AIPAK ENGINEERING Pharmaceutical Autoclave

AIPAK ENGINEERING Pharmaceutical autoclave uses saturated steam as the sterilization medium, and through pulsating vacuum, the saturated steam completely penetrates the surface of the item. The high temperature saturated steam under high pressure is used to kill all microorganisms and their spores, and the sterilization effect is reliable. It is the most effective method in physical sterilization. Eliminating the influence of cold air on temperature through pulsating vacuum exhaust, and finally combining vacuum dehumidification with jacket drying for sterilization of items. It is mainly used for damp heat sterilization of the following products: sterile clothes in b/c clean area, various antibiotics, filling rubber plugs, aluminum caps and aluminum barrels, rubber plugs, aluminum caps and aluminum barrels for lyophilized powder needles and other occasions with high requirements.

AIPAK ENGINEERING Pharmaceutical Autoclave

SQS/SYS Series Water Shower Pharmaceutical Autoclave

AIPAK ENGINEERING SQS/SYS series water shower pharmaceutical autoclave is widely used in thesterilization of sealed large-capacity liquid products (large glass bottle infusion, plastic battle infusion, soft bag packaging infusion, glass bottle oral liquid, and etc.). Its temperature control is wide (80-126 ℃), and has rapid heating and cooling function, which reduces the effect to the drug by high-temperature sterilization. And because its good temperature evenness control can effectively prevent the packages from deformation, it could also be used for the sterilization of (tinplate packaging, cocking bag packaging) food , functional drinks and etc.

304 or 316L stainless steel material chamber

GMP verification interface

Industrial control system PLC + HMI

AQS Series Steam Ampoule/oral Liquid Leak Test Pharmaceutical Autoclave

AIPAK ENGINEERING series steam ampule /oral liquid leak test pharmaceutical autoclave adopts saturated steam as sterilization medium, which is used for high temperature sterilization, leak test and cleaning treatment of small regulatory capacity (smaller than 10ml) water injection and oral liquid products, such as ampules, vials and tube bottles.

Independent temperature monitoring system

F0 value and temperature time double guarantee sterilization effect

Uniform sterilization temperature of products

AQS-S Series Water Shower Ampoule/oral Liquid Leak Test Pharmaceutical Autoclave

AIPAK ENGINEERING AQS-S series of water shower ampule (oral liquid) leak test pharmaceutical autoclave adopts high temperature circulating water as sterilization medium, which is mainly used for water spray sterilization, leak detection, and cleaning treatment of injection and oral liquid, such as ampules, vials and tube bottle. Its temperature evenness is good, and temperature control range is wide (80-126℃). Vacuum leak test plus color water test insure 100% waste check rate. Temperature time and Fo dual control meet the requirements of pharmacopoeia.

Convenient for users to carry out equipment verification at any time

Precise control system

Unique door lock mechanism

XQS/XYS Series Rotary Water Shower Pharmaceutical Autoclave

AIPAK ENGINEERING XQA/XYS series of rotary water shower pharmaceutical autoclave adopts high temperature circulating water as sterilization medium. It is mainly used for high temperature sterilization of ampules and infusions, which are filled with suspension, emulsion, and other kind liquid that is easy to precipitate or have thermo-sensitive chemical characteristic. During the sterilization process, the liquid is in relative motion state, the product sterilization temperature is more even by this way, which helps to eliminates the phenomenon of precipitation and crystallization completely.

Accurate temperature control

Stable operation

Intelligent drying system

KQS/KYS Series Rapid Cooling Pharmaceutical Autoclave

AIPAK ENGINEERING KQS/KYS Series rapid cooling pharmaceutical autoclave adopts saturated steam (or pure steam) as sterilization medium, which is widely used in the high-temperature sterilization and rapid cooling operation of all kinds of sealed heat-resistant glass bottles or oral liquid packed infusion. It is widely used in the pharmaceutical, hospital preparations, food and other industries that have product requirement for the equipment capacity less than 5m3, and sterilization temperature between 105℃and 126℃.

Internal and external double structure

Complete electrical and mechanical safety interlocking device

Easy to operate

MQS Series Motor Door Pulse Vacuum Pharmaceutical Autoclave

AIPAKENGINEERING series motor door pulse vacuum pharmaceutical autoclave adopts saturated steam (or pure steam) as a sterilization medium. It eliminates the impact of cold air on the temperature by pulse vacuum. Vacuum dehumidification combined with jacket heating for drying the items. And finally, the sterile air is emptied to achieve pressure balance.

Advanced technology,

Superior performance

Simple operation and reliable operation

CQS Series Pure Steam Pharmaceutical Autoclave

AIPAK ENGINEERING CQS Series pure steam pharmaceutical autoclave is mainly used for the high temperature sterilization of clothes, metal utensils, aluminum cap plug that will be used in hundred level clean areas or other places that high standard requirement. It adopts pure steam as sterilization medium, all parts that contact with the sterilization items (chamber, pipeline, valve, loading cart and etc.) directly are made by 316L stainless steel. It eliminates the impact of cold air on the temperature by pulse vacuum.

Large energy, sterilization effect is excellent

Simple structure, easy operation

Suitable for many fields such as industry and medical treatment

MQS-P3 Series Biological Safety Pharmaceutical Autoclave

AIPAK ENGINEERING MQS-P3 Series biological safety pharmaceutical autoclave adopts saturated steam as sterilization medium, which is equipped with high efficient bio-safety filter. It is mainly used for the high temperature sterilization for the toxic substances in P3 laboratory and biological pharmaceutical industry. Meanwhile, this series equipment has varieties of loading and sterilization programs for users to choose for sterilizing items in different properties. And this machine could be accessorized with secondary living bacilli exterminate system, and biological hard sealing or biological soft sealing to partition the loading and unloading side door area.

GQS Series General-purpose Steam Pharmaceutical Autoclave

AIPAK ENGINEERING GQS Series general-purpose steam pharmaceutical autoclave is multi-function integrated type high-temperature sterilization equipment, adopting pure steam as sterilization medium. All parts in contact with the sterilization items (chamber, pipe, valve, loading shelves, etc.) are made by 316L stainless steel. This equipment eliminates the impact of cold air on the temperature by pulse vacuum. Vacuum dehumidification combined with jacket heating for drying the items.

Reliable disinfection and sterilization effect

Convenient operation, safe use

Energy-saving and durable

TQS/TYS Series Ventilation Pharmaceutical Autoclave

AIPAK ENGINEERING TQS/TYS Series ventilation pharmaceutical autoclave adopts mixed clean steam and air as sterilization medium, equipment and product pressure balance and back pressure protection can be well controlled by this way, so this equipment is widely used for the items that need to keep shape and sealed in the same time of sterilization. Force convection fan and air guide plate structure make the chamber non saturated steam well mixed to ensure the sterilization temperature evenness.

Fully stainless steel structure

Hand wheel type of quick-open door structure

Door safety lock system

ZQS/ZYS Series Chinese Medicine Pharmaceutical Autoclave

AIPAK ENGINEERING ZQS/ZYS Series Chinese medicine pharmaceutical autoclave adopts clean steam as sterilization medium. Operated by special sterilization process, it is specifically for the high temperature sterilization and drying for the Chinese herbal medicine, Chinese medicine powder products, and some kind of food such as spices. It eliminates the influence of cold air on the temperature by pulse vacuum, vacuum dehumidification combined with jacket heating for drying, and finally, the sterile air is exhausted to achieve pressure balance. For some products that have high drying effect requirement, the equipment can also be installed with heating coil.

Over temperature&over pressure auto-protection

Safe protection of water lacking

Self-inflating type seal

PQS/PYS Series Culture Medium Pharmaceutical Autoclave

AIPAK ENGINEERING PQS/PYS Series culture medium pharmaceutical autoclave adopts saturated steam as sterilization medium, which is specifically used for the high-temperature sterilization of medium loaded by non-sealed container. Its temperature is adjustable, and temperature detect method is flexible. It has reliable sterilization effect for the culture medium in varieties of standard and volume. Temperature time and Fo dual control meet national pharmacopoeia requirements.

Automatically shut off with beep reminding after sterilization

With two stainless steel sterilizing baskets

Easy to operate, safe and reliable

DMH Series Dry Heat Pharmaceutical Autoclave

AIPAK ENGINEERING DMH Series dry heat pharmaceutical autoclave is used for depyrogenation of high temperature bearing items after cleaning by successive circulation of high temperature air. It is widely used for the high-temperature sterilization operation of injection ampule, vials, oral liquid bottles and other medical glass bottles and stainless steel utensils in pharmaceutical factories.

Over pressure auto-discharging

Over current auto-protection

Over temperature auto-protection

DZK Series Low Temperature Vacuum Pharmaceutical Autoclave

AIPAK ENGINEERING DZK series low temperature vacuum pharmaceutical autoclave is suitable for drying heat sensitive materials which are easy to decompose, polymerize or deteriorate at high temperature. It can be disinfected before drying, and no impurities are mixed into the material during the drying process. It is static type vacuum dryer, so the shape of dry material will not be damaged after the cycle. It is mainly used for drying medicine extract, herbal medicine and raw material medicine powder.

High quality SUS304 stainless steel material

Dual scale indicate pressure gauge

Light indicate working status

VHP Series Hydrogen Peroxide Pharmaceutical Autoclave

AIPAK ENGINEERING VHP series hydrogen peroxide pharmaceutical autoclave this transfer chamber sterilize the surface of the interior chamber and items inside the chamber by using vaporized hydrogen peroxide sterilization technique, to ensure that items will not bring new microbial contamination to the high grade clean area after passing through the sterile transfer chamber.

LED digital display screen

Microcomputer control system

Temperature, time of sterilization can be set

AIPAK ENGINEERING Pharmaceutical Autoclave Applications

AIPAK ENGINEERING Pharmaceutical Autoclave Video

The Buyer's Guide

Pharmaceutical Autoclave: The Complete FAQ Guide In 2025

How to maintain safety and quality of products in the pharmaceutical industry?

Picture Courtesy: Ethide Laboratories

Nevertheless, sterilization is the most essential point that plays a significant role in balancing sterility and hygiene in the pharmaceutical sectors.

In the post ‘Pharmaceutical Autoclave: The Complete FAQ Guide In 2025’ we are going to discuss all basic queries related to pharmaceutical autoclave. For instance, its designs, working, benefits, and much more.

1.What is a pharmaceutical autoclave?

Pharmaceutical Autoclave

A pharmaceutical autoclave which can also be referred to as a steam sterilizer is mainly used to clean items via using the concept of positive pressure and high temperature

This is hollow equipment where steam is mainly used as a principal source of sterilization that completely eradicates microbes such as bacteria, spores, fungi, viruses, etc. Let me explain you in an easy way! You must have seen or used a pressure cooker, of course, it is the rapid way to get your food prepared quickly.

Autoclave- Picture Courtesy” Plant cell technology

A French scientist Denis Papin in 1697 brought the concept of steam digester which was just like a pressure cooker where items were treated with heat, and it was suggested that moisture produced by steam is very efficient to penetrate or transfer and eliminate microbes.

In 1884, the first pharmaceutical autoclave was utilised for healthcare applications by Charles Chamberland, and it was confirmed that steam and hot air both have combined disinfectant properties that are the strongest as compared to dry heat. Hence 1933, an advanced autoclave came into pharmaceutical application with pressure and steam properties in high-temperature chamber.

Today you can see various types of pharmaceutical autoclaves used in different fields and are based on pre-vacuum cycles, steam flush, and various significant techniques.

2.What is the role of pharmaceutical autoclave?

A pharmaceutical autoclave has some particular roles in the pharmaceutical manufacturing setup. Some of them are described below:

Pharmaceutical autoclave- picture courtesy: ARES Scientific

Sterilization of Pharmaceutical Equipment

Pharmaceutical items- picture courtesy:westlab

Equipment such as beakers, flasks, pipettes, petri dish, round bottom flasks, and related tools that are frequently used in pharmaceutical industries, especially in the manufacturing, quality control, Research, and development areas are recommended to be used if they’re properly passed through the pharmaceutical autoclave.

Cleaning of Waste Products

Biohazards- picture courtesy: Carl Roth

In the pharmaceutical industry, there are various other substances to be autoclaved apart from equipment. During processing, you can find different waste products to be disposed of; but discarding directly would be harmful to the ecosystem. The pharmaceutical autoclave is mainly used for encountering generalized and waste products to be safe before final discard. These are mainly included with the waste filter paper, vials, pathogenic solutions, gowns, masks, etc.

Sterilizing raw materials

Raw ingredient- picture courtesy:Norex flavour

Certain pharmaceutical raw materials must be properly sterile before implementing them into manufacturing processes. Such ingredients involve raw media that are mainly used for cell culturing, distilling water, and water injection (in certain cases).

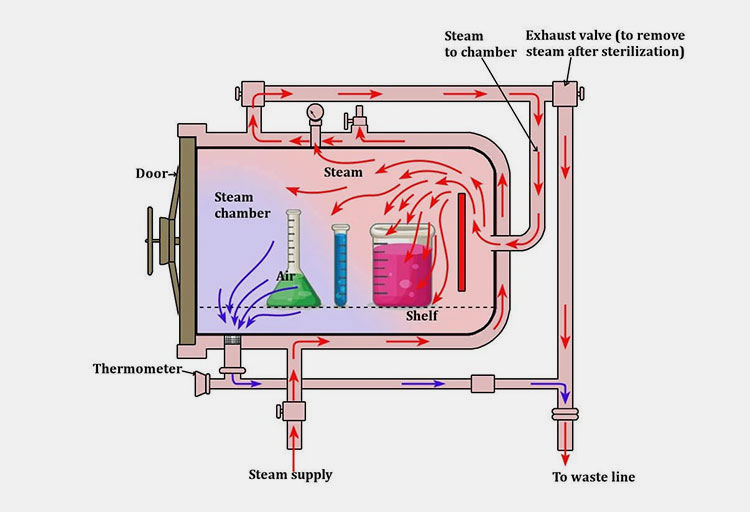

3.What is the working process of a pharmaceutical autoclave?

Working principle of pharmaceutical autoclave

Whether there's a small-size pharmaceutical autoclave or a bulk size, its working principle is always based on the same way as you use a pressure cooker in your kitchen. Of course, based on steam, when you're sealing the door or lid of it, the air inside transforms into steam.

With time, heat induction pressurizes the inside environment and brings the process of sterilization following a certain period. Once attaining a required cycle, the developed steam is pumped out and you can grab your items to be sterilized.

The entire procedure takes place in the following important steps:

The working graph of pharmaceutical autoclave

Purge Phase

This is the first phase that is mainly based on the development of the steam inside the autoclave as well as slight induction of the pressure. In this phase, the air starts to displace slowly with steam side by side you can observe the purging of the temperature and pressure.

Exposure (Sterilization) Phase

Once the system reaches to required temperature and pressure, now it is considered as a controlled unit where an ideal medium is maintained to decline the activity of the present microbes around the surface of items as the system is entirely fixed and closed (exhaust valves). The desired set point or desired temperature which is known as a dwell time allows proper exposure to your items.

This is well known as the boiling point of water followed by an atmospheric pressure of 760 mm of Hg. So, once the boiling point rises the pressure inside the system increases too. Therefore, heat penetrates very deep into the items exposed to certain environments making microbial activity almost irreversible and causing them to be destroyed. So in this system, the temperature is with the pressure of 15 psi or 775 mm of Hg.

Exhaust Phase

Once the desired time for the specific items is completed, the pressure has to be released by opening the exhaust valve. Now the material inside is extremely hot and should be allowed to touch once they are cool down properly.

4.What are the specific applications of pharmaceutical autoclave?

You might be surprised to know that a pharmaceutical autoclave is the only apparatus of choice when it comes to attaining proper way of sterilization in mostly industrial settings. This equipment has a significant tremendous role in various industries. Some of the important industries we have enlisted for you are:

Pharmaceuticals Industry, Dental, and Pharmacies

Sector for pharmaceutical autoclave -Picture courtesy: the economic times

The purpose of a pharmaceutical autoclave is to offer excellent performance and technical support during the manufacturing of pharmaceutical goods, providing central sterilization in dental and pharmacies for maximum possible cleaning and patient-controlled treatment related to OT, prosthetics, and related protocols.

Healthcare Offices or Institutions

Healthcare institutions- Picture Courtesy: Melag autoclave

As medical, healthcare institutions must have to take extra care for maintaining cleaning and sterilization, therefore a pharmaceutical autoclave is known as the best tool. There are commonly used items such as tools used in surgeries, scalpels, forceps, syringes, protective equipment, and glassware that must be repeatedly sterilized after each use, therefore you can be capable of using them again without any chances of infection and keep the patient completely safe.

Tattoo, Salons, Or Piercing Shops

Usage of pharmaceutical autoclave

This is true that many body shaping centers are believed to be very sterile and the pharmaceutical autoclave is the state-of-the-art equipment used to ensure greater sterilized tools prior to using them on clients.

Since the tools used for such purposes as needles, tattoos, or skin cleaning mostly penetrate your skin therefore there are greater chances of infection or disease spread if not properly cleaned. In order to protect individuals from blood-borne diseases, a pharmaceutical autoclave is utilized for sterilization.

Food and Beverage Industry

Food and Beverage Preparation- Picture Courtesy: Terra Food Tech

Foodborne diseases are always very critical and can impose risk on the overall public. Therefore, this unit of manufacturing and packing is highly regulated where almost every item is used after being passed through a pharmaceutical autoclave to destroy the presence of fungi, bacteria, or other microorganisms that progress illness and contaminate foods.

Water and Wastewater Treatment

Water and Wastewater Treatment- Picture Courtesy: Melag Autoclave

The pharmaceutical autoclave is very important in the area of water and wastewater to subside the occurrence of pathogens by inducing a sterilization process. This equipment is used in water treatment plants for the effective decline of micros and disrupts them by rendering the process of further reproduction.

Laboratory and Research Facilities

Research labs- picture courtesy: Westerville

No lab or research facility is capable of operating without adding a pharmaceutical autoclave as it ensures aseptic working conditions. There are wide range of glassware, and operating equipment like pipettes, Petri dishes, and testing tooling in the lab, and R&D requires sterilization by pharmaceutical autoclave.

Cosmetics and Personal Care Products

Cosmetic formulation- picture courtesy: Medical equipment service

The personal care products and cosmetic industries process and utilize pharmaceutical autoclaves for product quality and improved safety. This is because pathogen mostly invades your cosmetic products such as lotions, creams, or related products if containers are not properly sterilized. The contamination comes in the form of microbes and causes skin infections. Therefore, pharmaceutical autoclaves are used to ensure the utilized materials are free of contaminants or media for them.

Hospital, Hotels, and Travel Industry

Pharmaceutical autoclave uses- picture courtesy: Cocoon IT Services

The following areas rely on pharmaceutical autoclaves to ensure that your guests or clients are treated with sterile items during travel, hospitals, hotels, or related activities. Proper sterilization maintains a clean and safe environment for guests and prevents nosocomial infections.

Veterinary Practices

Veterinary health practices- picture courtesy: whatcomesvethospital

Your pet needs safe treatments; that’s why a good institution must follow regulated SOPs to protect animals against infections spread by uncleaned tools. The pharmaceutical autoclave is used to sterile all related materials and items that are applied for animal treatment to offer promising services.

5.Why are Pharmaceutical Autoclaves more in demand?

A pharmaceutical autoclave is known as the best equipment for preventing medical settings from invasion of pathogens. There are a few reasons behind its demand in manufacturing industries and healthcare setups.

Consistency and Reliability

Picture courtesy: terra food tech

A pharmaceutical autoclave offers you highly consistent and reliable outcomes upon usage, which means that when your materials are treated with this robust equipment then there won't be any chances of infection or harming patients.

Broad Range of Usage

Sterilizing broad range items- picture courtesy: SWS group

This excellent machine is capable of dealing broad range of applications. Whether it is instrumentation treating biohazard, or biological samples; pharmaceutical autoclave offers diverse settings for the sterilization of these items.

Non-Toxic Process

No harsh chemical required- Picture Courtesy: Bulb Laboratory

If you see its working principle, a pharmaceutical autoclave's main functionality is relying on water or steam and pressure. So, there are no harmful reagents or any toxic substances that your material or you encounter. This is promisingly safe for you and you can assess greater sterilization by its processing.

Safety Measures

Safe way of sterilization- Picture Courtesy: Men Health

The following machine features a tremendous safety valve that is highly protective in terms of user safety. It is designed with pressure lockers, which means you cannot open it if in case of high pressure inside, similarly, the pressure is gently released from the chamber making it safe for you if built high inside.

Heat Tolerance and Penetration

Effective sterilization- Picture Courtesy: AdvinHealthcare

The machine generates high temperature and pressure, thus giving a more effective way of sterilization without damaging your items.

Environmental Safety

Eco-system friendly- Picture Courtesy: Ecosteryle

This machine is known as eco-friendly and helps in neutralizing those products that are potentially harmful to you and the environment such as biohazardous.

Economic Efficiency

Economic way of sterilization- Picture Courtesy: cleanco waste

A pharmaceutical autoclave is just an initial investment, but when using it and gaining benefits is comparatively more than you spend. This is the most important aspect behind its high demand in various healthcare sectors, pharmaceuticals, and various institutions.

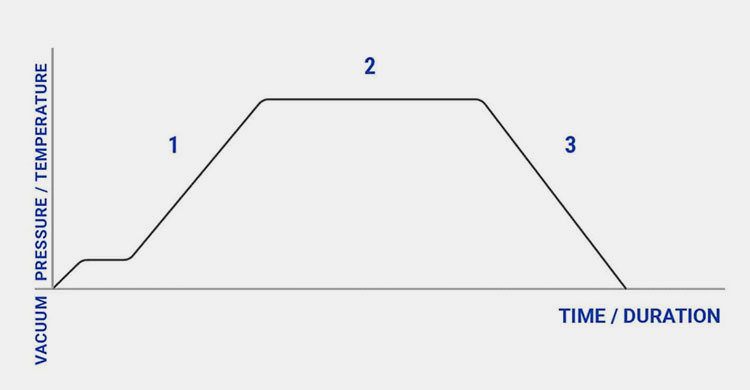

6.What are the parts of a pharmaceutical Autoclave?

Basic parts of pharmaceutical autoclave

The main parts of the machine are described below:

Handwheel

This part is used to tighten the system and ensures that no heat can escape from the inside unit.

Screw Rod

This is a preventive component that helps in the avoidance of accidental opening units.

Drainage Valve

The unwanted waste can be drained out the unit by means of the draining device.

Door Gasket

A supportive part that improves the strength of the machine by securing more temperature and pressure.

Chamber

A chamber is used to provide exposure time and is composed of shelves to place the items.

Control Panel

You can add a protocol, temperature setting, duration of sterilization, number of cycles, and related points via provided keys.

Door Bellow

It features firm securing of door and reducing the risk of pressure or temperature escape from the unit

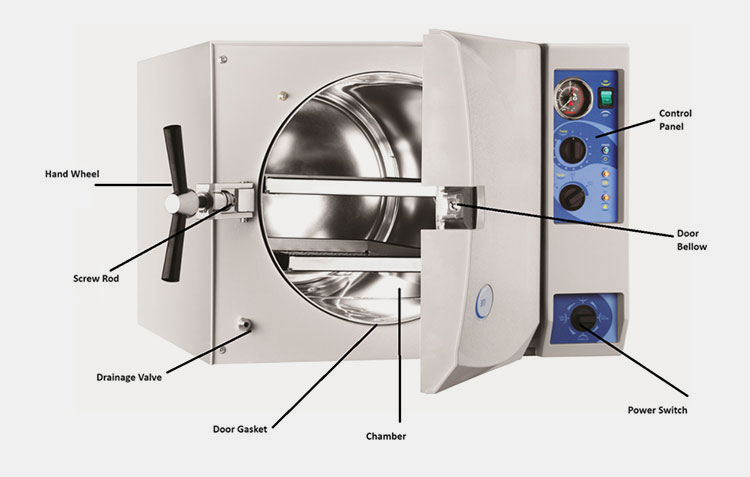

7.What are the main types of pharmaceutical autoclave?

Various types of pharmaceutical autoclaves can be differentiated from each other due to specific characteristics as mentioned in the below classification. The mentioned types of pharmaceuticals are:

Classification of pharmaceutical Autoclave

Types of pharmaceutical autoclaves categorized by loading

The pharmaceutical autoclave basically works at high temperatures and high pressure to clean the items and related products. The basic function of items mainly allows how to load and sterile them. Therefore, the two types of pharmaceutical autoclave are:

Vertical Pharmaceutical autoclave

Vertical pharmaceutical autoclave- Picture courtesy: Raypa

This type of pharmaceutical autoclave has a top lid where you can load material to be treated.

This kind of machine is used in laboratory and clinical setups where you mainly have a small capacity to install and set the machine.

Horizontal Pharmaceutical Autoclaves

Horizontal pharmaceutical autoclave

This is known as a front-loading pharmaceutical autoclave where the machine is mostly designed with a larger footprint and a broader chamber. This machine is occupying a larger installation space and can deal with many items per day.

Gravity displacement pharmaceutical autoclaves

Gravity displacement pharmaceutical autoclave

This is the most popular type of autoclave where a dense intensity of pressure steam is developed that displaces air out of the chamber. Such equipment helps in the loading of various items such as surgical equipment, biohazards, etc.

Pre-vacuum (prevac) Pharmaceutical Autoclaves

Vacuum pharmaceutical autoclave

You can call it the most versatile method of sterilization. This machine mainly utilizes a vacuum that pumps and removes the presence of air and ensures better steam penetration into each item presented inside the chamber. This is the best way can sterilize a broad range of such as you can load fabric porous items, as well as large items. Not only this, but you can also put materials with high-density polyethylene including sharp objects, syringes etc.

Different Types of Pharmaceutical Autoclaves Categorized By Class

This is a category that is based on a class of sterilization that is applied to items exposed to it. For example:

Sterilization class of pharmaceutical autoclave- Picture Courtesy: British dental nurse

Class N autoclaves

This is mostly a simple class that is only used for minimal medical tools and pharmaceutical items and a specific amount of air is displaced by the machine to sterilize the objects.

Class S autoclaves

This is known as another or sub-type of displacement pharmaceutical autoclave that utilizes dense steam in a constant repetitive interval such as approx. thrice time to ensure high cleanup.

Class B autoclaves

This is the most faster and premium type which sterile your product by using a powerful dose of creating a vacuum. Due to this feature, such a class is considered the most premium and very effective that is utilized in various medical facilities.

Different types of pharmaceutical autoclaves by capacity

This is a pretty forward type which is very important and based on the size of pharmaceutical autoclaves and mainly selected by customers depending on their item’s sizes and processing capacities.

Large or Bulk Pharmaceutical Autoclave

Large Pharmaceutical Autoclave- Picture courtesy: packaging machine

This type of pharmaceutical autoclave has a range of capacity from 110 to 880 Liters and is preferably used by sectors that are connected to notable quantities of materials to be sterilized. Such as pharmaceuticals, hospitals, hotels, food, etc.

Medium-Sized Pharmaceutical Autoclave

Medium Pharmaceutical Autoclave- Picture Courtesy: steelco

The capacity range of medium sized pharmaceutical autoclave lies between 75 to 200 Liters and this is an ideal choice for clinics, pharmacies, laboratories, research labs, dental and operation theatres,

Small (Benchtop) Pharmaceutical Autoclave

Benchtop Pharmaceutical Autoclave

The capacity range of benchtop pharmaceutical autoclaves lies at approx. 16 to 25 Liters. It is indeed a compact form of sterilization hooked to limited applications and small spaces.

8.What are the Dos and Don’ts when using a pharmaceutical autoclave?

Every pharmaceutical industry uses the pharmaceutical autoclave to sterile different items because it is an effective and environment-friendly method that uses natural steam as opposed to other sterilization methods.

Here are some important dos and don’ts when using a pharmaceutical autoclave to ensure complete sanitation of items.

Do Wear PPE When Using Pharmaceutical Autoclave

Wear PPE-Picture Courtesy: All States M.E.D.

Although it is safer to handle the pharmaceutical autoclave than use chemicals, still one must wear PPE like eye protection glasses, heat-resistant gloves, and overalls when using the autoclave. It is essential to cover your arms, hands, and face to prevent steam from burning the skin.

Do Check the Pharmaceutical Autoclave before Application

Inspection of Pharmaceutical Autoclave- Picture Courtesy: LinkedIn

Operators are trained to clean the pharmaceutical autoclave after use, however, sometimes they forget to clean them. It is, for this reason, the pharmaceutical autoclave must be checked before every use to ensure its cleanability and sterility. Spills and debris should be inspected before use. Moreover, examine the door gasket before use to ascertain it does not need repair or replacement.

Arrange Your Items

Arrange Items- Pictured Courtesy; Medical Equipment Services

For proper steam circulation and penetration, it is a must to arrange your autoclavable items. There should be sufficient space between every item and be aware of the pouching effect.

Put Heavier Objects at the Bottom

Heavier Objects at Botton- Picture Courtesy: ERD

Place lighter objects on the top of the pharmaceutical autoclave and put weighty items at the lower portion of the autoclave to allow steam to circulate on every side.

Use Chemical or Biological Indicator

Biological Indicator- Picture Courtesy: HealthMark

To measure the sterilization quality of the item, it is necessary to use chemical or biological indicators. This indicator tells you about the completion of the sterilization process.

Select Correct Cycle

Selecting Right Cycle- Picture Courtesy: Microbiology International

Different materials have different sterilization temperatures. So, choosing the right cycle will make a big difference. Selecting the right temperature, wrapping, or unwrapping items is crucial for successful sterilization.

Don’t Overcrowd Pharmaceutical Autoclave

Overcrowd Pharmaceutical Autoclave- Picture Courtesy: Medical Equipment Service

If the autoclave is overcrowded and overloaded it could lead to ineffective sterilization. This is because steam does not reach every surface, consequently increasing the risk of infection. Also, items should not touch the walls of the pharmaceutical autoclave or its door, as it will cause poor sterilization.

Don’t Open the Door of Pharmaceutical Autoclave During Cycle

Opening the Door During Cycle- Picture Courtesy: Alpha Scientific

It is important to fully lock and seal the doors of the pharmaceutical autoclave before the beginning of the sterilization cycle. Wait for the completion of a cycle before opening the door. If you need a certain item, first stop the cycle and wait for depressurization before holding the item.

Don’t Take Out Item Quickly

Taking Items Quickly- Picture Courtesy: MELAG Autoclave

It is tempting to remove the items as soon as the cycle finishes. But first, wait for pressure and temperature to fall to zero. Once the chamber is depressurized then slowly take out the items while keeping your face away to avoid direct exposure to steam.

9.How long do your items remain safe & sterile after a pharmaceutical autoclave?

Sterility of Items in Pharmaceutical Autoclave-Picture Courtesy: Electro-Steam

In pharmaceutical autoclaves, sterilization occurs by heating instruments and packaging containers above boiling points.

The expiry period of sterility after a pharmaceutical autoclave depends upon several factors like wrapping of instruments, storage condition, transportation, and processing guidelines.

If the packaging integrity is not compromised, then materials have a longer sterile life. Items stored in a closed environment with little fluctuations of humidity and temperature remain safe and sterile after a pharmaceutical autoclave for a longer period. Items stored and transported in dusty or uncleaned environments quickly lose their sterility.

The main factor for ensuring sterility is the careful handling of intact packaging. If ideal conditions are met, then items remain sterile for 96 weeks.

10.What Items are recommended for a pharmaceutical autoclave?

Pharmaceutical autoclave sterile broad range of items. This autoclave is commonly used for sterilizing solid items like medicines and drugs. It also has sterile pharmaceutical water. Various other components sterile by pharmaceutical autoclaves are:

| Glass Wares | Breakers, glass jars, pipettes, test tubes |

Picture Courtesy: deepaskincare.in |

| Packaging Containers | Cups, trays, medicine pouches |

Picture Courtesy: MSI Precision Instruments |

| Surgical Items | Scissors, clamps, forceps, scalpels, blades, |

Picture Courtesy: MELAG Autoclave |

| Rubber Items | Syringe plunger, gloves, gaskets, seals, rubber tubing |  |

| Pharmaceutical Materials | Syringes, ampoules, vials, stoppers |

Picture Courtesy: Excelsior Scientific |

| Packaging Materials | Pouches, Aluminum foil wraps |

Picture Courtesy: Cardinal Health |

11.What items should be avoided from the pharmaceutical autoclave?

Items Placement in Pharmaceutical Autoclave- Picture Courtesy: MedicalSearch

Some materials cannot tolerate high temperature and pressure, so these items should not be placed in the pharmaceutical autoclave. These items can also emit harmful substances that contaminate other materials and cause harm to autoclaves as well. These items are:

Plastic Wares

Polyethylene, polystyrene, polyurethane, and other plastic wares should not be placed in the autoclaves. Plastic containers are not pharmaceutical autoclave safe as they have low melting temperatures between 105-140°C. This melted plastic ruins the walls of autoclaves and other items and disrupts the autoclavable cycle because pharmaceutical autoclave needs to be cleaned upon encountering melted plastics.

Flammable Chemicals

These chemicals ignite and explode at high temperatures and include alcohol, acetone, and other flammable solvents.

Corrosive Chemicals

These chemicals damage the pharmaceutical autoclave and can include strong acids, bases and bleach.

Volatile Chemicals

These emit hazardous chemicals upon high pressure and temperature. These chemicals are chlorine, sulfates, hypochlorite, etc.

Hazardous Materials

Radioactive materials and pathological wastes including animal tissues, organs, bodies, etc should be avoided from pharmaceutical autoclaves.

Metals

Reactive metals like sodium, and potassium and corrosive materials like iron and regular steel react and corrode, respectively in steam presence.

12.What are the maintenance points for pharmaceutical autoclave?

Pharmaceutical autoclave- picture courtesy: Alldent

The maintenance points for pharmaceutical autoclave are the following:

Daily Pharmaceutical Autoclave Maintenance

It includes special attention to inside chamber cleaning where mostly chances of spilling the reagents or items are high such as fluids, waste material, etc. therefore it is mostly done by using a damp cloth.

Weekly Pharmaceutical Autoclave Maintenance

It is involved with the full cleaning of pharmaceutical autoclaves. For example, the exterior and interior of the machine. The inside walls are cleaned by applying scouring pads with mild detergent and water with a final application of antibacterial wipes. It is suggested to avoid aggressive cleaning chemicals such as chlorine, or hydro-oxides.

Visualize the door check its movement and apply to grease if required. For long-lasting gasket, you should keep checking weekly. Check the drain and exhaust vent and clear if any blockade there.

Monthly Pharmaceutical Autoclave Maintenance

The monthly maintenance includes flushing of standing water or accumulated waste and cleaning of the interior chamber followed by a final antibacterial spray.

13.What are the problems and troubleshooting related to a pharmaceutical autoclave?

It is the ideal case in which a pharmaceutical autoclave always works as planned. However, problems are encountered with this equipment. The answer to troubleshooting them is to identify different problems.

Here we will overview some frequent problems in the pharmaceutical autoclave and how to troubleshoot them.

The Set Temperature Point in the Autoclave is Not Reached

Set Temperature Point in Autoclave is Not Reached- Picture Courtesy: The George Washington University

| Cause | Troubleshooting |

| The steam generator is not turned on.

Defective steam generator. Clogging in the chamber drain prevents air from discharging from the vessel and steam does not reach the right pressure and temperature. The set temperature is greater than the highest temperature allowance. |

Ensure the steam generator is turned on.

Repair the faulty steam generator. Unclog the chamber drain. Reset the temperature and ensure it is within the maximum range of the pharmaceutical autoclave. |

No Steam in Jacket

No Steam in Jacket- Picture Courtesy: Medical Equipment Services

| Cause | Troubleshooting |

| Damaged heating elements.

Improper feeding of steam line in pharmaceutical autoclave. There is no power supply to the steam generator. |

Fix and repair the heating element.

Adjust and refeed the steam line properly in the pharmaceutical autoclave. Turn on the power supply for the steam generator. |

Premature Termination of Sterilization Cycle

Premature Termination of Sterilization Cycle- Picture Courtesy: gbu-hamovniki.ru

| Cause | Troubleshooting |

| The longer heating time of large liquid loads leads to the end of the sterilization cycle. | It is suggested to place liquids in small containers to avoid the untimely conclusion of the sterilization cycle. |

Items are Not Sterilize

Items are Not Sterilize- Picture Courtesy: gbu-hamovniki.ru

| Cause | Troubleshooting |

| Inaccurate loading that shields drain opening and overcrowding.

Defect in the pharmaceutical autoclave. Inadequate quantity of steam Error in input cycle time. |

Properly place the items in the pharmaceutical autoclave to avoid covering critical points and overcrowding.

Check and repair the defective component in the pharmaceutical autoclave. Reset the correct cycle type. |

Item is Spoiled by Pharmaceutical Autoclave

Item is Spoiled by Pharmaceutical Autoclave- Picture Courtesy: STERIS

| Cause | Troubleshooting |

| Items are not autoclaved safe.

Liquid loss due to boiling and evaporation. Sugars are burnt at high temperatures in a pharmaceutical autoclave. |

Train staff in using autoclave-safe items.

Use a specialized liquid cycle that gradually lowers the pressure. To avoid the sugar caramelization point, it is recommended to increase the duration of the sterilization cycle and reduce the sterilization temperature. |

14.What are the points to be remembered when looking for a pharmaceutical autoclave?

Selecting the right pharmaceutical autoclave for your industry is a critical process that affects the productivity and safety of your sterilization function. To make an informed choice, you must methodically and carefully ponder on key consideration points.

Here we will explain different points to remember when looking for a pharmaceutical autoclave.

Loading Capacity

Loading Capacity- Picture Courtesy: News-Medical

Before going out, first, determine the volume of items needed to be sterile in every cycle. This will give you an estimate of the loading capacity of a pharmaceutical autoclave. If you process smaller loads in each cycle, then it is best to save money and opt for a pharmaceutical autoclave with a smaller capacity.

Size and Space Utilization

Size and Space Utilization- Picture Courtesy: Syntegon

Compact pharmaceutical autoclaves utilize less space. Similarly, vertical pharmaceutical autoclaves need more head space but less floor space. This autoclave is useful for plants with space constraints. Horizontal pharmaceutical autoclave with its horizontal loading has a larger footprint.

User-Friendly Controls

User-Friendly Controls- Picture Courtesy: Hvax Technologies

When looking for pharmaceutical autoclaves, it is best to consider ease of use. This ease of use is vital in various processes like loading and unloading, moving, and storing. A meticulous and systematic arrangement is required when loading the front-loading pharmaceutical autoclave. Conversely, the stacking arrangement makes it easy to load a vertical pharmaceutical autoclave.

Easy Installation and Setup

Easy Installation- Picture Courtesy: Belimed life Science

The installation process for a pharmaceutical autoclave can be complicated and expensive. Some models of pharmaceutical autoclaves need dedicated water and steam systems. Thus, these can only be installed in specific places. However, other models have integrated water reservoirs, thus they are installed easily anywhere, needing only an electricity source.

Cost-Efficiency

Cost-Efficiency- Picture Courtesy:sigmonlawpllc

Cost is a factor of paramount importance when making any purchase and pharmaceutical autoclave choice is no exception. Initial investment is important but consider the cost-effectiveness of your purchase in the long run.

Conclusion

Hopefully, the blog ‘Pharmaceutical Autoclave: The Complete FAQ Guide In 2025’ has provided essential about the roles, technical aspects, and related areas. As a renowned global provider, AIPAK ENGINEERING distributes pharmaceutical autoclave that tremendously satisfy your needs at any department you belong to such as OT, central sterile regions, clinics, manufacturing facilities, and so on. We have been meeting your expectations for many years with top-notch and high performance. For procurement, please contact us now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours