Glutathione Liquid Supplements Manufacturing: The Complete FAQ Guide In 2025

Do you know that you can bolster body health, repair cell damage, improve organ function, and more through glutathione? Are you aware that glutathione liquid supplements are more health-boosting than their capsules?

Due to their higher demand, more and more nutraceutical companies have expanded their production approaches to include glutathione liquid supplements manufacturing. But before jumping straight into this manufacturing, it is a must that manufacturers know how it works, what are instruments involved in this production, its testing measures, and more.

So, to facilitate you and other business firms out there, we have compiled the informative and factual FAQ guide. In this article, all the vital aspects, features, attributes, and workflow will be detailed for your knowledge. Let’s get ready!

1.What is glutathione liquid supplements?

Glutathione Liquid Supplements

Glutathione liquid supplements constitute a very vital ingredient- glutathione. The latter is an antioxidant typically formed in the body cells naturally. It is composed of three amino acids- glutamine, glycine, and cysteine. You can think it of as a master antioxidant.

It offers bucket loads of benefits like reducing oxidative stress and chances of disorders such as diabetes, cancer, and rheumatoid arthritis. It also boosts immunity and fixes liver function.

Glutathione liquid supplements are the type of glutathione supplements in liquid form and are taken orally to boost the levels of glutathione in the body. As it is best to fight off oxidative stress and other associated disorders.

Furthermore, it is also acquiring traction owing to its superior cosmetic and aesthetic benefits. Men and women favor it as it is anti-aging, brightens complexion, and tightens skin.

2.What is glutathione liquid supplements manufacturing?

Glutathione liquid supplement manufacturing

In simple words, you can visualize glutathione liquid supplements manufacturing as a production process in which liquid preparation containing glutathione is produced. It is a set of steps- each equally essential- involved in devising a liquid nutraceutical formulation of glutathione.

Simply put, this industrial process encompasses a wide array of machines, raw materials, techniques (mixing, homogenization, emulsification, filtration), and quality assessment approaches to manufacture safe, stable, efficacious glutathione liquid supplements.

3.What raw materials and ingredients are involved in glutathione liquid supplement manufacturing?

You should know what is present in the glutathione liquid supplements as these ingredients directly affect your health. With a rising fitness mindset, consumers first look and search for components of formulation before taking it.

Hence, we have enlisted some major raw materials and ingredients of glutathione liquid supplements manufacturing below for your information:

First and Foremost: Glutathione

Glutathione- Picture courtesy: Biome probiotic

It is the chief active ingredient in the glutathione liquid supplements. It is obvious that most of the health benefits come from this ingredient. You would find it fascinating that glutathione is present in two different forms in glutathione liquid supplements. These are:

Reduced glutathione- This is the most prevalent type formulated in the supplements. Because it is easily available and low-priced. Moreover, you can easily dissolve it in water-based solutions without following hectic procedures.

Liposomal Glutathione- It is a type of glutathione supplement that is covered by a layer of fat molecules called phospholipids. It boosts higher rates of bioavailability because the fat molecules shield the inner glutathione from the breakdown in the stomach, thus it travels across hostile environments.

Solvent Medium and Vehicle

Solvents- Picture courtesy: Heidolph

They are effective in dissolving the glutathione and other components. Yes, as with other liquid preparations, water is readily used as the solvent. It is because it is readily available, has higher dissolution potential, and is fair-priced. However, you can use other carrier vehicles as well, such as glycerin, lecithin, or ethanol.

pH Adjusters & Stabilizers

pH Adjusters & Stabilizers- Picture courtesy: Justdial

As mentioned above, glutathione is easily oxidized and is more sensitive to pH fluctuations, so there is a need for a stabilizer in this formulation. You can use natural ingredients, for instance, citric acid and vitamin C to provide stability. Vitamin C is the best antioxidant to keep glutathione from degradation.

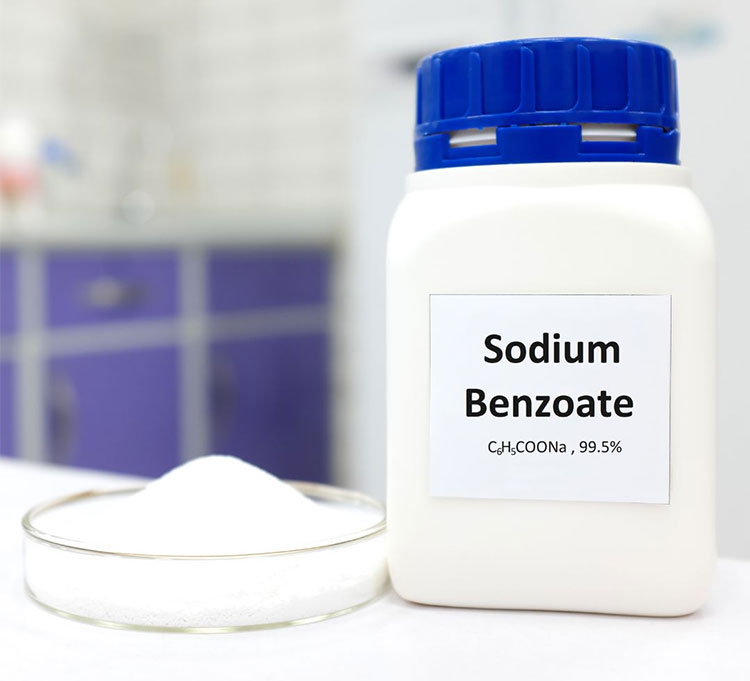

Preservatives

Preservatives- Picture courtesy: Bumblebee organics

Glutathione liquid supplements have a long expiry period. Have you ever wondered about its reason? Well to inform you, there is an ingredient called preservative incorporated in this product, which protects it from molding and bacterial contamination. The most common preservatives are potassium sorbate, sodium benzoate, rosemary extracts, etc.

Flavoring Ingredients

Flavoring agents- Picture courtesy: NOREX

In the case of oral liquid preparation, this supplement has an appetizing and delicious taste to appeal to young consumers. To mask a strong sulfurous taste, manufacturers normally include both natural and artificial flavoring agents, such as orange, lime, vanilla, and berry during production steps. You can add sweeteners to provide it sugary or sweet taste.

Emulsifier

Emulsifier

You might be thinking about the function of an emulsifier. So, to put your mind at ease, they are like helpers that assist in the mixing of liposomal glutathione formulations. This doesn’t allow them to separate from solvents. Some emulsifiers are soy lecithin and polysorbate 80.

4.What type of benefits does glutathione liquid supplements manufacturing bring to businesses and users?

Businesses are in constant pursuit of gaining higher incomes and noteworthy standing in the competitive market. And with more and more consumers seeking health supplements, the business of glutathione liquid supplements is booming.

Consequently, glutathione liquid supplements manufacturing not only provides monetary resources to businesses but also is the source of positive therapeutic effects to users.

Liquid Supplements for Better Bioavailability

Liquid Supplements for Better Bioavailability

More often than not, liquid supplements are said to have better bioavailability. They get absorbed more rapidly in blood circulation. Glutathione liquid supplements are not different in this aspect. Hence, with glutathione liquid supplements manufacturing, you can attain quicker health outcomes than standard pills.

Higher Profits Guaranteed

Higher Profits Guaranteed

You must be aware that the market of glutathione liquid supplements has been on the rise since the dawn of this century, Customers are prioritizing their body and skin health, therefore, the demand for this anti-aging, skin brightening, and, immune boosting supplements is all-time high.

That's why investing in glutathione liquid supplement manufacturing is bound to generate higher profits for businesses.

Best for Diverse Patients Demographics

Diverse Patients Demographics- Picture courtesy: Liposomal.it

Patients find it easier to adopt and include glutathione liquid supplements in their diet. Since, they are easier to consume spoonful or can be mixed in liquids, such as juices. They are good for individuals- such as senior adults and young children- who have a fear of taking pills and often struggle with them. Moreover, people with stomach irritability and digestive issues also favor these supplements.

Boosts Wide Array of Wellness Uses

Wide Array of Wellness Uses

You would be happy to learn that glutathione liquid supplements manufacturing also has in store multiple advantages for consumers. They serve as powerful antioxidants and are the backbone of cellular vitality and immune response. You can take them to detoxify your liver and restore its proper functioning. Also, individuals in far and wide countries use this supplement to prevent skin aging and promote lighter skin complexion.

Formulation Customization

Formulation Customization

Yes, glutathione liquid supplements manufacturing offers the brands a choice to tailor their formulation blends in order to acquire differentiation in the market. For this, they add various flavors and nutrients, for instance, Vitamin C, NAC, Alpha-Lipoic Acid, or CoQ10 during preparation. This provides customers with different options and more sales for businesses.

5.What are available dose types of glutathione liquid supplements manufacturing?

Glutathione liquid supplements manufacturing is available in mentioned doses:

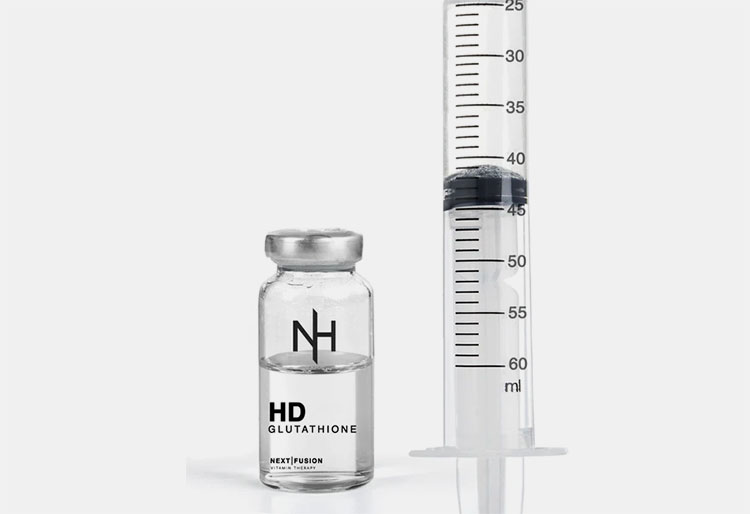

Injectables

Glutathione liquid supplements- Picture courtesy: Burick centre

Glutathione liquid supplements injectables are administered to patients commonly nowadays. This is available to attain an effective and rapid mechanism of action and is mostly designed in dosage concentrations of 200 milligrams to thousands of milligram vials. They are mainly administered using an IV or IM route in the form of drips or bolus.

Oral Liquid Syrup/Drops

Oral Liquid Syrup/Drops- Picture courtesy: Actinovo

These are other common dosage formulations that are available in the viscous form. They are administered either by making volume with water or just by adding a few recommended drops or spoons.

Softgel Capsule

Glutathione liquid supplements- Picture courtesy: Evieskincare

The glutathione liquid supplement manufacturing is also available in softgel capsules. This is mainly used as a daily recommended dose either once daily or prescribed by a medical practitioner for attaining healthy body functions.

6.What are the chief working steps in glutathione liquid supplements manufacturing?

You certainly would have thought about the working stages in glutathione liquid supplements manufacturing. A complete knowledge of these steps guarantees efficiency in managing production.

Hence, we are detailing the diverse working steps of glutathione liquid supplements manufacturing for your information:

Preparation of Raw Materials

Raw Materials- Picture courtesy: Mesoestectic

Before starting the actual manufacturing, first, you should first prepare and select every kind of starting material whether glutathione form, excipients, or, additives. Next, purify and decontaminate every solvent to obtain a sterile formulation.

Recipe Formulation

Recipe Formulation- Picture Courtesy: Centrespringmd

After the above step, now you are required to combine every ingredient, like glutathione, solvents, preservatives, stabilizers, and more according to the manufacturer’s recipe. Also, you should modify pH and the combination of different components in the mixture to ensure better therapeutic results of glutathione and its stability.

Mixing

Mixing- Picture courtesy: Caframo Lab Solution

Now comes the main stage of actual homogenization of ingredients. In this step, you will use various blenders, mixers, and homogenizers to properly distribute the particles in formulation.

Furthermore, if you want to manufacture liposomal glutathione liquid supplements, you’ll have to utilize advanced approaches, such as high-pressure homogenization or ultrasonication to enclose glutathione in lipid carriers or liposomes.

Purification and Sterilization

Purification and Sterilization- Picture courtesy: Röchling Group

Drug authorities mandate that every supplement formulation must be ultra-pure. To fulfill this guideline, nutraceutical sectors utilize modern filtration equipment, for instance, micro-aperture screens or ultrafiltration to filter out every impurity in liquid supplements.

Also, at this stage, you must carry out quality control tests to distribute safe and efficacious products to your customers.

Filling, Sealing, & Labeling

Filling, Sealing, & Labeling

Now the product is ready for packaging. Generally, sterile, dark-colored, and air-proof bottles are used for packaging. Numerous fillers are integrated into glutathione liquid supplements manufacturing for filling precise volumes of products. After that, these bottles are tightly closed with anti-tampering seals and caps.

Finally, you employ labeling equipment to paste or glue FDA-mandated labels on bottles.

7.What is the specialized kind of equipment for glutathione liquid supplements manufacturing?

Are you planning to add glutathione liquid supplement manufacturing to your production plant? If yes, you would be surely curious to learn about specialized equipment involved in glutathione liquid supplement production.

So, let’s get ready to learn about machines generally found in glutathione liquid supplements manufacturing.

Water treatment machine

AIPAK ENGINEERING water treatment plant

To manufacture the liquid, the applied water for processing and volume-making should be treated with water treatment distillation machines. The machine mainly works by evaporating the water and condensing the steam into liquid. In this way, pure vapors are collected and used in this method.

Mixers

They are the most important instrument to attain even and uniform dispersion of ingredients in liquid products. For example:

| High Shear Mixers

|

They are high-tech mixers that use high shearing forces to disintegrate large clumps into smaller pieces for homogeneous mixing. It can provide you with high-quality emulsification and distribution. Agitators are core components in this machine, allowing fluidity of particles and mixing. |

Filtration machine

AIPAK ENGINEERING equipment

The glutathione liquid manufacturing is pure and sterile preparation. In this case, even a minute particle can cancel the whole batch. Therefore, the filtration plant is used to clean and filter the liquid mixture. The machine has the ability to filter the solution with ranges of 0.002-3mm in diameter of particle size.

Without this machine, you would surely affect the well-being of your consumers. The machine can screen or sieve with nano or micro-sized pores to filter tiny impurities, metallic ions, salts, organic matter, etc. from glutathione liquid supplements.

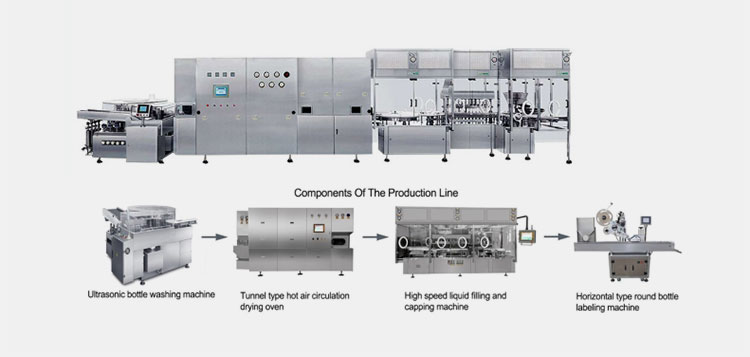

Glutathione Liquid Supplement Bottle Filling Production Line

AIPAK ENGINEERING Glutathione liquid supplement bottle filling production line

These machines assist you in depositing precise quantities of glutathione liquid supplements in bottles. The production line is composed of a bottle-washing machine, a sterilization tunnel, and a bottle-filling machine.

By utilizing this, the set of machines can offer accurate and sterile filling of glutathione liquid supplements in each bottle. By the end, you can receive an airtight-filled bottle with a formulation that is suitable for long-term storage without risk of oxidation or spillage.

Glutathione Liquid Supplement Vial Production Line

AIPAK ENGINEERING Glutathione Liquid Supplement Vial Production Line

The glutathione liquid supplement vial production line is composed of an ultrasonic washing machine that helps in the cleaning and washing of the vials to be filled with the formulation. The next machine is a sterilization tunnel where hot air circulates and ensures the drying and sterilization of the vials. The vial filling machine is composed of various filling nozzles. The purpose of fillers is to allow the dispensing of the formulation accurately. Once the filling is done, the cork is inserted into the vial with the help of mechanical arms followed by twisting caps.

Glutathione Liquid Supplement Encapsulation Machine

AIPAK softgel encapsulation machine

For softgel glutathione liquid supplements, a highly advanced softgel encapsulation machine is used. The machine is capable of forming a ribbon of gelatin and ensuring the encapsulation of glutathione liquid in an optimized volume followed by hermetic sealing and cutting of softgel capsules.

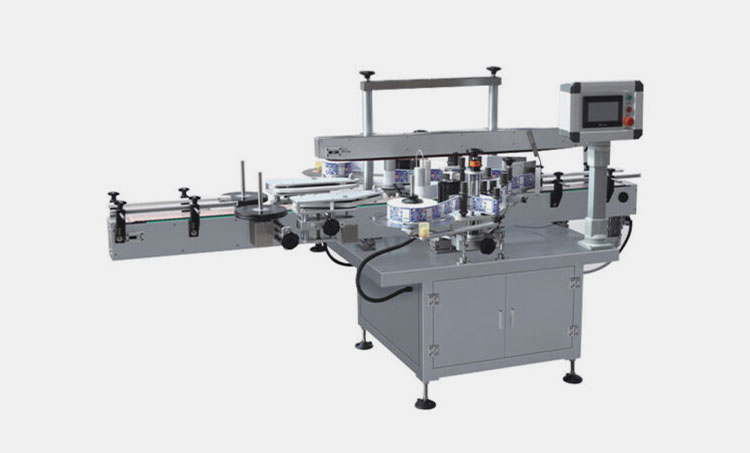

Labeling machine

AIPAK labeling machine

The final packaging products are now subject to labeling machines. The unit works by unwinding the labeler and applying it over each vial or bottle at the fixed position. In the presence of pressers, the applied label is adjusted so it can’t be displaced later.

8.How are glutathione liquid supplements manufacturing different from glutathione capsule supplements manufacturing?

Glutathione Liquid Supplements & Glutathione Capsule Supplements Manufacturing

Since glutathione liquid and capsule supplements are significantly different from each other, hence, there is a great deal of variation between both of these manufacturing. Without wasting time, let’s discuss the major differences between glutathione liquid supplements manufacturing and glutathione capsule supplements manufacturing:

| Features | Glutathione Liquid Supplements Manufacturing | Glutathione Capsule Supplements Manufacturing |

| Formulation | In this manufacturing, a stable liquid product is formed using various solvents, such as water, glycerine, and others. It also uses stabilizers, emulsifiers, and, flavoring agents. | On the other hand, this manufacturing involves the encapsulation of pure glutathione powder inside a gelatin or vegan shell. It generally uses fillers or anti-caking agents. |

| Production Steps | It is comprised of various manufacturing stages like mixing, sterilization, bottling, and sealing. | It has an entirely diverse set of steps than glutathione liquid supplements manufacturing, for example, powder mixing, encapsulation, capsule polishing & dedusting, and packaging. |

| Machine | Various equipment like mixers, ultrasonicators, microfluidizers, UV sterilizers, liquid fillers, etc, is present in glutathione liquid supplements manufacturing. | Whereas, powder blenders, capsule encapsulation machines, capsule counting devices, and capsule polishing machines are found in this type of manufacturing. |

| Absorption | It produces supplements that are already present in liquid form and, therefore, have more absorption. | This manufacturing normally forms stable and delayed-release capsules that are slowly absorbed in the blood. |

| Taste | Due to the use of flavoring agents, liquid supplements have a fruity flavor. | Capsule supplements are taste-neutral. |

9.How do manufacturers maintain the purity of glutathione during glutathione liquid supplements manufacturing?

Think about it: glutathione liquid supplements are always in pure form. There is no tiny bit of impurity or unwanted particles inside them. Why? Because manufacturers go the extra mile to ensure the complete sterility of products.

But how is that possible? Well, there are some techniques- mentioned below- to maintain the purity of glutathione and other components during glutathione liquid supplements manufacturing.

Obtaining Ultra-Pure Starting Ingredients

Ultra-Pure Starting Ingredients

You should know that the purity or sterility of every single step down the line is based on sourcing highly pure components. So, it is the rule of thumb to procure pharmaceutical-grade glutathione to satisfy the purity criteria set by global regulatory authorities.

Also, manufacturers employ reverse osmosis water or pharmaceutical-grade pure water to ensure there is absolutely no possibility of contamination.

Controlled Working Setup

AIPAK ENGINEERING clean rooms

Everyone in the pharmaceutical industry is aware of standard cleanroom practices (ISO 7 or 8) to maintain sterile working processing. It prevents the entrance of airborne particles. Furthermore, your equipment must be clean and disinfected to ensure the purity of the product.

Furthermore, your working force should wear personal protective equipment to avoid microbial or other physical contamination.

10.What is the shelf-life of products after glutathione liquid supplements manufacturing?

Glutathione liquid supplements shelflife

Learning about the shelf-life of glutathione liquid supplements is crucial to their safe consumption. Usually, stabilizers, oxidation-protecting agents, and preservatives are incorporated in these products while processing to boost their expiry period.

These chemicals act as a guard and keep the active ingredient- glutathione- safe from harm or damage. Hence, on average, your glutathione liquid supplements are good for 6 months to 2 years. The expiry period is related to the type of formulation, for example, standard glutathione liquid has a shelf-life of 6-12 months while liposomal glutathione has a consumption period of 12-24 months.

Manufacturers employ nitrogen flashing to lengthen the consumption time of these products. Hence, it is recommended to refrigerate them at (2–8°C) to improve their expiry period. Don’t expose glutathione liquid supplements to heat or sunlight, as the latter diminish product quality.

11.Can you enlist some critical quality tests for glutathione liquid supplements manufacturing?

Quality Tests For Glutathione Liquid Supplements Manufacturing

It is a universal fact that there should be no compromise on quality. Superior quality of product means happy and contented customers. Therefore, businesses make it their rule to keep the product at its best throughout manufacturing.

Subsequently, they have come up with some trade-mark quality tests for glutathione liquid supplements manufacturing. Here are some chief quality assessment procedures employed during the production of glutathione liquid supplements:

| Purity and Concentration Testing | This testing is a fundamental type of quality control assessment procedure in which you’ll measure concentration, purity, and active forms of glutathione. Some kinds of tests are High-Performance Liquid Chromatography and UV-visible spectrophotometry. |

| Stability Testing | Are you aware this assessment is necessary to determine the stability of the product? In this assessment, you’ll estimate the amount of glutathione and the chemicals after exposing them to high temperature, humidity, and light. Accelerated and real-time stability tests are the main forms of stability tests. |

| Oxidation Testing | It is employed to assess the levels of oxidized vs active forms of glutathione. Furthermore, it measures the antioxidant activity of glutathione. Its examples are the Peroxide Value Test and Free Radical Scavenging Assay (DPPH Test). |

| Microbial Growth Testing | The total count of microbes, such as fungi, E-coli, Salmonella, and, others are determined in these procedures. Moreover, you can also check whether the product is free of bacterial endotoxins or not from these tests. |

| Heavy Metal Screening | The presence of heavy metals in glutathione liquid supplements is quite dangerous for the health of consumers. Therefore, tests, for instance, ICP-MS examine the quantities of lead, arsenic, and mercury in supplements. |

12.What are the main technical problems that arise in glutathione liquid supplements manufacturing?

Numerous individuals in nutraceutical businesses are apprehensive due to technical problems in glutathione liquid supplements manufacturing. These issues are major reasons for the loss of financial success and reputation of brands in the market.

But no issue is insurmountable because by searching you can get a lot of answers. Therefore, for your convenience, we are penning some common technical problems and their solutions.

Glutathione Breakdown with Time

Degradation of active ingredients

By now you would have learned that glutathione is quite sensitive to oxidation, which decreases its potency. When exposed to environmental agents, like air, heat, light, and metal ions, this reaction is increased drastically.

Solution

You will surely be wondering what to do in this case. Well, its solution involves a sophisticated approach- nitrogen flushing. It introduces nitrogen in mixing tanks or packaging bottles to force oxygen out, which saves formulation from oxidation.

Another technique greatly significant in this aspect is keeping the pH of the solution at the stable range of 5.0-7.0. You can also add some natural and synthetic antioxidants to stabilize the formulation.

Fluctuations in pH Levels

Alteration in pH Levels

You’ll find it concerning that pH fluctuation is linked with the destabilization of glutathione. Like low pH (< 5) or high pH (> 7), will speed up the reactivity of preparation components.

Solution

You should not neglect maintaining and tweaking pH, so, it is on the desired threshold. Simple ways like the addition of food-grade buffer and citric acid or sodium bicarbonate easily fine-tine pH to optimal range.

Possibility of Microbial Growth

Possibility of Microbial Growth

Microbes are more likely to populate liquid supplements than capsules. Your glutathione liquid supplements will have bacterial, yeast, or mold growth if you don’t follow hygienic approaches.

Solution

To overcome this challenge, you must eliminate spores or cells of microorganisms by using 0.22-micron membrane filters. It is an ideal way to attain product cleanness. Furthermore, manufacturing must be carried out in GMP cleanrooms to avoid any ingress of microbes. Last but not least, you could add preservatives to ban the entry of microbes into the product.

Separation of Ingredients

Separation of Ingredients

It is a more common problem than you expected. Glutathione liquid supplements may separate upon storage. You will also notice that ingredients settle down in the bottle after some time. This lowers the product quality and leads to poor reception by consumers.

Solution

This problem has a fairly easy fix. You can utilize high-shear mixers or homogenizers to have consistency in the blend. Likewise, you can adjust the surfactant amount in formulation to attain stability. Moreover, you can carry out stability tests to prevent the suspension of ingredients.

Conclusion

Now it’s time to conclude this informative FAQ guide about glutathione liquid supplements manufacturing. We are positive by reading this guide, you will have picked some valuable information. In simple terms, you can invest in this production line to produce high-value nutraceuticals and achieve major growth milestones in the nutraceutical market. This manufacturing is the ultimate solution to all your issues with low production rates, human errors, and sterility. Then don’t waste any time and immediately visit the AIPAK Engineering website for the best machines and deals.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

AIPAK high shear mixer

AIPAK high shear mixer