenishing fluids and providing electrolytes, and nutrients. It is used for infusion therapy and comes in containers that are larger than 100 ml. These containers are sterilized by heating or other methods.

These large volume parenterals (LVP) have a volume of about 100 to 1000 ml. Their routes of delivering drugs may be intravenous, intraperitoneal, or subcutaneous. These are used to administer large quantities of drug medications to the blood system and other specialized tissues of the patient through infusion.

These large volume parenterals (LVP) are popular for their sterility, the efficacy of treatment, and, contamination-free delivery.

2.What is the History of Large Volume Parenterals (LVP)?

History of Large Volume Parenterals (LVP)- Picture Courtesy: oldfoolrn

The history of the development of large parenterals (LVP) goes hand in hand with the progress of parenteral administration. In the 17th century, Sir Christopher Wren and other scientists attempted to inject saline and other solutions into the blood circulation of animals. In the 19th century, Louis Pasteur and Joseph Lister improved sterilization techniques for the safe administration of IV solutions.

In the 1930s and 1940s, glass bottles were invented to contain large volume parenterals (LVPs). In the 1950-the 60s, Baxter Company revolutionized the field of large volume parenterals (LVP) by introducing plastic bags for containing large volume parenterals (LVP). This ensures a safe and practical way to store large volume parenterals (LVP).

3.What is the Significance of Large Volume Parenterals (LVP)?

There are countless benefits of the large volume parenterals (LVP) in the hospital and health care settings. They serve the important therapeutic field of medical science. Some of the significant benefits of this modern therapy are discussed below:

Effective Therapy

Effective Therapy- Picture Courtesy: China Sinopharm International (Shanghai)

Large volume parenterals (LVP) are directly injected into the blood circulation system, hence, it goes to the direct target area without liver metabolism This increases the effectiveness and efficacy of therapy, and has complete bioavailability.

Rapid Onset of Action

Large Volume Parenterals (LVP) and Rapid Onset of Action- Picture Courtesy: Iven-pharma

It is used in emergencies to revitalize body functions. It provides an immediate onset of drug action. The patients do not have to wait for long hours for therapy to provide relief.

No Irritation

No Irritation by Large Volume Parenterals (LVP)- Picture Courtesy: Micoope

Because this therapy is injected into the bloodstream and does not pass through the stomach and other digestive areas. This does not irritate the stomach and causes adverse reactions like diarrhea, nausea, and constipation.

Patient Compliance

Patient Compliance by Large Volume Parenterals (LVP)- Picture Courtesy: Forbes

Large volume parenterals (LVP) have patient compliance because it does not have irritating aftertaste and swallowing issues. It saves the patient from taking medications again and again. Thus, this therapy is generally accepted by the patients. Sometimes, patients suffer from stomach problems and cannot ingest medication by mouth. Therefore, large volume parenterals (LVP) are an effective means to restore health.

No Pyrogens

No Pyrogens in Large Volume Parenterals (LVP)- Picture Courtesy: Nasco Healthcare

Large volume parenterals (LVP) are regarded as a safe therapy because they are sterilized using different methods to remove microbes and pyrogens. Thus, it does not cause infection in the body and this treatment does not cause discomfort in patients.

4.What are the Uses of Large Volume Parenterals (LVP)?

If the oral administration is impractical large volume parenterals (LVP) are used for delivering different types of medication, electrolytes and nutrition. These are used in different medical situations such as:

Fluid Replacement

Fluid Replacement- Picture Courtesy: immunehealthcare.com

One of the major uses of large volume parenterals (LVP) is fluid replacement. This therapy is used for rehydrating the body when diarrhea, vomiting or high vomiting causes severe loss of electrolytes and water. Different solutions like electrolyte solutions like Ringer solution and saline aid in regulating blood pressure, sustaining organ function, and reinstating fluid balance.

Rectification of Electrolyte Disproportion

Rectification of Electrolyte Disproportion- Picture Courtesy: Niwa Aesthetics Wellness

Large volume parenterals (LVP) are also used in rectifying the electrolyte imbalance. This can happen due to different diseases like renal and metabolic disease and also in case of long periods of vomiting and diarrhea. These electrolyte imbalances are cured by administrating different solutions having potassium, calcium, magnesium, and bicarbonate to stabilize body functions.

Delivering of Medication

Delivering Medications- Picture Courtesy: The Telegraph

Large volume parenterals (LVP) are also used for dispensing drug therapies that are not ingested orally and require immediate drug actions. These include antibiotics, chemotherapy, and, anesthesia. These large volume parenterals (LVP) ensure that medication is delivered to the target area quickly.

Total Parenteral Nutrition

Total Parenteral Nutrition- Picture Courtesy: New Me Clinic

In some cases, individuals cannot ingest food or absorb nutrition via the digestive tract, so in these occurrences, total parenteral nutrition is delivered via large volume parenterals (LVP). To customize patient requirements of nutrition, different amino acids, lipids, carbohydrates, vitamins, and minerals are administered by the large volume parenterals (LVP).

Pain Treatment

Pain Treatment- Picture Courtesy: Health

Large volume parenterals (LVP) are also effective in treating acute or chronic pain. This is because analgesics or pain relievers are dispensed using large volume parenrtals (LVP). It is used after surgeries, and in the palliative care settings.

Volume Resuscitation

Volume Resuscitation- Picture Courtesy: IV Fluids - Parenteral Solutions

Large volume parenterals (LVP) are also effective in blood volume expansion by administrating artificial plasma or albumin to treat and stabilize blood pressure in trauma situations and during surgery.

Dialysis

Large volume Parenterals (LVP) Dialysis- Picture Courtesy: American Red Cross

Yes, large volume parenterals (LVP) are also used during dialysis treatment like in hemodialysis to aid in the elimination of toxic, waste and byproducts from the bloodstream of the patients. By administrating large volume parenterals (LVP), renal insufficiency is treated.

Maintains Diastolic Arrest

Maintains Diastolic Arrest- Picture Courtesy: Fresno Bee

Large volume parenterals (LVP) are also used during heart surgery operations to avoid injuring the protective layer of the heart. It upholds diastolic arrests and decreases reperfusion.

Countering Acidosis

Countering Acidosis- Picture Courtesy: Jefferson City News Tribune

These large volume parenterals (LVP) containing bicarbonates are used for treating severe acidosis. These bicarbonate solutions counter and neutralize the acidity and reinstate the pH balance.

5.What are the Types of Large Volume Parenterals (LVP)?

Large volume parenterals (LVP) are categorized based on their usage, composition, and different disorders they treat in hospital settings. The main types of large volume parenterals (LVP) are written below:

Crystalloids

Crystalloids- Picture Courtesy: Faces Consent

These are the solutions containing different salts as well as water-soluble compounds. Examples of these include normal saline and lactated Ringer solutions that contain different concentrations of sodium chloride, potassium chloride, and lactate. These large volume parenterals (LVP) solutions are either used as a vehicle for delivering medications, treating electrolyte imbalance or also for fluid replacement.

Colloids

Colloids- Picture Courtesy: Groupon

These are the aqueous solutions having large insoluble molecules like albumin and gelatins. These increase osmotic pressure and blood volume by serving as plasma expanders.

Lipid Emulsion

Lipid Emulsion- Picture Courtesy: medzell

These are oily formulations containing different fatty acids. These are used for treating metabolic disorders in which the body cannot absorb fatty acids through diet. Lipid emulsions are also delivered with other nutrients like amino acids and glucose.

Electrolyte Solution

Electrolyte Solution- Picture Courtesy: cobetter

These are the aqueous solutions containing different minerals like potassium, magnesium, and calcium. These are essential in treating electrolyte imbalances in patients, who have high sodium in the blood circulation or low levels of potassium in the bloodstream.

Buffer Solution

Buffer Solution- Picture Courtesy: AntiTeck

These are the solutions used for rectifying disproportions of acids and bases in the patients. An example of a buffer is sodium bicarbonate, used for curing severe acidity in patients.

Dialysis Solutions

Dialysis Solution- Picture Courtesy: WFYI

These are the fluids that remove toxic materials from the bodies of patients suffering from renal failure or renal insufficiency. These are designed to imitate the osmolarity of the blood.

Chemotherapy Solutions

Chemotherapy Solution- Picture Courtesy: www.kapsamsaglik.com.tr

These large volume parenterals (LVP) solutions are also used as a vehicle for dispensing and administrating different formulations of chemotherapy to cancer patients because of their safety and effectiveness.

6.What are the Solvents in Large Volume Parenterals (LVP)?

Solvents in Large Volume Parenterals- Picture Courtesy: NeuMed Modern Urgent Care + IV Therapy

Different solvents form large volume parenterals (LVP) solutions and emulsions. These solvents in large volume parenterals (LVP) are stated below:

| Water | It is one of the most frequently utilized solvents in the formulation of large volume parenterals (LVP). It provides a medium to dissolve different solutes like glucose, amino acids, electrolytes, etc. It is used in sterilized and distilled forms. |

| Ethyl Alcohol | It is used for different drugs that do not dissolve in water. The use of ethyl alcohol is strictly regulated because of irritation. |

| Propylene Glycol | It is used in some large volume parenterals (LVP). It is used because it does not allow large volume parenterals (LVP) to freeze at cold temperatures. |

| Oils | Different types of oils are used when non-aqueous vehicles are prepared to form large volume parenterals (LVP). These include corn oil, peanut oil, cotton seed oil, etc. |

7.What is the Composition of Large Volume Parenterals (LVP)?

Composition of Large Volume Parenterals (LVP)

The composition of large volume parenterals (LVP) is as follows

| Component | Example | Percentage |

| Vehicle | Water

Water miscible vehicle (Alcohol) Non-aqueous vehicle (oil) Solid Vehicle |

90% or more |

| Active Ingredients | Drug

Nutrients |

0.1-10% |

| Tonicity Adjusters | Electrolyte, NaCl,

Non-electrolyte, Dextrose |

0.5 – 0.9%

4-5% |

| Buffers | Acetate/Citrate

Phosphate Glutamate |

<10% |

| Antioxidants | - | 0.1-0.5% |

| Complexing agents | Chelating agents

Cyclodextrins |

0.01-0.05% |

| Surfactants | Lecithin | 0.05-0.5% |

| Antimicrobial Agents | - | 0.01% |

| Bulking Agents | Cryoprotector or Lypoprotector | 1-10% |

8.What are the Volumes of Large Volume Parenterals (LVP)?

Composition and Volumes of Large Volume Parenterals (LVP)- Picture Courtesy: IV Therapy

There are various compositions and volumes of large volume parenterals (LVP) solutions like:

| Ringer Solution

|

Ringer solution is available in volume ranges of 250, 500, and 1000 ml. It typically contains amount of sodium chloride, potassium chloride, and calcium chloride about 8.6, 0.30, and 0.33 g/L, respectively. |

| Lactated Ringer Solution | It is also present in 250 ml, 500 ml, and 100 ml volumes. It contains sodium chloride, potassium chloride, and calcium chloride about 6, 0.42, and 0.24 mg/L, respectively. It also contains lactates. It corrects electrolyte imbalance and dehydration. |

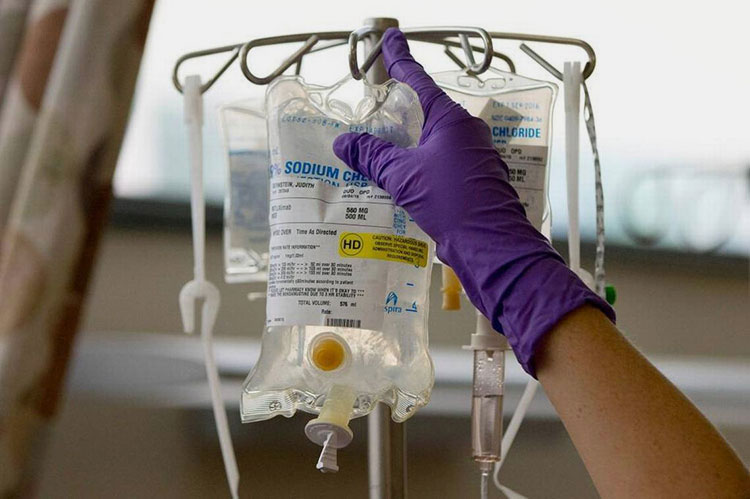

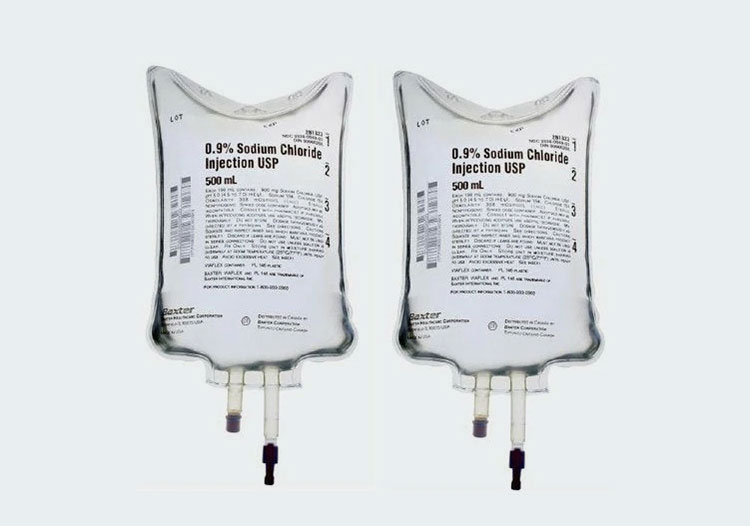

| Normal Saline | This type of large volume parenterals (LVP) has 0.9 g of sodium chloride of sodium dissolved in 1 Liters of water. It is a vehicle for delivering medications. |

| Half Normal Saline (½ NS) | It contains 0.45% saline in 1000 ml of water. It is used for restoring water in patients with hypernatremia. |

| 5% Dextrose Solution | It is another frequently used type of large volume parenterals (LVP). It is used for renal excretion of solutes and to provide energy. It contains 50g of dextrose in 1 litre of water. It is available in 250 and 500ml. |

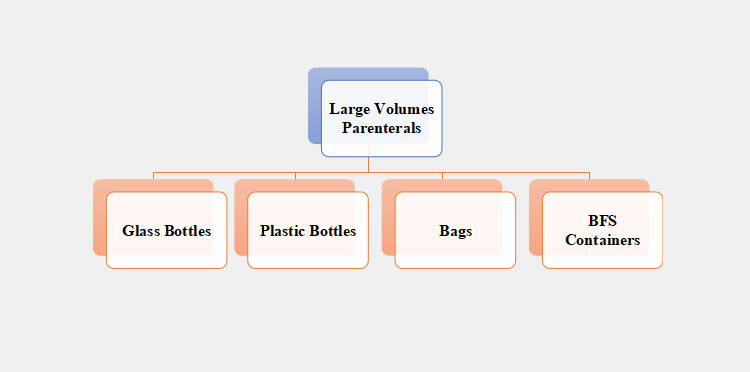

9.What are the Material Formats for Large Volume Parenterals (LVP) Having a Volume of 100 ml or more?

There are four main types of packaging formats supported by the large volumes parenterals (LVP). These packaging formats are discussed below:

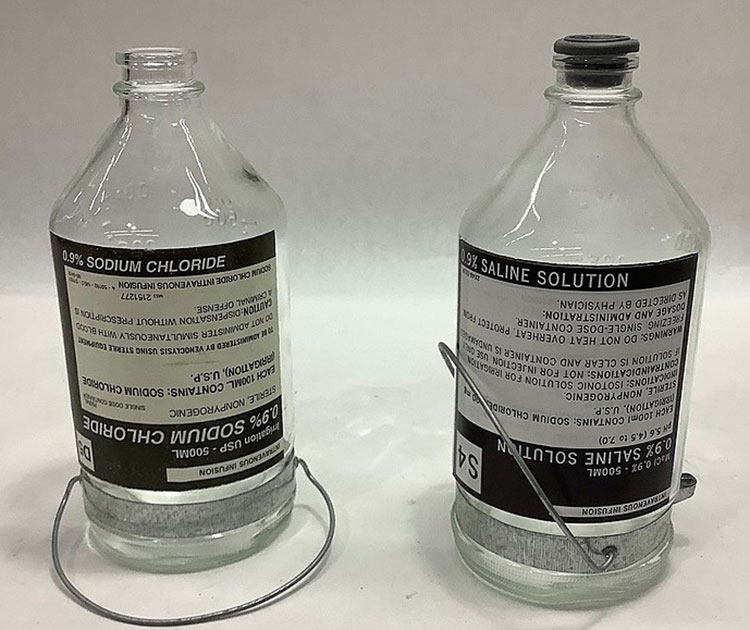

Glass Bottles

Glass Bottles- Picture Courtesy: Empire Props

These are one of the earliest forms of large volumes parenterals (LVP). These bottles have excellent clarity if the visual examination of large volumes parenterals (LVP) is required. These bottles have decreased permeability to air and water vapours. Glass bottles IV solution production line sterilizes glass bottles and packs large volume parenterals (LVP) in these glass bottles.

Plastic Bottles

Plastic Bottles- Picture Courtesy: Shanghai Marya

It is an excellent alternative to glass bottles and is light in weight. These bottles are available in different volumes and do not break during rough transportation or handling. Moreover, these are not suspectable to cuts that are normal with the glass bottles.

However, plastic bottles do not have higher impermeability to gases and vapours. For packaging the large volumes parenterals (LVP) in the plastic bottles, the plastic bottle IV solution production line is utilized. It maintains aseptic conditions during the packaging of large volumes parenterals (LVP) in plastic bottles.

Plastic bottles are made of these materials:

| Polyethylene (PE) | It is one of the most commonly used materials for making large volume parenterals (LVP) bottles. |

| Polypropylene (PP) | It is lightweight, has high clarity and excellent chemical and fatigue resistance. |

| Polyvinyl chloride, plasticized (PVC) | It is the first type of plastic used for making flexible plastic bottles. |

| Polyamide (Nylon) | It is a high-weight polymer and is popular because of its increased strength and scratch resistance. |

| Ethylene-vinyl acetate (EVA) | It is developed to improve the compatibility of the materials and to decrease moisture permeation. |

| Polyolefin | It is a layered material composed of PE, PP, EVA and Nylon. |

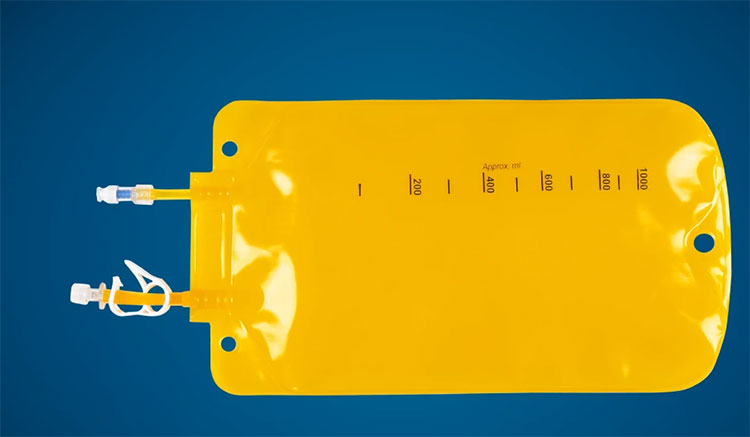

Bags

Large Volume Parenterals (LVP) Bags- Picture Courtesy: BD

These plastic bags are increasingly used for containing large volumes parenterals (LVP). These are lightweight and are more compact than large volumes parenterals (LVP) bottles, offering easier transportation and storage. These are flexible and require less space for storage. When emptied of large volumes parenterals (LVP) plastic bags, they collapse, hence; reducing wastage.

The large volumes parenterals are filled and sealed in plastic bags by the Non PVC soft bag IV solution production line.

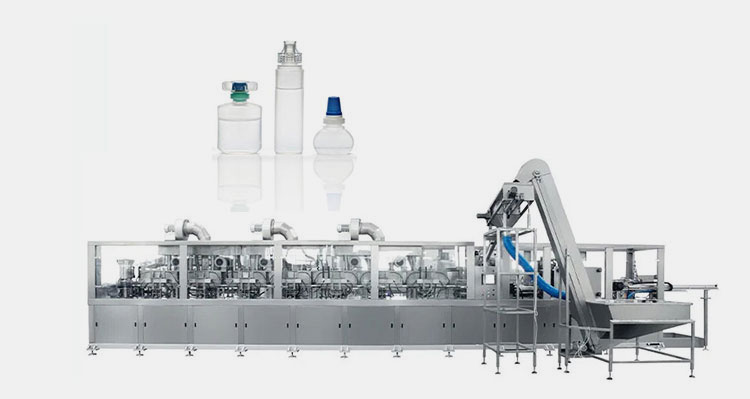

Blow Fill and Seal Containers

Blow Fill and Seal Containers- Picture Courtesy: Brevetti Angela

These containers are innovative packaging formats, formed using plastic granules. These containers are formed by the blow, fill, and seal machine. This machine makes BFS containers itself instead of using already formed containers. These are processed, filled, and sealed under sterile conditions, removing the need for terminal sterilization.

10.What are the Risks Associated with Large Volume Parenterals (LVP)?

Like other medical therapies, the administration of large volume parenterals (LVP) has some associated risks. These risks are dependent on the patient type, dispensing method, and formulation type. Some of these risks are penned below:

Infection

Infection- Picture Courtesy: Emergency Physicians

Sometimes, large volume parenterals (LVP) become contaminated with bacteria and other microbes during the manufacturing process, leading to infection. Also, poor aseptic techniques during the administration of large volume parenterals (LVP) cause infections.

Allergic Reactions

Allergic Reactions- Picture Courtesy: Complete Care

Due to large volume parenterals (LVP) formulation, the patients suffer from allergic and hypersensitivity reactions like mild rashes and breathing problems.

Fluid Overload

Fluid Overload- Picture Courtesy: Everyday Health

If the large volume parenterals (LVP) is administered too rapidly, it will cause some serious symptoms of fluid overload like edema, heart failure and loss of renal function. It could be fatal in some cases.

Electrolyte Imbalance

Electrolyte Imbalance- Picture Courtesy: Medindia

If the large volume parenterals (LVP) contain large quantities of sodium chloride or potassium chloride then it could lead to hypernatremia (high sodium), hyperkalemia (high potassium) or hypokalemia (low potassium), leading to pounding heart and weakness.

Thrombosis or Phlebitis

Thrombosis or Phlebitis- Picture Courtesy: Medical News Today

Sometimes, the use of catheters of longer duration could cause the formation of clots or blockage of the blood vessels. If the solutions are hypertonic or have irritating large volume parenterals (LVP) formulation then irritation or inflammation of the vein occurs at the site of infusion.

Air Embolism

Air Embolism- Picture Courtesy: CIDRAP - University of Minnesota

Insertion of the catheter can accidentally introduce an air bubble in the systematic circulation, causing a hindrance in the blood flow.

11.What are the Antioxidants in Large Volume Parenterals (LVP)?

Antioxidants in Large Volume Parenterals (LVP0- Picture Courtesy: Verywell Health

Although, preservatives are not used in the formulation of large volume parenterals (LVP). The antioxidants also called reducing agents are added in the large volume parenterals (LVP. These aids in extending the shelf life of the drugs by preventing medication from oxidizing

Different sulfurous acid salts like sodium bisulfite are the most frequently used during the preparation of large volume parenterals (LVP).

12.How Large Volume Parenterals (LVP) are Manufactured?

Manufacturing of Large Volume Parenterals (LVP)- Picture Courtesy: LinkedIn

Large Volume Parenterals- Picture Courtesy: Ocean Property

The processing, preparation, and packaging of large volume parenterals (LVP) is an essential process that requires stringent aseptic manufacturing conditions. This manufacturing process includes several important steps, providing strict control of sterility and contamination-free formulation. These steps are discussed briefly below:

| Water Purification | The water added in the formulation of the large volume parenterals (LVP) is passed through different purification steps like distillation, and deionization to fulfil strict regulations of sterility. |

| Formulation Preparation | In the first step, high-quality ingredients like drugs, electrolytes, and salts are selected and then the solution is prepared by weighing and mixing ingredients in the large steel tanks. |

| Sterilization | After preparing a uniform solution or other formulation, the next step is the sterilization of the solution. This solution undergoes different filtration steps to ensure contamination-free processing. |

| Container Choice and Sterilization | The containers like glass bottles, plastic bags, etc. for packaging the sterile large volume parenterals (LVP) solution are prepared and sterilized in the next step. The sterilization step is carried out using steam, dry heat, chemicals or radiation. |

| Filling and Sealing | Filling of sterile containers with large volume parenterals (LVP) is carried out under the airflow hoods and isolators to prevent contamination risk. These containers are instantly hermetically sealed after filling to meet the sterility requirements |

13.What is the Production of Large Volume Parenterals (LVP) Made of?

The production line of large volume parenterals (LVP) is made of many machines like non-PVC soft bag production line, bottle IV production line, and plastic bottle BFS (blow fill seal) machine LVP (large volume parenteral) production line.

The steps in this production line are discussed one by one below:

Non-PVC Soft Bag Production Line

Aipak Engineering Non-PVC Soft Bag IV Solution Production Line

| Film Opening | At the start, the film is loaded on the unwinding disk. Then it begins to unwind by the film open plate. It is folded and transported to the printing section of the production line. |

| Film Printing | Different kinds of information essential to notify operators and patients are printed on the film at this station. |

| Bag Creation | Bilateral moulding moving up and down, molds a bag from a film. Heating and cooling steps are essential in bag formation. |

| Port Welding | Single and double ports are then placed in the formed bag. Heat sealing is used for welding the ports. |

| Filling | In the sterile working environment, aseptic large volume parentals (LVP) are dispensed inside the bag. |

| Sealing | Heat and ultrasonic approaches seal the open side of the filled large volume parentals (LVP) bag. |

Bottle IV Production Line

Aipak Engineering Glass Bottle IV Production Line

| Bottle Washing | The bottles are carried to bottle bottle-washing rotary table and are cleaned with water and dry air to avoid large volume parenterals (LVP) contamination. |

| Bottle Sterilization | Different techniques like heat or steam are used for sterilization of the bottle which eliminates chances of microorganism development in large volume parenterals (LVP). |

| Filling | Large volume parenterals (LVP) solutions are accurately dispensed into the bottles at this stage. |

| Stopping and Capping | A crimping machine is used to add stoppers or caps on the open end of bottles. These bottles are then labelled and discharged from the production line. |

Plastic Bottle BFS (Blow Fill Seal) Machine LVP (Large Volume Parenteral) Production Line

Aipak Engineering Plastic Bottle BFS(Blow Fill Seal)Machine LVP (large volume parenteral) Production Line

| Extrusion | At high temperatures, the heating of plastic granules occurs. The extrusion step is performed to form a parison. |

| Moulding | Parison is enclosed by specially designed moulds and sterile gas is blown to form a container of the desired dimension. |

| Filling | Large volume parenterals (LVP) solution is fed inside the container by the filling nozzle placed inside the neck of the container. |

| Sealing | The sealing jaws heat seal the containers. These containers are hermetically sealed at the open end. This process maintains the sterility of the large volume parenterals (LVP) containers. |

14.What Technological Advances are Influencing Large Volume Parenterals (LVP) Production?

Quality control and safety during the manufacturing process of large volume parenterals (LVP) are achieved through different technological advancements in this field. These technological advancements continuously shape the horizon of the large volume parenterals (LVP). Some of these technological advancements are detailed below:

Advanced Aseptic Manufacturing

Advanced Aseptic Manufacturing- Picture Courtesy: Staubli

Isolators, laminar airflow hoods, and RABS systems are the few technological advancements in aseptic processing. These barrier systems maintain the strict sterility and aseptic environment during large volume parenterals (LVP) preparation and packaging. These prevent contamination risk.

Robotics

Robotics- Picture Courtesy: Forbes

These are introduced in the field of large volume parenterals (LVP) to fill and pack large volume parenterals (LVP). It minimizes human involvement and therefore, reduces the chances of contamination.

Real-time Monitoring

Real-time Monitoring- Picture Courtesy: PPD

Different frameworks, sensors, and data analysis tools are added in large volume parenterals (LVP) production lines to allow the real-time monitoring and control of the manufacturing process. This ensures the consistent performance of the system while maintaining the quality control.

Smart Packaging

Smart Packaging in Large Volume Parenterals (LVP)- Picture Courtesy: PDC Healthcare Blog

Different innovations have made been in the packaging systems like bottles and bags of large volume parenterals (LVP). This allows the incorporation tamper tamper-evident features and smart labels like QR codes.

15.What are the Challenges and Solutions of Large Volume Parenterals (LVP) Production?

There are several challenges when it comes to manufacturing of large volume parenterals (LVP). To resolve these challenges, manufacturers must incorporate some innovative solutions. Below mentioned are challenges and solutions of large volume parenterals (LVP) production.

Maintaining Sterility

Maintaining Sterility- Picture Courtesy: Pharmaceutical Networking

Sterility is crucial during the manufacturing of large volume parenterals (LVP) for averting microbial contamination. Failure to do so can result in product recall and can be fatal to the health of the patient.

Solution

Maintain the aseptic conditions during the preparation and processing of large volume parenterals (LVP) by implementing innovative aseptic methods like isolators and RABS. These systems improve sterility by putting a pause on contamination.

Regulatory Compliance

Regulatory Compliance- Picture Courtesy: Finance Magnates

Regulatory measures are continuously evolving. Adherence to these protocols requires huge resources and skills.

Solution

Instigating systematic training programs for the workforce to improve their skills and regularly updating regulatory protocols can resolve this challenge.

High Production Costs

High Production Costs- Picture Courtesy: Tranquil ERP

The price of setting up large volume parenterals (LVP) production is very high and is further increased by the changing technologies and equipment.

Solution

This cost can be lowered by implementing single-use systems because it reduces the requirement of complicated sterilization. Embracing lean manufacturing processes can increase production efficiency.

Quality Control

Quality Control- Picture Courtesy: Decision Resources, Inc.

It is crucial to maintain uniform quality control in each batch in large volume parenterals (LVP) production.

Solution

Incorporating strict quality control procedures can help to maintain quality across every batch. Furthermore, the use of real-time analytics can aid in upholding quality standards.

Conclusion

Large volume parenterals (LVP) is a significant innovation in medical science, expanding continuously and shaping itself by technological advancement. From preparation to packaging, every step in the production of large volume parenterals (LVP) must be carefully regulated and monitored to ensure sterility. If you are planning to expand your business by adding large volume parenterals (LVP) production, we would like to suggest searching for companies that are champions in the machine related to large volume parenterals (LVP). But, do not search further, as Aipak Engineering is the best place to buy equipment related to large volume parenterals (LVP) manufacturing. Please contact us immediately for promising turnkey solutions.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours