Hepatitis B Vaccine Production:The Complete FAQ Guide In 2025

Have you ever heard of hepatitis B and hepatitis B vaccines? You may not, but you may have get vaccinated. Hepatitis may get a series of bad influence for you and your families. You should know more hepatitis B vaccine and its production to get your most suitable vaccines.

What is hepatitis B production process? What are the main challenge you may meet for hepatitis B vaccine production? How people caught hepatitis B and how to avoid them? How about the current hepatitis B vaccine production and what are the future trend of hepatitis B vaccine production? Here are the answers about hepatitis V vaccine production! Come on and have a reading!

1.What Is Hepatitis B?

Hepatitis B-Sourced:cdc

Hepatitis B is a kind of virus which makes the great affect for your liver. It may have no obvious influence for patients daily life. And it makes the lasting latency in people’s body for decades years later. It may lead disease like liver cancer, liver inflammation and so on.

Hepatitis B gets spread mainly from blood, body fluids and so on. For people with weak immune system, hepatitis B is easy to affect them. There is still the condition of people dead from this inflection and the chance of getting inflected is so high. You should make efforts for the defending of this disease.

2.What Is Hepatitis B Vaccine Production?

Hepatitis B Vaccine Production-Sourced:bocsci

To make the defending of hepatitis B virus, you should inject the hepatitis B vaccine which made of the protein that get from surface of virus. The production of hepatitis B vaccine get the surface protein and get them into the yeast cells. The many protein get from surface of virus are the main raw material for hepatitis B vaccine production.

The production of hepatitis B vaccines required the complex and standard manufacturing process. The production of hepatitis B vaccine covered the process of bacteria developing, sterilization, mixing and so on. For the effective and high qualified hepatitis B vaccine production, every steps are important.

3.What Are The Types Of Hepatitis B Vaccine?

Here are different types of hepatitis B vaccines. And there are the main types of hepatitis B vaccines.

According to vaccine speciality

Monovalent Hepatitis B Vaccine

Monovalent hepatitis B vaccine is the type of vaccine which makes the special work for hepatitis B virus. It has different type with content little change for different age group. And it is the common vaccine type in market.

Combination Hepatitis B Vaccines

Combination Hepatitis B Vaccine-Sourced:drugs

Combination hepatitis B vaccine makes the versatile work with the hepatitis B vaccine and other types of vaccines. And you may find the common combination with DTP, HIB, IPV and so on.

According to protecting group

Hepatitis B vaccine for all age

Engerix-B-Sourced:medicomart

Engerix-B and Recombivax HB are the versatile hepatitis B vaccine which makes the protecting for infants, children and adults. It is reliable and effective and can serve people of different group. You may find its widely use for hepatitis B vaccination.

Hepatitis B vaccine for adult

Heplisav-B-Sourced:medpagetoday

Heplisav-B and PreHevbrio are the hepatitis B vaccine which makes the special protection for adult. The two vaccines are the vaccines which make the great protection for adults. There are also Twinrix which makes the great protecting for adults from hepatitis A and hepatitis B.

Hepatitis B vaccine for infants

Pediarix and vaxelis are the kind of vaccine which makes the versatile protection for adult from diphtheria, whooping cough, tetanus, polio and so on. This kind of vaccine makes the effective and efficient protecting for infants.

4.What Is Hepatitis B Production Process?

Hepatitis B production has complex production process. There are many steps which should all be performed with high accuracy and high standard.

Material preparing

You should first prepare the material for hepatitis B production. After the getting of your raw material, you should then screen, amplify and preserve the microorganisms for the virus strain manufacturing. You should make sure the high quality of your raw material which is the base of your high qualified hepatitis B vaccines.

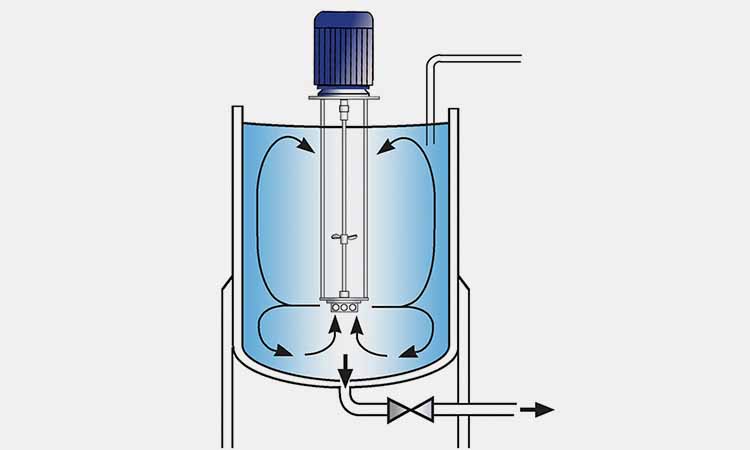

Fermentation

Fermentation-Sourced:fermentorchina

Fermentation is a process which makes the protein and enzymes for your hepatitis B vaccines. It is essential in manufacturing the antiviral medicines, monoclonal antibodies, cells, enzymes, and recombinant proteins.

Cell harvesting

Cell Harvesting-Sourced:facellitate

Cell harvesting and cell lysis are the common way for getting the cell for the better purity and production scale. Centrifugation is the most common way for the cell harvesting. You should pay attention to the high speed contrifugation work as it may hurt the cell group.

Protein purification

Protein Purification-Sourced:biocompare

Protein purification is the process which divides a type of protein or a group of protein from complex mixture. Protein vaccine has the wide applying in hepatitis A, hepatitis B vaccine, diphtheria, tetanus, pertussis and so on. For the protein hepatitis B vaccine, protein purification is the important process.

Chemical modification

Chemical modification in vaccine makes the modification for macromolecules. There are phosphorylation, ubiquitination,lipidation, glycosylation, methylation, and proteolysis as the common chemical modification methods. You may also apply chemical modification for enzymes besides protein for your hepatitis B vaccine.

Formulation

Formulation-Sourced:news-medical

The formulation is the core of your efficient and safe hepatitis B vaccines. You should make the standard tests for the getting of the suitable hepatitis B vaccine formulation. The formulation should also test many times for the efficacy and safety prove.

Antigens producing

Antigens Producing-Sourced:cnbc

The next step of hepatitis B vaccine production is to produce the antigens. You can apply fermentation as the important process for your large-scale culturing. You should control temperature and PH for the culturing of bacteria and virus.

Inactivating treatment

Inactivating Treatment-Sourced:engineering.tamu

The prepared virus should be inactivated for the safety of further use. You should make the inactivation and verify the inactivation. For this step, there is inactivation tank for the applying. Inactivation is the prove of your safe and effective hepatitis B vaccines.

Emulsify mixing

To make the stable vaccine products, your antigens should be mixed with oil adjuvant. The stable emulsion, either water-in-oil or oil-in-water, is the prove of your high qualified products. The even and uniform emulsifying or mixing work can affect the quality of your products greatly.

Filling and packaging

Filling And Packaging-Sourced:csl

The filling and packaging of your hepatitis B vaccines is the last step of your hepatitis B vaccine production. You should fill your vaccines into sterile container and seal them. The stable and reliable filling and packaging are also essential as your hepatitis B vaccine requires the transporting and storing in many occasions. The labeling can be also made in the process.

Quality control and testing

Quality Control And Testing-Sourced:pillayinternalmed

The quality control and test is the central process which proves the quality of your hepatitis B vaccine products. Besides the safety and efficacy of your hepatitis B vaccine, you should also pay attention to the filling, packaging and other information for the high qualified hepatitis B vaccine products.

Cold chain storage

Cold Chain Storage-Sourced:mesalabs

For the finished hepatitis B vaccines, you should make the reliable storing for the efficacy of the products. The cold chain storage can keep the frozen of products at 2-8℃. You should equip the cold chain storage for your hepatitis B vaccine production work.

GMP compliance design

GMP Compliance Design-Sourced:spice

You should make the reliable design for the hepatitis B vaccine manufacturing process. You should make the strict zone district for the production area like liver virus area, inactivation area, clean area and so on.

5.What Is The Manufacturing System Applied For Hepatitis B Production?

The manufacturing system applied for hepatitis B production isn’t complex. Here is the common manufacturing system.

Core production system

Strain/virus strain preparation system

Strain/virus strain preparation system is the system which screens, amplifies and preserves highly immunogenic pathogenic microorganisms, bacteria or viruses. You may apply the equipment like strain library, cell culture chamber, biosafety cabinet, liquid nitrogen tank and so on or the strain recovering, purity detecting, master seed batching and so on in the system.

Large-scale culture system

Large-scale Culture System-Sourced:actip

Large-scale culture system makes the industrial production of antigens. You may apply fermentation tank, centrifuge and so on for the work of this system. In this process, you should control the temperature, PH, oxygen level for the great quality products.

Inactivation treatment system

Inactivation Treatment System-Sourced:ritaibioreactor

You may have the safety ensured from inactivation treatment system. It inactivates pathogens and retains immunogenicity. You may apply inactivation tank, inactivator and so on for the sanitary and inactivation prove.

Emulsification mixing system

Emulsification Mixing System-Sourced:silverson

Emulsification mixing system helps mix the inactivated antigen with the oil adjuvant to form a stable emulsion. You may apply high-pressure homogenizer, emulsification tank, adjuvant preparation tank as the main equipment for this system.

You may take emulsification temperature, speed and particle size uniformity detection as the important factor for the quality prove. There are also high pressure homogenizer and such equipment for your emulsify mixing.

Filling and packaging system

Filling And Packaging System-Sourced:healthcarepackaging

The filling and packaging of vaccines should be more careful for the hygiene and effect prove. Here you may apply fully automatic filling machine, capping machine, labeling machine and packing line for the vaccine filling and sealing in the sterile containers. Here are automatic filling and capping machine for your use. You may check the injection solution here for the reliable and smooth work here.

Quality control system

Raw material testing

The great material is the base of your effective hepatitis B vaccine production. The first step of the quality control is to make the comprehensive test for your raw material. You should test the virus purity, adjuvant composition, sterility of culture medium and so on.

Production process monitoring

The monitoring in hepatitis B vaccine production is also important. In the process of hepatitis B vaccine production, you should make the intermediate inspection for quality like inactivation effect, antigen concentration and emulsification stability.

Finished product inspection

Finished Product Inspection-Sourced:vitronic

For the finished hepatitis B vaccines, you should make the full test about the safety, efficacy and stability of your products. And the tests for the three factors cover sterility test, abnormal toxicity test, animal challenge test, antibody titer determination, accelerated aging test, shelf life verification and so on.

Laboratory equipment

You should apply the high qualified laboratory equipment for the high qualified hepatitis B vaccine production. There are PCR instrument, ELISA detection system, cell culture equipment and animal experimental facilities as the important equipments for quality prove.

Auxiliary facilities

Pure water and steam system

Pure Water And Steam System-Sourced:tsaprocessequipments

Pure water and steam system helps make the sanitary prove for your hepatitis B vaccine production. Pure water and steam system can provide the purified water for cleaning and preparing. There are purified water system for you to take care of this work.

Air purification system (HVAC)

Air purification system can make the deeper purifying prove for your hepatitis B vaccines production. You should apply HVAC in the fermentation area of filling area for the air purifying work.

Sterilization equipment

Sterilization Equipment-Sourced:getinge

Sterilization equipment is applied for the sterilizing of raw material, vaccine products or container. There are wet heat sterilizer, dry heat sterilization tunnel and such equipment as the important sterilization equipments.

Waste treatment system

The waste comes form the hepatitis B vaccine production makes the waste in the manufacturing process. The great dealing with the waste can make the great protect for your environment and your products quality.

Automation control system

Automation Control System-Sourced:mikrodev

You should apply PLC and SCADA system for the improving of automation level of your hepatitis B vaccine production road. The high automation level refers to the less mistake and higher efficacy.

6.What Are The Main Challenge You May Meet For Hepatitis B Vaccine Production?

In the production for hepatitis B vaccine, here may exist some challenges. And here are the main challenges you may meet.

Cost and accessibility

Cost is the important factor you should consider while producing the hepatitis B vaccines. The low cost of your hepatitis B vaccine means the better accessibility. And the great accessibility makes the better serve for people all over the world.

Vaccine storage and stability

Vaccine storage and stability-Sourced:news-medical

Vaccine storing is the important thing you should consider in your hepatitis B vaccine production. Cold chain storage is the thing you needed for the hepatitis B vaccine transporting to the topical and remote area.

Vaccine hesitancy

Vaccine Hesitancy-Sourced:news-medical

Vaccine hesitancy is also the thing you should consider for your hepatitis B vaccine production. The wrong information and skeptcism of hepatitis B vaccines may lead the problem for the global vaccination work.

7.How DoesThe Production Process Of The Hepatitis B Vaccine Evolve Over The Years?

Hepatitis B vaccines makes the consistent evolving over the years. Here are the production process of hepatitis B vaccines.

Hepatitis B Vaccine Evolve-Sourced:nephroplus

Early production

The early production of hepatitis B vaccines makes the extracting of virus from patient’s blood. There is the potential risk of having vaccines contaminated. The small production scale and supply problem promotes the abandoning of this hepatitis B producing way.

Recombinant technology

Recombinant technology makes the higher efficient producing and lower pollution risk for hepatitis B vaccine production. The recombining of DNA technology makes the yeast cell vaccine production possible. This can also make the higher consistency of your hepatitis B vaccines.

New innovation

With the developing of cell culture technology and vaccine manufacturing process, the production of hepatitis B vaccines is more efficient and more reliable. It can now be more accessible and more feasible for people all over the world.

8.How About The Current Hepatitis B Vaccine Production?

Current Hepatitis B Vaccine Production-Sourced:english.ahram

How about the current hepatitis B vaccine production? There is a large group of people which is infected with the hepatitis B virus. Nowadays, the infection of hepatitis B virus is more than 1.5 million on world. There are 2 million people on world which is infected with hepatitis B virus on world chronically.

The applying of hepatitis B vaccine on world makes little affect as the hepatitis B has the same incidence rate with ten years ago. For the defending of hepatitis B virus, there is the great need of hepatitis B vaccine. As the coverage rate of hepatitis B vaccine is only 46%, there is the need of large hepatitis B vaccine production for the goal in 2030 of covering 90% vaccination rate.

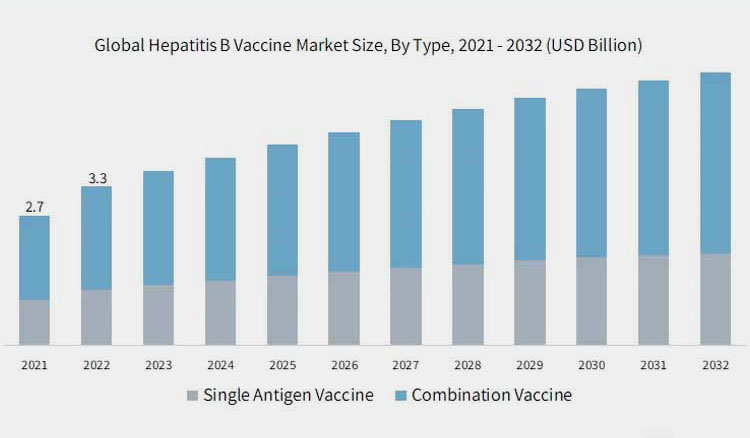

9.What Are The Future Trend Of Hepatitis B Vaccine Production?

Future Trend Of Hepatitis B Vaccine Production-Sourced:gminsights

The developing of hepatitis B vaccine production will benefit us in a comprehensive way. What are the future trend of hepatitis B vaccine production. First of all, the effect and consistency of hepatitis B vaccine will be improved greatly. The technology developing will make the better hepatitis B vaccine production.

Second, the production of hepatitis B vaccine will be larger. For the goal of eliminating the hepatitis B virus and have the protection for people all over the world. It will gave the large production of hepatitis B vaccines for the great goal. And the hepatitis B vaccines production will make more efforts for the infants vaccination.

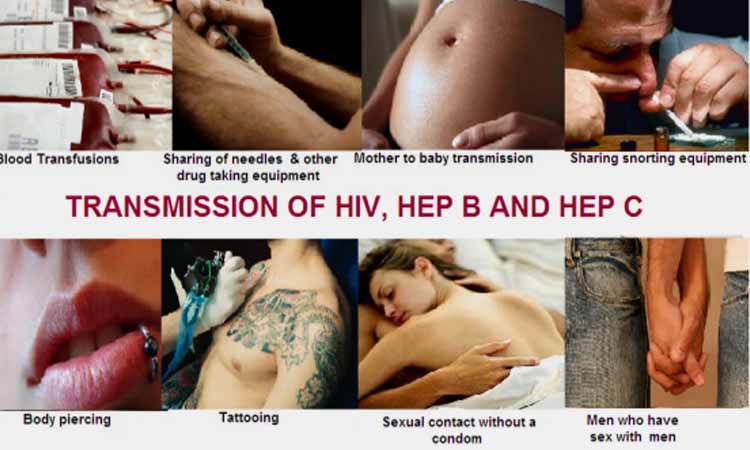

10.How People Caught Hepatitis B And How To Avoid Them?

How people caught hepatitis B and how to avoid them? Here you may check the answers.

Hepatitis B getting

Hepatitis B Getting-Sourced:hepbandcni

Blood contacting

Blood contacting is the most common way for the hepatitis B virus infecting. The casual contact of blood in sharing razor, toothbrushes and so on may lead the inflection. You should avoid the contacting with blood from injection or sharp instrument contacting.

Body fluid

Body fluid can also lead the hepatitis B virus infection. Sex contact or saliva contact can make the transporting of hepatitis B virus for you. You should also take measures for the semen, body fluid and so on.

Baby birth

Baby birth makes the high hepatitis B virus infection rate. Mommy can make the direct transmitting of hepatitis B virus to baby. Infants have the weak immune system, you should make the quick hepatitis B vaccine vaccination for baby.

Hepatitis B vaccine avoiding

Hepatitis B Vaccine Avoiding-Sourced:cdc

Hepatitis B vaccine has the long incubation period and many hepatitis B carriers have no reacting with the virus for decades of years. For the avoiding, you should get the hepatitis B vaccine injection. Besides, in daily life, you should pay attention to the fluid, blood and other contact with hepatitis B carriers or other people.

11.What Should Be Cared Before Taking Hepatitis B Vaccine?

The taking of hepatitis B vaccine is important for people of all age. Here are the thing you should care before taking hepatitis B vaccine.

Allergy identifying

Allergy Identifying-Sourced:okoa

Are you allergic to any material in hepatitis B vaccine? The yeast or lax in vaccine may make the allergy for people easily. Before taking hepatitis B vaccine, you should make clear the potential allergens.

Disease identifying

For people with the weakened immune system or any acute disease, you should consult doctor or hospital for it. There are also the disease which may prevent you from the vaccination of hepatitis B vaccine.

Body condition

Your body condition connects also with the hepatitis B vaccine injection. The pregnant women or women with pregnant plan should avoid the taking of hepatitis B vaccine. Besides, for people who is breastfeeding and plan to breastfeed, the taking of hepatitis B vaccine should be avoided.

Medicine taking

Medicine Taking-Sourced:assemblyresearchmatters

Hepatitis B vaccine may affect the medicine products or supplementary products you are taking. You should also make the careful consulting about the nonprescription medicine, nutritional supplements, herbal products and so on for the better effect of vaccine and your medicines.

Conclusion

Hepatitis B vaccine is the common and efficient vaccine which makes the great help for many people. Hepatitis B vaccine production is the important process which affect the products effect and accessibility. For any problem and question about hepatitis B vaccine, you may contact AIPAK Engineering for consulting!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours