Insulin Syringe and Vial: The Complete FAQ Guide In 2025

What is the biggest health problem of today’s physiological disease? None other than diabetes mellitus. It was recorded in 2021 that around 537 million of people suffered from this pandemic. The story is not ended; it was expected to be many times till 2030. Currently many strategies are in the market treating this problem. Insulin syringe and vial is popular one!

This is our topic of today, ‘Insulin Syringe and Vial: The Complete FAQ Guide In 2025’ article is based on the facts and important discussions related to its background, therapeutic strategies, making, machineries, handling, packaging, and so much more.

Let’s start our discussion!

1.What are insulin syringe and vial?

Insulin Syringe and Vial- Picture Courtesy: Diabetes Qualified

Insulin is a regulating protein that acts as a safeguard of your body. It helps in the transportation of body glucose inside the cell. If your body compromises this hormone, then the insulin syringe and vial play a significant role in keeping this process balanced.

The insulin syringe is particularly designed to inject a specific unit of insulin into your body. This is quite easy to administer. An insulin vial, on the other hand, requires drawing of particular dose from it, and once it is opened, you can refrigerate it and take the required volume of insulin when needed.

2.How early insulin syringe and vial introduced?

History- Picture courtesy: ACS

The tremendous story of insulin syringe and vials emerged in the early 1920s. At that time large syringes were used with reusing sharp needles. The method was implemented under sterilized protocols with the help of boiling them when used.

However, for sharpening of needles, the pumice stone was used. With time, practices were changed, and insulin syringe and vial were the common drug administration options.

The reusable sources were replaced with disposable options to improve hygiene and patient safety. Since then, till now, you have seen so many new innovations and flexibility in insulin syringe and vial. The reason behind this is only increasing the palatability and more user compliance with insulin treatments.

3.What is the dose of insulin syringe and vial?

Insulin syringe and vial comes in different doses and sizes. The insulin syringe offers fewer units than the vial. We have described the volume of the insulin syringe and vial below:

Insulin Syringe and Vial- Picture Courtesy: syringesneedlesdepot

Insulin syringes are presented with graduated lines. It is small and capable of accommodating little volume such as 1millliliters or mL of insulin which is corresponded to 100 units. If you observe its barrel, they’re indicated with units instead of millilitres so provide a very accurate and precise volume of insulin.

Moreover, the size of the barrel helps to know how much volume is stored, and the needle gauge tells thickness. As much thin as your needle is the more painless administration will you have. The length of the needle with tell the inside penetration of insulin.

The commonly available doses of insulin syringes are:

| Dose | Description | Length of Needle | Gauge |

| 0.3 mL | It means the syringe is designed to offer 30 units of insulin with numbering half to 1 unit of interval. | 3/16 inch or 5 mm | 28 |

| 0.5 mL | This insulin syringe is based on storing 30 to 50 units of insulin with numbered at single-unit intervals. | 5/16 inch or 8 mm | 29, 30 |

| 1.0 mL | It has more than 50 units and is numbered with 2 units for each interval. | 1/2 inch or 12.7 mm | 31 |

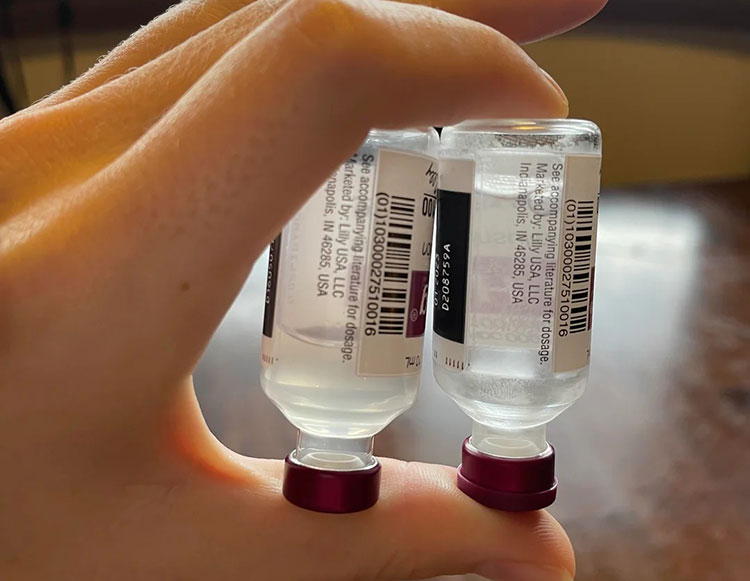

Insulin Vial

Insulin Vial

Insulin vials are designed to fill large volumes of formulation and they’re mainly able to hold 100 units of insulin/mL.

The typical insulin vial volume is 3 mL or equivalent to 300 units in each vial. However, it is also available in 10 mL which is equivalent to 1000 units.

4.What are the types of insulin syringe and vial?

Types of Insulin Syringe and Vial

A person can normally start taking insulin when their own body cannot produce the insulin hormone by itself to control the blood sugar level. Your pancreas produces insulin hormone and controls the blood sugar level by converting it into energy. Then, if your body cannot produce it, then you need to take insulin.

Your physician will decide the right time and dosage for you keeping in view your blood sugar readings. The insulin syringe and vial have several types available. We have described them below:

| Disposable Insulin Syringe | Such a type of insulin syringe is a time-useable solution. You can discard the syringe soon after injecting. |

| Reusable Insulin Syringe | This type of insulin syringe is designed with a cartridge that you can use every day till the time of insulin expires. It takes around one month time to expire and is mainly used for long-acting, short-acting, intermediate-acting insulin, and mixed-acting insulin. |

| Insulin Syringe Pen | This is a modern injectable where an insulin syringe looks like a pen with a sharp and thin needle. It has the option to refill by replacing the cartridge with filled insulin. |

| Insulin pumps | These are the kind of injectables which is not commonly used. It is designed to offer a continuous flow of insulin dose and is prescribed for diabetes type 1 and 2. |

Insulin Vial

Insulin Vial

Insulin vial comes in various types that is based on its action mainly. For example:

| Rapid Acting Insulin Vial | This is mainly used before taking a meal to manage blood glucose levels after eating. The action produced by this insulin is mainly estimated as 15 to 30 minutes. The common examples of this formulation is insulin aspart, insulin lispro, and glulisine. |

| Short-Acting Insulin Vial | This is also known as a regular insulin vial that produces its action within 30 minutes of injecting the dose and can have an effective therapeutic response for a longer time. The common example of short-acting insulin is insulin neutral. |

| Intermediate Acting Insulin Vial | This is mainly producing its action of therapeutic response in one to two hours of injecting the dose but keep maintain them for 12 to 16 hours. The common example of an intermediate insulin vial is isophane or NPH. |

| Long-Acting Insulin Vial | Such insulin vial is prescribed for slow action but for longer therapeutic response which is mainly for 24 hours. For example, glargine and detemir. |

| Mixed Insulin Vial | This is the combination of insulin doses which is mainly composed of short acting with intermediate insulin to offer a broad spectrum of therapeutic responses. For example: Humalog mix 50, mixture mnbgt564430/70 and other. |

5.Where do you inject insulin syringe and vial?

Insulin Syringe and Vial- Picture Courtesy: Medical News Today

The insulin syringe and vial need a specialized delivery unit that helps in the administration of insulin only in the subcutaneous layer of skin but does not reach far into fascia or muscles. Mean it can be suitable for skin thickness which is ∼2.0–2.5 mm.

The safest way you can start taking insulin medication is after consulting a doctor. The doctor will prescribe the right dose according to your needs and overall health. Also, a doctor will guide you on how to take it through a syringe since it’s a very complex process and requires a lot of safety and attention. It is important to store it according to the instructions and monitor blood sugar level regularly.

Moreover, the thickness also varies on ethnicity, age and BMI with certain variations of mm in the layer. The suggested areas for injecting insulin syringe and vials are:

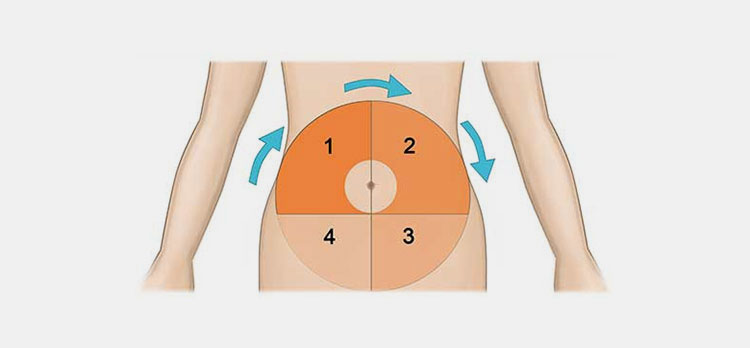

Belly

Belly- Picture Courtesy: Healthxchange

This is the popular site for insulin syringe and vial; preferred and acceptable for various patients too. Here the absorption rate is also rapid with consistency. It is recommended that injection should be administered by following rotation way thus your skin can’t be hardened and it must be 2 cm away from the naval button.

Thighs

Thighs – Picture Courtesy: Terveyskylä

This is also another preferred site for insulin syringes and vial where your prescriber can recommend injecting long term insulin syringe and vial. It is not suggested to use legs and site must be away from the groin and knee. The preferred area should be the top or outer region in the fatty tissues but not the inner or back thigh.

Upper Arms

Upper Arms – Picture Courtesy: Nursing Time

This site may be not so easy but many of you prefer using this way. Here, an insulin syringe and vial dose can be administered in the fatty tissue surface of back section of the upper arm. As compared to belly the site of absorption is low and be get harder soon if you’re frequently administering the doses.

Buttocks

Buttocks- Picture Courtesy: The Guardians

This is a suitable area for insulin syringe and vial that offer slow absorption of medication. For some people, you may need assistance such as old and children for administration.

6.How do you administer insulin syringe and vial?

The method of administering insulin syringe and vial is briefly discussed below:

Insulin Syringe and Vial

Insulin Syringe

Administering insulin syringe is comparatively easier than a vial. Just remove the cap or lid attached to the syringe and remove the air bubble which is based on the drawing few units of insulin. For example, approximately you can draw 2 units of insulin so the air bubble can be removed and ensure smooth injection. Also, it is recommended to shake the syringe several times gently to mix the solution properly.

Now pinch a small portion of your skin and inject the syringe by positioning the needle around the 45- 90 angle. Once it is inserted subcutaneously by pushing the whole needle, draw the insulin unit and wait for 10 seconds and remove the syringe, and dispose off the used needle.

Insulin Vial

An insulin vial, which is composed of insulin solution, can be shaken gently to mix the solution. Remove the cork and insert the syringe to draw the required units of insulin you need. The syringe should be inserted by taking air so that the desired concentration can be easily drawn into it without an air bubble. Use a similar procedure of injection as above and do not refrigerate the remaining; rather, keep it at room temperature for 28 days.

7.How are insulin syringe and vial made?

Insulin Syringes and Vials

The preparation of insulin syringes and vials includes various primitive steps of manufacturing insulin and then its storage. The manufacturer should make sure the dosage is correct because even a small error can risk a patient’s health.

To ensure the accuracy of insulin dose the manufacturers use high-functioning and well-equipped filling machines with sensors and weight check systems. In the process, quality checks are also performed and the machines are regularly calibrated to achieve accuracy.

Steps of Making Insulin Syringe and Vial

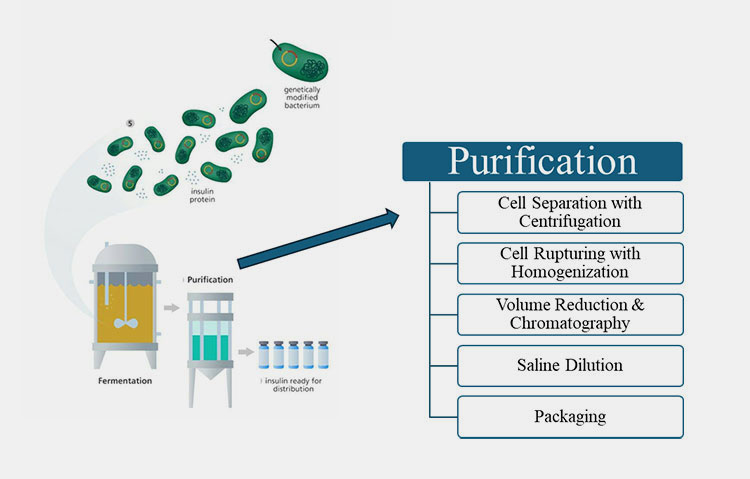

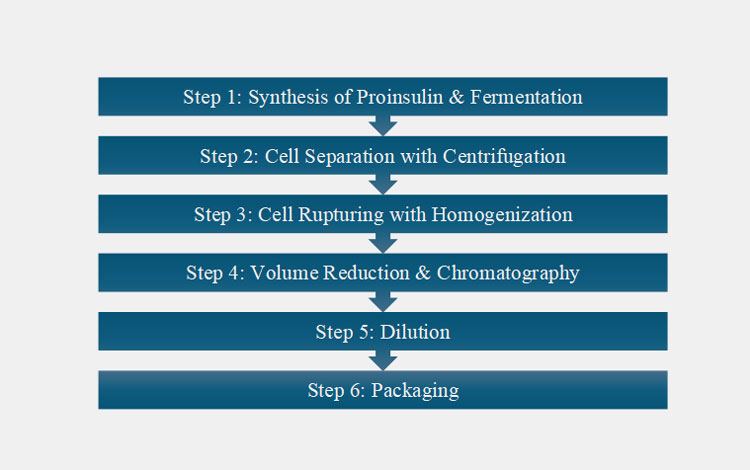

There are the following steps are involved in the making of insulin such as:

Step 1: Synthesis of Proinsulin & Fermentation

This is the first step, which is associated with the chain method, such as chains A and B of insulin are prepared separately. The recombinant technique where E.coli is responsible for making proinsulin and transforms the cells to increase the count of cells and inoculate into the media for further progression using a bioreactor that provides favorable conditions such as optimum temperature of 37°C followed by pH of 7 and 30% oxygen level for 24 hours to improve the growth of insulin.

Step 2: Cell Separation with Centrifugation

This step is significant and known as cell harvesting, where insulin cells are harvested with the help of filtration as well as the centrifugation method to get a high density of cells.

Step 3: Cell Rupturing with Homogenization

The proinsulin bodies are embedded in the cells of precursor insulin that are released by the disruption of the cell membrane with the help of high-pressure homogenization. This method is sensitive and cannot damage the proinsulin molecules, therefore helping in attaining proinsulin in the intact state without any cell debris or cytoplasmic materials.

Step 4: Volume Reduction & Chromatography

After homogenization, the proinsulin is further passed through a series of processes such as solubilization, sulfitolysis, centrifugation, and renaturation to form a pure and optimized concentration of proinsulin molecules.

Nonetheless, there are still some doubts about impurities that are cleared by reagents and buffer for complete isolation. However, the purification process is effectively done by affinity chromatography and reverse-phase high-performance liquid chromatography.

Step 5: Saline Dilution

The obtained insulin product is treated with saline dilution and stored below 4 ℃, which helps in the integrity of the insulin and ensures the activity of the insulin will remain potent when you inject it into your body.

Step 6: Packaging

The prepared formulation is now transferred to the filling and packaging area, which is sterile. Under controlled rooms and a sterile environment, the filling of insulin is achieved in syringes and vials. Insulin is a basic yet essential drug.

It’s made of proteins and if it gets too hot or too cold it can lose its effectiveness and stop working. The temperature that should be maintained to store insulin is between 2ᵒC to 8ᵒC but don’t freeze it since freezing damages the insulin and makes it useless.

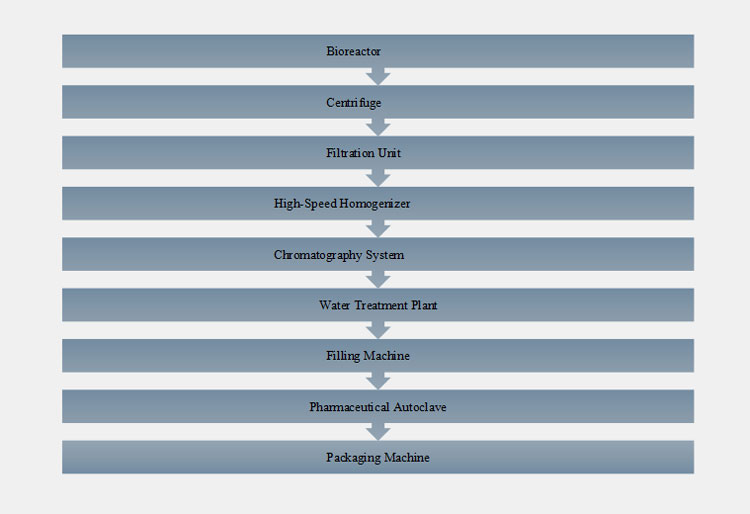

8.What are the mandatory machines for manufacturing insulin syringe and vial?

From the above discussion about the synthesis and manufacturing of insulin syringe and vials; we have designed various equipment used in the process. I would suggest having a deep look at them so you will find them helpful when assessing the production requirement for insulin syringe and vial. Here we go!

Bioreactor

Bioreactor- Picture courtesy: LabX

To provide controlled conditions for the fermentation of proinsulin, the genetic engineering product technique for E. coli requires a bioreactor. The purpose of this equipment is to offer the required temperature, oxygen, and relative humidity with either shaking or without agitation of the media to get ideal insulin production. The machine is designed with stainless steel and sterile materials to resist unwanted debris formation and offer easy cleaning, thus ideal for sterile formulations and processing.

Centrifuge

Insulin centrifuge- Picture courtesy: GEA

The centrifuge machine is responsible for separating layers of supernatant and down-settled proinsulin. The working of the machine is based on high-speed circulatory movement which occurs in hundreds to thousands of RPM and offers quality purification and cell harvest.

The high-speed movement is the reason behind layer separation where the denser layer is composed of useful content of E.coli responsible for making proinsulin production. There are small, moderate, and large sizes of centrifuge machines available, and you can pick any unit based on your production needs.

Filtration Unit

Insulin filtration unit

The filtration machine helps in the separation of undesirable particles and makes the insulin solution very clear. Although the centrifuge machine also assists the separation process on the level of microfiltration, the filtration unit is really helpful and essential.

High-speed homogenizer

High-speed homogenizer

The homogenizer is mainly used at the level of biotechnological assessments. The machine helps in the homogenization of suspension which is composed of E. coli. The high speed causes rupturing of the cell membrane and the exclusion of proinsulin masses. This is also a critical unit and delicately treating the solution hence does not damage the cellular activity and inside mass.

Chromatography System

Chromatography System- Picture courtesy: Teledyne

The machine is useful in the further purification of the solution where specified biomolecules are separated and helps in the obtaining of the purest form of insulin. The machine is mainly composed of pressure pumps, a column with silica, and a detecting unit where different fractions are isolated and detected.

Water Treatment Plant

AIPAK Engineering Water Treatment Plant

From scratch till the final production of insulin, the water requirement is fulfilled by using purified and sterile water. The water treatment plant is used for this purpose which ensures the international standard processing and significantly facilitates the disinfectant water to bring the ideal production and safe for use.

The machine is designed with a compact structure where each unit is connected to other parts of the system. With enclosed pipes made up of sterile materials, the unit resists corrosion or rapid microbial progression making it ideal for pharmaceutical formulation.

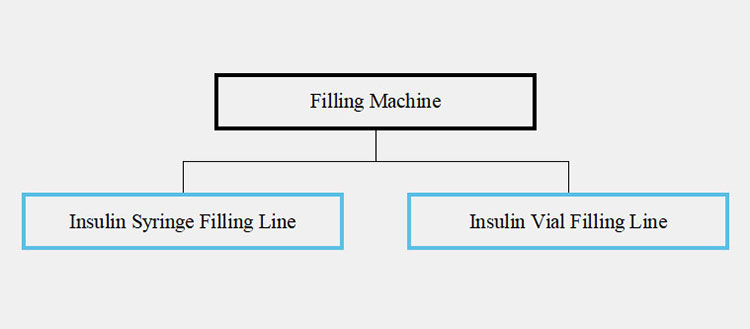

Filling Machines

For the filling of insulin syringe and vial, you will need separate machines. For example:

Insulin Syringe Filling Line

AIPAK Engineering Insulin Pre-filled Syringe Line

This is an advanced machine composed of various functional units to treat empty syringes and fill them with insulin. This is composed of a tray loading belt, loader of syringes, plunger for filling of solution, stopper unit, HMI, and others. The machine is designed with a number of heads that allow the filling of several syringes at one time. This is ideal for bringing sterile operation effectively and features greater automation hence entire process takes place in less time and reduced manpower.

Insulin Vial Filling Line

AIPAK Engineering liquid vial production line

The insulin vial filling line is composed of a vial washing machine, a vial sterilization unit followed by a dryer machine, the vial filling machine with stoppering machine, and the final unit integrated is a capping machine.

The washing process is taken by fast and sharp showering of water to clear and sterile the vials and the sterilization machine ensures the killing of microbes if present. The filling machine allows accurate filling of the insulin inside the vials with nitrogen flush that protects the solution. The vials are secure with stoppering and final capping. The entire process takes place under highly strict regulations that adhere to machine designs and a controlled environment.

Pharmaceutical Autoclave

AIPAK Engineering Pharmaceutical Autoclave

To sustain sterility and hygiene, the pharmaceutical autoclave machine is used that facilitates high steam and pressure which penetrates inside the membrane of microbes and makes them die or denature. You can install the machine for sterility of bottles, vials, syringes, and ampoules. The usual temperature utilized to kill the microbial colony is 80-126°C. Therefore, this machine is a highly critical and mandatory option for every production facility of pharmaceuticals and healthcare departments.

Packaging Machines

AIPAK Packaging Machine

This is included with the labeling machine and cartoning machine. The insulin vials and syringes are externally treated with labeling machines where automatic sensors ensure the presence of objects and the implication of labels over them. It is required for conveying information related to products and customer help. For example, the name of the product, dose, information about storage, volume, manufacturing, and expiry date, etc. Secondly, the product is secure when positioned in a carton. The cartoning machine is used to place them for distribution and final protection from external hazards.

9.What age group people require insulin syringe and vials the most?

Insulin syringe and vial are usually needed among two main age groups:

Children and Teens (Type 1 Diabetes)

Children and Teens (Type 1 Diabetes)- Picture courtesy: Medtigo

Kids and teens usually need insulin because their bodies have stopped producing insulin. Dealing with type 1 diabetes in children and teens requires special attention. Type 1 diabetes is a self-reactive condition where your pancreas produces little to no insulin. It typically initiates in childhood and therefore, requires all-time synthetic insulin consumption. The total daily dose of type 1 diabetes depends upon a person’s weight, age, and blood sugar patterns.

Adults over 40 (Type 2 Diabetes)

Adults with type 2 diabetes- Picture courtesy: UVM

Adults may require using insulin when their blood sugar remains high even after controlled diets, medicines, or exercise. Insulin will help the body control the blood sugar level and will keep it at a balanced range. Similar to type 1 diabetes, the dosage of type 2 diabetes also depends on a person’s weight, blood sugar level, age as well as other medications.

Gestational Diabetes

Gestational Diabetes- Picture courtesy: OSF

This is not a chronic problem but females during the gestational period are mostly affected with diabetes. If untreated it can result in serious health problems to the pregnant person and baby. The insulin syringe and vial are mostly recommended in this case to prevent complications and ensure a healthy pregnancy.

10.What are the problems and solutions when preparing insulin syringe and vials?

There are certain problems and solutions when preparing for insulin syringe and vials; for example:

Contamination During Preparation

Contamination

Keeping insulin sterile and clean is super important. The manufacturers take special care of cleanliness since even a tiny bit of contamination can be harmful to patients. There are certain ways that are carried out to ensure safety and a clean environment for insulin packing.

Solution

To maintain sterility, the insulin is filled inside a sterile environment to ensure germ-free and clean formulation. There’s also a HEPA air filter in the room which eliminates the risk of contamination. Aseptic techniques are carried out, as well as frequent cleaning and quality control checks are carried out regularly to mitigate the risk of contamination. Incorporate sterile elements and maintain aseptic methods. Ensure regular cleaning and sterilizing of machine components that are in contact with insulin.

Incorrect Dose Volume

Insulin Dose

There may be a deviation in the fill volume caused by the machine. The deviation can cause the solution to either overdose or underdose. This is a dosage error.

Solution

Perform consistent calibration of filling nozzles. Use high-accuracy sensors and a weight monitoring system. In-process quality checks must be conducted regularly.

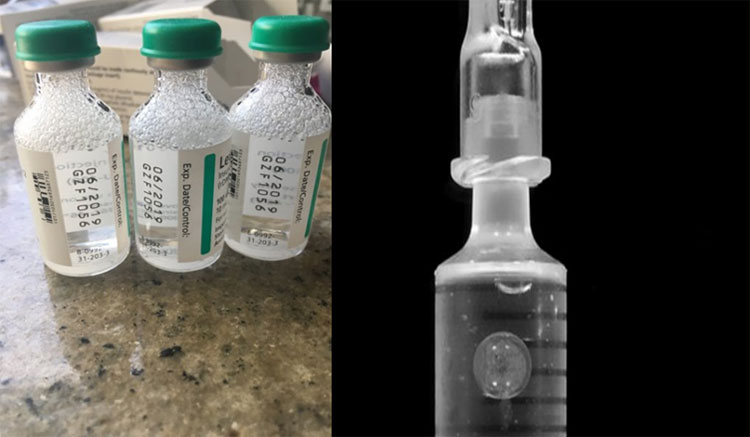

Trapped air inside vials and syringes

Air bubble

The formation of air bubbles inside vials and syringes can lead to imprecise dosing, resulting in health risk of patient.

Solution

Carry out air removal using degassing equipment prior to filling. Optimize angle and speed for maximum accuracy. Also, apply vacuum filling when needed.

Leaks and Sealing Defects

Leaks and Sealing Defects

Syringe caps or rubber stoppers on vials not sealed properly can cause leaks which could result in compromised drug efficiency and safety. It could also lead to insulin being exposed to air and cause potential contamination.

Solution

Ensure proper and effective sealing techniques during the process of packing. Conduct daily quality control and routine inspection to ensure proper sealing and packing of vials and syringes. Implement regular calibration of equipment to optimize performance.

Conclusion

Now we hope that you have thoroughly learned about the process of insulin syringe and vial. You must be aware of how a tiny dose is crafted with special attention and immense cleanliness, from taking care of tiny little bubbles, avoiding leaks, and maintaining a special environment, it’s all about ensuring the quality of dosage to prevent any health risk that can be caused. However, reliable machines from trusted companies can make the process more easy and professionally sound. If you need more information, please reach out to AIPAK ENGINEERING by giving us a response.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours