Cod Liver Oil Emulsion Manufacturing: The Complete FAQ Guide In 2025

Do you know that the world of medicine has been associated with cod liver oil emulsion since the 1870s? At that time, doctors were used to prescribing it to their patients and the journey began from Manchester. It was the best-known treatment for the management of rickets in pediatrics medication.

What are the current uses of cod liver oil emulsion manufacturing? In this article, you will be going to understand the in-depth knowledge of cod liver oil emulsion and its manufacturing. Come on let’s start with our topic.

1.What is cod liver oil emulsion?

Cod liver oil emulsion

This is a nutritional boosting and energizing supplement that originated from the liver oil of the codfish. The codfish is a largely popular type from the genus Gadus and used as a diet since the Stone Age, especially in European diets.

Due to its subtle and mild flavors and unique flesh, this is opted to eat and export to the different regions. Moreover, along with its dieting popularity, it is used for therapeutic purposes too.

The cod liver is a treasure that is enriched with unsaturated fatty acids. So, it was identified and used by a daring pharmacist and his partner in the 1800s. Alfred B Scott and Samuel W Bowne did an experiment to extract the cod liver oil and prepared the emulsion.

The cod liver oil emulsion is also known as Scott’s emulsion. However, this is popular with the image of a man carrying fish on his shoulder for promotion.

The emulsion is therapeutically used for treating various symptomatic ailments and is composed of various vitamins such as A, D, and calcium that give energizing effects to your immune system.

2.What is cod liver oil emulsion manufacturing?

Cod liver oil emulsion manufacturing- Picture courtesy: ABC

Cod liver oil emulsion manufacturing is the combination of two phases. One is the oil phase, and the other is the water phase. In this process, you will need to acquire a few sets of ingredients and with the help of an emulsifying agent, the final emulsion is prepared which is free from face separation problems.

There are various methods of cod liver oil manufacturing where the water phase is composed of utilizing some extracts, solvents like chloroform, and water such as purified water.

Besides, this number of other ingredients are used to enhance the flavor and aroma and make the emulsion palatable and user-pleasing. The manufacturing process is based on a series of steps where you will need to determine the strength of the emulsion, for example, 30%, 20%, 10%, etc.

Along with ingredients design, there are specific kind of types of machinery used in cod liver oil manufacturing including from extractor to final labeling machine. The latter part of this article is included with details related to ingredients, equipment, and handling.

3.What are the benefits associated with cod liver oil emulsion manufacturing?

Consuming cod liver directly is way more challenging, no one can even think of it. But on the other hand, if you see how beneficial cod liver oil is for you it might be the compelling factor. However, the strategies followed in ancient days. Since after 1800s, cod liver oil emulsion manufacturing emerged to make sure that you’re receiving medication or supplements not in a crude form. There are certain benefits and reasons behind cod liver oil emulsion manufacturing. For example:

First choice of special population

Cod liver oil age group- Picture courtesy: theAsianparent

Cold liver oil emulsion is a treasure of oral supplements that provide essential vitamins and fatty acids to your body. But, we all know that children are picky eaters and drinkers, they don’t tolerate whatever is bad in taste.

The orange flavor nutritional supplement with embedded vitamins and APIs is now their first choice in the form of cod liver oil emulsion. It gives you benefits by masking the unacceptable taste and flavor by turning it into a pleasing sugary taste and fruity flavor. Moreover, the emulsion has opened the gateway to make it a pleasant supplement for other age group individuals too.

Making easy-to-consume oils

Easy administration- Picture courtesy: The motherhood

The majority of oils are not able to be taken directly due to many reasons. Same in the case of cod liver oil too!. The emulsion offers you a rapid way to consume and it reaches the active site and is firmly absorbed to promote therapeutic effects. The emulsion is based on oil and water for the purpose of providing more bioavailability in your physiological system along with easy consumption.

Exact doses per day

Accurate dosing- Picture courtesy: Science News explores

The purpose of emulsion is to offer an accurate spoon of supplements which is composed of per day requirement of vitamins and supplements. There won’t be any chances of either overdose or side effects due to excessive dosage consumption.

You can receive whatever is promised on its packaging. Additionally, this also depends on person to person and their basal metabolic rate or BMR which is calculated by pharmacist.

A potent product

Potent formulation- Picture courtesy: Daily news

As you know cod liver oil is composed of sensitive nutrients and is capable of degrade rapidly if not stored properly. This means that if you get even fresh fish, still you will have a high chance of cod liver oil constituent oxidation. However, cod liver oil emulsion manufacturing takes place under a controlled condition with expert technicians and scientists that promises you a potent and stable product bottle that you consume.

4.What are the ingredients of cod liver oil emulsion manufacturing?

The cod liver oil emulsion manufacturing takes place once you start harvesting the codfish. There are a series of important steps that we have enlisted for you in an easy way with interactive illustrations. There are various ingredients used in its manufacturing.

The purpose of describing the comprehensive details is to make you fully understand the basic concepts of extracting cod liver oil for manufacturing of emulsion.

Extraction of Cod Liver Oil

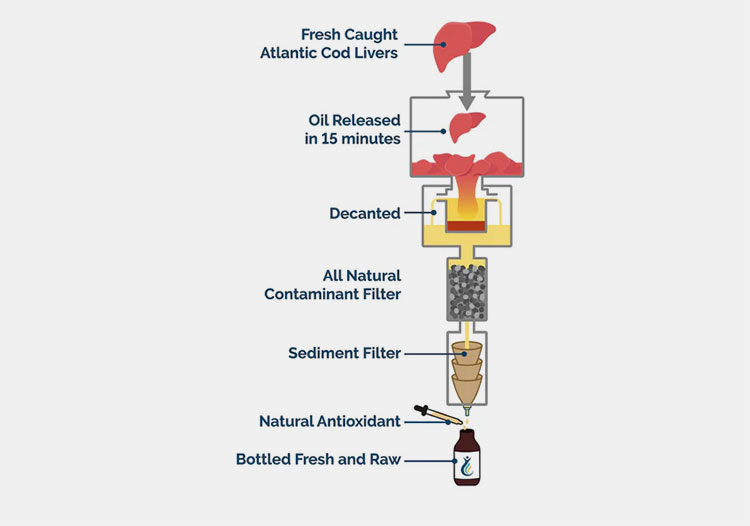

Cod liver oil production- Picture courtesy: Rosita

| Catching | The catching of codfish process takes place days to week when your ship is in the sea. During this time, several hundreds to thousands of codfish are harvested and kept for a certain period of time. Remember, the codfish loss their potency of kept for long periods therefore, it has to be sent to a rendering facility after the collection of livers. |

| Washing | The cleaning, hygiene, and purity are maintained by cod liver to clean the unwanted particles or contaminants. |

| Oil Release | The liver oil is ground to make a slurry. You need to keep and bring the process under controlled heat, temperature, and humidity. This is because the fatty oil has the ability to degrade in the presence of air and light. Therefore, you must prevent the oxidation of polyunsaturated fatty acids.

The crud substance is now subjected to centrifugation. This step helps in the clear separation of oil, water, and remaining plasma. |

| Decantation | The remaining solution is now further subjected to decantation where the oil and presented impurities are removed as it is mostly settled in the bottom. |

| Filtration | To ensure highly cleared oil, the filtration is carried out. In this process, the presence of sedimentation or natural contaminants is removed. |

| Final extraction of cod liver oil | Once the oil is extracted the addition of antioxidants is taken place that will make cod liver oil stable for human consumption. This can be either vitamin E, ascorbic acids, or sometimes a chunk of spices. Now the pure and potent cod liver oil is transferred to the containers. Additionally, the flavoring agents are also added that can be either lemon peel or natural fruity flavors. |

Water

Water

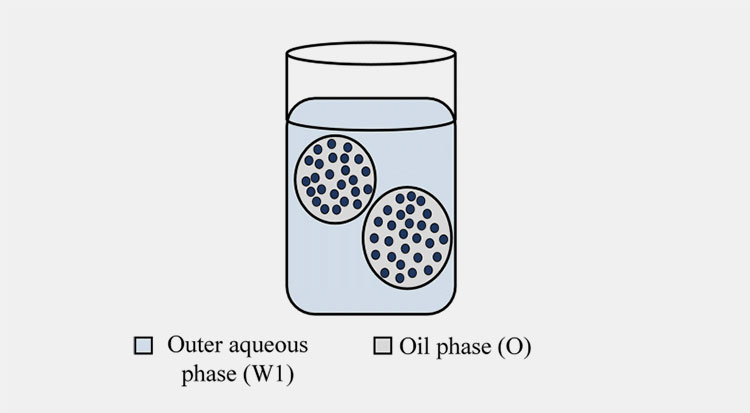

When preparing a cod liver oil emulsion, the continuous phase is known as water. It allows the oil phase to disperse in it. Therefore, the emulsion types are mainly water in the oil phase or W/O emulsion. This can be described by the presence of water globules dispersing in the oil phase.

Examples of the water phase include purified water, cinnamon water chloroform, peppermint water, etc.

Emulsifying agent

Emulsifying agents

This is the main ingredient that will help you in the making of stable cod liver oil emulsion. As the name suggests, an emulsifying agent, adsorbs the oil-water interface which is produced during the preparation of emulsion against the phenomena of recoalescence (to form a large globule or phase separation).

In an easier word, it forms and facilitates a quality and easy emulsion. Without an emulsifying agent, the water and oil mixing would have been challenging.

In the cod liver oil emulsion, the natural emulsifying agents are used based on vegetable sources emulsifiers such as acacia, xanthan gums, tragacanth, and alginates, etc.

Thickening agents

Thickening agents- Picture courtesy: Vrindawan University

To improve the viscosity of emulsion, the thickening agents are used. It ensures the preparation of emulsion with more stability. It helps in the strengthening and binding of the oil phase and water phase and facilitates the thickening properties. The commonly used thickening agents are starches, guar gums, locust bean gum, etc.

Preservative

Preservatives

Your product becomes prone to microbial invasion when it is mixed with other phases, such as water and oil. The preservative incorporation ensures protection against the progression of microorganisms. The traditionally used preservatives are included with certain salts, benzoic acids, potassium sorbates, etc, while the synthetic preservatives are included with paraoxybenzoate, parabens, benzalkonium chloride, in a smaller concentration.

Flavoring agents

Flavoring agents

The flavor of cod liver oil is undoubtedly not good; to improve its acceptance and make users take their doses easily, you do add flavoring agents. The orange is a commonly used flavoring agent used in the cod liver oil emulsion. Although, you can use flavoring agents depending on your choice and demand such as cherry, apple lemon, etc.

5.What are the process steps of cod liver oil emulsion manufacturing?

The process steps of cod liver oil emulsion manufacturing are very easy and simple. The emulsion is followed by easy step and can be prepared in small labs to large facilities by implementing the same working principle. For instance:

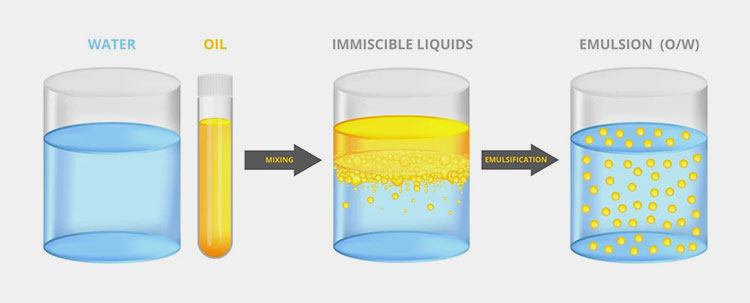

STEP 1: Incorporation of two phases

Phases

The process begins when you start the mixing game. This means the calculated concentration of cod liver oil is added into the mixing tank along with gradual incorporation of the water phase with constant homogenization. The step is carried out in the presence of adding emulsifying agent which will help in the smooth procedure and result formation. Remember, the temperature of both solutions must be the same to ensure and enjoy interruption-free workflow.

STEP 2: Addition of further constituents

Adding other elements

Now you can add elements like thickening agents, flavoring agents, and sweeteners along with water to make up the volume.

STEP 3: Mixing & Emulsification

Emulsification- Picture courtesy: Silverson

Keep mixing the formulation and subject it to mixing homogenization to improve the consistency and minimize the particles up to your requirement. By the end, a smooth, viscous, and quality emulsion will be formed. It is time to fill and pack them followed by quality testing.

6.What equipment is used for cod liver oil emulsion manufacturing?

For cod liver oil emulsion manufacturing, you will need some set of equipment. The reason for using the machine is to break down the particles used in emulsion properly and evenly. Remember to avoid coalescence or instability of the emulsion, one must apply proper equipment that helps you in the distribution of particles in both phases (water in oil or vice versa).

Ultrasonifiers

Ultrasonifiers- Picture courtesy: Altrasonic

This is a small scale emulsion preparation solution and is used in clinical and laboratory setups. It is mainly hooked to limited output and though expensive too. The working of the machine is based on producing ultrasonic waves that collide the particles with the blades and wall of the mixing container. The medium pressures observed by this machine range from 150 to 350 psi. In this way, it generates agitation and produces oil in water emulsion effectively.

Colloid mills

AIPAK colloid mill

The colloid mill is commonly used for the preparation of cod liver oil emulsion manufacturing process. The machine is capable of generating intensified shear forces that ensure the production of tiny globules of cod liver and minimizing the particle size. The machine is ideal for producing the cod liver in a reduced form and making it ready for further processes.

Centrifuge machine

AIPAK ENGINEERING Horizontal screw centrifuge filtration equipment

To separate the layer of cod liver oil liquor and solid particles, the cod liver solution is passed from this machine. The centrifuge machine takes some time to centrifuge the subjected solution and by the end, you can easily collect the cod liver oil and remove the undesirable substances by the machine’s filtration system. As a result, you receive with required cod liver oil which is absolutely medicinal grade.

Vacuum dryer

Aipak static round vacuum dryer

On the industrial scale, cod liver oil manufacturing is subjected to vacuum drying process to eliminate the presence of water molecules in the oil. Therefore, the vacuum drying process is carried out which is entirely safe to treat sensitive materials such as cod liver oil and ensure promising evaporation of water molecules.

Water distiller

AIPAK ENGINEERING water distiller machine

For cod liver oil emulsion, the distilled water is used. The water distillation machine works a boiling and evaporation mechanism. Here the water reaches to boiling temperature and turns it into the steam form.

Upon applying the condensation process, it is cooled and condensed to again liquid phase. In this machine, liquid is turning to gas state and condensed back to liquid. Now this liquid is highly purified because it is free from pyrogen, because this process make microorganisms or any undesirable particle left behind.

Vacuum emulsifying mixers

AIPAK vacuum emulsifying mixer

An industrial-scale production of cod liver oil manufacturing is perfectly achieved by utilizing a vacuum emulsifying mixer.

As its name shows, the emulsification task is involved with the action of multiple factors, mixing, vacuum, and particle size reduction. The entire assembly of the machine is based on the storage tanks, that is allowing entry of the oil phase or cod liver oil while other tank ensures gradual incorporation of the water phase.

Both are introduced into the emulsifying tank by the help of integrated circulatory pipes. During mixing the vacuum is created and mixing blades' movement helps in stable force so the solution is prepared.

Micro fluidizer

Micro fluidizer- Picture courtesy: microfluidics

When it comes to preparing cod liver oil emulsion where you want to have nano-size particles, then a microfluidizer is the ideal option. The machine is ideal for high-viscosity formulation runs the particles with high shear force and is used for oil in water emulsions. Additionally, it is used for making solid and oil suspensions too. The machine is compact in structure and can be adjusted as a benchtop unit to floor setups.

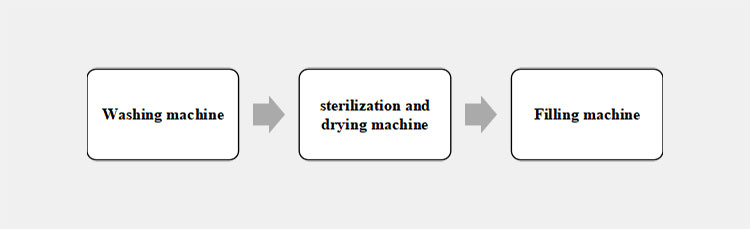

7.What is the cod liver oil emulsion manufacturing production line?

Extracting the cod liver oil and making its emulsion is the half manufacturing process. However, the journey has still to be completed if you have a goal for professional cod liver oil emulsion manufacturing. For that, we have discussed briefly the set of machines involved in the production line.

Cod liver oil emulsion filling production line

AIPAK engineering liquid filling production line

The production line is composed with set of three units which includes, washing, sterilization, and filling machine.

Washing machine

To produce prepared, sterile, and aseptic bottles for filling of cod liver oil emulsion, it must be cleaned. There are various types of machines available that ensure 100% cleaning of the bottles based on simple water rinsing. The machine itself allows turning over of the bottles for thorough washing along with continuous oscillations and induction of ultrasonic waves of water which knocks the surface of the bottle to wipe the presence of any foreign particles.

Sterilization machine

The washed and cleaned bottles are now further passed through the sterilization tunnel for the drying task. The unit ensures pyrogen and dust-free bottles by induction of heating and drying mechanisms inside the tunnel. The machine works by generating a laminar or hot stream of air ranges 300 to 350 °C and is ideal for disinfecting the containers due to uniform heat distribution. Cleaned and dried bottles are fed into the next machine for filling task.

Filling machine

The cod liver oil emulsion is filled by using the filling machine that detects the presence of bottles when reaches the nozzle of the unit. The accurate amount of emulsion is dropped down by the machine by using the specialized nozzles depending on the manufacturer's choice such as gravity, piston, or vacuum pressure.

The entire process is carried out in an intricate manner without chances of spill or leak. The filled bottles with cod liver oil are finally secured by twisting the caps. This is the major step where an automatic capping machine detects the position and allows the grippers to fix the cap with torque to secure it firmly. The capping must be correctly fixed and offer an air-tight closure to keep the supplement potent and stable for a longer time.

Labeling Machine

Automatic labeling machine

Labeling machine is used to improve professional appearance as well as application of labels with descriptions of products, their manufacturing time, date, batch, dosage, etc. The labeling rolls unwind and stick appropriately over the surface of the bottles by using either pressure, glue, cold or hot pressing, or other method.

Cartoning Machine

AIPAK cartoning machine

There are so many options available for cartoning machines which help you in making of bottle cartons and ensure the proper positioning of the bottles respectively. The machine is capable of folding the flat carton and tucking it in by utilizing the gripers and preparing the carton. This machine is ideal for the large-scale production line, but if you’re running small to moderate batches, the cartoning machine is also available to cater to that capacity as well.

8.What industries use cod liver oil emulsion manufacturing process?

Today the process of cod liver oil emulsion is widely expanded and used in various larger industries for the manufacturing of different formulations. Such as:

Medicinal and Pharma industries

Pharma industry- Picture courtesy: starcircle

In the manufacturing of medicines, such as vaccines, painkillers, antibiotics, and chemotherapeutic agents, a related method is used. For example, extraction of the main ingredient by using the process of centrifugation, filtration, drying, blending etc., all mentioned above processes are used to manufacture pharmaceutical grade emulsion.

Food industries

Food industries- Picture courtesy: stylist

Various food products are basically prepared by using the cod liver oil manufacturing method. You may have used mayonnaise, bottles of ketchup, seasoning, etc products in your regular life. All of them are packed for you by using a similar process with controlled sterility and preventive agents to inhibit the oxidation and rancidity of your food.

Nutraceutical industries

Nutritional industry- Picture courtesy: The Providence Journal

The nutritional supplements in the nutraceutical industry are being prepared by implementing controlled processes such as cod liver oil manufacturing. Whether it is prebiotics, probiotics, enzymatic supplements, hair, nails, skin, and the extraction of constituents like minerals, vitamins, and oils are taken from natural sources in a comparable way as above.

Herbal industries

Herbal industries- Picture courtesy: Skincare

You can’t ignore the herbal industry when it comes to manufacturing emulsions. The natural products are obtained from plants and organic sources. Moreover, by process of freeze drying and component separation, oil is obtained, therefore, herbal emulsions are prepared in industries by using the same protocols and machines involved in cod liver oil emulsion.

Chemical industries

Chemical industry- Picture courtesy: Mr.gutter

In the chemical industry, products like hair dyes, paints, water and oil colors, polishes, cleaners, etc, are prepared, for that cod liver oil emulsion method and related list of machines are used for effectively bring the fulfillment of materials.

9.What are the therapeutic effects of cod liver oil emulsion manufacturing?

Cod liver oil emulsion- Picture courtesy: Health central

Apart from its technical discussion, there are various factors behind its manufacturing. That’s of course the requirement. The cod liver oil emulsion is shown to be a highly popular supplement as it gives you amazing therapeutic effects. We have talked about some of their good properties. For example:

| Good Fat | Your every cell needs good fats, the cod liver oil emulsion is composed of omega-3 fatty acid. It is a beneficial source of obtaining the fats to bring various responsibilities to be effectively performed by your body. |

| Good bone health | Due to the presence of good fats or polyunsaturated fatty acids and a number of minerals, it is ideal as a supplement for boosting your bone’s health and efficiency. Because the emulsion is helpful in minimizing the symptoms of inflammation thus problems like arthritis are treated with it. |

| No Neurodegeneration | With time, we all get age. Our brain cells too, show lesser efficiency because of neurodegeneration problems. The presence of nutrients such as eicosapentaenoic acid or EPA, and docosahexaenoic acid or DHA are magical substances that are proven to imparting the lowering of neurodegeneration problems. |

| Good heart’s health | Various studies showed that heart problems like atherosclerosis as well as related problems can be minimized with the intaking of cod liver oil emulsion. This is because it acts as a powerful antioxidant, thus you won’t be facing chances of heart muscle blockade, hardening, clotting of blood, inflammation, etc. |

| Fast wound healing | Research studies confirm that your body's performance toward injury and healing is fast when taking cod liver oil emulsion, that’s why this potent ingredient is also used in topical applications. |

| Good brain performance | A cod liver oil emulsion is a magical drink that is composed of vitamins like A and D. These are the best entities that promote your brain function and performance. Therefore, it is highly recommended to use in every age group, especially old age. |

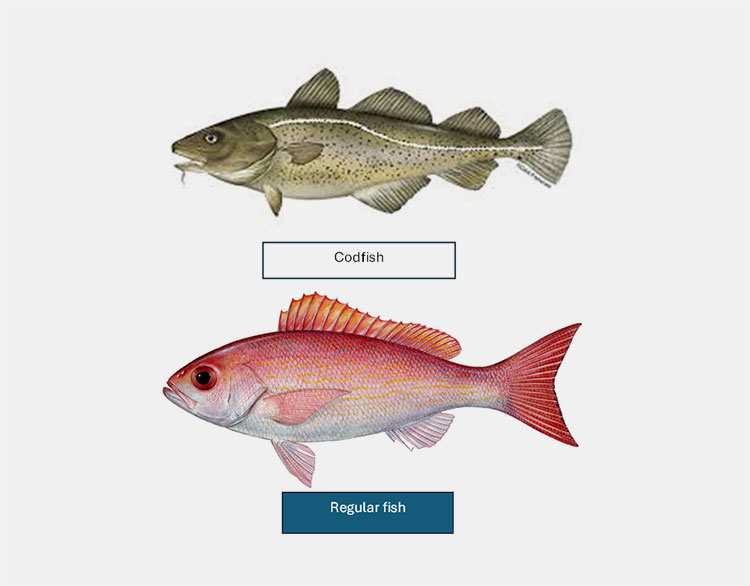

10.What is the difference between cod liver oil manufacturing and fish oil manufacturing?

Cod fish VS regular fish- Picture courtesy: biggerthansea

The cod liver oil manufacturing and fish oil manufacturing may give you the nutrients but the quantity may be slightly different. There are some variations in their manufacturing and composition. For example:

| Points | Description |

| Harvesting | The catching of the cod liver oil is just confined to codfish which is obtained from specific regions of the sea. Whereas the fish oil catching can be picked from any region of the water. It can be either from a river, pond, sea, etc. |

| Specification | The process is specific in the case of codfish harvesting, on the other side, you have a broad room of fish catching. |

| Constituents | The codfish liver is composed of yield oils and vitamins such as A and D. Moreover, for other fishes, it may be composed of fatty acids but not other vitamins. You may have to add them during the manufacturing process. |

| Level of essential fatty acids | The level of DHA and EPA is very high in cod liver oil emulsion, whereas the low ratio of DHA and EPA is found in other fishes. |

| Oil Extraction | The oil taken from cod liver oil is mainly from steaming or low temperature, however, the other fish’s oil can be separated by pressing the liver. |

11.What are the recommended doses for cod liver oil emulsion manufacturing?

Cod liver oil emulsion doses

There are various dosage intakes of cod liver oil emulsions by different groups of people. The standard dosage administration of emulsion is mainly suggested as taking 1 tablespoon which is approximately 15 mL of the cod liver emulsion thrice time a day.

This is mainly suggested for children and adults. The cod liver oil emulsion actually does not associate with harsh and reactive side effects. That’s the reason, people take them as a regular and casual routine. However, the standard prescribed dosage description is mentioned below:

Children from age 1 to 6 years mainly takes 1 tablespoon per day

Aged 7 to 12 years age, they are required to take 1 tablespoon twice times a day

Whereas above this age, you can take 1 tablespoon of cod liver oil emulsion three times daily.

12.How long cod liver oil emulsion manufacturing product is stable?

Stability- Picture courtesy: Checkers

The cod liver oil itself has a shorter shelf life, this is because the unrefined and crude form degrades rapidly by the action of light and air. However, the cod liver oil emulsion is prepared from a number of steps including extractions, filtration, drying, packaging, etc.

The purpose of running the series of processes is to offer a potent emulsion with a greater shelf life.

Just like all manufactured medicines and nutritional supplements, the cod liver oil also has some extents and limitations. It is mainly suggested to use the emulsion within 6 months soon after opening it. The reason behind this is that you will be consuming the effective ingredients inside it.

Moreover, the sign of rancidity is also very simple, if you feel the smell of fish, or sour taste, or have some bitterness. Then it means the cod liver oil emulsion is expired. Although the packaging date of cod liver emulsion is almost greater.

An unopened bottle of cod liver oil is potent for 24 months. However, it is advisable to store the bottle in a cool and dry place with a temperature of 6 to 8 degrees.

13.Are there challenges associated with cod liver oil emulsion manufacturing?

Cod liver oil manufacturing is nevertheless a challenging process. There are several critical points that you may face and must be considered when planning to manufacture the cod liver oil emulsion. We have talked about certain issues with possible solutions.

Phase separation

Phase separation

In the cod liver oil manufacturing process, you mix the two phases, the oil phase, and the water phase. There are the most chances of layering or phase separation.

Solution

When mixing the two phases, you must keep the temperature and mixing environment the same. Utilizing thorough homogenization when incorporating the phases and using good mixing would minimize the chances of phase separation. The proper filtration of phases before the manufacturing process can improve the emulsion process.

Instability of cod liver oil emulsion

Instability- Picture courtesy: Biolin Scientific

After manufacturing, there might be chances of instability of your formulation that directly affects the efficacy and quality.

Solution

Keep the manufacturing condition optimized and controlled to avoid aftereffects. The temperature, air level, light, and mixing must be used by using a pre-calculated speed and protocol. Add the optimized concentration of the emulsifying agent or increase its concentration.

Oxidation of the cod liver oil emulsion

Oxidation- Picture courtesy: Research outreach

This is the prime and foremost point, where you have to take care of the main ingredient throughout the process. The oxidation process can affect the overall texture, taste, and potency of the emulsion.

Solution

It is recommended to keep the cod livers at a controlled temperature soon after harvesting. Moreover, the addition of antioxidants can also ensure that the process of rancidity or oxidation can be controlled. Keep the manufacturing process and materials in a controlled light. The packaging of the emulsion must be done in dark bottles. After manufacturing, you must take care that the emulsion is treated and kept at a controlled temperature.

Conclusion

After reading the blog, you might be also thinking of grabbing the bottle of cod liver oil emulsion. This is undoubtedly a health treasure that is absolutely safe for you, your children, and other age group individuals. However, when it comes to cod liver oil manufacturing, the process details are also extensively described in the article along with interactive illustrations. We hope the entire content will be worth reading and exploring for you. Do you still have queries? Contact our expert right now! AIPAK ENGINEERING is the hub of providing all related machines used in cod liver oil emulsion manufacturing. We will cater to your queries along with free guidance related to equipment. Get connected to us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours