Codeine Syrup Manufacturing: The Complete FAQ Guide in 2025

Codeine syrup manufacturing involves the formulation of a syrup dosage form of codeine for pain management and soothing persistent coughs. The syrup contains codeine as an active ingredient which is used when pain management needs opioid treatment.

The codeine is a potent drug (causes addiction), so the manufacturing must adhere to safety protocols and strict regulations. The little variations in the concentration of codeine can alter the therapeutic outcomes. Due to the misuse of opioids being an emerging challenge, manufacturers must oversee legal and health regulations for product safety and effectiveness.

In this guide, we’ll address various questions related to codeine syrup manufacturing, covering the primary steps of the process, equipment used, safety measures, regulations, and challenges faced by manufacturers.

1.What’s meant by syrup dosage form in codeine syrup manufacturing?

Syrup Dosage Form

Syrups are liquid oral dosage forms, composed of a concentrated aqueous solution of a sugar or a substitute of sugar. They maintain viscosity and provide sweetness to mask the bitterness of medicine.

In codeine syrup manufacturing, this dosage form acts as a carrier for uniform distribution and dispersion of codeine.

In syrup dosage form an accurate amount of codeine is incorporated into the suspension, maintaining its therapeutic efficacy and enabling correct dosing. During manufacturing, the careful preparation of the syrup base is essential to achieve the proper concentration and consistency, allowing an effective drug delivery of codeine.

2.How is codeine syrup manufacturing different from other pharmaceutical manufacturing processes?

Regulatory Restrictions- Picture Courtesy: CNN Health

Some important aspects of codeine syrup manufacturing differ from other pharmaceutical manufacturing processes. Codeine is an opioid that requires special consideration due to its potential for misuse or abuse as it’s highly addictive.

Its manufacturing requires strict control for the correct dosing of codeine in liquid form. If there is an incorrect dosing or uneven distribution of codeine in syrup, it can lead to overdose or misuse. The liquid nature of codeine syrup increases the risk of consumption in larger quantities.

Extra care is needed during manufacturing to avoid adulteration and diversion of codeine. The safe handling, packaging, and, proper storage conditions preserve potency and minimize syrup contamination.

Quality control measures are crucial to ensure the correct concentration of codeine. A slight variation in potency has remarkable effects on therapeutic outcomes and safety.

The codeine syrup as a controlled medicine, demands strict regulatory implementation on distribution, and prescription management.

3.Why is codeine syrup prescribed and manufactured in syrup form?

Prescribed as Controlled Medicine

The following are the medicinal uses of codeine syrup:

Analgesic Effect

Pain Management- Picture Courtesy: Midsouth

Codeine belongs to a group of drugs known as opiates or narcotics. It works by binding with mu-opioid receptors in the brain and spinal cord to block pain signals. In the liver, it’s metabolized into morphine further enhancing the analgesic effect. Codeine syrup is used to manage mild to moderate pain in conditions such as post-operative pain, injury, or certain chronic conditions. It’s often used in combination with acetaminophen or NSAIDs such as ibuprofen.

Cough Suppressor

Soothes Persistent Cough

Codeine syrup suppresses the urge to cough by acting on cough receptors in the medulla. It decreases the frequency and intensity of cough by inhibiting the signal that triggers the cough reflex. This mechanism is particularly helpful in suppressing dry or persistent cough. It often comes in combination with promethazine or NSAIDs like salicylic acid to treat cough, cold, flu, and, other respiratory conditions.

Now the question is why need it in syrup form? There are some reasons for its manufacturing as syrup:

Ease of Administration

Convenient Drug administration

The syrup is easily administered in dosage form and useful for individuals who have difficulty swallowing tablets and pills, such as children, elderly patients, and those with swallowing disorders.

Accurate Dosing

Precise Dose Measurements

Since patients need an accurate dose of opioids like codeine for effective treatment, liquid formulations such as syrups are suitable for precise dosing.

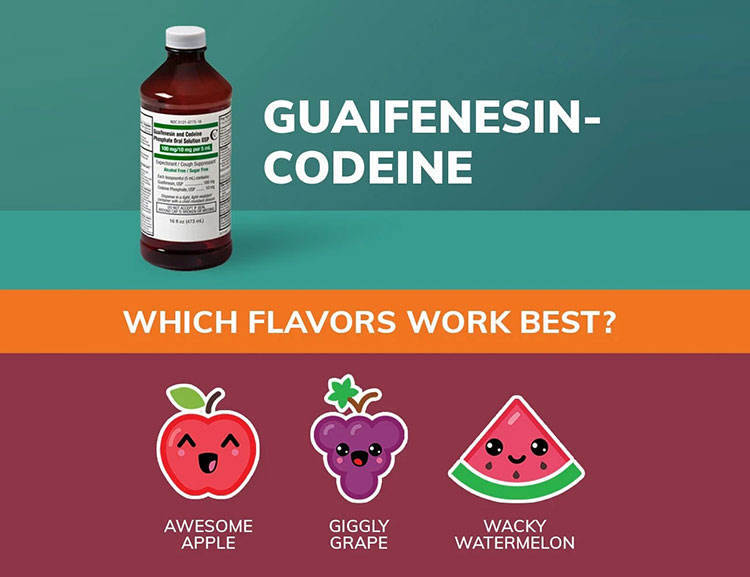

Palatability

Taste Masking- Picture Courtesy: FlavoRx

The flavored syrups help mask the bitter taste of codeine making it pleasant for pediatric patients as well as those sensitive to taste.

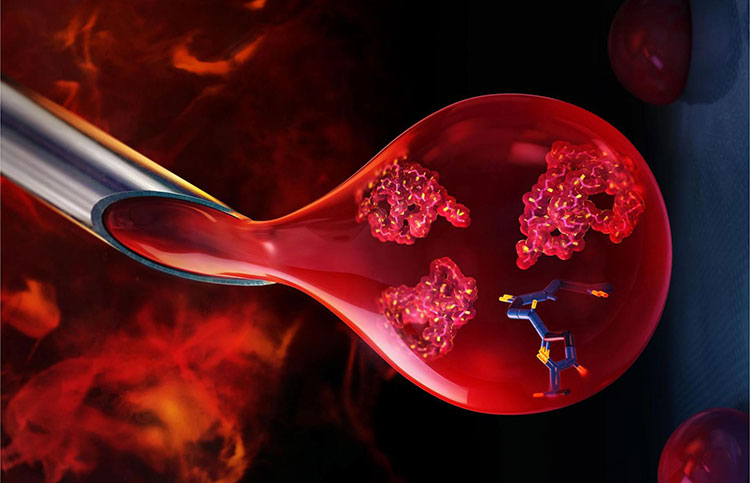

Faster Absorption

Quick Absorption in Body- Picture Courtesy: EurekAlert

Codeine may be absorbed more quickly in syrup dosage form by the body as compared to solid dosage form, allowing faster therapeutic outcomes.

4.What ingredients are commonly used in codeine syrup manufacturing besides codeine?

Codeine Syrup Formulation

Besides codeine, the following are some common ingredients incorporated in codeine syrup manufacturing:

Sugar/ Sugar Substitute

Liquid Sucrose- Picture Courtesy: Healthline

These ingredients are added in codeine syrup manufacturing to create the syrup base as well as add sweetness to the syrup. They also act as a thickening agent to give the desired consistency of syrup. Sugar such as sucrose, and dextrose, and non-sugar such as sorbitol, glycerin, and propylene glycol are commonly used in syrup.

Flavoring Agents

Variety of Flavoring Agents

Certain natural or artificial flavors are added to mask the bitter taste of codeine and improve patient compliance.

Preservatives

Preservatives Addition- Picture Courtesy: AZ Laboratories

Preservatives are incorporated to prevent microbial growth and extend shelf life. For example, sodium benzoate and sodium propionate.

Solvent

Sterile Water as Solvent

Most commonly purified water is used as a primary solvent to dissolve the ingredients and produce a uniform solution. Alcohol may be used in certain syrups as a solvent and preservative.

Thickening Agents

These agents include glycerin, xanthan gum, or cellulose derivatives to improve the viscosity of syrup.

Buffering Agents

Buffers and pH Modifiers

These agents are used to maintain the pH and stability of the syrup. Citric acid, sodium citrate, and ascorbic acid are widely used as buffering agents.

Medicinal Agents

Medicated Syrup- Picture Courtesy: Norex

Besides codeine, other medicinal compounds are also added according to the intended use. Such as promethazine as an antihistamine to suppress cough or phenylephrine as a decongestant to relieve nasal congestion.

Coloring Agents

Colorants Enhanced Physical Appearance

These agents are added to make the product visually appealing.

5.What are the methods of codeine sourcing for codeine syrup manufacturing?

Papaver Somniferum- Poppy Plant

The codeine is sourced through two primary methods that are:

Natural Extraction

Extraction from Natural Sources

Codeine is extracted from the poppy plant i.e. opium poppy (Papaver somniferum) where it’s found naturally in small quantities.

Semi-synthetic Production

Codeine semi-synthetic production- Picture Courtesy: Rudabe

Codeine can be produced semi-synthetically by methylation of morphine, a more abundant alkaloid found in the plant. This is particularly useful for a controlled and consistent supply of codeine when natural extraction is limited.

Codeine sourcing is a highly regulated process under national and international law since it’s classified as a controlled substance. These regulatory agencies ensure that production and distribution are strictly monitored to prevent misuse, diversion, or illegal production.

Authorized facilities must comply with strict guidelines including secure storage, keeping accurate records and reports to keep control over the substance throughout the supply chain.

6.What steps are involved in codeine syrup manufacturing?

Syrup Manufacturing Equipment- Picture Courtesy: Propack Technologies

Codeine syrup is a controlled pharmacprodueutical product, so its manufacturing process requires precise formulation, adherence to regulatory guidelines, and careful thorough quality control measures. The manufacturer makes it possible for the whole process to be done according to these considerations for patient safety.

Any deviation during its manufacturing can lead to product recall from the market, legal actions, and most importantly serious health risks. The process contains several steps to ensure the final product is safe and effective. Let’s have an overview of the whole process of codeine syrup manufacturing:

Raw Material Selection and Preparation

Sourcing of Key Start Material- Picture Courtesy: Jomfruland.net

The procurement department and quality assurance department are responsible for ensuring that all the ingredients are pharmaceutical grade and must comply with good manufacturing practices (GMP). They should ensure that licensed suppliers provide codeine and all transactions are properly documented.

Active Pharmaceutical Ingredient (API)

Codeine as API in Syrup manufacturing- Picture Courtesy: UKAT

The codeine is used as an API in codeine syrup manufacturing which may be available as codeine sulfate or codeine phosphate. It should be measured accurately according to formulation. Since it is opioid content, subjected to strict handling and regulations.

Liquide and Solid Ingredients

Flavoring Agent- Picture Courtesy: Chelsweets

Some ingredients are liquid while others are in the solid state. All the ingredients are selected according to formulations. These include purified water (must be USP or EP standard), sweeteners, preservatives, flavoring agents, colorants (FDA/EMA approved dyes), thickening agents, pH adjusters, and anti-foaming agents.

Before formulation development, all these ingredients are checked for quality i.e. purity, stability, and contamination.

Weighing and Measuring

Load Cells- Picture Courtesy: Dewesoft

All ingredients are accurately measured using calibrated dosing systems i.e. load cells for solids and flow meters for liquids.

Sugar Solution Preparation

Sugar Syrup

Sucrose is most commonly used to prepare sugar solutions. The sugar is sieved and transferred to vessels where distilled water is added. The solution is prepared by heating the water at a controlled temperature gradually adding the sugar and stirring it continuously until it dissolves completely. The prepared sugar solution served as a base for syrup production providing viscosity and taste.

Mixing

Sugar Syrup Dissolving Tank

Once the sugar solution is prepared it is transferred to a mixing vessel, where all other ingredients are incorporated including codeine. For mixing of ingredients stainless steel tanks equipped with an agitation system are used. A controlled stirring speed ensures uniform dispersion while regulated temperature aids the dissolution and prevents degradation of API.

Note

Codeine requires pre-mixing in purified water or another solvent for uniform distribution. Likewise, preservatives and sweeteners are sometimes pre-dissolved before being added to the main batch to avoid precipitation.

Heating

Electrical Heating Sugar Syrup Tank

If heating is required to accelerate the dissolution of some ingredients, the solution is then gently heated commonly at 40-60°C. The mixture is then gradually cooled to prevent degradation. Prolonged high temperatures should be avoided since codeine can decompose or lose potency.

Filtration

Syrup Filtration Machine

The prepared syrup is then allowed for cooling and passed through the fine mesh or membrane filters to remove particulate and microbial contaminants. Appropriate mesh size is used for filtration to remove unwanted particles while avoiding loss of API (codeine or other medicinal agents).

Quality Control

Quality Check- Picture Courtesy: ISSPLLAB

The final product goes through some quality measures before packaging and storage to ensure regulatory compliance.

| API Assay

An assay is performed to confirm the concentration of codeine within an acceptable range. |

pH Measurements

pH of the solution is measured by a pH meter to ensure that the pH is within range for product stability and consistency. |

| Viscosity Testing

The viscometer measures the thickness of the solution, ensuring that the product has sufficient thickness for easy consumption and accurate dosing. |

Microbial Testing

It’s performed to ensure that the product is free from bacteria, fungi, and endotoxin contamination. |

| Stability Studies

Stability studies are conducted to analyze how the sample performs under various storage conditions. Samples are tested for changes in physical appearance, consistency, and efficacy. |

|

Storage

Syrup Storage Tank

After filtration and quality check, the syrup is stored in a stainless steel tank under controlled conditions with continuous agitation preventing the settling of ingredients. Temperature, humidity, and light exposure are carefully monitored.

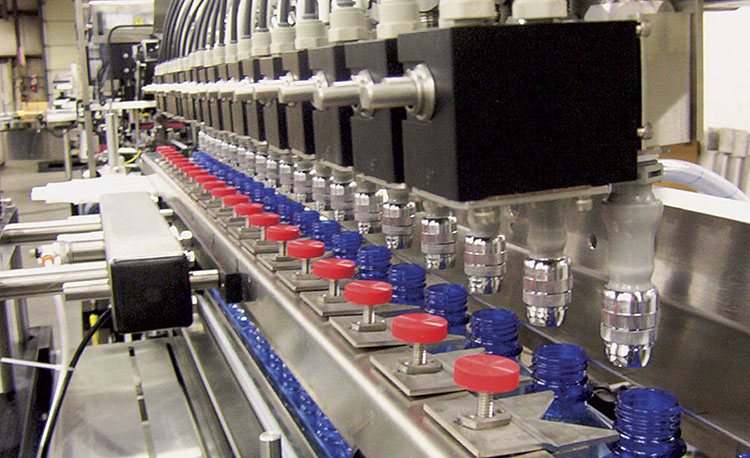

Filling and Packaging

Syrup Filling- Picture Courtesy: Adinath International

The syrup is transferred to the filling machine by using the sanitary pumps. Opaque or amber bottles are sterilized and filled. The filled bottles are then capped, labeled, and batch-coded. Temper-evident and child-resistant caps are used as required by law.

Quality Inspection

Inspection of Bottles for label and leakage- Picture Courtesy: Don Velley Pharma

A final inspection is done to check leaks, label accuracy, and proper sealing. After clearing all the tests, the batch is ready for market release. Proper regulatory documentation must be completed for traceability and audit before distribution.

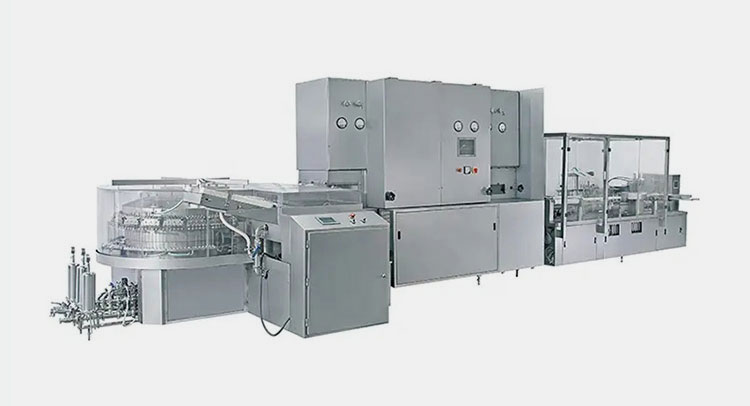

7.What equipment is utilized in codeine syrup manufacturing?

Codeine Syrup Manufacturing Plant- Picture Courtesy: Adinath International

Some key equipment is needed to streamline the production process at an industrial scale. The plant usually consists of a closed circuit system where the sugar melting vessel, manufacturing vessel, and storage vessels are connected to minimize manual handling of liquid. Let’s discuss them:

Water- Treatment Equipment

AIPAK Engineering Water Purification system

Water treatment is necessary before sugar solution preparation to ensure that the water utilized in dissolving sugar is free from microbes, unwanted particles, and ions.

| 1. Pre-Treatment | 2. Reverse Osmosis System |

| The pre-treatment system includes:

Sand and Multimedia Filter (removes large particles and sediments). Activated Carbon Filter (removes chlorine and other organic contaminants as well as odor). |

The RO system includes:

High-pressure RO Pump (utilizes to push water through membranes for purification). RO Membrane Unit (helps to remove dissolved solids, bacteria, and viruses). Pre-RO Filters (such as cartridge filter to protect RO membrane from clogging). |

| 3. Deionization Equipment | 4. Sterilization and Final Filtration |

| Mixed Bed Ion Exchange Resins (further purification by removing ions).

|

Ultra-violet (UV) Sterilizers (kill bacteria and other microorganisms by exposing UV light.

Final Filtration (includes micron filters or ultra-filtration units to remove endotoxins and fine particles). |

Sugar Syrup Vessel

Sugar Syrup Making Vessel with agitator- Picture Courtesy: Propack Technologies

In sugar syrup vessels water and sugar can be loaded in many ways i.e. with a vacuum system or mechanically or manually. The features of this vessel include:

- High-speed stirrer

- Electrical heating/ steam heating facility

The preparation of sugar takes place at a controlled temperature and then transfers to the manufacturing vessel. The transfer of sugar syrup is done either by vacuum or by transfer pump.

Manufacturing Vessel

Syrup Mixing Vessel

In manufacturing vessels dissolution of all ingredients with sugar solution takes place. The agitation system coupled with the heating system ensures the uniform dispersion of ingredients throughout the solution developing a homogenous product.

Storage Vessel

Storage Vessels for Syrup

The storage vessel is connected to a floating tank which supplies the liquid solution to the syrup-filling machine.

Transfer Pumps

Syrup Transfer Pump

You need sanitary pumps to transfer the sugar solution from the sugar solution vessel to manufacturing vessels as well as to discharge the prepared liquid into the storage vessel.

Syrup Filling Machine

AIPAK Engineering Syrup Filling Production Line

These machines use a peristaltic pump or gravity-filling system to fill the syrup into bottles. A variety of liquid viscosities and different sizes of containers can be filled by these machines.

These machines automatically place and tighten the caps on the bottles and labelled them after the syrup is filled ensuring the proper sealing to avoid leakage.

8.How is the consistency of syrup maintained in codeine syrup manufacturing?

Consistency of Syrup

The consistency of syrup is crucial during codeine syrup manufacturing and can be maintained if the following measures are taken:

Taking proper ratios of codeine, sugar, water, and other ingredients and weighing and dispensing is done by using an exact weighing and automated dispensing system

High-speed homogenizers or agitators should be used to develop a uniform solution while temperature and stirring speed should be controlled to prevent inconsistencies in viscosity.

Use of suspending agents such as xanthan gum provides a uniform texture and prevents the settling of ingredients.

pH adjustment is crucial for proper dissolution to prevent crystallization or precipitation.

Deaeration helps prevent inconsistencies in the texture and density of syrup.

The final product should be stored at optimal temperature to prevent thickening or separation.

Continuous mixing of solution in storage vessels maintains consistency before filling of syrup into the bottles.

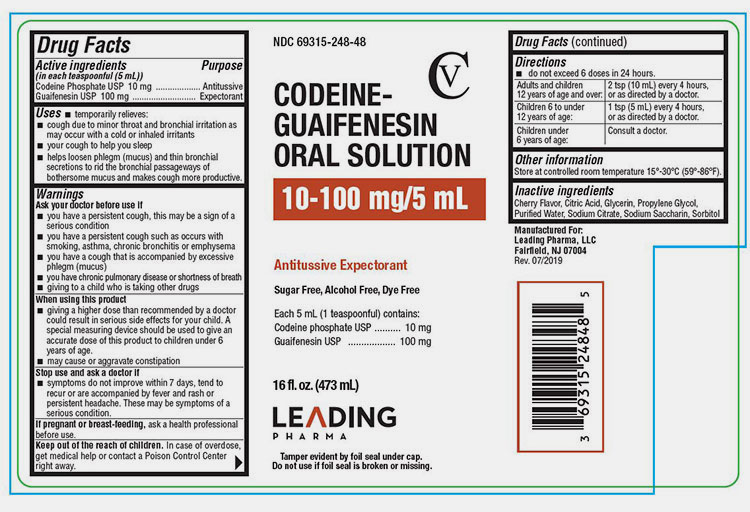

9.How to evaluate the correct concentration of codeine in codeine syrup manufacturing?

Codeine Concentration in Syrup- Picture Courtesy: DailyMed

Ensuring the correct concentration of codeine in syrup requires adherence to GMP and conducting thorough testing of the product during production and after the finished product.

In-process Sampling and Testing

Batch Testing

During production, regular batch testing by taking the sample at different stages for content uniformity of codeine ensures uniformity throughout the batch and helps in early detection of deviation and corrective actions.

Final Product Assay

HPLC Instrument

The finished product is tested for codeine potency before its market release by using analytical methods. These methods ensure that the syrup contains the correct concentration of codeine.

To evaluate the correct concentration of codeine in syrup, the pharmaceutical manufacturers may use any of the following precise analytical methods:

High-performance Liquid Chromatography: It’s the most common precise method for quantifying the codeine content with accuracy.

UV-visible spectrophotometer: It can be used for rapid analysis by measuring the absorbance of codeine at specific wavelengths.

Mass spectrometry: This helps quantify the codeine at a trace level.

10.What are the consequences of illegal or unauthorized codeine syrup manufacturing?

Judicial Consequences- Picture Courtesy: AGH Attorneys

If you are a manufacturer and planning to set up a plant for codeine syrup manufacturing, make sure that the manufacturing should be legal and authorized. In case of violation of legal requirements, you can face several legal, health, and safety consequences.

Judicial Consequences

By unauthorized manufacturing of codeine syrup, you are violating the drug manufacturing regulations, resulting in criminal charges, large fines, and imprisonment.

Heath Risk

There is a health risk associated with regulatory oversight in the codeine syrup manufacturing.

11.What happens when you take too much cough syrup with codeine? What you should do in case of overdosing?

Side Effects of Overdosing- Picture Courtesy: Healthline

The intake of excessive codeine syrup can cause potentially life-threatening effects since codeine is an opioid drug. So consumption of codeine in large quantities can depress the central nervous system which can lead to adverse consequences:

| Respiratory Depression

It can cause labored or slow breathing by affecting the brain’s respiratory centers. High doses can lead to completely stopped breathing causing hypoxia. |

Pinpoint Pupils

The codeine causes abnormal constriction of the pupil which is a key indication of overdosing. |

| Drowsiness

An individual may feel drowsiness and unconsciousness, as a CNS depressant, it can lead to extreme sedation. Overdosing might lead to coma. |

Cold Clammy Skin

Due to low blood circulation and body temperature regulation, an overdose of codeine makes skin cold and sweaty. |

| Low Blood Pressure

The overdosing of codeine can lower blood pressure which in turn causes low blood circulation and oxygen delivery to vital organs. |

Confusion and Dizziness

Due to suppression of brain function, it can lead to disorientation making it difficult for individual to stay awake or respond to their surroundings. |

Now the question is what are the possible immediate actions that should take place in case of overdosing? Remember time is critical in preventing serious adverse effects and death. Let’s list them out:

Call your local emergency services number immediately.

Administered opioid antidote i.e. naloxone, which can temporarily counteract the effects of codeine.

If the affected person is conscious, try to keep them awake and push them to breathe deeply.

12.What legal restrictions apply to codeine syrup manufacturing and why are they necessary?

Legal Restrictions on Codeine Syrup Manufacturing- Picture Courtesy: Legal Vidhiya

As we discussed codeine syrup is an opioid-based cough suppressant and due to its potential for abuse, dependency, and health hazards, it is subjected to legal restriction. Here are some common legal restrictions worldwide, let’s discuss them:

Prescription-Only Medicine

Classified as Prescription Only Medicine- Picture Courtesy: Pharmacy Connection

In many countries, codeine syrup is classified as a prescription-only medicine. It can only be purchased if you have a valid prescription written by a health care professional.

Sales Restriction

Abuse of Codeine Syrup- Picture Courtesy: Nigeria Health Watch

Under the strict supervision of pharmacists, some regions allow over-the-counter sales of codeine syrup. Even some countries have completely banned non-prescription sales.

Restrictions on Production and Distribution

Supply Restrictions- Picture Courtesy: Independent

The strict guidelines are imposed by different countries’ regulatory bodies on manufacturing, labeling, and supply to prevent illicit consumption.

Reasons for Legal Restrictions

Purple Drink

Recreational Use of Codeine- Picture Courtesy: MedPage Today

The recreational use of purple drink i.e. a mixture of codeine with soda or candy, is common in some music and drug cultures. It causes euphoria, drowsiness, and relaxation. However, its excessive use can lead to adverse effects like slowed breathing, confusion, dizziness, seizures, unconsciousness, and even fatal overdose. Long-term use can lead to addiction, organ damage, psychological issues, and cognitive impairment.

High doses

Consumption of High Doses

Some individuals may consume high doses to experience euphoria because they feel a morphine-like high due to the conversion of codeine into morphine inside the body.

Combining codeine with other substances

Respiratory Depression- Picture Courtesy: North Brisbane

The codeine is often combined with alcohol or other drugs that have depressant effects that pose a high risk of respiratory depression and fetal overdoses.

World Health Organization (WHO) and the United Nations Office on Drugs and Crime (UNODC) have implemented strict regulatory guidelines on opioid medicines. Most of the healthcare systems encourage the use of non-opioid suppressants, and herbal remedies to curb misuse of codeine.

13.How do manufacturers prevent codeine syrup abuse during the production and distribution process?

Codeine Syrup Manufacturing Restrictions- Picture Courtesy: White Sands Treatment

The following are some of the measures that should be adopted by manufacturers to avoid the abuse of codeine during the production and distribution process:

| Security Measures

To avoid the illegal diversion of codeine syrup, safety measures must be utilized. Such as factories should force 24/7 monitoring and restrictions on access to manufacturing areas during production. |

Temper-evident Packaging

Guarantee temper evident packaging to avoid misuse or tempering of the syrup, in case they have been opened showing the illegal alterations. |

| Documentation

Manufacturers must maintain documented records of production volume, and distribution, for traceability and accountability to guarantee codeine syrup doesn’t end up on the black market. |

Regulatory Authorities Collaboration

Manufacturers should collaborate with regulatory bodies like the FDA to track suspicious activities such as bulk purchases by unlicensed sellers. |

Conclusion

Codeine syrup manufacturing involves sophisticated equipment for a smooth production process. AIPAK Engineering offers cutting-edge machinery such as syrup manufacturing vessels with electric heating and agitators, automatic syrup filling machines, and temper-evident packaging machinery. AIPAK Engineering’s highly advanced machinery not only streamlines the process but also aids in meeting global healthcare standards.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours