Ampoule Sealing Machine: The Complete FAQ Guide In 2025

Do you know how rapidly the market value of ampoule sealing machines is growing?

Today’s market depicts a strong influence of ampoule sealing machines on boosting your profit across various manufacturing industries. What makes it quite unique? How can it bring sealing so accurately? In this article, Ampoule Sealing Machine: The Complete FAQ Guide In 2025, you will find prominent information that will be helpful in your practical life. Without further ado, let's get started!

1.What Is an Ampoule Sealing Machine?

Ampoule sealing machine- Picture Courtesy: ROTA

This is an advanced machine that facilitates you with tremendous encapsulation of medicine in a glass container or you can term it as glass capillary which is considered as an ampoule once it is sealed.

The glass ampoule is highly resistant to heat and can withstand high pressure and intense temperatures. The micro-torch of the machine is used to melt the layer of glass capillary, seal it, and cut it to form an ampoule.

The glass ampoule is mainly composed of very lightweight materials which are in fact lighter than a mass of stainless-steel high-pressure capsules.

So, this machine is composed of several ampoule holders that help in the integrity of the ampoule and hold it firmly till sealing occurs (can tolerate high temperatures as 500°C).

2.What makes the ampoule sealing machine special?

Ampoule sealing machine is a special equipment in manufcaturing industries as it is a reliable option and offering you the certain mentioned benefits.

Drug Safety

Drug Safety

Your drug inside the ampoule is very safe from unwanted factors that can rapidly react with active pharmaceutical ingredients and make it oxidize ultimately affecting therapeutic effects. Therefore, an ampoule sealing machine is a promising solution in terms of hermetic sealing that secures medicines inside.

Large Production Output

Large Production

The compact configuration of the ampoule sealing machine is equipped with components that give filling, sealing, and cutting in one go. Here, you can enjoy all processes in a limited time with a greater output. that is why, it is very popular among various industries that deal with high demand ampoule filling to meet with their output.

The Exact Volume of Medicine

An exact volume of medicine

The ampoule sealing machine helps in the protecting the medicine inside from spillage. The volume of the medicine which is filled by the manufacturer exactly reaching you the same as it is sealed by the machine. Therefore, you can trust it as it knows how to protect the patient’s life by delivering the doses that you want.

Diverse Sample Sizes

Various Ampoule Sizes

It offers a quick changeover and is capable of dealing with multiple sample sizes. No matter, if the filling volume is 5ml, 10ml, or 25ml; you can effectively attain it by ampoule sealing machine.

Improving Visual Attractiveness

Better Appearance

The ampoules sealed by the machine are presented with a smooth and professional sealing that anyone can trust and pick them. Therefore, an impressive appearance of the ampoule can directly impact on customer’s views and confidence. Don’t you think it is a profitable strategy that the ampoule sealing machine offering you? Undoubtedly, this is a reliable way to attain your production goals with excellent ampoule sealing.

Guaranteeing Medicinal Stability

Stable Product Inside

This is well known that the ampoule sealing machine is facilitated with a coil torch for melting and sealing of ampoule’s layer. Indeed, a high temperature is required to seal but it is quite safe for your medicine, and you should not be worried about losing active potential ingredients (APIs). Modern engineering biosciences have created the machine in a way to keep your drug entirely safe.

No Structural Failure

Stable Ampoule Sealing

The machine gently caters to ampoules therefore it has no likelihood of breakage. So, you can save the medicines against spillage, but it gets bunches of ampoules sealing without any harm or structural deformities.

3.What are the Types of Ampoules Sealing Machine?

An ampoule sealing machine is available in various types that we’ve discussed with suitable diagrams for your understanding.

Manual Ampoule Sealing Machine

A Manual Ampoule Sealing Machine- Picture Courtesy: Cozzoli

This is quite simple in structure and designed compactly, therefore this machine is used in small production lines. The machine is quite efficient enough to give you a professionally perfect sealing of the ampoules by either following the tip or pull sealing method.

The machine produces flame polish from the different torches. You can hold the different ampoules one by one to melt the layer and seal them properly. With the application of a delicate spatula, you can keep maintaining shape.

Automatic Ampoule Sealing Machine

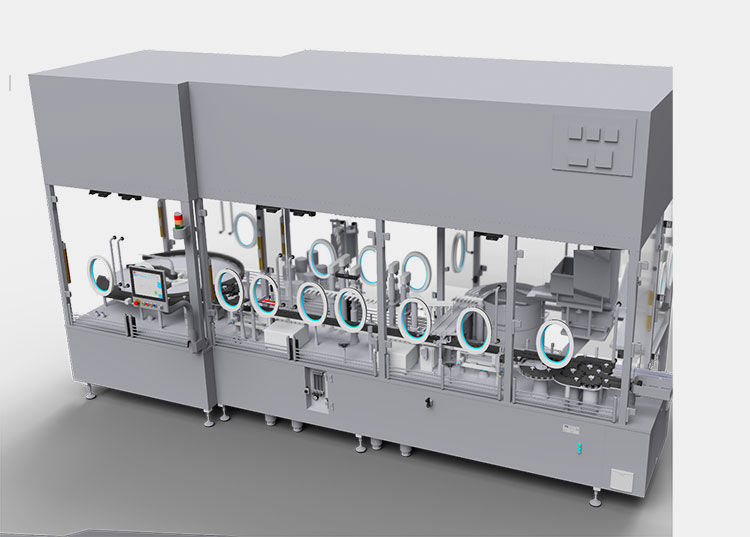

AIPAK ENGINEERING Ampoule Sealing Machine

This is a modern and innovative solution technician involvement is not very important as the equipment itself is capable of running and proceeding with the main task itself. Therefore, you don’t need to stand still for longer as it is designed in a manner that can execute large batches automatically that involves feeding, filling, sealing, and discharging. You can only load the number of glass capillaries or can be loaded via an integrated unit.

Due to high automation, safety, and perfection, this machine is mainly recommended to a larger production industry such as medicinal, healthcare, veterinary, etc.

4.Where An Ampoule Sealing Machine Is Needed?

An ampoule sealing machine is a proven technology that is accepted in industrial sectors worldwide to fill and seal their formulation in individual ampoules. What are those industries or manufacturing platforms? To answer this, please check below:

Research and Development

Research And Development Sectors

Ampoules are the best entity for the storage of various unstable and research-based samples and keep them stable under controlled conditions to carry research-based tests and estimation of compounds related to pilot tests, clinical trials, and related. For that, an ampoule sealing machine is an integral unit that is installed in facilities to carry out a smooth streamlined process without interrupting the workflow.

Pharmaceutical Industry

Medicines

The pharmaceutical preparations are mainly divided into solid dosage forms and liquid dosage forms. The parenteral formulations are basically composed of liquid form and are filled and sealed in ampoules of various sizes. Whether it is a painkiller, anti-allergy, cancer drug, hormones, or any medicine, they are mainly filled in ampoules and sealed by an ampoule sealing machine.

Nutraceutical Industry

Nutraceutical Boosters- Picture Courtesy: Direct Derma Supplies

Do you know ampoules can make your formulation to store for several years? The nutraceutical industry mainly deals with substances directly extracted from organic or plant-based sources and supplements your body with essential macro, or micro-nutrients, multivitamins, hair, nails, skins, immune boosters, and much more. The ampoule sealing machine is ideal equipment you can use in filling and sealing nutraceuticals filling and sealing to allow you to attain quality products and enjoy a healthy life.

Veterinary Industry

Veterinary Industry- Picture Courtesy: Old Town Veterinary

Various veterinary medicines around you are available in ampoules. This included vaccines, probiotics, anti-allergy, anti-pyretic, and medicines that can be used for adjunctive therapies such as gingivitis, managing runny noses, stomach-ache or burning of the stomach, etc, therefore, to facilitate proper storage ampoule sealing machine is used in the veterinary industry for fast production and delivery of medicinal preparation.

Chemical Industry

Preservative chemicals ampoules- picture courtesy: Fisher Scientific

Whether it is research-related chemicals, pesticides, raw materials, organic, and inorganic, etc., they are first prepared in the chemical industry and act as a resource sector for various industries. There are various chemicals in liquids, and powder formulations are mainly designed and manufactured in ampoules and preserved by using an ampoule sealing machine effectively.

Cosmetic Industry

Cosmetic Industry- Picture Courtesy: Saltair

Today various cosmetic formulations such as skin glowing serums, primers, and aesthetic preparations such as collagen stimulating therapy, skin whitening solutions, lip fillers, and face lifting therapies are mainly available in the set of ampoules. Consequently, an ampoule sealing machine is the foremost unit that is required to prepare and pack cosmetic products and can be delivered in a potent form.

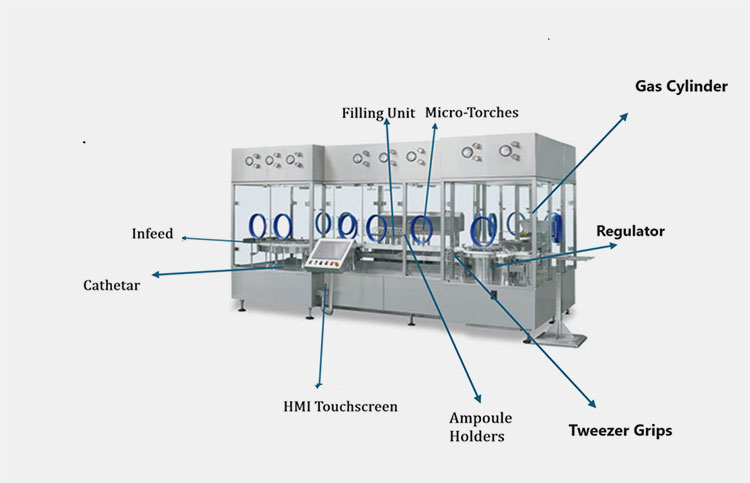

5.Can you explain the parts of the ampoule sealing machine?

Ampoule Sealing Machine

When seeing the view of the equipment, it seems complex. Indeed, it is! For your understanding, we have illustrated this diagram by mentioning the highlighted structure. I know, this would be now way too easy. So, read the parts of the ampoule sealing machine just below:

| Infeed | The number of empty ampoules or glass capillaries enter the machine by the gentle movement of the conveyor belt. Its function is mainly introducing the ampoules inside the machine till all processes are done and leaving the unit. The speed of the infeed can be regulated easily depending on your protocol and production sizes. |

| Catheter | It is a kind of micro-pipette that facilitates the sample inside the ampoule very accurately and precisely. However, there are fewer chances to have maximum exposure to the external environment and filling takes place cleanly and hygienically. Whether it is a liquid or solid powdery substance, it can easily be positioned inside the ampoule with the help of a catheter. |

| Filling Unit | It is a unit composed of the catheter, valve controllers, gas cylinder, holder, etc. to carry the filling process flexibly. |

| Micro Torch | Do you know what seals the ampoule? It is a set of burners which is known as micro-torch, that liberates fire to melt the layer of capillary to acquire a shape and secure the sample by simple formation of a hermetic seal, so your product is now safe and secure till it is broken by the practitioner, nurse, or doctor for usage. |

| HMI Touch Screen | Whether to control the machine, regulate parameters, troubleshoot, etc, you can feed the data by using an HMI touchscreen. It is kind of a connector between you and the machine. You can just enter the keys and settings, and the interpretation can be done by the unit to bring your demand well. |

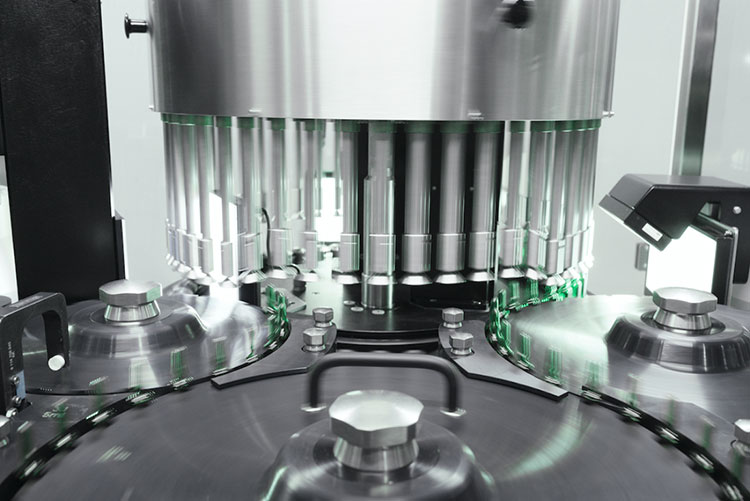

| Ampoule Holders | Before and after sealing, the ampoule holder ensures that these are held firmly without the chances of falling or making the blockage. In this equipment, the design of ampoule holders is rotary or linear depending upon the user’s choice. |

| Tweezer Grips | To maintain the position of ampoules, tweezer grips are designed in the ampoule sealing machine that allow a strong grip on the ampoules for correct positioning. |

| Gas Cylinder | Ampoules, prior to seal, are treated with inert gases that displace the presence of oxygen molecules inside to prevent the oxidation process or progression of microbes after sealing. Hence, it is done to secure your substances. So, gas cylinders are fitted inside the machine that is mainly used to purge argon, nitrogen, or propane gas to create an inert environment and make medicine stable for a longer time. |

| Regulator | The flow of gases, pressure of procedure, and various elements such as regulation of gases and fire are controlled by a regulator. |

6.Do You Know the Working Principle of an Ampoule Sealing Machine?

Working principle of ampoule sealing machine- Picture Courtesy: ROTA

The working principle of an ampoule sealing machine is a little bit tricky. It means the machine processes various steps such as catheterization, sealing, cooling, and discharging. The following steps are taken place gently but consistently to produce large batches rapidly. Let’s have a look to understand the working principle.

| Step 1: Entry of Glass Capillaries | A designed conveyor in the automatic ampoule sealing machine is meant to execute the number of glass capillaries or you can say them empty ampoules into the unit. |

| Step 2: Catheterization | The micro-pipettes are attached to the filling unit or the sample reservoir of the machine helps in the transportation of the fluid easily and with the help of small micro-pipettes, the solution is introduced inside the ampoules. Once it is filled, the ampoule moves ahead toward the sealing procedure. The entire is repetitively takes place.

This procedure is known as a ‘catheterization’, the purpose of which is to draw liquid inside the ampoule very precisely and achievable as glass capillaries are smaller in size and it is not possible to fill them without implementing such techniques as it may result in spillage and product’s wastage. |

| Step 3: Sealing | The machine is designed with several micro-torches, or you can call them a brushed fire head track that is meant to blow fire to melt the layer of glass capillaries finely. Once the layer or the ampoule’s neck is in a molten state it is sealed hermetically and now it is known as an ampoule |

| Step 4: Final Ampoules | Once the ampoules are sealed, they are discharged from the machine and sent to the inspection and labeling units for assessment of sealing under high magnification machines and ensure removal of residual or any pinholes remaining after sealing or fire polishing. |

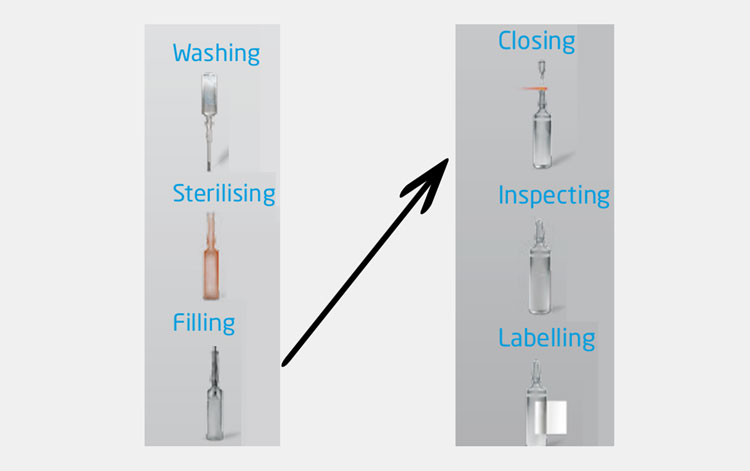

7.What is the complete production line of ampoule sealing machine?

Production Line Steps of Ampoule Sealing Machine

An ampoule sealing process is a versatile and multi-step process that is not meant to be dealt with by one machine. However, it is composed of a series of units that bring step-by-step processing. Thus, a whole production line is based on various sequences of machines that we have discussed below:

Ampoule Washing Machine Cleaning

Ultrasonic Ampoule Washing Machine

To initiate any process, this is the essential unit that you must not ignore. Here, glass capillaries or empty ampoules are subjected to the machine for cleaning and rinsing.

These steps are followed by using detergent, and thorough flushing with water (distill water and water for injection). By application of ultrasonic waves, the high frequency knocking on the wall of ampoules ensures losing and cleaning fragments and makes them particle-free.

Ampoule Drying And Sterilization Machine

Hot Air Drying and Sterilization Machine

To achieve dryness of the ampoules and attain a high level of sterility an ampoule drying and sterilization machine is used. This machine offers hot air laminar airflow inside the sterilization chamber. Thus, it helps in achieving drying but assuring you that ampoules are free from pyrogen and there are no risks hooked to it. This is an essential component of the production line that gives you the flexibility to integrate with other units.

Ampoule Sealing Machine

Ampoule Filling and Sealing Machine- Picture Courtesy: Syntegon

After washing, drying, and sterilization; ampoules are now subjected to an ampoule sealing machine for the dispensing of your formulation followed by micro-torching that helps in the sealing of the ampoules respectively.

Ampoule Inspection Machine

Ampoule Inspection machine- Picture Courtesy: Syntegon

For parenteral formulation, it is necessary to distribute final the ampoule with 100% patient safety. Therefore, the ampoule inspection machine is integrated soon after the filling and sealing machine. it is used to improve your production line by detecting aesthetic defects any leakage, or any unwanted leftovers in the ampoule.

Thanks to this long-lasting inspection machine that is designed with an amazing state-of-the-art solution available in fully automatic and semi-automatic status. It directly offers you product safety by examining through camera-based inspection and helping you to achieve enhanced detection even with minor problems.

Ampoule Labeling Machine

Ampoule Labeling Machine- Picture Courtesy: Aipak

Labeling is required to mention the name of the brand, the manufacturing and expiry date, batch number, volumes, etc. Therefore, once it is sure that the ampoules are perfect and approved by the inspection machine; it directly goes to the labeling machine for the mandatory application of labels.

To label small ampoules, a specialized ampoule labeling machine is designed belonging to different types such as paper labels, self-adhesive, thermal printers, etc.

8.What is the temperature of the ampoule sealing machine for sealing?

Sealing Temperature of the Ampoules

Various types of glass materials are used for ampoules. Ideally, every material has its specific melting temperature on which machine sealing is permissible by the user., a uniform heating field is provided around the spinning neck of the ampoule that typically goes to 1425 °C. This range of temperature is mainly considered as an ideal or suitable one for the sealing of the ampoule neck. Besides this, the temperature of oxyhydrogen flame ranges as high as 2800°C and can melt and seal ampoules rapidly.

Moreover, along with temperature, the exposure time, thickness of glass, and the rotational velocity of the ampoule also matter to attain a suitable sealing.

9.What are the common sealing methods used in Ampoule Sealing Machine?

The sealing of ampoules can be basically achieved by two following methods. For example:

Tip Ampoule Sealing

This is also known as the bead-like sealing method. This method of sealing is very safe and helps in the hermetic bonding of the ampoule neck when it is exposed to fire brushes that melt the edges of the neck.

The continuous spinning of ampoules takes place to form a smooth closing of ampoules to create a hemispherical shape. It is considered the safest procedure as it doesn’t require much technical expertise than the pull method, and it flexibly forms secure sealing.

Pull Ampoule Sealing

Pull Ampoule Sealing

This is the way more technical form of seal that is implemented on ampoules of thin glass. Here, the ampoule’s neck is melted when exposed to high flame and you can pull the edges with a spatula to create a firm sealing. Upon cooling, a tip-like closure is formed.

10.What problems you can encounter with the ampoule sealing machine? how to deal with them?

An ampoule sealing machine has special built-in properties that allow you easy processing. But it may have some technical issues that you should know how to handle. Have a look at possible issues and their solutions.

How to handle volatile materials? What happens when filling material is flammable?

Ampoules with Volatile Content

This is common that ampoules are also filled with volatile materials. For example: acetone, anaesthesia, or any other chemical reagents.

Solution

To solve this problem, modern machines are already built with high precision to manage flammable substances. However, utilization of a vacuum or partial vacuum will help you to prevent materials from fire. Secondly, try to regulate the torch with little to medium flame, so, it can slowly melt the edges of the glass keeping the content safe.

How to manage the irregular or clamped flat ampoule tip?

Irregular Or Clamped Flat Ampoule Tip

When the sealing heat of the ampoule sealing machine is not optimized or the preheating flame as well as sealing flame is low or the glass of the ampoule is thicker than the ideal sealing temperature, it may result in a clamped flat ampoule tip.

Solution

It is recommended to regulate and monitor the front as well as the rare sealing temperature of the torch related to the ampoule thickness. Moreover, check and regulate the rotating speed of ampoules during sealing to provide sufficient heat to the edges of the ampoule and get a uniform sealing.

A big bubble is formed in the ampoule during the sealing process.

Big Bubble During Seal- Picture Courtesy: European Pharmaceutical

When the flame intensity is too strong the ampoule sealing is achieved by an unwanted big bubble that makes the ampoule disqualified as well as easily breakable.

Solution

It is recommended to regulate the intensity of the flame and allow limited exposure time to the ampoule. Moreover, the distance between the ampoule and the fire brushes should be adjusted till the acceptable centreline.

Conclusion

Whenever glass capillaries are to be processed, it would be challenging. Undoubtedly, ampoules need to be handled critically, for that, an ampoule sealing machine is the solution. It allows low and high-volume ampoule filling and sealing tasks. This is a hi-tech innovation that is facilitated with several burning torches, and filling stations, and capable of integrated with various units to make your production line a good supportive system. If you are planning to achieve your dream goal related to ampoule sealing machine, Why Not Trying Us? AIPAK ENGINEERING is the hub of providing series of machines involved with preparation and packing of parenteral formulations. Discuss your plan with us to avail excellent solutions related to ampoule sealing machine. contact us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours