Chicken Hormone Injection: The Complete FAQ Guide In 2025

Have you ever been to the delightful experience of biting a juicy chicken breast? May be yes! But at the same time, wondering what is inside? Chicken is consumed in almost all parts of the world for its taste as well as essential protein it provides. But have you ever heard about the concept of hormone in relation to chicken? Well, this debate simply ends with Chicken Hormone Injection!

Chicken Hormone Injection is simply a type of injection containing essential ingredients which are used for the growth and development of chicken. It not only enhance the muscles growth of chicken but also increase its weight within few weeks. Where it is famous for chicken growth and associated benefits, there are some reservations about its use which you will be knowing in this guide. So, stay tuned and keep reading to explore the manufacturing process, equipment, and administration ways for Chicken Hormone Injection!

1.What Is Meant By Chicken Hormone Injection?

Chicken Hormone Injection in a hand- Picture Courtesy: businesstoday.in

Like other living organisms, chicken also undergoes the growth stage to become mature. In the past, this process of chicken growth and development occurred naturally in 3 to 4 months. However, in modern era, the use of Chicken Hormone Injection is commonly given to chickens to increase their growth rate within weeks.

This hormone based injectable solution promotes the muscle growth in chickens as a result of which their size and weight grow faster. The chicken hormone injection is manufactured using synthetic hormones in industries. The modern day poultry farms used it to boost their production quantity by increasing meat in chickens.

2.Explain The Benefits Of A Chicken Hormone Injection?

You might be thinking about how the use of a chicken hormone injection can have benefits! But that's true! It is not only useful for the production of meat in chicken rather also benefits your poultry farm business. So, let's uncover these hidden advantages!

Boost Production

Poultry farm- Picture Courtesy: Adobe Stock

The foremost concern of every entrepreneur is to boost production, so, that he can stand in the market. In this way, the use of a chicken hormone injection can help you grow and sell your chicken fastly which is considered an attribute of efficient producer.

Easy Administration

Chicken Hormone Injection sites- Picture Courtesy: clorofil.org

Chicken hormone injection is easy to administer in fixed sites which are neck or thighs. It does not require any specialization rather can be given by a layman. You just need to draw the dosage into syringe and deliver it into chicken. Hence, the convenience make it more feasible to use it.

Minimum Rearing Duration

Injection for various sizes of chickens- Picture Courtesy: biocamp.com.br

In poultry farm business, the main focus is on finishing up more batches of chickens in a year. However, this is not possible with the conventional way of rearing chicken which takes almost 4 months for a single batch. Thus, with the use of chicken hormone injection, rearing duration for chicken is reduced to 3 months.

Less Need for Feed

Hand holding feed for cock- Picture Courtesy: extension.umd.edu

If you are dependent upon feed as the only food for your chicken to grow then you will have to arrange variety in it for healthier chickens. It will again cost you more and will consume more resources with extended time period. On the other hand, if you use chicken hormone injection, then there will be less need for expensive feed.

Increase Value

The use of chicken hormone injection help building the muscles of chicken and in turn the meat produced by chicken is healthy and large in amount. Therefore, the value of your chicken is consequently increased.

3.Name The Essential Ingredients Used In A Chicken Hormone Injection?

Chicken hormone injection is mainly composed of active ingredients and excipients. Active ingredients of the injection constitute those compounds which are responsible for showing the desired results. While as, excipients are the inactive ingredients which are used for the preservation, stability, and safety of chicken hormone injection. These ingredients are listed below:

| No | Ingredients | Picture |

| 1 | Active Ingredients

Active ingredients used in chicken hormone injection include synthetic hormones, such as anabolic steroids, somatotropin analogues, and derivatives of testosterone. These compounds help in growing the muscles and cells in chicken. |

Hormone icon- Picture Courtesy: endocrine.org |

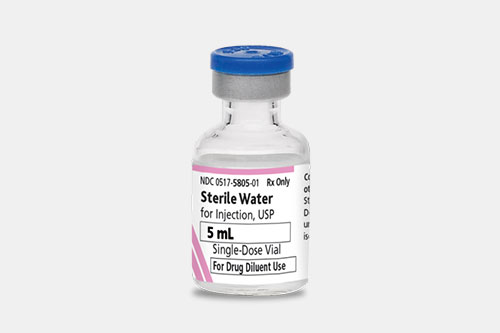

| 2 | Water for Injection

Water is another essential component of chicken hormone injection. It is the highly purified form of water which is used during manufacturing process. |

Sterile water for injection vial- Picture Courtesy: americanregent.com |

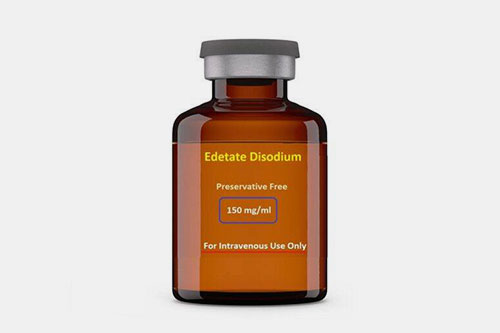

| 3 | Chelating Agents

Chelating agents are chemical compounds which bind to metal ions. The role of chelating agents is to prevent the degradation of active ingredients. |

Edetate Disodium vial- Picture Courtesy: emedz.net |

| 4 | Antimicrobial Preservatives

As the title shows, antimicrobial preservatives are substances added to chicken hormone injection in order to prevent the growth of microorganisms. Benzyl alcohol and phenoxyethanol are the two most common types of antimicrobial preservatives used in the injection formulation. |

Benzyl Alcohol- Picture Courtesy: oxfordpeptides.com |

| 5 | Suspending Agents

There are some particles which are insoluble but used in the chicken hormone injection. For this reason, suspending agents are used to suspend these particles and improve the uniformity of drugs. Methylcellulose, carbomers, and hydroxypropylmethylcellulose are the few examples. |

Methylcellulose container- Picture Courtesy: specialingredientseurope.com |

| 6 | Stabilizers

Stabilizers are the essential excipients which are used to protect the active ingredients in chicken hormone injection from oxidation. These include Glycine 80, Poloxamer 188, and Tween 20. |

Poloxmer 188- Picture Courtesy: Corning |

| 7 | Buffering Agents

Buffering agents are necessary for maintaining pH of the injection formulation. Buffer agents such as acetate, phosphate, citrate, and glutamate are crucial for the activity of active ingredients. |

Phosphate filled hands-on Picture Courtesy: Shutterstock |

| 8 | Solvents

Solvents refer to the liquid substances such as water, propylene glycol, and ethyl oleate which are used to dissolve drug formulation. |

Propylene glycol Jerry Can- Picture Courtesy: groupesomavrac.com |

| 9 | Antioxidants

These agents are used to prevent the oxidation in chicken hormone injection. Examples include ascorbic acid and sodium sulfite. |

Ascorbic acid vial- Picture Courtesy: olympiapharmacy.com |

4.Are There Any Disadvantages Of A Chicken Hormone Injection?

Despite so many benefits one can get by using chicken hormone injection, there are some potential disadvantages which are necessary to be known. These are explained below:

Premature Growth

A man examining broiler chicken- Picture Courtesy: dreamstime.com

Chicks which are grown into chickens by using chicken hormone injection are early mature than their real age. This premature growth is the result of quick muscle and cells development which only increase the size of chicken but not their age.

Physically Inactive

Inactive chicken laying on ground- Picture Courtesy: extension.umd.edu

Have you ever noticed the dullness in broiler chickens reared in poultry farm? The reason is simply their weak immune system and skeleton system due to which they remain inactive and even cannot stand on their own.

Prone to Diseases

Veteran diagnosing chicken- Picture Courtesy: iStock

Chicken hormone injection is only used for the physical boost of chickens but not their internal strength to survive. These chickens are unable to fight minor illness. They are prone to diseases which can cause health hazards for chicken consumers.

5.Explain The Manufacturing Process For A Chicken Hormone Injection?

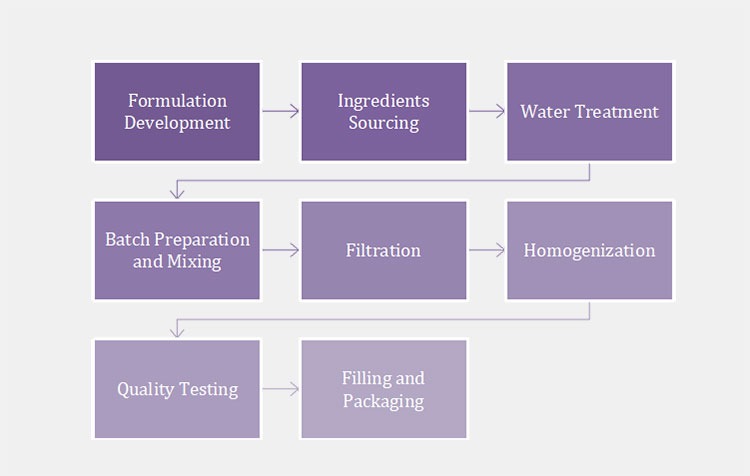

The manufacturing process for chicken hormone injection is a step-by-step process which could be understood in the same manner. The details are given below:

Formulation Development

A pharmacist pouring liquid into a beaker- Picture Courtesy: Tayana Solutions

The first step for the manufacturing of chicken hormone injection involves the development of formulation where active ingredients and excipients for desired effect are selected. This formulation step is carried out by specialists in the field in order to ensure the optimal combination of selected compounds.

Ingredients Sourcing

A pharmacist mixing pharmaceutical ingredients- Picture Courtesy: iStock

The second stage include gathering raw materials for both active as well as inactive ingredients from high quality sources. It is determined to take fresh ingredients from suppliers who meet stringent quality criteria.

Water Treatment

Water treatment system

The next step is to prepare water for mixing with the ingredients. The water is prepared by distillation process and reverse osmosis in order to make it free from contamination and pyrogens. This highly purified water is then used as solvent or diluent in chicken hormone injection formulation.

Batch Preparation and Mixing

Liquid mixing into a vessel- Picture Courtesy: tapflo

Now, it is the time for accurately weighing and measuring the required amount of active components and excipients. During batch preparation, equipment with controlled environment and temperature are used to ensure precision. All the ingredients are thoroughly mixed for getting uniformity and consistency in the final formulation.

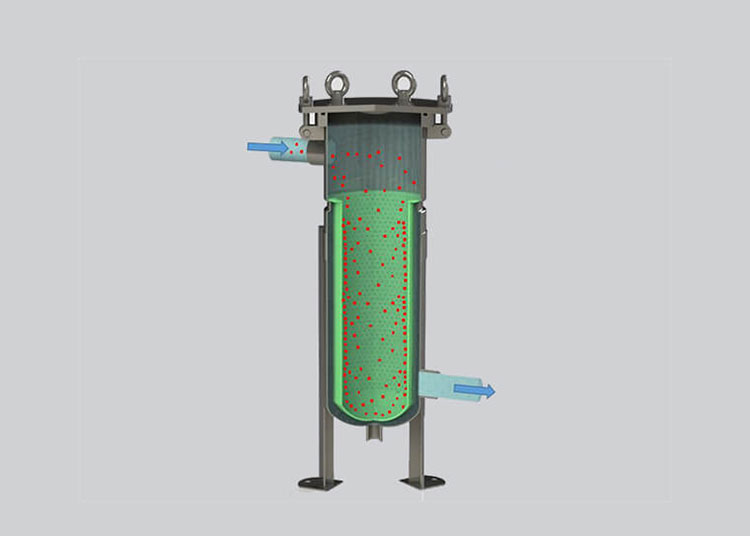

Filtration

Liquid filtration in a filter machine- Picture Courtesy: Seadon Filtration

At this point of chicken hormone injection manufacturing, the prepared liquid mixture undergoes the filtration for removing any particulate or foreign matter which have been introduced during mixing process.

Homogenization

RX Vacuum Homogenizer Mixer- Picture Courtesy: Ginhong

Once the initial mixing is done during batch preparation, it is the time for second round where homogenization takes place. It is necessary to break down any kind of agglomerates or large particles present in the formulation. This in turn enhance the drug stability and bioavailability.

Quality Testing

Quality testing of liquid filled vials- Picture Courtesy: Alispharm

Quality testing is another crucial step for the compliance of produced drug formulation to quality standards. Here, inspection and tests including clarity test and stability test are undertaken to ensure that final product meets all specifications.

Filling and Packaging

Vial filling and capping- Picture Courtesy: Syntegon

Finally, after the final formulation of chicken hormone injection, it is transferred to the filling machines. These machines then accurately weigh the precise dosage and dispense into containers such as vials and ampoules. For additional safety, secondary packaging is done to protect glass vials and ampoules during transit.

6.Describe The Various Machines Used For The Production Of A Chicken Hormone Injection?

The production of chicken hormone injection is done by using latest technology equipment. Each step is carried out by a specific machine which are all described below:

Water Treatment System

Aipak Engineering- Pharmaceutical Purified Water Treatment System

Water treatment system refers to the sophisticated assembly which is designed for the purification of water for chicken hormone injection manufacturing. It uses semi-permeable membrane to remove out the dissolved salt, minerals, and other impurities such as pyrogens from water. It works on the reverse osmosis process to make water bacteria and virus free.

Mixing Tank

YX Vacuum Mixing Tank- Picture Courtesy: ginhong.com

Mixing tank, also known as mixing vessel, is a device employed to mix together various liquids and solid particles. It is used to mix active ingredients and excipients for making chicken hormone injection. The equipment has corrosion resistant stainless steel vessel with double jacket for heating and cooling inside which mixing process takes place. Apart from this, the motor located on the top side of tank is attached with an agitator inside the tank to carry out proper functioning.

Storage Tank

Aipak Engineering- Stainless Steel Water Tank For Purified Water Storage

Storage tank can be simply described as large stainless steel vessel design to hold liquids under controlled temperature. The size and design of storage tanks vary, however, their function remain the same. It is used during the manufacturing of chicken hormone injection where liquid formulation is stored in it for later use. The storage tank may be directly integrated with other machines for liquid transfer.

Vacuum Emulsifying Mixer

AIPAK- Vacuum Emulsifying Mixer

Vacuum emulsifying mixer is a specialized machine tailored with unique features to get done with the homogenization of two or more immiscible liquids. It has two hygienic stainless steel vessels for containing liquid and a pot for mixing these liquids. The machine perform operation by emulsifying various liquids together in order to produce a uniform mixture while removing air bubbles. It is made up of many parts such as main frame, liquid storage tanks, mixing vessel,an agitator, control board, and electric system.

Filter Machine

Stainless Steel Vacuum Filter Machine ForSetup Solid Liquid Lab Separation- Picture Courtesy: toptiontech.com

Filter machine is another important equipment designed to separate unwanted solid particles from the liquid formulation of chicken hormone injection. It is made up of stainless steel body that is fully resistant to corrosion. The major components of filter machine include material hopper, perforating plate, valves, universal wheels, and clamps etc.

Clarity Tester

Allpack- APK-4000A Clarity Tester

Clarity tester is developed to check the quality of various liquid formulations such as injections, large infusions, and bottled liquid medications. It consists of a fluorescent lamp, brightness adjustment unit, black background, white background, base, control panel, and a power button. It can be utilized by placing ampoule of vial containing chicken hormone injection or other solution over the base. Upon turning the light on, particles inside the solution will appear after both white and black background.

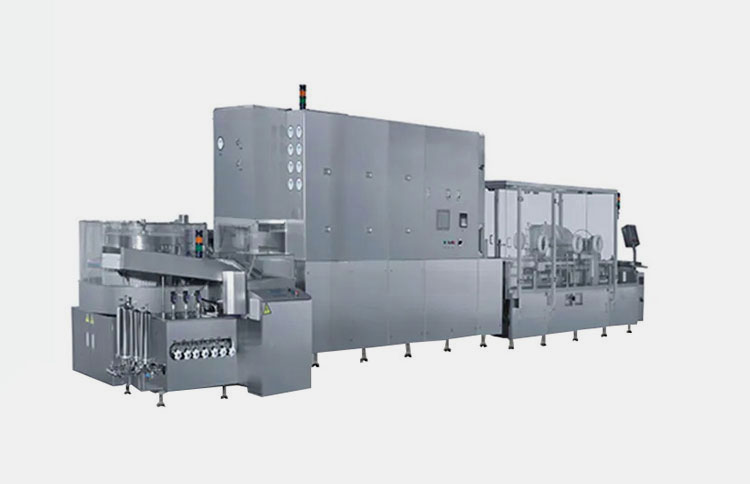

Vial Filling Line

AIPAK Engineering liquid vial production line

Vial filling line is a huge equipment combining several independent units for the thorough production of vials. These units include ultrasonic bottle washing machine, sterilization tunnel, drying unit, vials conveying assembly, filling machine, and capping machine etc. The entire process of vial from cleaning to sterilization, drying, filling, and capping is done automatically. It ensures precision and consistency throughout operation.

Ampoule Filling Line

AIPAK Engineering 1-20ml ampoule filling Line

Ampoule filling line is an assembly of different machines integrated together to form a sophisticated production line. It is designed to carry out entire processing of sterile ampoules for filling injection formulations. The process involves washing and cleaning of ampoules after which these ampoules are transferred to filling unit where precise dosage of liquid mixture is poured in them. Finally, the sealing of filled ampoules is done using fire.

Labeling Machine

AIPAK APK-ALM2586 high speed double tunnel horizontal automatic labeling machine

Labeling machine is a device used to apply printed labels around containers such as bottles, vials, and ampoules etc. It works automatically by unwinding the film from roll and apply around the passing containers. The machine consists of different parts including electric enclosure, main frame, conveyor, control panel, film unwinding wheels, and label applying unit.

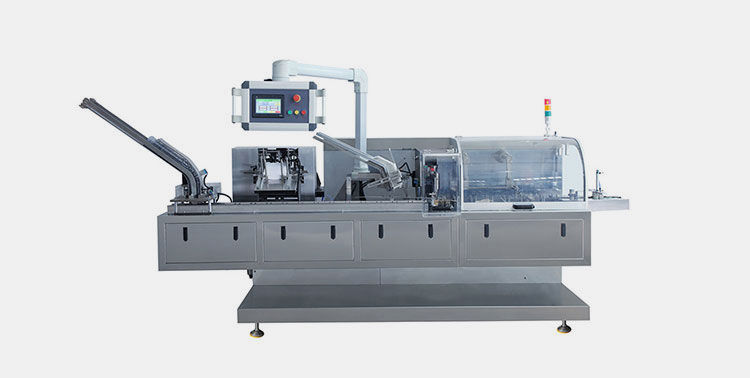

Cartoning Machine

AIPAK- WZH-120 Horizontal Boxes Packaging Cartoning Machine

Cartoning machine is the ultimate equipment which is required for the final secondary packaging of filled vials and ampoules. Containers containing chicken hormone injection are packed into cartons by using this machine. It automatically carries out carton feeding, erecting, filling, leaflet inserting, flaps sealing, and cartoning embossing. It has high working efficiency and effective performance in terms of quality packaging.

7.What Are The Packaging Formats For Chicken Hormone Injection?

As far as the packaging formats for chicken hormone injection are concerned, so, these include glass vials and ampoules which are hygienic enough to retain the originality of drug formulation. These are described below:

Vials

A vial of glass- Picture Courtesy: nipro-group.com

Vials refer to the small size containers usually made up of glass. These vials are characterized by typically cylindrical shape with an aluminum or plastic cap which are essential for maintaining the sterility of drugs. Unlike ampoules, vials are available in different sizes and are more resistant to environmental factors.

Ampoules

Various ampoules- Picture Courtesy: Shutterstock

An ampoule is a small, sealed glass vessel with unique design. It is highly sterile in its structure but quite useful for storing the drugs like chicken hormone injection. There are several types of ampoules available in market including form B, C, and D.

8.Can You Explain The Administration Ways For A Chicken Hormone Injection?

You may be curious about knowing the sites and routes for administering chicken hormone injection in chickens. So, we have come up with interesting set of information which will surely address your eagerness. Let's know these methods for injection in detail!

Cutaneous Injection Way

Veteran injecting syringe in the wing of a chicken- Picture Courtesy: learnpoultry.com

The term cutaneous simply refers to skin which is the second layer after epidermis. In chickens, chicken hormone injection can be injected directly into cutaneous sites which include wing-web. This method has the longest absorption time as the drug formulation takes time for travel. This methods of injection administration is quite easy and favorable for large scale poultry farm business.

Subcutaneous Injection Way

Person injecting syringe in the neck of a chicken- Picture Courtesy: Shutterstock

Subcutaneous injection is a method of administering chicken hormone injection into the subcutaneous tissue which is the layer of fat situated under the skin. The routes for subcutaneous injection in chicken are inguinal fold and neck. This method has slow and steady release of drugs. Although, it requires effort to inject, however, it is faster in results than cutaneous injection way and is good for medium scale poultry farm business.

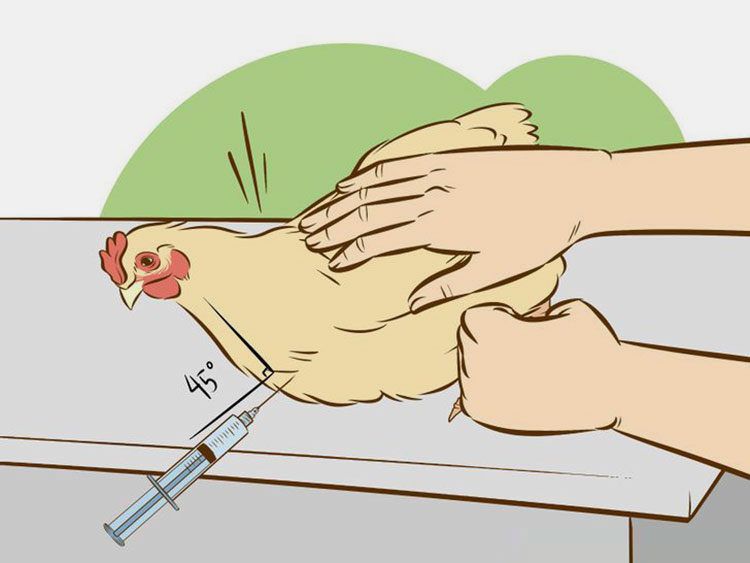

Intramuscular Injection Way

Administration of an injection into a chicken breast- Picture Courtesy: sites.psu.edu

Intramuscular injection way may be described as the way of injecting chicken hormone injection directly into the chicken muscles. These routes are breast and leg with instant effect as formulation enters to the bloodstream. However, this way of drug administration is quite difficult and requires the person to hold the chicken tightly. Consequently, it is desirable for small scale poultry farms where handling of chickens is easy.

9.How Much Time It Takes For A Chicken Hormone Injection To Show Results?

Veteran drawing injection solution from a vial for the chicken- Picture Courtesy::Agri Farming

Well, there might be a question in your mind that how much time it takes for a chicken hormone injection to show results?, So, it is completely a valid question. Being the producer of a poultry farm, whether small of large, it is necessary to have prior knowledge about the effects before using it.

One thing is for sure, that if you are intending to grow your chickens on chicken hormone injection instead of feed or other traditional methods, then you will need to inject the growth hormones in chicken on daily basis.

In this way, the time needed for a chicken hormone injection to show results vary. It depends upon several factors such as injection site, dosage, and chicken age etc. Normally, it takes almost ten days that you can observe the growth in chicks size. However, the actual growth in form of mass development and weight could be seen at least after three weeks.

10.What Are The Best Practices For Safe Storage Of A Chicken Hormone Injection?

Similar to other drugs, chicken hormone injection also need proper storage as it contains active ingredients and excipients which require specific environment to sustain.

Various liquid vials with a syringe- Picture Courtesy: Drug Target Review

In this manner, the first practice to adopt is the safe and tight packaging where the hormone injection formulation could be preserved. For this, vials and ampoules are perfect choice which are sterile and hygienic to protect the mixture against moisture, light, and pollution etc.

Secondly, the chicken hormone injection must be stored in a cool and dry place as temperature play vital role in retaining the essence of formulation. Moreover, the shelf life is also affected by the form of injection in which it is kept. For instance, liquid form may be effective for three years. While the same chicken hormone injection in lyophilized form can have a life up to four years.

Conclusion

To wrap up this informative review on Chicken Hormone Injection, we are glad that you have gone through it thoroughly. In the realm of today's modern era, methods in almost every field of life and production are evolving. Same is the case with poultry farms where traditional way of rearing chickens on feed is now fading away. With technological advancements, focus is more on increasing production output and getting more benefits. Thus, where Chicken Hormone Injection offer many benefits, it also have potential side effects. Apart from this, its manufacturing is a long process that requires key equipment. So, if you are keem to learn more about it, then please stay in contact with us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours