Your Best Injection Solution Provider

- Advanced technology&Integrated Function

- Non-aseptic packaging

- Automatic CIP/SIP

AIPAK Engineering Injection Solutions

AIPAK Engineering Injection solutions consist of several types of solutions which include BFS process solution,ampoule filling solution,vial powder injection solution,vial liquid solution and pre-filled syringe solution.All these solution production lines adopt advanced technology and integrate moulding,filling and sealing under complete control,which enables liquid to be packaged into various containers like polypropylene/high-density & low-density polyethylene plastic bottle,glass bottle,vial bottle and syringe,and the whole production process are completed automatically in an aseptic environment.All AIPAK Engineering injection solutions have the feature of automatic, humanized and intelligent with stable performance and quick and simple maintenance. High production efficiency and low production cost, with high quality product.

BFS Production Line

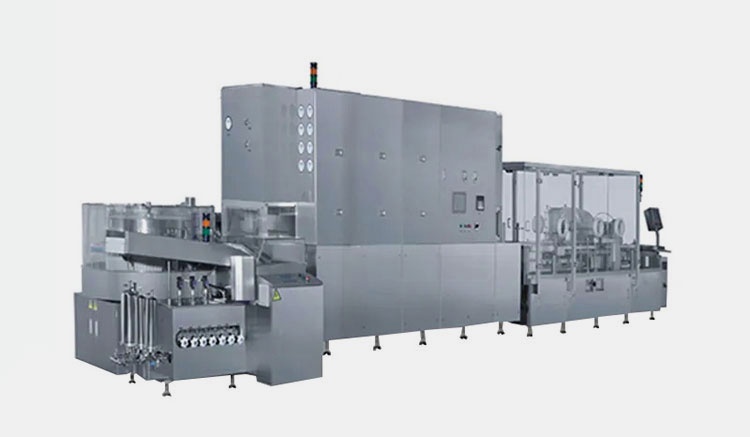

Medical Injection Bottle BFS Production Line

AIPAK Engineering medical injection bottle BFS production line is made by vertical ultrasonic cleaning machine, sterilizing dryer and filling and stoppering machine. The production line is suitable for 1 ml to 5 ml injection bottles. It can automatically complete processes like ultrasonic cleaning, flushing, silicone oil spraying, drying, sterilizing, stoppering, filling, capping, and more. Due to its high degree of automation, the production line achieves a high capacity of 12000 pcs/h. With a length of 9000 mm, a width of 2100 mm and a height of 2600 mm, it has a weight of 7000 kg. The electric capacity is 61 kW.

GMP or FDA drug production standards

High production efficiency

Filling Accuracy: ≤ ±1%

Ampoule Filling Line

High Quality/Output/Precise 1-20ml Ampoule Filling Line

AIPAK Engineering 1-20ml ampoule filling Line is composed of ultrasonic bottle washing machine, dryer sterilizer and ampoule filling and sealing machine. It can complete spraying water, ultrasonic cleaning, air & water flushing of inner and outer wall of ampoule bottle, preheating, drying and sterilization, heat source removing, cooling, (nitrogen pre-filling), filling, (nitrogen post-filling), ampoule sealing and other complex functions, realizing automatic production of the whole process. Each machine can be used separately or in linkage line.

Meet the size range from 1-20ml ampoule of washing,drying and sterilizing

High degree of automation

No-bottle-no-filling function and squeeze stop function

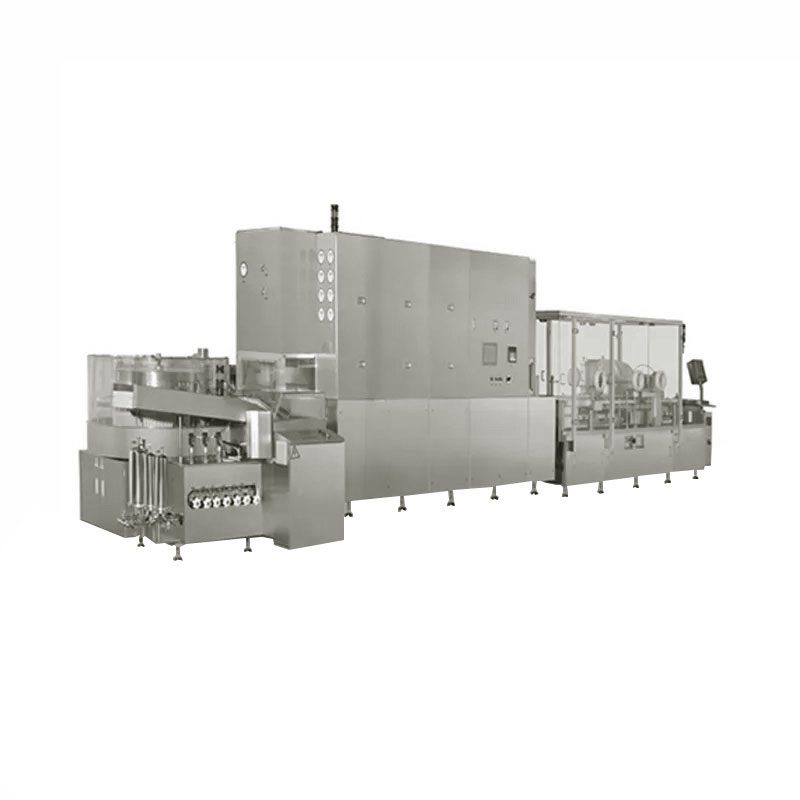

Vial Powder Injectable Production Line

Vial Lyophilization Powder Injectable Powder Production Line

AIPAK Engineering vial lyophilization powder injectable powder production line is composed of ultrasonic bottle washing machine, sterilization dryer, filling and stoppering machine, capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, removing heat source, cooling, bottle clear-up, (pre-filling nitrogen), filling, (nitrogen filling), plug clear-up, press plug, cap clear-up, capping and other complex functions, realizing automatic production of the whole process.

Contact part is made of SUS 316L

Easy to clean and without contamination

Low noise, precise filling, low energy consumption

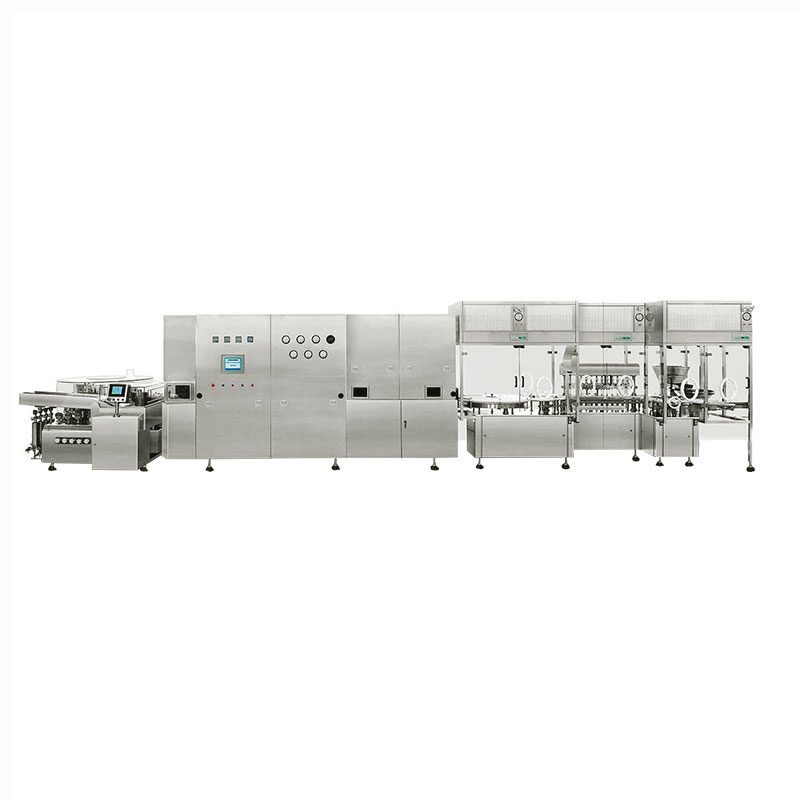

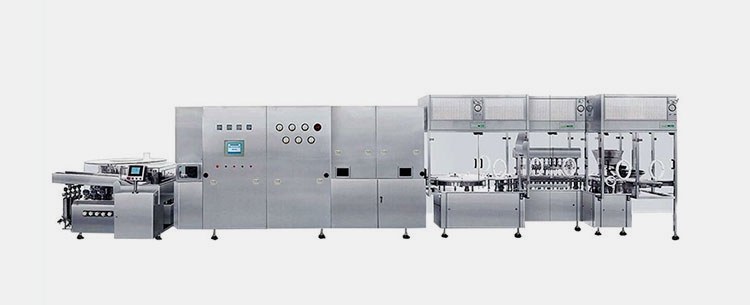

Liquid Vial Production Line

High Output Aseptic Liquid Vial Production Line

AIPAK Engineering liquid vial production line is composed of ultrasonic bottle washing machine, dryer sterilizer, filling stoppering machine, and capping machine. It can complete spraying water, ultrasonic cleaning, flushing of inner and outer wall of bottle, preheating, drying and sterilization, heat source removing, cooling, bottle unscrambling, (nitrogen pre-filling), filling, (nitrogen post-filling), stopper unscrambling, stopper pressing, cap unscrambling, capping and other complex functions, realizing automatic production of the whole process.

Meet with GMP standard

Filling Accuracy: ≤ ±1%

Compact and simple structure, small occupied area

Pre Filled Syringe Production Line

Highly Accurate Pre Filled Syringe Production Line

AIPAK Engineering pre filled syringe production line is mainly used for the unpacking, tearing, filling and pluging of disposable syringes in honeycomb trays in pharmaceutical plants. It's mainly for the production and packaging of various aseptic products such as vaccines, monoclonal antibodies, small molecule heparin, insulin and hyaluronic acid.

Adopts servo control system&Full automatic

No bottle no filling, no bottle no capping

PLC automatic control

The Buyer's Guide

Injection Solution: The Complete FAQ Guide In 2025

Do you know some people prefer injection solutions over solid-dose medication like tablets? This is because injection solution is directly injected into the body without requiring the need to ingest medications.

Today, injection solution is considered safe and is used for patients belonging to all age groups. This is because the injection solution has better bioavailability and acts faster. However, for administering injection solutions, proper skill and certification are required.

But how to define an injection solution? Are you a health practitioner or general audience seeking answers about the injection solution? Then you are at the right place. In this blog, we will explain the injection solution, its kind, importance, and all other necessary details.

1.What is an Injection Solution?

Injection Solution

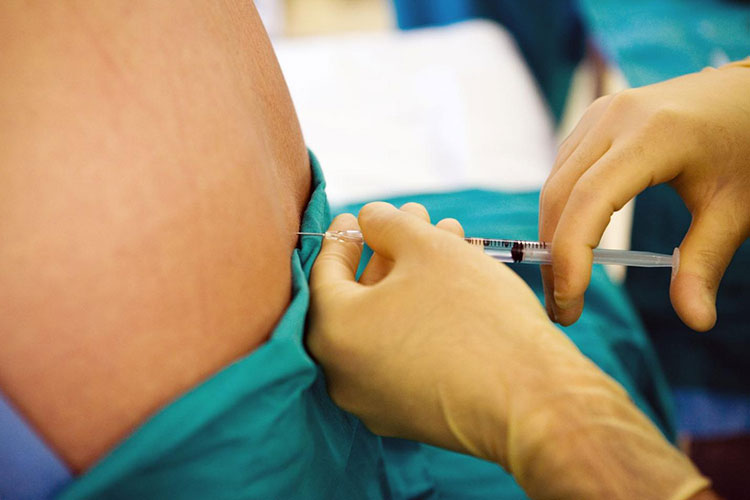

An injection solution is a special medical and cosmetic intervention. It is a solution prepared by formulating different ingredients like solvents, excipients, and active ingredients. A needle and syringe are used to directly inject different types of injection solution into the specialized tissues like muscles, skin, and veins.

Injection solution is also defined as sterile liquid therapeutics consisting of drug medication and different types of solvents like water and alcohol. The purpose of injection solution is treatment, nutritional support, diagnostic, and also prophylactic.

The injection solution is important in the medical field due to its accurate and efficient approach to dispensing different medications and nutrients directly into the bloodstream or other tissues of the body.

2.Why Injection Solution is Popular?

Injection solution offers a distinct advantage over the drug delivery methods so it is quite popular in medical practice. The popularity of this medication stems from its flexibility and rapid onset of action. Here are some important advantages of the injection solution.

Rapid Onset of Action

Rapid Onset of Action

Injection solution has an immediate and fast onset of action. It is particularly useful in emergencies like cardiac arrest, or severe pain, where rapid response is important. The oral medications are slow and first metabolize in the liver before they start acting. The injection solution does not go to the digestive tract instead it dispenses ingredients directly to body tissues.

Bypassing Digestive Tract

Bypassing Digestive Tract

Numerous drugs are not formulated as oral medications because these are disintegrated in the acidic pH of the stomach or the liver metabolizes these drugs. It is called first-pass metabolism and a major concentration of a drug is released from the body without any therapeutic effect. Injection solution bypasses first-pass metabolism, and as a result, a higher amount of drug reaches the targeted site.

Accurate Dosing

Accurate Dosing

Injection solution is very crucial for drugs with narrow therapeutic windows because injection solution delivers accurate dosing to the intended site. This gives the required therapeutic effect without causing major adverse reactions. It increases the efficacy of treatment and ascertains patient safety.

Targeted Therapy

Targeted Therapy

Injection solution is directly introduced into body sites like joints, spinal cord or cancerous tissues. This targeted delivery method reduces body exposure and limits the chances of adverse reactions while making therapy more effective.

Aptness for Non-Oral Routes

Aptness for Non-Oral Routes

For patients, who have nausea or vomiting or cannot swallow medications by mouth, injection solution is crucial because it ascertains they take appropriate therapy without going for oral route.

Versatility and Flexibility

Versatility and Flexibility

Different substances can be accommodated in the injection solution. Both water-soluble and fat-soluble substances are formulated as the injection solution. Even bigger molecules like hormones and smaller molecules like glucose and sodium chloride are included in the injection solution. Thus the versatility of injection solution makes it applicable in a broad range of medical sectors.

3.What are Different Routes of Injection Solution?

Since injection solution is injected into different sites and there are different kinds of injection solution, hence there are different routes of injection solution. We are detailing these routes one by one below:

Intravenous Route

Intravenous Route

This type of route involves injecting a solution directly into the vein of the patient. This injection solution enters into the bloodstream of the patient, hence it allows for maximum drug absorption and this leads to fast drug response.

The common sites for the intravenous route include the backside of the hands, the elbow pit, and the front side and back side of the lower arm

Intramuscular Route

Intramuscular Route

This route of injection solution involves the patient's muscles. The muscles are rich in blood vessels, which aids in quick absorption of therapy. The injection solution consisting of vaccines, antibiotics, and hormones is injected into the muscles of patients.

The most frequent sites for the intramuscular route are hip (buttock area), shoulder muscle, outer thigh muscle, and upper arm area

Subcutaneous Route

Subcutaneous Route

In this route, an injection solution is administered just below the skin into fatty tissues. These fatty tissues are present down the skin tissue and above the muscles. Smaller injection needles are used for administering subcutaneous injections. The medications are absorbed more slowly than the intramuscular route as there is a limited supply of blood vessels in subcutaneous tissues.

However, it is not painful and less risk of adverse reactions is associated with the subcutaneous route. It is used for administering insulin, blood thinners, painkillers, and fertility drugs.

For subcutaneous routes, the most frequent injection administration sites are below the belly button area, outer thigh just above the knee, and back side of the upper arm

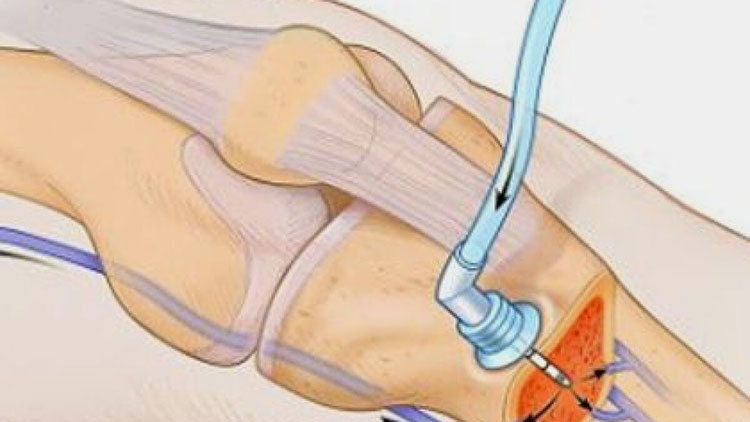

Intraosseous Route

Intraosseous Route

In this route, an injection solution is administered in the veins of bone marrow tissue. A specialized needle is used to puncture bone marrow to reach the veins. The drug is immediately absorbed into the bloodstream because bone marrow has a much larger blood supply.

The intraosseous route is only used in case of emergencies when it is difficult to access the intravenous route like in case of serious injuries, poisoning, electrocution, stroke etc. It is a fast way to give different fluids, medications, blood plasma and other related products.

The area just below the knee, lower leg, and forearm are the common sites for an intraosseous route.

Intradermal Route

Intradermal Route

It involves injecting medication just below the skin. A small bump known as bleb or wheal is created for administering intradermal injection solution. Out of all injection types, this route has the longest absorption period. It is used for tuberculosis diagnosis.

The inner side of the upper arm and between the shoulder blades are the frequent delivery sites for intradermal routes.

Intrathecal Route

Intrathecal Route

In this route, injection solution is delivered into the spinal cord and the substances in this injection solution directly go into the cerebrospinal fluid. It delivers medication to the central nervous system by bypassing the blood-brain barrier. Different injection solutions like spinal anesthesia and analgesics are directed by this route.

The lower back and neck area are two frequently used sites for administrating intrathecal injection.

Intraarticular Route

Intraarticular Route

This route involves dispensing injection solution directly into the joint. It has the benefit of treating local joint disorders and decreasing systemic adverse reactions. It includes medications for treating joint inflammation and arthritic disorders.

The frequent sites for the intraarticular route include the shoulder joint and knee joint.

4.What are Different Formulation of Injection Solutions?

There are numerous range of formulations in the injection solution. These formulations make different types of injection solutions. Let’s explore some common formulation of injection solutions.

Saline Solution

Saline Solution

These contain normal concentration or half concentration of sodium chloride that is 0.9% and 0.45%, respectively. This injection solution is prepared by dissolving sodium chloride in water. It is used for treating fluid replacement and electrolyte imbalance.

Dextrose Solution

Dextrose Solution

This type of injection solution has 5% to 50% dextrose dissolved in water. This injection solution is used for treating hypoglycemia and dehydration. It offers a swift means of energy and calories.

Lactated Ringer’s Solution

Lactated Ringer’s Solution

This injection solution has a balanced concentration of all important elements like sodium, potassium, and calcium along with lactate compounds. It is mainly used for curing fluid resuscitation or electrolyte imbalance.

It has the same concentration of electrolytes, as is found in blood plasma, thus is useful for patients experiencing nausea or vomiting or who have undergone surgery.

Insulin Solution

Insulin Solution

It contains insulin in different concentrations and is used for treating diabetes. It controls blood sugar levels in patients. It is available as a rapid-acting, intermediate-acting and long-lasting injection solution to meet patient requirements for insulin.

Antibiotic Solution

Antibiotic Solution

This injection solution contains different types of antibiotics and is used as a therapeutic intervention for treating bacterial infections. If oral antibiotics do not show any effect or are portly absorbed into the bloodstream then this injection solution is used as targeted antibacterial therapy.

Vitamin Solution

Vitamin Solution

This solution has vitamins in different concentrations for supplementing nutrients and also for medical purposes. This injection solution is crucial in treating vitamin deficiencies as well as treating different medical disorders that need higher doses of vitamins.

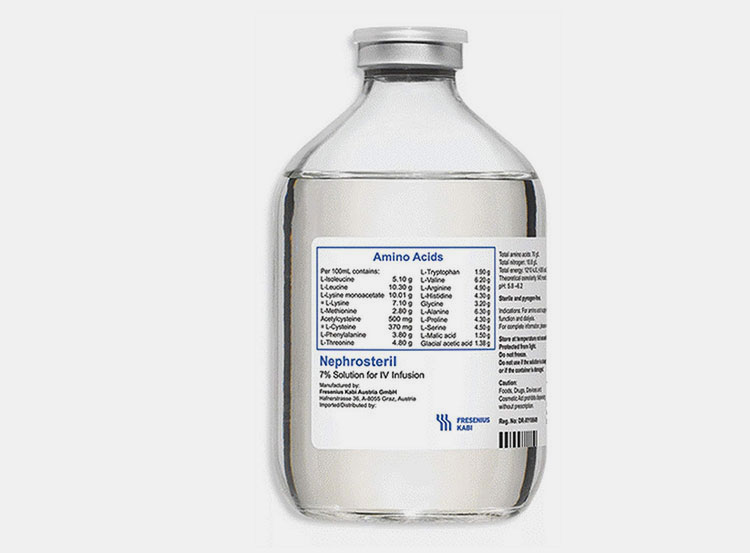

Parenteral Nutrition Solution

Parenteral Nutrition Solution

This type of injection solution formulation has a balanced proportion of all essential micronutrients like glucose, amino acids, and fatty acids. It is used for treating malnutrition or malabsorption.

5.What are the Uses of Injection Solution?

As there are different types of injection solutions, so there are diverse uses of injection solutions across different medical sectors. This injection solution is utilized for diagnostic, therapeutic, and nutritional purposes. Some of the uses of the injection solution are penned below:

Therapeutic Use

Therapeutic Use

Due to its fast absorption and onset of action, injection solution is widely used for therapeutic purposes. This solution is directly fed into the body tissues and is not ingested by mouth, hence is used for delivering drugs like painkillers, steroids, chemotherapy agents, blood thinners and many more.

Nutritional Use

Nutritional Use

It is quite common in the nutritional sectors as the injection solution readily delivers different types of macro and micronutrients to patients who cannot absorb nutrients via oral or enteral route. The injection solution is used for treating nutritional imbalances in patients with gastrointestinal disorders.

Contrast Imaging Use

Contrast Imaging Use

The injection solution is used for diagnostic purposes like in contrast imaging. This diagnostic injection solution has an iodine contrast agent that increases the visualization of different body parts like blood vessels, organs, and tissues.

Allergy Diagnostic Use

Allergy Diagnostic Use

The intradermal injection solution is also utilised in diagnosing allergies. A small quantity of allergens is administered in the body and with this testing, the body's response to allergens is measured.

Cosmetic And Aesthetics Use

Cosmetic And Aesthetics Use

Yes, the injection solution has also found its use in the cosmetic industry. Different types of hyaluronic injections are administered to the skin to prevent wrinkling, enhance beauty features and decrease aging of the skin.

Anesthesia Use

Anesthesia Use

The injection solution has anesthetic agents and is administered by intravenous and epidural routes. It has a use in inducing anesthesia during surgeries, delivery, and other treatment procedures.

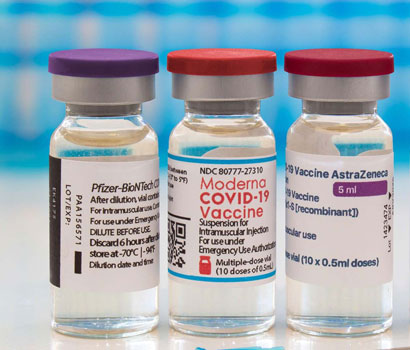

Vaccination and Immunization Use

Vaccination and Immunization Use

Different injection solutions contain vaccines and are used for increasing the immune response and to induce passive immunization in case of viral infections like influenza, measles, mumps, hepatitis, etc.

6.Are There Any Risks Associated with Injection Solution?

Yes, there are many risks associated with the injection solution that vary from patient to patient, type of medication and the injection route. Some of these risks associated with the injection solution are as follows:

Allergic Reactions

Allergic Reactions

Certain components in the injection solution cause allergic reactions in some patients. These allergic reactions can induce itching or rashes as well as life-threatening anaphylaxis reactions that could be fatal.

Infection

Infection

Since the injection solution is directly introduced into the body, it does not induce an immune response. If injections are not sterile or proper aseptic cautions are not taken then there is a chance of introducing microbes into the body which could cause life-threatening infections like AIDS.

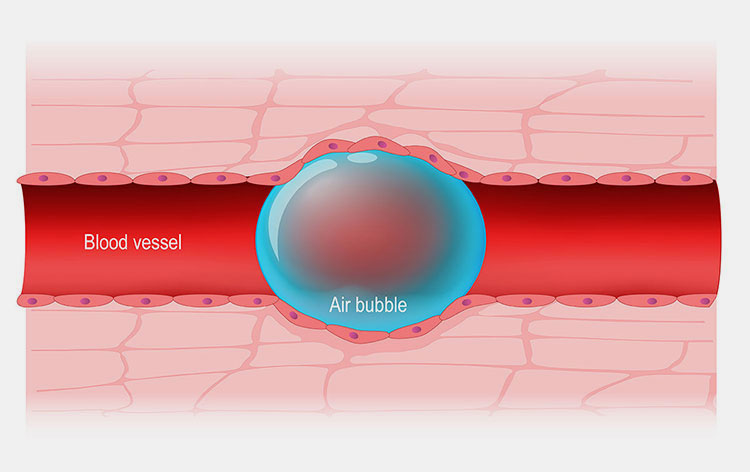

Air Embolism

Air Embolism

It is the phenomenon in which air is introduced into the blood vessels that could cause blockage in the supply of the blood. It could be harmful to patients in some cases and other cases, symptoms are resolved on their own.

Medication Error

Medication Error

If a dose of injection solution is not measured properly, or medication is not read properly it could lead to administering an incorrect dose or medication that could have severe consequences for the patients.

Phlebitis and Thrombophlebitis

Phlebitis and Thrombophlebitis

If intravenous injection solution is not administered properly, it could cause thrombophlebitis (inflammation of the veins). Sometimes, the medication contains irritants that deteriorate the walls of veins causing pain and swelling and in some cases creation of blood clots.

Tissue Damage

Tissue Damage

It is also an uncommon risk associated with the injection solution. If medication is too acidic or alkaline it could cause tissue damage or death that is painful.

Drug Interactions

Drug Interactions

If a patient is taking other medications, then injection solution can interact with them, leading to side effects. Proper caution should be taken to avoid interaction between other medications and the injection solution.

Nerve Damage

Nerve Damage

If an injection solution is introduced in the areas, where large networks of nerve are present then it could result in nerve damage. Symptoms of nerve damage range from temporary or permanent loss of sensation or motor function and severe pain.

7.How Injection Solution is Manufactured?

Manufacturing of Injection Solution

Stringent aseptic conditions are required for the manufacturing of the injection solution. These aseptic conditions ensure the sterility and efficacy of the treatment. Let’s explore the manufacturing steps of the injection solution.

| Formulation Development | First, the formulation is developed having the right concentration of active ingredients, excipients, and solvents. This formulation's ingredients must be compatible with each other and stable. Furthermore, the formulation should achieve the desired therapeutic effect without causing side effects. |

| Ingredients Preparation and Compounding | In these steps, raw ingredients are weighed and dissolved in appropriate solvents like water for injection. Compounding should be carried out in a clean room and under controlled conditions. |

| Washing and Ultrasonic Cleaning | First water is sprayed on the different injection solution packaging containers like vials, ampoules, and bottles. The containers are cleaned by passing ultrasonic waves. Afterward, the inner and outer walls of the containers are flushed with water. These steps are effective in thoroughly cleaning different injection solution packaging containers by removing debris and dust. |

| Drying | The containers are dried by preheating step. The dried containers are dried or autoclaved. Heat is used for drying and removal of microbial contaminants from the containers. |

| Sterilization | Sterilization is an important step that ascertains the injection solution is free of any microbial contamination. Commonly heat sterilization is performed for injection solutions that can tolerate high temperatures. Chemical sterilization uses chemical agents for sterilization but it is less commonly used because of possible chemical contamination. |

| Filling | The injection solution is loaded into sterile packaging containers like vials, ampoules or prefilled syringes. This step is executed under aseptic conditions to eliminate chances of contamination. Laminar flow hoods are used for this purpose. Before filling, the nitrogen is filled in the containers. This step is called nitrogen prefilling. Afterward, numerous sets of filling nozzles are employed for filling precise amounts of injection solution in the containers. After filling, nitrogen is again filled in the container in a step called nitrogen post-filling. |

| Sealing and Capping | Upon filling, the next containers are properly sealed to uphold the sterility of the injection solutions.

The vials are sealed using rubber stoppers and aluminum cap crimping while the glass of ampoules is melted for sealing. |

8.What are various types of injection solutions?

The types injection solution is composed on the following categories.

Medical Injection Bottle BFS Line

AIPAK Engineering's Medical Injection Bottle BFS Production Line

This is an aseptic medical injection bottle BFS production line which is designed to bring pharmaceutical sensitive items packaging in a controlled manner. The production line is capable of filling of injection solution from 1 to 5 ml of volume accurately.

This production is highly efficient showing high turnover due to high speed & high volume.

Composition of BFS injection solution type

BFS injection solution type

The composition of the BFS injection solution included with lightweight plastic containers that are easy to store and easy to use. This composition gives an extended and safe life to the medicine. This is mainly composed of different shapes and sizes with various flexibility ratio such as squeezable to rigid. The material used in this production line is involved with PP, PE, and HDPE.

Ampoule Injection Solution Line

AIPAK Engineering's Ampoule Injection Solution Filling Line

This is a special way for handling the filling and sealing of ampoules which range from small to medium volume i.e. 1 to 20ml effectively.

A highly regulated unit where there is no ampoule, there won't be filling.

This is an enclosed and precisely designed production line that ensures you that the entire process has taken place following modern techniques with high speed and high-quality processing.

Composition of ampoule injection solution type

This is the unique type which is composed of either plastic or glass ampoules that are used for single unit medication.

The plastic ampoules are made from polypropylene polymer which is formed by melted them and acquiring the shape like ampoule. This can be used by inserting the needle for sucking the injection solution.

The glass ampoule is commonly used to preserve the sample and store for a longer time. This is the most traditional way of dispensing medicines where you can snap the tip to obtain the injection solution.

It is sealed by using high heat which melts the top of ampoule and creates a hermetic sealing. There is always some space is filled with inert gas like nitrogen for presvering and preventing the injection against unwanted factors

Vial Powder Injection Solution Line

AIPAK Engineering's Vial Powder Injectable Production Line

A complete set of equipment which is designed for vial powder injectable filling provides fast and reliable processing. The entire set of equipment is constructed with SUS 316 which promises refined operability with no chances of cross-contamination, hence you can achieve high cleanliness and safe production.

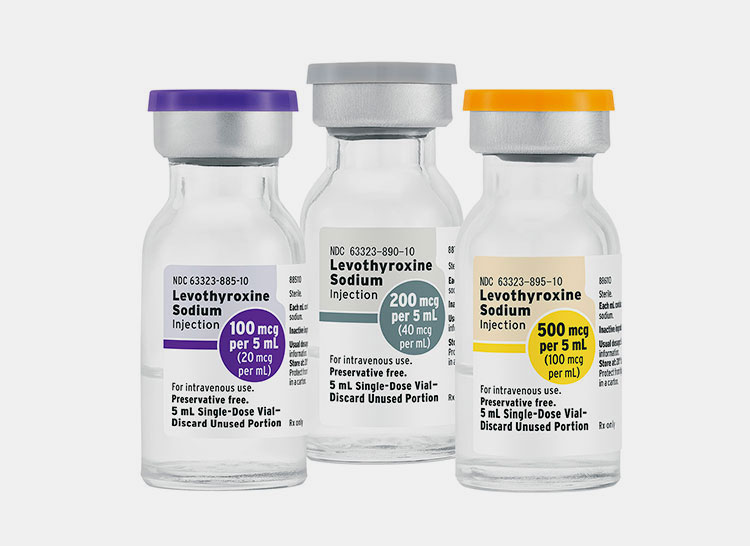

Composition of the Vial Powder Injection solution type

A sterile preparation of dry powder injectable into vials under industrial grade machines that is regulated with high hydraulic system. Therefore safe and precise filling of powders are taken place in the vials with precise welding for firm sealing i.e cork, steel frame and a cap.

The vials are mostly made up of transparent glass with optimized quantity of powder with controlled or no wastage.You just need to insert the needle for incorporating of liquid for miing of powder content . this is extremely hygienic and long lasting method compliant with high sanitization and quality product.

Liquid Vial Injection Solution Line

AIPAK Engineering's Liquid Vial Production Line

This production line is mainly recommended for the automatic filling of liquids in the vials.

This is the most commonly used production line in pharmaceutical industries for high-quality and clean production of medicines.

The machine is ideal as it gives a simple processing protocol with the least footprint or space requirement.

Composition of the Liquid vial injection solution type

Liquid vial injection solution- Simtra biosolution

The is type of injection solution line is responsible for making of liquid vials injection solution with a dedicated high speed mechanism. This is mostly used in a clinical setup medications that are composed of either vaccines, monoclonal antibodies, chemotherapeutic medicines and other.

A glass bottle vials varies in sizes of 2 ml till 100ml in liquid injection solution and mainly filled by rotary or peristaltic pump into the vials. You can puncture it by using injection and can use it for dose administration directly.

Pre Filled Syringe Injection Solution Line

AIPAK Engineering's Pre-Filled Syringe Production Line

In the medicinal and research fields, a prefilled syringe production line is showing high demand as it is a complete packaging of filling and packing injection solution in an aseptic environment.

For example vaccines, anti-coagulants, monoclonal antibodies, anti-diabetic therapies, etc.

This production is highly useful and ideal in the dispensing of precise and accurate volumes of drugs in a safe manner.

Composition of the Pre-Filled Syringe injection solution type

Pre-filled syringe

The composition of pre filled syring injection solution is basically depended on pre-made product which is ready to administered. It is prepared in a aspectic environment using a pre-filled syring production line with regulated pressure and temperature.

The components of pre-filled syring are included with a plunger, stopper, barrel and needle. All components must be fitted properly to secure the injection solution till end user.

9.Is There any Difference between Injection Solution and Injection Suspension?

Injection solution and injection suspension both are introduced into the body by the injection, still, there are some signification differences between these two mixtures.

| Features | Injection Solution | Injection Suspension |

| Picture |

Injection Solution |

Injection Suspension |

| Definition | An injection solution is a uniform mixture in which pharmaceutical ingredients are fully dissolved in the solvent for example water or alcohol. | It is a heterogeneous mixture and solutes (active agents) do not completely dissolve in the solvent. |

| Appearance | The injection solution is clear or translucent. | It is opaque or cloudy. |

| Particle Presence | No particles are seen in the injection solution. | Tiny particles settle at the bottom of the injection suspension. |

| Routes | Usually administered through intravenous, intramuscular, or subcutaneous routes. | It is administered through intramuscular and subcutaneous routes. |

| Onset of Action | It has a fast onset of action. | It has a slow onset of action. |

| Examples | Normal saline, dextrose solution, insulin solution | Depot formulation of drugs |

10.What are Important Considerations for the Injection Solution?

The injection solution is a significant form of medication, so care should be taken while manufacturing and administering the injection solution for efficacy and safety. Here are some important consideration points for injection solution:

Sterility

Sterility

It is the most important factor when manufacturing the injection solution because of contamination of microbes. The vials, ampoules, and syringes must be sterile to prevent infection risk.

Dosage Accuracy

Dosage Accuracy

The dosing accuracy of the injection solution is crucial for the intended drug effect. Overdosing or underdosing of active ingredients in the injection solution can cause lethal side effects or decrease drug response, respectively. For this properly calibrate devices and adhere to precise dosing processes.

Compatibility

Compatibility

The route of administration should be suitable for the delivery of the injection solution. Moreover, different medications in the injection solution should be compatible with each other. Proper compatibility studies must be carried out to avoid drug-drug interactions in the injection solution.

Stability

Stability

The injection solution must be stored properly to preserve its potency and efficacy during its consumption life. Therefore, it is critical to carry out stability tests for estimating suitable storage conditions and expiration periods.

Regulatory Compliance

Regulatory Compliance

The injection solution must adhere to regulatory guidelines imposed by the FDA (Food and Drug Administration) or EMA (European Medicines Agency). Moreover, maintaining and upholding good manufacturing practices protocols is a means to achieve quality and safety standards during the manufacturing processes.

Conclusion

The injection solution market is expanding because of health-related disorders and increased demand for injections. An injection solution is the preferred means of delivering medication in emergencies or when oral administration is not possible. High sterilization and indispensable handling are ensured during each step of manufacturing, formulation, packaging, and administration of the injection solution. Therefore, if you are planning to focus your efforts on manufacturing the injection solution, we would suggest getting in contact with companies’ experts in this field. We, AIPAK Engineering, are an answer to all your questions about manufacturing and packaging injection solutions. Please contact us now to procure machines related to injection solutions.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours